The global laser welding market is experiencing robust expansion, driven by increasing demand for high-precision joining solutions across automotive, aerospace, and medical device manufacturing. According to a 2023 report by Mordor Intelligence, the market is projected to grow at a CAGR of 7.8% from 2023 to 2028, fueled by technological advancements and the rising adoption of automation in industrial processes. As part of this trend, Andes, a prominent player known for its high-power fiber laser systems, has emerged as a key supplier in the laser welding space. This growth trajectory has intensified competition among manufacturers striving to enhance beam quality, energy efficiency, and integration capabilities. Below are the top four Andes laser welder manufacturers shaping the industry with innovative, data-backed performance improvements and expanding global footprints.

Top 4 Andes Laser Welder Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 High

Website: junyi-laser.com

Key Highlights: Looking for a high-quality Andes handheld laser welder? Zhejiang Junyi Laser Equipment Co., Ltd. offers top-notch laser welding equipment for your business ……

#2

Website: andelaser.com

Key Highlights: Home · About Ande · Products · Laser Plate Cutting · Laser Tube Cutting · Laser Welding · Laser Marking&Engraving · Laser Cleaning….

#3 Laser 1500W Air Cooling Mini Metal Handheld Laser Welding …

Website: hurawalhi.com

Key Highlights: Laser 1500W Air Cooling Mini Metal Handheld Laser Welding Machine portable · You May Also Like · GET 20% OFF!…

#4 Wage Determinations Davis

Website: sam.gov

Key Highlights: This is a U.S. General Services Administration Federal Government computer system that is “FOR OFFICIAL USE ONLY.” This system is subject to monitoring….

Expert Sourcing Insights for Andes Laser Welder

H2: Market Trends for Andes Laser Welder in 2026

By 2026, the global market for laser welding technology, including products such as the Andes Laser Welder, is expected to experience significant transformation driven by advancements in automation, increased demand for precision manufacturing, and the expansion of electric vehicle (EV) and renewable energy sectors. Below is an analysis of key market trends shaping the landscape for Andes Laser Welder in 2026:

-

Growth in Industrial Automation and Smart Manufacturing

The continued rise of Industry 4.0 is accelerating the adoption of automated welding solutions. Andes Laser Welder, known for its precision and integration capabilities, is well-positioned to benefit from the increasing deployment of smart factories. By 2026, manufacturers are expected to prioritize laser welding systems that offer real-time monitoring, IoT connectivity, and seamless integration with robotic arms—features that Andes has been enhancing in its product line. -

Expansion in the Electric Vehicle and Battery Manufacturing Sector

The EV market is projected to grow exponentially by 2026, with global production surpassing 40 million units annually. Laser welding is critical in battery pack assembly, particularly for copper and aluminum components requiring high conductivity and minimal thermal distortion. Andes Laser Welder’s ability to deliver stable, high-quality welds in thin and dissimilar metals makes it a competitive solution for EV battery manufacturers, especially in Asia-Pacific and North America. -

Rising Demand in Precision Industries

Industries such as medical device manufacturing, aerospace, and consumer electronics demand micron-level welding accuracy. Andes’ focus on compact, fiber-based laser systems aligns well with this trend. In 2026, the company is likely to see increased adoption in high-tech sectors requiring miniaturization and high repeatability, particularly in countries with strong electronics manufacturing bases like China, Japan, and South Korea. -

Regional Market Shifts and Localization Strategies

Emerging markets in Southeast Asia, India, and Eastern Europe are investing heavily in advanced manufacturing infrastructure. By 2026, Andes may expand its market presence through localized service centers, partnerships with system integrators, and customized solutions tailored to regional industrial needs. This regional focus will help Andes compete with global players like IPG Photonics and Trumpf. -

Sustainability and Energy Efficiency Trends

As industries adopt greener manufacturing practices, energy-efficient equipment becomes a priority. Fiber laser welders, including those from Andes, offer higher electrical efficiency compared to traditional welding methods. By 2026, sustainability certifications and energy consumption metrics are expected to influence purchasing decisions, giving Andes a competitive edge if it emphasizes eco-design and lifecycle efficiency. -

Competitive Pressure and Technological Innovation

The laser welding market will remain highly competitive in 2026, with ongoing innovations in beam delivery, hybrid welding techniques, and AI-driven process optimization. Andes will need to continue investing in R&D to enhance weld speed, reduce maintenance costs, and improve user interfaces. Adoption of AI for defect detection and adaptive control could differentiate Andes in mid-tier industrial applications.

In conclusion, the 2026 market for Andes Laser Welder will be shaped by technological innovation, sector-specific demands, and global manufacturing trends. By aligning with automation, sustainability, and high-growth industries like EVs and electronics, Andes can strengthen its position as a key player in the global laser welding ecosystem.

Common Pitfalls When Sourcing Andes Laser Welders (Quality and IP Concerns)

Sourcing Andes Laser Welders—particularly from third-party suppliers or lower-cost manufacturers—can present significant risks related to product quality and intellectual property (IP) infringement. Being aware of these pitfalls is crucial for businesses aiming to protect their investments and avoid legal or operational complications.

Poor Build Quality and Performance Inconsistencies

One of the most frequent issues when sourcing non-genuine or counterfeit Andes laser welders is compromised build quality. These units may use substandard components—such as inferior optical lenses, unreliable cooling systems, or low-grade electrical parts—that lead to inconsistent weld quality, frequent breakdowns, and shorter equipment lifespans. Users may experience reduced precision, poor penetration, or unstable laser output, directly impacting production efficiency and product integrity.

Lack of Certification and Safety Compliance

Authentic Andes laser systems comply with international safety and quality standards (e.g., CE, FDA, ISO). Counterfeit or unauthorized copies often lack proper certification, posing serious safety risks to operators and facilities. Non-compliant units may not include essential safety interlocks, proper shielding, or adequate labeling, increasing liability and potentially violating workplace regulations.

Inaccurate or Missing Technical Documentation

Genuine Andes equipment comes with comprehensive, accurate technical documentation, including user manuals, maintenance guides, and calibration procedures. Imitation products often provide incomplete, poorly translated, or entirely missing documentation, making installation, troubleshooting, and training difficult. This can result in improper use, increased downtime, and safety hazards.

Risk of IP Infringement and Legal Exposure

Sourcing counterfeit or cloned Andes laser welders may expose your company to intellectual property violations. Andes holds patents and trademarks on its laser technology and designs. Purchasing unauthorized copies—even unknowingly—can lead to legal action, seizure of equipment by customs or regulatory bodies, and reputational damage. Businesses found complicit in IP infringement may face fines or lose certifications.

Voided Warranty and Lack of After-Sales Support

Counterfeit or grey-market Andes welders typically do not come with valid manufacturer warranties. Without access to official technical support, spare parts, or software updates, users are left to resolve issues independently. This lack of after-sales infrastructure increases total cost of ownership and extends machine downtime.

Misrepresentation of Specifications and Capabilities

Unscrupulous suppliers may falsely represent the power output, wavelength, or automation compatibility of imitation units. For example, a device may be advertised as a 1500W fiber laser but deliver significantly less power due to downgraded components. This misrepresentation can lead to unexpected project failures, especially in high-precision industrial applications.

Supply Chain and Traceability Issues

When sourcing from unauthorized distributors or online marketplaces, traceability of the product’s origin is often unclear. This opacity makes it difficult to verify authenticity, assess manufacturing conditions, or respond to recalls. Poor supply chain transparency increases the risk of receiving stolen, reconditioned, or blacklisted equipment.

To mitigate these risks, always purchase Andes laser welders through authorized dealers, verify product serial numbers with the manufacturer, and conduct due diligence on suppliers. Investing in genuine equipment ensures reliability, safety, compliance, and protection against IP-related legal issues.

Logistics & Compliance Guide for Andes Laser Welder

This guide provides essential information for the safe, efficient, and compliant handling, transportation, importation, and operation of the Andes Laser Welder. Adherence to these guidelines ensures regulatory compliance, protects personnel, and maintains equipment integrity.

Shipping & Handling

- Packaging: The Andes Laser Welder is shipped in a robust, custom-designed crate with internal foam supports to prevent movement during transit. Ensure packaging remains intact until installation.

- Weight & Dimensions: Verify the unit’s weight and dimensions prior to shipment to ensure compatibility with loading docks, elevators, and doorways. Typical configurations may exceed 200 kg; use appropriate lifting equipment.

- Lifting Instructions: Always use a forklift or overhead crane with slings rated for the unit’s weight. Never lift by handles or external components. Refer to the manual for designated lifting points.

- Environmental Conditions: Avoid exposure to extreme temperatures, moisture, or dust during transport and storage. Store in a dry, indoor environment with temperatures between 5°C and 40°C.

Import & Export Compliance

- HS Code: The Andes Laser Welder typically falls under HS Code 8515.31 (Laser welding machines). Confirm with local customs authorities as classifications may vary by region.

- Export Controls: This equipment may be subject to export regulations due to its laser power and industrial application. Check compliance with:

- EAR (Export Administration Regulations, USA): May require a license depending on destination country and end-user.

- Wassenaar Arrangement: Controls on dual-use goods; laser systems above certain power thresholds may be listed.

- Documentation: Provide commercial invoice, packing list, bill of lading/airway bill, and Certificate of Origin. Include technical specifications for customs clearance.

- Restricted Destinations: Verify that the destination country is not under trade sanctions or embargoes (e.g., via U.S. OFAC or EU sanctions lists).

Regulatory Certifications

- Laser Safety: The Andes Laser Welder complies with:

- IEC 60825-1: Safety of laser products – Equipment classification and requirements.

- FDA 21 CFR Part 1040.10 (U.S.): Performance standards for laser products.

- Labeled as a Class 4 Laser Product – requires strict safety controls.

- Electrical Safety: Certified to:

- IEC 60204-1: Safety of machinery – Electrical equipment of machines.

- CE Marking (EU): Indicates conformity with health, safety, and environmental protection standards.

- UL/CSA (North America): Available upon request; confirm model-specific certification.

- EMC Compliance: Meets IEC 61326-1 for electromagnetic compatibility in industrial environments.

Installation & Operational Compliance

- Site Requirements:

- Stable power supply: 3-phase, 400V ±10%, 50/60 Hz. Use a dedicated circuit.

- Ambient temperature: 15°C to 35°C, humidity <70% non-condensing.

- Adequate ventilation and dust extraction if integrated with automated systems.

- Laser Safety Measures:

- Install in a controlled access area with interlocked enclosures.

- Use appropriate laser protective eyewear (OD 6+ at 1070 nm) for personnel.

- Post laser warning signs at entrances per ANSI Z136.1 or IEC 60825.

- Conduct a laser safety audit before operation.

- Training: Operators must complete laser safety training and equipment-specific operation courses. Maintain training records.

Maintenance & Documentation

- Scheduled Maintenance: Follow the manufacturer’s maintenance schedule (e.g., optical alignment, cooling system checks) to ensure compliance and performance.

- Service Records: Keep logs of all maintenance, repairs, and safety inspections. Required for regulatory audits.

- Spare Parts: Use only OEM-approved components to maintain certification integrity.

Disposal & End-of-Life

- Waste Electrical Equipment: Dispose of the laser welder in accordance with WEEE Directive (EU) or local e-waste regulations.

- Batteries & Capacitors: Handle high-voltage components per hazardous waste protocols.

- Laser Optics: Recycling or disposal of optical components may require special handling; consult local environmental agencies.

Contact & Support

For compliance documentation, technical support, or certification verification, contact Andes Technical Support:

Email: [email protected]

Phone: +1 (800) 555-ANDES

Website: www.andeslaser.com/compliance

Conclusion: Sourcing the Andes Laser Welder

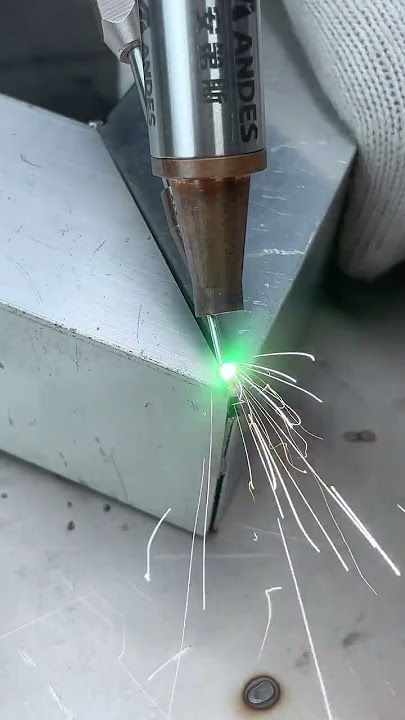

After a thorough evaluation of available laser welding technologies and suppliers, sourcing the Andes Laser Welder emerges as a strategic and competitive choice for enhancing manufacturing precision, efficiency, and quality. The Andes Laser system offers advanced fiber laser technology, known for its reliability, energy efficiency, and superior weld consistency on a range of materials, including stainless steel, aluminum, and other reflective metals.

Key advantages of sourcing the Andes Laser Welder include:

- High Precision and Speed: Enables fine, clean welds with minimal heat distortion, ideal for intricate or high-tolerance components.

- Robust Build and Low Maintenance: Designed for industrial environments with minimal downtime and service requirements.

- Cost-Effectiveness: Competitive pricing compared to other high-end laser systems, with long-term savings through reduced consumable use and energy consumption.

- Strong Technical Support and Service Network: Andes provides reliable training, after-sales service, and spare parts availability, ensuring operational continuity.

- Scalability and Integration: Compatible with automation and robotic systems, supporting future production scaling and digital manufacturing initiatives.

Furthermore, sourcing from Andes supports supply chain diversification, especially as the company maintains a strong presence in global markets with localized support options.

In conclusion, the Andes Laser Welder represents a well-balanced investment that aligns with both current production needs and long-term growth objectives. It delivers advanced performance, operational efficiency, and strong vendor support—making it a recommended choice for organizations aiming to elevate their welding capabilities in a competitive manufacturing landscape.