The global flow measurement market is experiencing robust growth, driven by increasing demand for precision instrumentation across oil & gas, chemical, power generation, and water treatment industries. According to a report by Mordor Intelligence, the flow meter market was valued at USD 8.2 billion in 2023 and is projected to grow at a CAGR of over 4.5% from 2024 to 2029. Annubar flow transmitters—known for their reliability in measuring gas, liquid, and steam flows with minimal pressure loss—have become a preferred choice in high-pressure and high-temperature applications. This surge in adoption is further supported by industrial digitalization and stricter regulatory standards requiring accurate flow monitoring. As demand rises, several manufacturers have emerged as leaders in innovation, accuracy, and industrial scalability. The following analysis highlights the top four Annubar flow transmitter manufacturers shaping this growing segment.

Top 4 Annubar Flow Transmitter Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

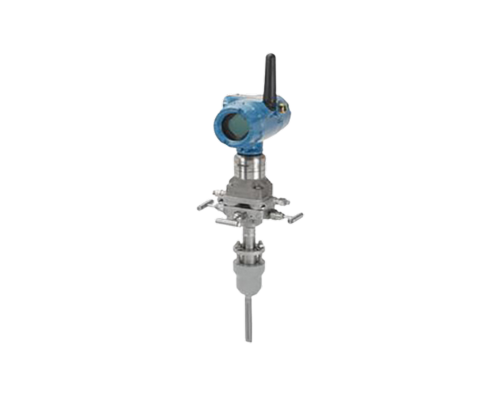

#1 Rosemount 3051SFA Annubar Flow Meter

Domain Est. 1995

Website: emerson.com

Key Highlights: For best-in-class performance in many applications, this flow meter combines the patented Rosemount Annubar and Rosemount 3051S Flow Transmitter….

#2 Rosemount Annubar® Flowmeter Series

Domain Est. 1995

Website: videos.emerson.com

Key Highlights: Emily Vinella showcases the features and benefits of the Rosemount Annubar Flowmeter including the Rosemount 3051SFA Flowmeter and the Rosemount 585 Annubar ……

#3 Flow application

Domain Est. 2011

Website: emersonexchange365.com

Key Highlights: This is the official online community site of the Emerson Global Users Exchange, a forum for the free exchange of non-proprietary information among the ……

#4 Annubar Flow Meters & Averaging Pitot Tubes

Domain Est. 2014

Website: bcstgroup.com

Key Highlights: The Annubar flow meter offers a highly accurate and energy-efficient solution for measuring flow in clean fluids, especially in large pipes. [3] Its reliability ……

Expert Sourcing Insights for Annubar Flow Transmitter

2026 Market Trends for Annubar Flow Transmitter

Rising Demand in Oil & Gas Drives Adoption

The global Annubar flow transmitter market is projected to experience steady growth by 2026, primarily fueled by increasing demand in the oil and gas sector. As upstream, midstream, and downstream operations expand—especially in regions like the Middle East, North America, and parts of Asia-Pacific—there is heightened need for reliable, low-maintenance flow measurement solutions. Annubar transmitters, known for their insertion-style design and ability to handle high-pressure and high-temperature environments, are increasingly favored for custody transfer, flare gas monitoring, and pipeline flow measurement. The industry’s focus on operational efficiency and leak detection further accelerates deployment.

Expansion in Industrial and Water/Wastewater Applications

Beyond oil and gas, the Annubar flow transmitter market is gaining traction in industrial manufacturing and water/wastewater treatment plants. Industries such as chemical processing, power generation, and HVAC systems are adopting Annubar technology for its accuracy in measuring large pipe diameters with minimal pressure loss. Municipalities and utility providers are also investing in advanced flow monitoring to comply with environmental regulations and improve water conservation. By 2026, these sectors are expected to contribute significantly to market diversification and volume growth.

Technological Advancements Enhance Performance

Innovation is a key trend shaping the Annubar market through 2026. Manufacturers are integrating digital communication protocols (e.g., HART, Foundation Fieldbus, and wireless options) and enhancing transmitter electronics for better signal stability and diagnostics. Advanced materials and anti-corrosion coatings are improving longevity in harsh environments. Additionally, the integration of Annubar systems with Industrial Internet of Things (IIoT) platforms enables real-time data analytics and predictive maintenance, increasing their appeal in smart factory and digital transformation initiatives.

Regional Growth and Competitive Landscape

Asia-Pacific is anticipated to be the fastest-growing region due to rapid industrialization, infrastructure development, and rising energy consumption in countries like China and India. North America and Europe will maintain strong demand, supported by aging infrastructure upgrades and stringent regulatory standards. The competitive landscape is evolving, with key players such as Endress+Hauser, Emerson, ABB, and Siemens focusing on product differentiation, strategic partnerships, and geographic expansion to capture market share by 2026.

Common Pitfalls When Sourcing Annubar Flow Transmitters (Quality and Intellectual Property)

Sourcing Annubar flow transmitters—especially from non-original manufacturers or low-cost suppliers—can expose buyers to significant risks related to product quality and intellectual property (IP) infringement. Being aware of these pitfalls is crucial for ensuring long-term reliability, accuracy, and legal compliance in industrial applications.

Poor Build Quality and Material Substitution

Many third-party suppliers cut costs by using inferior materials or deviating from original design specifications. This includes substituting lower-grade stainless steel, using substandard welds, or reducing wall thickness. Such compromises can lead to premature failure in high-pressure or corrosive environments, resulting in unplanned downtime and safety hazards.

Inaccurate Flow Measurement Due to Design Deviations

The Annubar primary element relies on precise geometry and sensor placement to achieve accurate differential pressure measurement. Unauthorized copies often fail to replicate the patented multi-port averaging design correctly, leading to measurement inaccuracies. Even minor deviations in port placement or tube alignment can significantly affect performance, undermining process control and efficiency.

Lack of Calibration and Certification

Reputable Annubar transmitters come with individual calibration certificates traceable to recognized standards (e.g., NIST). Off-brand or counterfeit units frequently lack proper documentation or use generic calibration data. This absence makes it difficult to validate performance and can cause non-compliance with industry regulations in sectors like oil & gas, power generation, and pharmaceuticals.

Intellectual Property Infringement

The Annubar technology is protected by patents and trademarks, primarily held by major manufacturers like Emerson. Sourcing from suppliers that replicate these designs without licensing constitutes IP infringement. Buyers may face legal exposure, shipment seizures, or reputational damage—especially in regulated markets where due diligence on supplier legitimacy is required.

Inadequate Technical Support and Warranty

Low-cost suppliers often provide limited or no technical support, making installation, troubleshooting, and maintenance challenging. Additionally, warranties may be vague or unenforceable, leaving the buyer responsible for repair or replacement costs. This lack of post-sale support increases lifecycle costs and operational risk.

Misrepresentation and Brand Confusion

Some suppliers market their products using names or packaging that closely resemble genuine Annubar transmitters, creating confusion. Terms like “Annubar-type” or “averaging pitot tube” may be used to imply compatibility or equivalence, but without the validated performance and IP rights, these claims can be misleading and potentially deceptive.

Conclusion

To avoid these pitfalls, buyers should source Annubar flow transmitters from authorized distributors or manufacturers with verifiable IP rights. Conducting supplier audits, requesting calibration documentation, and verifying product authenticity can mitigate risks related to quality and intellectual property, ensuring reliable and legally compliant flow measurement solutions.

Logistics & Compliance Guide for Annubar Flow Transmitter

Product Overview and Identification

The Annubar Flow Transmitter is a primary flow element that uses an averaging pitot tube design to measure fluid flow rates in pipes. It is widely used in industries such as oil & gas, power generation, water treatment, and chemical processing. Proper logistics handling and compliance with international and local regulations are essential to ensure safe delivery, installation, and operation.

Packaging and Handling Instructions

Annubar transmitters are typically shipped in protective packaging designed to prevent mechanical damage during transit. The packaging includes:

– Rigid cardboard or wooden crates with internal foam or cushioning.

– Moisture-resistant wrapping to guard against humidity.

– Clearly labeled handling instructions (e.g., “Fragile,” “This Side Up”).

Ensure the device is stored in a dry, temperature-controlled environment before installation. Avoid exposure to extreme temperatures, direct sunlight, or corrosive atmospheres.

Transportation Requirements

- Domestic Shipments: Comply with carrier-specific hazardous material regulations if applicable (e.g., DOT in the U.S.). Most Annubar transmitters are non-hazardous and can be shipped via standard freight.

- International Shipments: Adhere to IATA (air) or IMDG (sea) codes if accessories contain restricted materials. Provide proper export documentation, including commercial invoice, packing list, and certificate of origin.

- Customs Clearance: Accurate HS (Harmonized System) code classification is required. Annubar transmitters typically fall under HS Code 9026.10 (instruments for measuring flow of liquids).

Import and Export Compliance

- Export Controls: Verify if the product is subject to export control regulations such as EAR (Export Administration Regulations) in the U.S. Most Annubar devices are classified as EAR99, meaning they are low-risk and do not require a license for most destinations.

- Sanctions and Embargoes: Ensure end-users and destinations are not on restricted parties lists (e.g., OFAC, BIS Denied Persons List).

- Import Duties and Taxes: Coordinate with local customs brokers to determine applicable duties, VAT, or GST based on destination country regulations.

Regulatory and Safety Standards

Annubar Flow Transmitters are designed and manufactured to meet international standards, including:

– ISO 5167: Measurement of fluid flow by means of pressure differential devices.

– ASME MFC-12M: Standard for insert probes for measurement of single-phase flow in closed conduits.

– ATEX/IECEx: Required for use in hazardous (explosive) atmospheres in Europe and globally. Devices must carry appropriate certification markings (e.g., II 2G Ex db IIC T6 Gb).

– SIL Certification: Available for safety instrumented systems (typically SIL 2 or SIL 3 per IEC 61508).

Environmental and Disposal Compliance

- RoHS Compliance: Annubar transmitters comply with the Restriction of Hazardous Substances Directive (2011/65/EU), limiting lead, cadmium, mercury, and other substances.

- WEEE Compliance: At end-of-life, products must be disposed of according to Waste Electrical and Electronic Equipment (WEEE) directives. Return to manufacturer or an authorized recycling facility.

- REACH: Registration, Evaluation, Authorization, and Restriction of Chemicals—ensure material declarations are available upon request.

Documentation and Traceability

Maintain the following documentation throughout the product lifecycle:

– Certificate of Conformity (CoC)

– Material Test Reports (MTRs) for wetted parts

– Calibration certificates (as supplied)

– ATEX/IECEx or other regional certification documents

– Packing list and shipping manifest

Ensure all documentation accompanies the shipment and is archived for audit purposes.

Installation and Operational Compliance

- Install per manufacturer’s guidelines and applicable industry codes (e.g., API, ANSI).

- Verify proper grounding and electrical installation to meet NEC (U.S.) or IEC (international) standards.

- Conduct initial calibration and periodic verification in accordance with site QA/QC procedures.

Support and Certification Renewal

Contact the manufacturer or authorized distributor for:

– Recertification of hazardous area approvals

– Calibration services

– Compliance documentation updates

– Technical support for regulatory inquiries

Adhering to this guide ensures safe, legal, and efficient deployment of Annubar Flow Transmitters across global operations.

Conclusion for Sourcing Annubar Flow Transmitter:

After a thorough evaluation of technical requirements, performance criteria, supplier reliability, and cost considerations, sourcing an Annubar flow transmitter proves to be a reliable and efficient solution for measuring flow in various industrial applications. The Annubar’s robust design, low maintenance needs, high accuracy, and ability to handle a wide range of fluids and pipe sizes make it a suitable choice for both liquid and gas flow measurement.

Key factors such as long-term stability, minimal pressure loss, and ease of installation further enhance its operational value. By selecting a reputable supplier offering certified calibration, adequate technical support, and compliance with industry standards (e.g., ISO, ASME, or API), organizations can ensure consistent performance and regulatory compliance.

In conclusion, sourcing an Annubar flow transmitter represents a cost-effective and technically sound investment for accurate, repeatable flow measurement, contributing to improved process control, energy efficiency, and operational reliability across industrial systems. Proper vendor selection and adherence to installation best practices are essential to maximize return on investment and system performance.