The global anchor manufacturing market has seen steady expansion, driven by rising offshore construction, maritime transportation, and marine infrastructure development. According to Mordor Intelligence, the global marine equipment market—which includes anchors and anchoring systems—is projected to grow at a CAGR of over 5.2% from 2023 to 2028. Similarly, Grand View Research estimates that the global marine and offshore mooring equipment market size was valued at USD 4.1 billion in 2022 and is expected to expand at a CAGR of 5.8% through 2030. With increasing demand for reliable mooring solutions in deepwater oil & gas operations, offshore wind farms, and commercial shipping, the performance and pulling capacity of anchors have become critical differentiators. This has elevated the importance of anchor manufacturers who specialize in high-pull designs capable of withstanding extreme marine conditions. Below, we spotlight the top 9 anchor manufacturers renowned for engineering robust, high-performance anchoring systems that lead the industry in holding power and innovation.

Top 9 Anchors With Pull Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Electrical Construction Hardware Manufacturer & Supplier. Anchors

Domain Est. 1996

Website: minerallac.com

Key Highlights: Concrete/Masonry Anchors · Hollow Wall Anchors · Plastic Anchors · Wall Dog Universal Anchors….

#2 Liberty Anchors

Domain Est. 1997

Website: dfsusa.com

Key Highlights: The DFS Liberty Anchor was designed for anchoring and through-bolting into hollow walls, ceilings and other blind space applications….

#3 McMaster

Domain Est. 1994

Website: mcmaster.com

Key Highlights: McMaster-Carr is the complete source for your plant with over 700000 products. 98% of products ordered ship from stock and deliver same or next day….

#4 TOGGLER – High

Domain Est. 1995

Website: toggler.com

Key Highlights: SNAPTOGGLE®. Heavy-Duty Toggle Bolts. Hollow Materials. The Perfect TV Mount In Stainless Steel And Zinc Plated Carbon Steel ; TOGGLER®. Plastic Toggle Anchors….

#5 Titen HD® Heavy

Domain Est. 1995

Website: strongtie.com

Key Highlights: A high-strength screw anchor for use in cracked and uncracked concrete, as well as uncracked masonry. The Titen HD offers low installation torque and ……

#6 Light Duty Anchors

Domain Est. 1997

Website: anchors.dewalt.com

Key Highlights: Mechanical Anchors, Wedge Expansion Anchors, Undercut Anchors, Cast-In Anchor Inserts, Screw Anchors, Sleeve Anchors, Bolt & Shield Anchors, Rod Hanging ……

#7 Rocna Anchors

Domain Est. 2004

Website: rocna.com

Key Highlights: “The Rocna was a powerful, impressive performer in our tests, recording instant sets at multiple 5,000 lb maximum (or near max) pulls at 5:1 scope….

#8 EZ Ancor

Domain Est. 2006

Website: easyanchors.com

Key Highlights: EZ Ancors are a simple, secure, fast, and easy way to install whatever you need into drywall, with a holding of strength up to 100 pounds in shear applications….

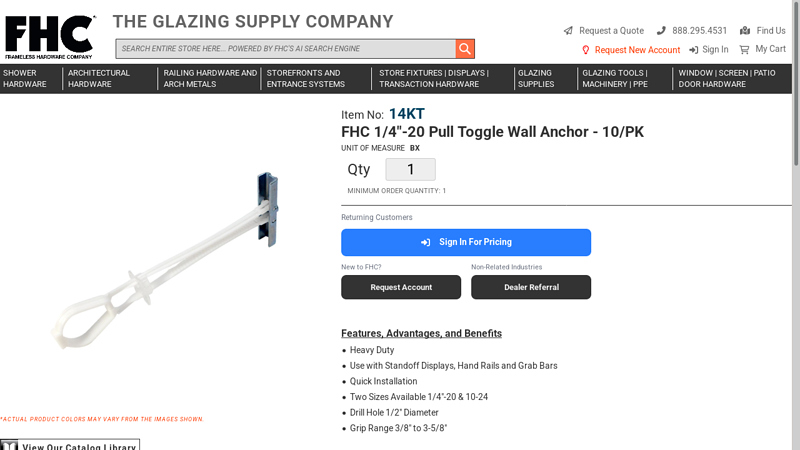

#9 FHC

Domain Est. 2019

Website: fhc-usa.com

Key Highlights: FHC Pull Toggle Wall Anchors are heavy-duty anchors that are used when installing standoff displays, hand rails or grab bars. Available in 1/4″ or 3/16″ and are ……

Expert Sourcing Insights for Anchors With Pull

H2: Market Trends for Anchors With Pull in 2026

In 2026, the global market for Anchors With Pull—commonly used in marine, construction, and offshore energy sectors—is expected to experience significant evolution driven by technological innovation, sustainability demands, and shifting industrial needs. Below is an analysis of key trends shaping the Anchors With Pull market in 2026:

-

Increased Demand in Offshore Renewable Energy

The rapid expansion of offshore wind farms, particularly in Europe, North America, and parts of Asia-Pacific, is fueling demand for high-performance anchoring systems. Anchors With Pull are critical for mooring floating wind turbines and platforms, especially in deep-water installations. As governments push for carbon neutrality, investments in offshore renewables are expected to rise, directly boosting the Anchors With Pull market. -

Advancements in Material Science and Design

By 2026, manufacturers are increasingly adopting high-strength, corrosion-resistant materials such as advanced composites and marine-grade alloys. These materials enhance the durability and load-bearing capacity of anchors, allowing for greater pull efficiency and longevity in harsh marine environments. Computational modeling and AI-driven simulations are also optimizing anchor geometries for specific seabed conditions. -

Automation and Smart Anchoring Systems

Integration of IoT sensors and real-time monitoring into anchoring systems is a growing trend. Anchors With Pull equipped with load sensors, GPS tracking, and automated release mechanisms are gaining traction, especially in commercial shipping and offshore operations. These “smart anchors” improve safety, reduce human error, and enable predictive maintenance. -

Sustainability and Environmental Regulations

Environmental concerns are reshaping anchor design and deployment practices. Regulatory bodies are imposing stricter guidelines on seabed disturbance and marine ecosystem protection. As a result, low-impact anchor solutions that minimize sediment disruption and support eco-friendly installation methods are becoming standard in sensitive areas. -

Growth in Emerging Markets

Developing regions such as Southeast Asia, Africa, and Latin America are investing heavily in port infrastructure and inland waterway transportation. This infrastructure development is increasing demand for reliable anchoring systems capable of withstanding variable water conditions and heavy usage, positioning Anchors With Pull as essential components. -

Supply Chain Resilience and Localization

Post-pandemic supply chain disruptions have prompted companies to localize manufacturing and diversify sourcing. In 2026, regional production hubs for marine hardware are emerging, reducing dependence on single-source suppliers and improving delivery timelines for Anchors With Pull. -

Rising Adoption in Aquaculture and Floating Infrastructure

The global aquaculture industry and floating city projects are adopting Anchors With Pull for securing cages, platforms, and modular floating structures. These applications require consistent pull performance and resistance to biofouling, stimulating innovation in anchor coatings and deployment techniques.

Conclusion:

By 2026, the Anchors With Pull market is poised for robust growth, driven by digitalization, sustainability mandates, and expanding offshore activities. Companies that invest in R&D, adhere to environmental standards, and adapt to regional market needs will be best positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing Anchors With Pull (Quality, IP)

Sourcing “Anchors With Pull” – whether referring to physical components like anchoring systems with tensioning mechanisms or metaphorical elements such as marketing hooks with engagement power – presents several recurring challenges, especially concerning quality and intellectual property (IP). Being aware of these pitfalls is essential to ensure reliability, compliance, and long-term success.

Poor Quality Control and Inconsistent Standards

One of the most significant risks when sourcing anchors with pull functionality is encountering substandard quality. Suppliers, particularly in competitive overseas markets, may cut corners on materials, manufacturing processes, or testing procedures. This can lead to anchors that fail under load, compromise structural integrity, or require premature replacement. Inconsistent tolerances and lack of adherence to international standards (e.g., ISO, ASTM) further exacerbate quality concerns, making performance unpredictable and potentially hazardous.

Inadequate or Missing Certifications

Reputable sourcing requires verification of product certifications, such as load testing reports, material traceability, and compliance with industry-specific regulations. Many suppliers may provide falsified or generic documentation that doesn’t reflect the actual product quality. Without proper certification, buyers assume undue risk, especially in applications involving safety-critical loads or public infrastructure.

Intellectual Property Infringement Risks

When sourcing specialized anchor designs—especially those incorporating patented mechanisms or proprietary technology—there is a real danger of inadvertently purchasing counterfeit or IP-infringing products. Some manufacturers replicate patented pull systems without authorization, offering them at lower prices. Buyers who source such products may face legal liability, shipment seizures, or reputational damage, even if unaware of the infringement.

Lack of Transparency in Supply Chain

Opaque supply chains make it difficult to verify the origin of components, materials used, and manufacturing practices. This lack of transparency increases the risk of receiving products made with subpar alloys, unethical labor practices, or non-compliant processes. It also complicates efforts to trace defects or enforce warranties when issues arise.

Misaligned Specifications and Functional Requirements

Anchors with pull mechanisms often have nuanced performance criteria—such as pull strength, corrosion resistance, or dynamic load capacity. Miscommunication or vague specifications during sourcing can result in components that don’t meet operational needs. Relying solely on supplier claims without independent verification or prototyping can lead to costly project delays or failures.

Overlooking Long-Term Support and Warranty

Some low-cost suppliers offer attractive initial pricing but provide little to no after-sales support, technical assistance, or warranty coverage. If an anchor fails or requires maintenance, the absence of reliable customer service or spare parts can disrupt operations and increase total cost of ownership.

Avoiding these pitfalls requires due diligence: conducting thorough supplier audits, demanding verifiable certifications, performing independent quality testing, and consulting legal experts to ensure IP compliance. A proactive approach to sourcing protects both project integrity and organizational reputation.

Logistics & Compliance Guide for Anchors With Pull

Anchors With Pull specializes in high-performance anchoring and mooring solutions. To ensure seamless operations, safety, and regulatory adherence, this guide outlines essential logistics protocols and compliance requirements for all shipments, installations, and business activities.

Order Fulfillment & Shipping Procedures

All orders are processed within 1–2 business days upon confirmation. Standard shipping options include ground, expedited, and freight delivery, depending on product size and destination. Oversized or heavy-duty anchors (e.g., deadweight, helix, or suction anchors) require freight shipping with lift-gate service. Customers will receive a tracking number and estimated delivery window via email. Signature upon delivery is required for all high-value shipments.

Packaging & Handling Standards

Products are packaged to meet international shipping and handling safety standards. Anchors are secured with protective coatings, wooden crating, or steel strapping where necessary to prevent transit damage. Handling instructions, including weight ratings and lifting points, are clearly marked on packaging. Customers must inspect all deliveries upon receipt and report any damages within 48 hours.

Import/Export Compliance

Anchors With Pull complies with all U.S. export regulations, including those administered by the Department of Commerce (Bureau of Industry and Security). Export Classification Numbers (ECCNs) are assigned to applicable products. Documentation such as commercial invoices, packing lists, and certificates of origin are provided for international shipments. Customers are responsible for customs clearance, duties, and compliance with local import laws.

Regulatory & Safety Compliance

Products are manufactured in accordance with ISO 9001 quality management standards and relevant marine engineering codes (e.g., ABS, DNV, or API specifications where applicable). Anchors are tested for load capacity, corrosion resistance, and structural integrity. Safety data sheets (SDS) are available upon request for treated metals or coatings. Installation must follow manufacturer guidelines and local maritime regulations.

Environmental & Sustainability Practices

Anchors With Pull adheres to environmental regulations concerning material sourcing, waste disposal, and emissions. We use recyclable packaging materials and partner with logistics providers committed to carbon reduction initiatives. Our galvanization and coating processes comply with EPA standards to minimize environmental impact.

Documentation & Recordkeeping

All transactions, shipping records, and compliance certifications are retained for a minimum of seven years. Required documents include:

– Bill of lading

– Certificate of compliance

– Test reports (e.g., tensile strength, non-destructive testing)

– Export control documentation (for international orders)

Customers may request copies of relevant documentation for audit or project reporting purposes.

Customer Responsibilities

Buyers are responsible for:

– Ensuring site readiness for delivery

– Providing appropriate equipment for offloading

– Verifying anchor specifications match project requirements

– Complying with local permitting and marine construction regulations

Failure to meet these responsibilities may result in project delays or liability for additional service charges.

Support & Issue Resolution

Contact the Anchors With Pull Logistics Team at [email protected] or +1 (800) 555-0199 for shipment inquiries, compliance questions, or delivery issues. We are committed to resolving logistics concerns promptly and maintaining full regulatory transparency.

Conclusion for Sourcing Anchors with Pull:

Sourcing anchors with pull requires a strategic approach that balances performance, reliability, and cost-effectiveness. It is essential to identify suppliers who offer high-quality anchoring solutions designed to withstand specific load requirements and environmental conditions. Key considerations include material strength, installation method, certification standards, and technical support. Evaluating supplier reputation, lead times, and post-purchase service ensures long-term project success. By prioritizing suppliers with proven expertise in tension and pull applications—such as mechanical, adhesive, or expansion anchors—organizations can ensure structural integrity and safety. Ultimately, effective sourcing of pulling anchors contributes to enhanced project efficiency, compliance, and overall durability of the installed systems.