The global analog panel meters market is experiencing steady growth, driven by increasing demand for precise measurement and monitoring solutions across industrial automation, energy, and manufacturing sectors. According to Mordor Intelligence, the global panel meter market was valued at USD 867.5 million in 2023 and is projected to grow at a CAGR of over 4.5% during the forecast period from 2024 to 2029. This expansion is fueled by the rising adoption of analog instruments in legacy systems, especially in regions with extensive industrial infrastructure, due to their reliability, ease of use, and cost-effectiveness in basic monitoring applications. Despite the growing shift toward digital instrumentation, analog panel meters continue to hold a significant market share, particularly in HVAC, power distribution, and process control industries where visual, real-time readings without power dependency remain critical. Against this backdrop, a select group of manufacturers have emerged as leaders, combining decades of engineering expertise with global supply capabilities to dominate the analog instrumentation space. Here are the top nine analog panel meter manufacturers shaping the industry today.

Top 9 Analog Panel Meters Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

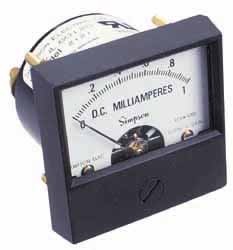

#1 Simpson Electric

Domain Est. 1997

Website: simpsonelectric.com

Key Highlights: Simpson Electric is the premier manufacturer of digital panel meters, analog panel meters, and test instruments and equipment for a wide variety of ……

#2 Analog Panel Meters Ram Meter, Inc.

Domain Est. 1998

Website: rammeter.com

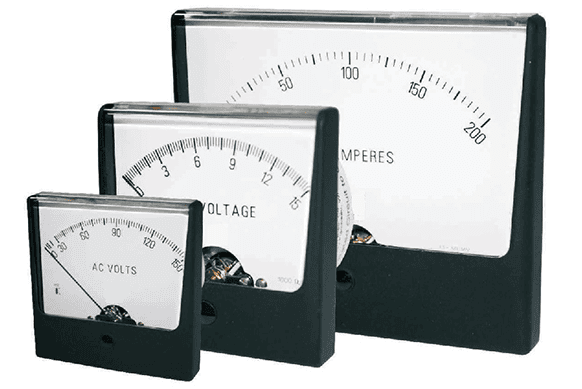

Key Highlights: 4–10 day deliveryAnalog panel meters can read a variety of inputs and are available in sizes from 1.5″ to 4.5″. Ram Meter Inc. is the source for all of ……

#3 Analog Panel Meters

Domain Est. 1999

Website: hoytmeter.com

Key Highlights: Hoyt high quality Analog Panel Meters are proudly made in the USA to meet your unique requirements for commercial, industrial and consumer using….

#4 Analog Panel Meters

Domain Est. 1994

Website: newark.com

Key Highlights: Free delivery over $150Newark provides a reliable range of analog panel meters designed for clear, real-time indication of electrical parameters….

#5 Analog Panel Meters

Domain Est. 1996

Website: electro-meters.com

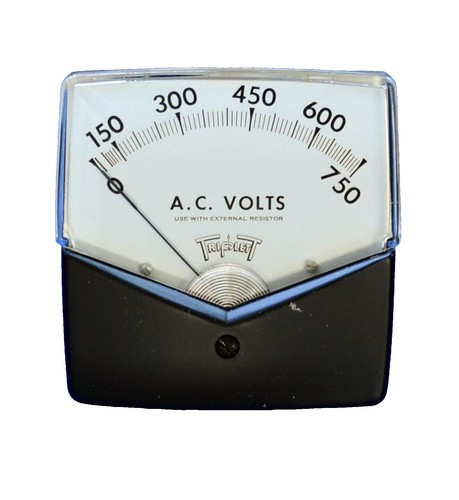

Key Highlights: Analog panel meters are simple and reliable instruments used for measuring and displaying various electrical quantities….

#6

Domain Est. 1997

Website: electronumerics.com

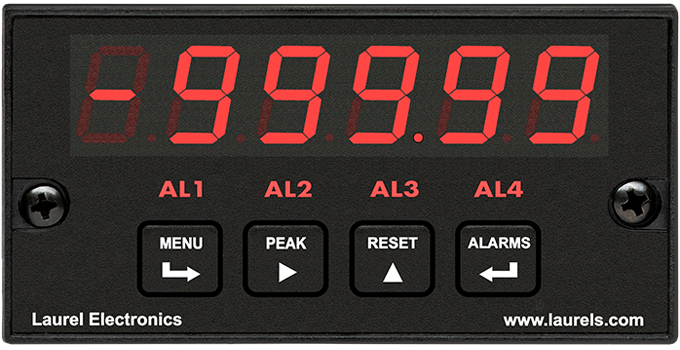

Key Highlights: Great Prices & Fast Shipping of Digital Panel Meters, Large Digit Displays, DC, AC, Process, Weight and Temperature Panel Meters, Counters & Timers….

#7 Analog Panel Meters

Domain Est. 2000

Website: jewellinstruments.com

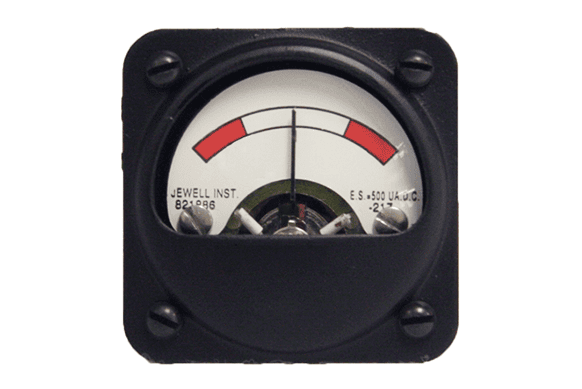

Key Highlights: Jewell Instruments offers a wide range of moving iron, moving coil, and stepper motor analog panel meters in A&M, Emico, Jewell, and Modutec Series….

#8 Analog Meters

Domain Est. 2000

Website: weschler.com

Key Highlights: Weschler analog meters are available in ANSI switchboard styles, as well as standard industry panel meter sizes. Made in USA….

#9 Brighton Electronics Panel Meters & Test Instruments

Domain Est. 2006

Website: beimeter.com

Key Highlights: Brighton Electronics offers various analog panel meters, digital panel meters including voltmeters and ammeters, and strain gauge load cell indicators….

Expert Sourcing Insights for Analog Panel Meters

2026 Market Trends for Analog Panel Meters

Market Resilience Amidst Digital Transformation

Despite the widespread adoption of digital instrumentation, analog panel meters are expected to maintain a stable niche presence in the 2026 market. Their enduring appeal lies in reliability, simplicity, and cost-effectiveness in specific industrial environments. Sectors such as heavy manufacturing, legacy system maintenance, and applications requiring immediate visual trend interpretation continue to favor analog displays. The absence of software dependencies or power fluctuations makes them ideal for harsh conditions where digital screens may fail, supporting sustained demand in oil & gas, power generation, and older production facilities undergoing gradual modernization.

Growing Demand in Retrofit and Maintenance Applications

A key driver for analog panel meters in 2026 is the need for replacements in aging infrastructure. As industries extend the life of existing equipment, there is a steady demand for compatible analog components to maintain operational continuity. Original equipment manufacturers (OEMs) and maintenance service providers are increasingly sourcing analog meters for repair and refurbishment projects, particularly in regions with slower industrial upgrade cycles. This trend is amplified by the longer lifespan of analog devices, which reduces total cost of ownership in low-data-frequency applications.

Regional Variations and Emerging Market Opportunities

While mature markets like North America and Western Europe show modest growth, emerging economies in Southeast Asia, India, and parts of Latin America represent rising opportunities. In these regions, analog meters are favored due to lower installation and training costs, making them accessible for small-to-medium enterprises (SMEs) and developing infrastructure projects. Additionally, educational institutions and training labs continue to use analog meters to teach fundamental electrical principles, ensuring a baseline level of demand.

Technological Integration and Hybrid Solutions

By 2026, the market is witnessing a shift toward hybrid instrumentation, where analog meters are integrated with digital backplanes or IoT-enabled monitoring systems. This allows for visual analog readouts while supporting data logging and remote diagnostics via connected sensors. Such innovations are extending the relevance of analog technology, blending traditional usability with modern connectivity. Manufacturers are responding by offering analog meters with optional digital outputs or compatibility with SCADA systems.

Challenges from Digital Alternatives and Sustainability Pressures

The primary challenge remains competition from advanced digital displays, which offer higher precision, data storage, and programmability. As Industry 4.0 initiatives accelerate, facilities upgrading to smart manufacturing systems often bypass analog solutions entirely. Additionally, environmental regulations and the push for energy-efficient components may limit growth, as analog meters typically consume more power than modern digital counterparts and lack energy monitoring features.

Conclusion

In 2026, the analog panel meter market will persist through strategic adaptation rather than expansion. Its trajectory is defined by reliability in legacy systems, cost advantages in specific applications, and incremental innovation through hybrid designs. While not a high-growth sector, it remains a vital component in the broader industrial instrumentation ecosystem, serving critical roles where simplicity and durability outweigh advanced functionality.

Common Pitfalls When Sourcing Analog Panel Meters (Quality, IP)

Poor Build Quality and Inaccurate Readings

Low-cost analog panel meters often suffer from subpar construction, including weak damping mechanisms, misaligned scales, and low-quality internal movements (e.g., inferior moving coil mechanisms). These issues lead to inaccurate readings, needle oscillation, and premature failure. Sourcing from unverified suppliers increases the risk of receiving meters that do not meet stated accuracy specifications (e.g., claiming ±2% but performing at ±5% or worse).

Inadequate or Misrepresented IP Ratings

Many suppliers, especially on open marketplaces, exaggerate or falsify Ingress Protection (IP) ratings. A meter advertised as IP65 may lack proper gaskets, use low-grade enclosures, or have poorly sealed terminals, making it unsuitable for dusty or wet environments. Without independent verification or certification, the meter may fail in harsh industrial conditions, leading to safety hazards and equipment damage.

Counterfeit or Non-Compliant Components

There’s a risk of receiving counterfeit meters that mimic reputable brands but use inferior internal components. These may lack essential safety certifications (e.g., CE, UL, RoHS) or fail to comply with regional regulations. Using such meters can result in non-compliance during audits and potential liability in case of system failure.

Inconsistent Calibration and Long-Term Drift

Cheaply sourced meters often come with poor or no factory calibration. Over time, these meters exhibit significant drift due to low-quality springs, magnets, and bearings, resulting in unreliable measurements. This necessitates frequent recalibration or replacement, increasing total cost of ownership.

Limited Temperature and Environmental Tolerance

Many budget meters are not designed for extreme temperatures, humidity, or vibration. Their performance degrades rapidly in industrial environments, leading to erratic readings or mechanical failure. Always verify operating temperature ranges and environmental specs, as published data may not reflect real-world performance.

Lack of Technical Support and Documentation

Sourcing from obscure suppliers often means limited access to technical datasheets, mounting dimensions, wiring diagrams, or application support. This complicates integration and troubleshooting, especially in mission-critical systems where reliability is paramount.

Supply Chain and Long-Term Availability Risks

Low-cost suppliers may discontinue models without notice or lack the capacity for long-term supply. This creates challenges for maintenance, repairs, and system upgrades, potentially leading to system downtime when replacement parts are unavailable.

Logistics & Compliance Guide for Analog Panel Meters

Product Classification and HS Code

Analog Panel Meters are typically classified under Harmonized System (HS) Code 9026.10, which covers instruments and apparatus for measuring or checking flow, level, pressure, or other variables of liquids or gases. Accurate classification is essential for determining import duties, taxes, and regulatory requirements in the destination country. Always verify the specific HS code with local customs authorities, as sub-classifications may vary by region or meter functionality.

Packaging and Shipping Requirements

Proper packaging is critical to protect sensitive analog components during transit. Use anti-static materials, cushioned inner packaging, and rigid outer cartons to prevent mechanical shock, vibration, and moisture damage. Clearly label packages with handling instructions such as “Fragile,” “This Side Up,” and “Protect from Moisture.” Include product identifiers, model numbers, and safety warnings. Ensure compliance with international shipping standards (e.g., ISTA, ASTM) and use carriers experienced in handling precision instruments.

Export Controls and Licensing

Analog Panel Meters generally do not require export licenses under most international regimes (e.g., U.S. EAR or EU Dual-Use regulations), as they are not considered strategic or dual-use items. However, verify export control classifications (ECCN) based on specifications and end-use. If integrated with digital communication or used in restricted industries (e.g., defense, nuclear), additional licensing may be required. Always conduct end-user screening and maintain records for audit purposes.

Import Regulations and Duties

Import regulations vary by country and may include conformity assessments, local certification, or labeling requirements. Check with the destination country’s customs authority for import duties, value-added tax (VAT), or other fees. Provide accurate commercial invoices, packing lists, and certificates of origin to avoid delays. Some countries may require third-party inspection or pre-shipment verification of compliance.

Electrical and Safety Compliance

Ensure analog panel meters comply with relevant electrical safety standards, such as IEC 61010-1 for safety requirements for electrical equipment used in measurement and laboratory applications. In North America, UL or CSA certification may be required. European markets require CE marking, demonstrating conformity with the Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive. Provide technical documentation and declaration of conformity with shipments.

Calibration and Traceability

For regulated industries (e.g., pharmaceuticals, energy), meters may require calibration traceable to national or international standards (e.g., NIST, ISO/IEC 17025). Offer calibrated units with certificates when requested. Maintain calibration records and ensure packaging protects calibration integrity during shipping.

Environmental and RoHS Compliance

Analog Panel Meters must comply with environmental regulations such as the EU’s Restriction of Hazardous Substances (RoHS) Directive, which limits the use of lead, mercury, cadmium, and other substances. Confirm that components and manufacturing processes meet RoHS and REACH requirements. Provide compliance documentation upon request, especially for shipments to Europe or environmentally regulated markets.

Labeling and Documentation

Include multilingual product labels where required, showing voltage, current ratings, safety symbols, and manufacturer information. Shipments must include user manuals, safety instructions, and compliance certificates in the language of the destination country if mandated. Maintain records of all compliance documentation for a minimum of five years.

Returns and Warranty Logistics

Establish a clear return material authorization (RMA) process for defective or non-conforming units. Define warranty terms, repair/replacement procedures, and responsibilities for return shipping. Ensure compliance with local consumer protection laws, especially in the EU and North America.

Summary

Successful logistics and compliance for Analog Panel Meters depend on accurate classification, robust packaging, adherence to safety and environmental standards, and thorough documentation. Proactive engagement with regulatory requirements in both origin and destination countries minimizes delays and ensures smooth global distribution.

Conclusion: Sourcing Analog Panel Meters

In conclusion, sourcing analog panel meters requires a careful balance between technical specifications, quality, cost, and availability. While digital instrumentation continues to advance, analog panel meters remain valuable in applications where visual trend monitoring, simplicity, reliability, and ease of integration are prioritized—especially in industrial, automotive, audio, and educational settings.

When sourcing these components, it is essential to consider factors such as measurement range, accuracy, physical dimensions, scale customization, input signal type (e.g., voltage, current), and compatibility with existing systems. Additionally, prioritizing reputable suppliers and manufacturers ensures long-term reliability and consistency in performance.

Despite the growing prevalence of digital alternatives, analog panel meters continue to serve a niche role where real-time, at-a-glance readings and aesthetic appeal are important. By evaluating both standard and custom solutions, and by building relationships with trusted component suppliers, organizations can effectively source analog panel meters that meet their functional requirements while maintaining cost-efficiency and supply chain resilience.

Ultimately, the successful integration of analog panel meters into modern systems reflects a thoughtful approach to instrumentation—one that honors proven analog technology while supporting current operational needs.