The global brass manufacturing industry is undergoing a transformation driven by rising demand for high-conductivity, corrosion-resistant materials in sectors such as plumbing, electrical components, and industrial machinery. A critical factor in ensuring the mechanical properties and workability of brass is the annealing process, which relieves internal stresses and enhances ductility. As manufacturers seek to improve efficiency and product consistency, the adoption of advanced annealing machines has surged. According to Mordor Intelligence, the global heat treatment equipment market—encompassing annealing systems—is projected to grow at a CAGR of 5.2% from 2023 to 2028, fueled by technological advancements and increasing industrial automation. This growth is further reinforced by expanding infrastructure and automotive industries, particularly in Asia-Pacific, which accounted for the largest share of brass consumption in recent years. Against this backdrop, selecting the right annealing machine has become a strategic decision for brass manufacturers aiming to optimize throughput, energy efficiency, and material performance. The following overview highlights the top nine annealing machines tailored to meet the evolving demands of modern brass production.

Top 9 Annealing Machine For Brass Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Annealing Equipment

Domain Est. 1996

Website: radyne.com

Key Highlights: Radyne is highly experienced in providing systems to anneal casings during every stage from cup annealing to the final neck taper annealing….

#2 Giraud Cartridge Case Annealer

Domain Est. 2003

Website: giraudtool.com

Key Highlights: Optimize your reloading with the Giraud Cartridge Case Annealer, offering precise and consistent annealing for improved brass longevity and performance….

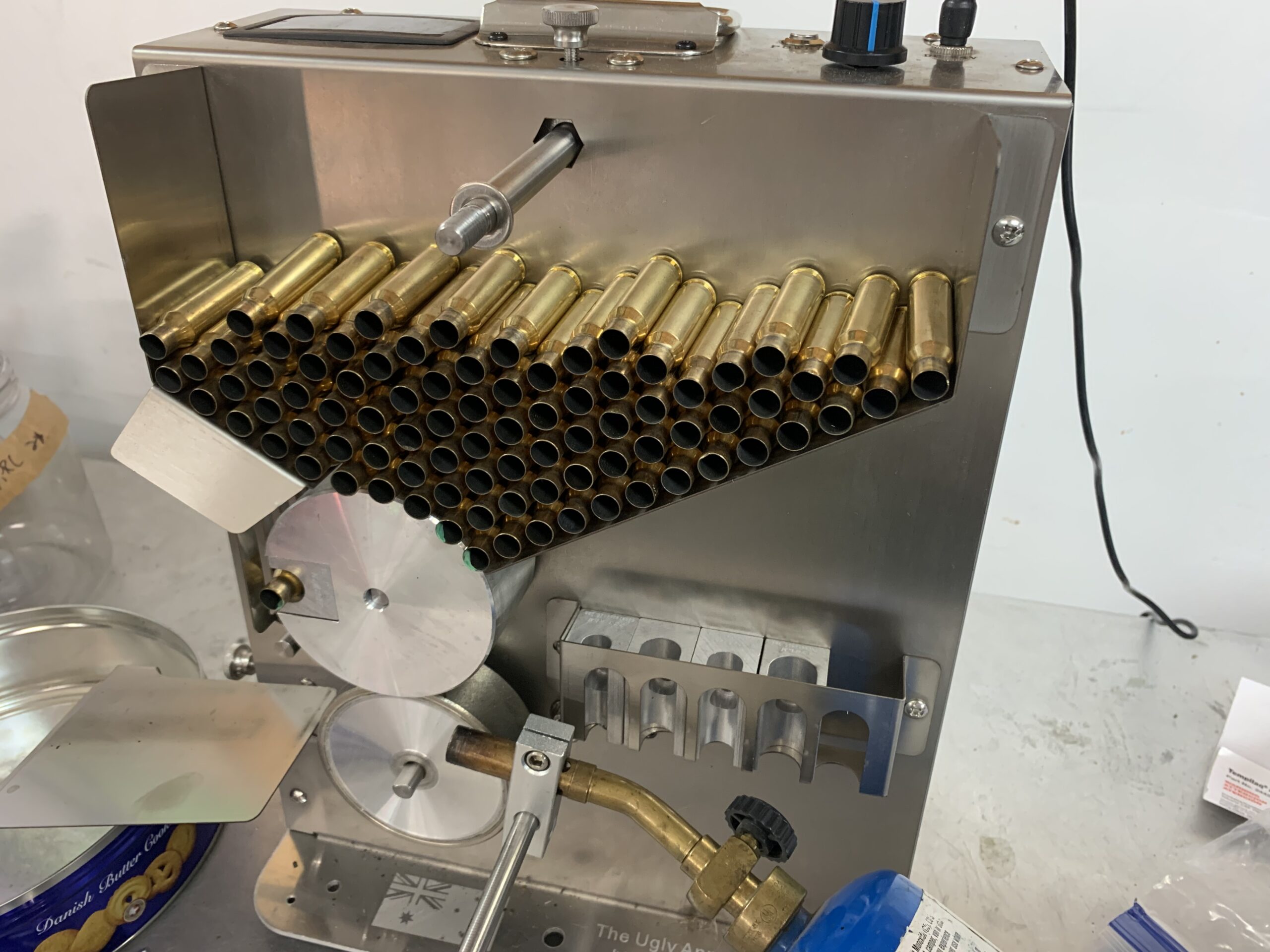

#3 Cartridge & Rifle Brass Annealing

Domain Est. 2009

Website: cartridgeanneal.com

Key Highlights: The Anneal-Rite guarantees perfect case neck annealing on every case. You can easily anneal 600 per hour, in our shop we annealed 97 ~ .223 Rem. cases….

#4 Induction Annealing Machine

Domain Est. 2012

Website: ampannealing.com

Key Highlights: We provide separate settings for standard brass and neck turnings of -0.001”, -0.002” and -0.003”. It is important to enter the correct setting….

#5 SuperbMelt Annealing Machines

Domain Est. 2015

Website: superbmelt.com

Key Highlights: SuperbMelt Wire Annealing Machine is used to heat and cool metal wires (gold, silver, copper, etc.) to alter their properties. Annealing involves heating the ……

#6 FAQ

Domain Est. 2019

Website: agscustomparts.com

Key Highlights: Annealing is a process which helps to restore the ductility of the brass. That makes it easier to size and less likely to crack or split….

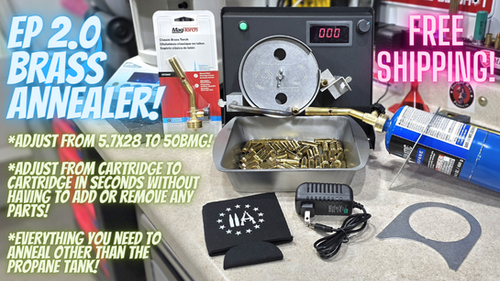

#7 EP INTEGRATIONS

Domain Est. 2020

Website: epintegrations.com

Key Highlights: EP INTEGRATIONS – Home of the EP 2.0 brass annealing machine! Easy, fast, and affordable brass annealer that can anneal from 5.7×28 to 50bmg without having ……

#8 Burstfire Annealer & Parts

Domain Est. 2020

Website: burstfireguns.com

Key Highlights: BACKORDER – Burstfire – 2 in 1 Brass Case Induction Annealing Machine & Case Prep Center. Burstfire. 31 reviews. $649.87. “Close (esc)”. Save $11….

#9 AGS Brass Annealer 3.1

Domain Est. 2023

Website: agsannealer.com

Key Highlights: AGS Brass Case Annealer 3.1 – compact flame annealer for reloaders who demand precision and repeatability. Consistent results, for calibers up to .408 ……

Expert Sourcing Insights for Annealing Machine For Brass

H2: 2026 Market Trends for Annealing Machines for Brass

As the global manufacturing and metal processing industries evolve, the demand for precision, energy efficiency, and automation is significantly shaping the market for specialized equipment such as annealing machines for brass. By 2026, the market for annealing machines tailored to brass processing is expected to experience steady growth, driven by technological advancements, rising demand from end-use sectors, and a shift toward sustainable manufacturing practices.

1. Rising Demand from Key End-Use Industries

The brass annealing machine market is closely tied to industries such as plumbing, electrical components, automotive, and consumer electronics. By 2026, increased infrastructure development—especially in emerging economies—and growing demand for energy-efficient electrical systems are expected to boost brass consumption. This, in turn, will drive the need for reliable and high-capacity annealing machines that ensure optimal ductility and workability of brass products.

2. Technological Advancements and Automation

Automation and digital integration are transforming heat treatment processes. By 2026, annealing machines for brass are expected to increasingly feature IoT-enabled monitoring systems, predictive maintenance capabilities, and precise temperature control via AI-driven software. These innovations improve process consistency, reduce energy consumption, and minimize human error—key factors for manufacturers striving to meet tight quality standards.

3. Focus on Energy Efficiency and Sustainability

Environmental regulations and corporate sustainability goals are pushing manufacturers to adopt energy-efficient annealing technologies. Induction-based and continuous belt-type annealing machines—known for lower energy consumption and reduced emissions—are gaining market traction. In 2026, vendors are expected to emphasize eco-friendly designs, including heat recovery systems and the use of renewable energy sources, to meet both regulatory requirements and customer expectations.

4. Regional Market Dynamics

Asia-Pacific, particularly China, India, and Southeast Asia, is projected to dominate the annealing machine market for brass by 2026 due to rapid industrialization and robust metal fabrication activities. Meanwhile, North America and Europe are expected to focus on upgrading aging infrastructure with advanced annealing systems that comply with stringent environmental and safety standards.

5. Customization and Modular Design

With diverse brass alloys and product specifications, there is a growing demand for customizable annealing solutions. Machine manufacturers are responding by offering modular systems that can be adapted for different brass thicknesses, production speeds, and required mechanical properties. This flexibility is expected to be a key competitive advantage in the 2026 market landscape.

6. Supply Chain and Raw Material Considerations

Fluctuations in copper and zinc prices—primary components of brass—may influence production costs and, consequently, investment in annealing machinery. However, the long-term outlook remains positive, as brass retains its value in applications requiring corrosion resistance, conductivity, and machinability.

Conclusion

By 2026, the market for annealing machines for brass will be characterized by innovation, sustainability, and regional expansion. Companies investing in smart, energy-efficient, and adaptable annealing technologies are likely to capture significant market share. As global demand for high-quality brass products continues to rise, the annealing machine sector will play a critical role in ensuring material performance and manufacturing excellence.

Common Pitfalls When Sourcing an Annealing Machine for Brass (Quality & Intellectual Property)

Sourcing an annealing machine specifically for brass requires careful attention to both technical performance and legal safeguards. Overlooking key aspects can lead to subpar equipment, production inefficiencies, or even legal disputes. Below are common pitfalls related to quality and intellectual property (IP):

Poor Temperature Uniformity and Control

One of the most critical quality pitfalls is inadequate temperature control within the annealing furnace. Brass requires precise and uniform heat treatment to achieve the desired ductility and grain structure. Machines with poor thermocouple placement, inconsistent heating zones, or outdated control systems often result in uneven annealing—leading to material warping, inconsistent mechanical properties, or scrap batches. Always verify temperature uniformity specifications (±5°C or better) and demand proof through calibration reports or third-party testing.

Inadequate Atmosphere Control Leading to Oxidation

Brass is prone to oxidation at high temperatures, which degrades surface quality and affects subsequent processing (e.g., drawing or plating). Sourcing a machine without proper protective atmosphere controls—such as nitrogen or dissociated ammonia gas systems—can result in excessive scaling or discoloration. Ensure the supplier provides a sealed furnace design with precise gas flow and dew point monitoring to maintain a reducing atmosphere.

Substandard Material and Construction Quality

Low-cost suppliers may use inferior materials for furnace components (e.g., low-grade heating elements, insufficient insulation, or thin steel housings), compromising durability and safety. Poorly constructed machines lead to frequent breakdowns, higher maintenance costs, and inconsistent performance. Evaluate the build quality firsthand or request factory audits. Look for reputable brands and certifications (e.g., CE, ISO 9001) as indicators of quality assurance.

Lack of Process Validation and Testing Data

Suppliers may promise performance without providing actual validation data for brass annealing. A major pitfall is accepting theoretical specifications without proof of successful operation on similar brass alloys (e.g., C26000, C27000). Always request trial runs with your specific brass material or detailed reports from previous customers in similar applications. Without empirical data, you risk investing in a machine that cannot meet your quality standards.

Ignoring Intellectual Property Risks in Machine Design

When sourcing from overseas or lesser-known manufacturers, there’s a risk of purchasing equipment that infringes on patented technologies—such as unique furnace designs, control algorithms, or energy-efficient heating methods. If your supplier uses copied or reverse-engineered IP, you could face legal liability or be forced to replace the machine. Conduct due diligence: ask for IP ownership documentation, patent clearance statements, or work with suppliers known for original engineering.

Failure to Secure Proper Licensing for Control Software

Modern annealing machines often include proprietary software for process automation and data logging. A common IP oversight is assuming the software is freely transferable or modifiable. Some suppliers restrict usage rights or charge additional licensing fees for updates or multi-machine deployment. Ensure licensing terms are clearly defined in the contract, including rights to use, modify, and support services.

Inadequate Documentation and Know-How Transfer

Even with a well-built machine, poor documentation—such as missing operating manuals, electrical schematics, or maintenance guides—can hinder quality control and troubleshooting. This also poses IP-related risks if custom process parameters or integration details aren’t properly recorded. Require comprehensive documentation as part of the delivery and verify that training includes transfer of operational know-how.

Avoiding these pitfalls requires thorough supplier vetting, technical validation, and legal awareness. Prioritize transparency, proven performance with brass, and clear IP terms to ensure a reliable and legally sound investment.

Logistics & Compliance Guide for Annealing Machine for Brass

Overview

This guide outlines the essential logistics and compliance considerations for transporting, installing, and operating an annealing machine specifically designed for brass. Ensuring adherence to international, national, and local regulations is critical for safe and legal operations.

Classification & HS Code

The annealing machine for brass falls under industrial machinery used in metal heat treatment. The appropriate Harmonized System (HS) Code is typically:

8417.80 – Industrial or laboratory furnaces and ovens (including incinerators) that are electrically heated or heated by gas, not elsewhere specified or included.

Note: Confirm the exact HS code with your customs broker based on machine specifications, as variations may apply.

Import/Export Regulations

- Export Controls: Verify if the machine contains dual-use technology (e.g., advanced automation or high-temperature control systems) subject to export control regimes such as the Wassenaar Arrangement.

- Import Duties & Taxes: Duties vary by country. Utilize the HS code to determine applicable tariffs. Some countries offer reduced rates for industrial equipment under trade agreements.

- Documentation Requirements:

- Commercial Invoice

- Packing List

- Bill of Lading/Air Waybill

- Certificate of Origin

- Technical Specifications and User Manual

- CE Marking or other regional compliance certificates (as applicable)

Transportation & Handling

- Packaging: Machines must be securely crated with shock-absorbent materials. Use wooden or metal crates compliant with ISPM-15 standards for international shipments.

- Weight & Dimensions: Confirm machine dimensions and weight for freight classification. Oversized loads may require special permits and routing.

- Mode of Transport:

- Sea Freight: Most cost-effective for heavy machinery. Use flat-rack or open-top containers if dimensions exceed standard sizes.

- Air Freight: Suitable for urgent deliveries; assess cost vs. weight limitations.

- Land Freight: Ideal for regional transport. Ensure trucks have sufficient load capacity and proper securing mechanisms.

- Handling Equipment: Forklifts, cranes, or rigging equipment must be available at both origin and destination to safely load/unload the machine.

Installation Site Preparation

- Facility Requirements:

- Adequate floor space with reinforced flooring to support machine weight.

- Proper ventilation and exhaust systems to manage heat and potential off-gassing during operation.

- Access to required utilities:

- Electrical supply (voltage, phase, and amperage as specified)

- Compressed air (if applicable)

- Cooling water (if equipped with water-cooled components)

- Safety Clearances: Maintain minimum clearance around the machine for maintenance, emergency access, and heat dissipation.

- Environmental Controls: Ensure ambient temperature and humidity fall within equipment specifications.

Compliance & Certification

- Safety Standards:

- CE Marking (EU): Complies with Machinery Directive 2006/42/EC, Low Voltage Directive, and EMC Directive.

- UL/CSA Certification (North America): Ensures electrical safety and fire hazard compliance.

- ISO 12100: General principles for machinery safety.

- Energy Efficiency: Comply with regional energy performance standards (e.g., EU Ecodesign Directive).

- Environmental Regulations:

- Manage heat emissions and ensure proper insulation to minimize energy waste.

- Follow local air quality regulations if off-gases (e.g., lubricant vapors) are generated.

- Operator Training & Documentation: Provide manuals in the local language and conduct safety training per OSHA (USA), HSE (UK), or equivalent national standards.

Maintenance & Operational Compliance

- Regular Inspections: Schedule routine checks of heating elements, insulation, electrical systems, and safety interlocks.

- Emissions Monitoring: If annealing involves protective atmospheres (e.g., nitrogen), monitor gas usage and leakage.

- Waste Management: Dispose of used furnace parts, insulation materials, or cleaning residues according to hazardous waste regulations if applicable.

Risk Management

- Insurance: Obtain cargo insurance for transit and property insurance for on-site equipment.

- Contingency Planning: Prepare for delays due to customs inspections, missing documentation, or infrastructure issues at the destination.

- Supplier Support: Confirm availability of spare parts and technical support in the destination country.

Conclusion

Proper logistics planning and regulatory compliance are vital for the successful deployment of a brass annealing machine. Engage qualified customs brokers, freight forwarders, and compliance consultants early in the process to ensure smooth transit and legal operation.

Conclusion for Sourcing an Annealing Machine for Brass

After a thorough evaluation of technical requirements, production needs, and supplier capabilities, sourcing an annealing machine for brass should prioritize precision, energy efficiency, and compatibility with your specific brass alloys and product dimensions. Continuous or batch-type annealing systems can be selected based on production volume and desired throughput, with options ranging from gas-fired to electric induction systems offering varying benefits in terms of temperature control and operational costs.

Key considerations such as uniform heating, controlled cooling rates, automation integration, and compliance with safety and environmental standards are essential to ensure high-quality, consistent annealing results that enhance the ductility, workability, and mechanical properties of brass components.

Ultimately, selecting a reliable supplier with proven expertise in metal heat treatment, strong after-sales support, and the ability to provide customized solutions will contribute significantly to long-term operational efficiency and product quality. Investing in a well-designed annealing machine tailored to brass processing not only improves material performance but also supports scalable and sustainable manufacturing practices.