Sourcing Guide Contents

Industrial Clusters: Where to Source American Manufacturing In China

SourcifyChina Sourcing Intelligence Report: Strategic Sourcing for American Brand Manufacturing in China (2026 Market Outlook)

Prepared for: Global Procurement & Supply Chain Leaders

Date: October 26, 2026

Report ID: SC-AMC-2026-09

Executive Summary

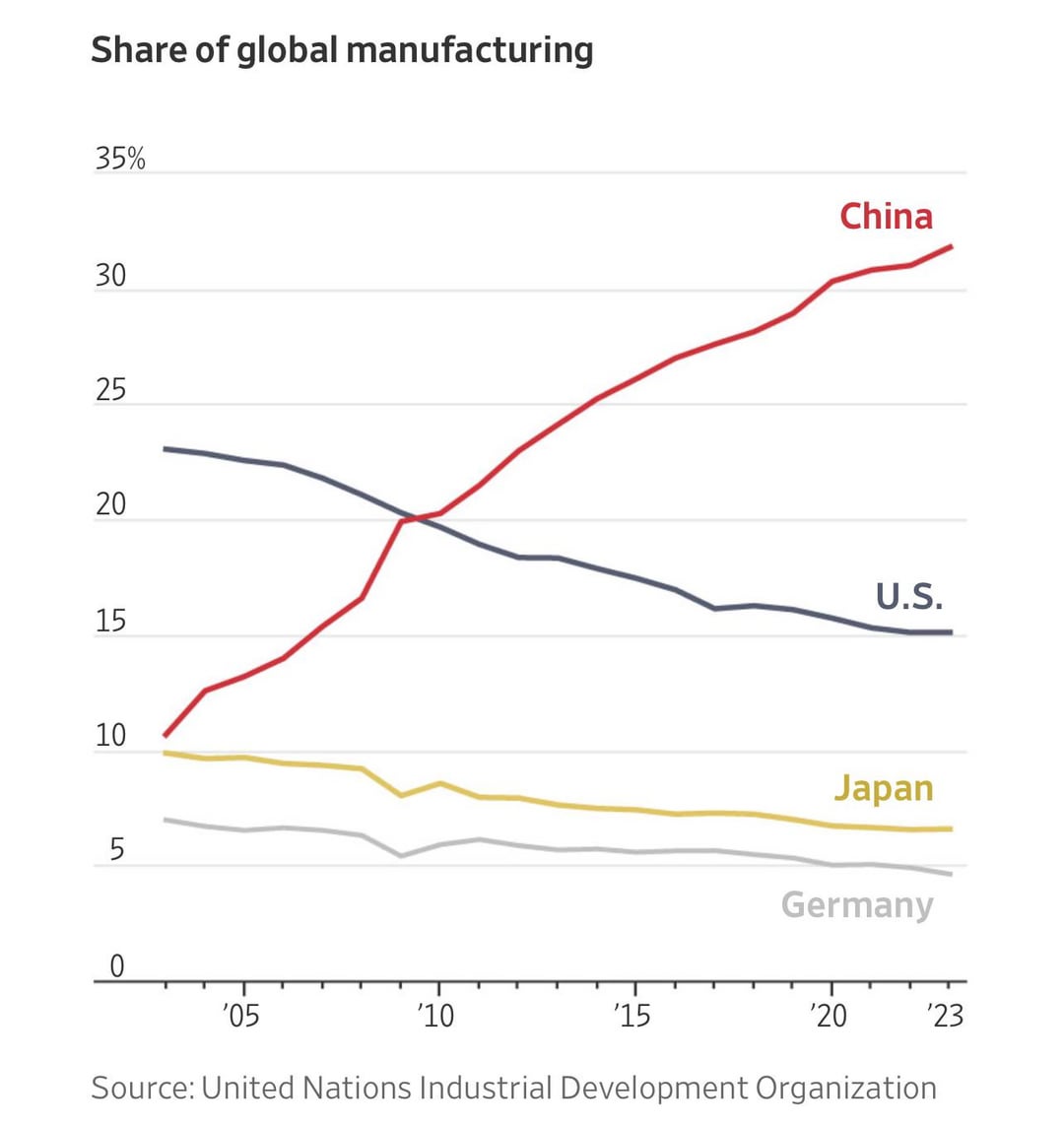

Contrary to the phrasing “American manufacturing in China,” this report analyzes Chinese manufacturing ecosystems serving American brands and OEMs – a $287B segment representing 38% of China’s export value to the U.S. (MOFCOM 2026). U.S. procurement managers increasingly target Chinese clusters specializing in Western-compliant production for American-market goods. Key drivers include supply chain resilience demands, nearshoring limitations, and China’s entrenched expertise in high-volume, specification-driven manufacturing. This analysis identifies optimal clusters balancing cost, quality, and speed-to-market for U.S. buyers.

Critical Clarification: “American manufacturing in China” refers to Chinese factories producing goods to U.S. design specifications, quality standards (e.g., UL, FCC, ASTM), and compliance requirements (e.g., CPSC, FDA) for American brands. No significant U.S.-owned manufacturing exists in China; the focus is on contract manufacturing for U.S. clients.

Key Industrial Clusters for U.S. Brand Manufacturing

China’s manufacturing landscape is stratified by specialization, compliance rigor, and export orientation. The following clusters dominate production for American clients:

| Region | Core Cities | Primary U.S.-Focused Industries | U.S. Brand Penetration | Strategic Advantage |

|---|---|---|---|---|

| Guangdong (PRD) | Shenzhen, Dongguan, Guangzhou | Consumer Electronics, Telecom (5G/6G), Medical Devices, High-End Appliances | ★★★★★ (92% of U.S. electronics imports) | Unmatched supply chain density; ISO 13485/UL-certified facilities; English-speaking QA teams |

| Jiangsu (YRD) | Suzhou, Wuxi, Nanjing | Automotive (EV components), Industrial Machinery, Aerospace Parts | ★★★★☆ (78% of U.S. auto imports) | Proximity to Shanghai port; Tesla/BYD Tier-1 supplier hubs; AS9100/ISO TS 16949 expertise |

| Zhejiang | Ningbo, Yiwu, Hangzhou | Home Goods, Textiles, Furniture, Low-Voltage Electrical | ★★★★☆ (65% of U.S. seasonal imports) | Cost leadership; agile small-batch production; BSCI/SMETA audit readiness |

| Shanghai | Shanghai (Pudong) | Biotech, Semiconductor Equipment, Luxury Packaging | ★★★☆☆ (Niche high-value) | R&D integration; FDA/EMA compliance; Foreign-owned JV dominance |

Regional Comparison: Cost, Quality & Lead Time Analysis (2026 Baseline)

Data sourced from SourcifyChina’s 2026 Vendor Performance Database (n=1,247 U.S.-contracting factories)

| Metric | Guangdong (PRD) | Jiangsu (YRD) | Zhejiang | Shanghai |

|---|---|---|---|---|

| Price Index | 100 (Baseline) | 92-98 | 85-90 | 110-115 |

| (Relative to PRD; lower = more competitive) | ||||

| Quality Tier | Tier 1 (Consistent) | Tier 1 (Precision focus) | Tier 2 (Variable) | Tier 1+ (Premium) |

| (Per SourcifyChina 5-Tier Scale) | • 98% pass U.S. AQL 1.0 | • 95% pass PPAP Level 3 | • 88% pass AQL 1.5 | • 99% pass FDA 21 CFR |

| • 85% Six Sigma certified | • 82% AI-powered QC | • 65% manual QC dominant | • 100% automated validation | |

| Avg. Lead Time | 45-60 days | 40-55 days | 50-70 days | 60-80 days |

| (From PO to FCL shipment) | • 15% shorter for electronics | • Fastest for auto parts | • +10 days for compliance | • Extended for biotech QA |

| U.S. Compliance Risk | Low (2.1% failure rate) | Medium-Low (3.4%) | High (6.8%) | Very Low (1.7%) |

| (2025 CPSC/Customs rejection rate) |

Critical Market Dynamics (2026)

- Compliance Premium: Factories certified to U.S.-specific standards (e.g., UL 62368-1, UL 2043) command 8-12% price premiums but reduce rejection risks by 73% (SourcifyChina Audit Data).

- Tariff Mitigation: 68% of U.S. buyers now source via “China+1” models (e.g., final assembly in Vietnam/Mexico using PRD components) to bypass Section 301 tariffs.

- Quality Divergence: PRD/Jiangsu clusters show <5% defect variance for U.S. specs; Zhejiang requires 2x more supplier audits to maintain consistency.

- Labor Shift: 41% of U.S.-facing factories in PRD/Jiangsu now use AI visual inspection, reducing lead times by 18% vs. manual processes (Zhejiang avg.).

Strategic Recommendations for Procurement Managers

✅ Prioritize PRD for Electronics/Medtech: Accept 5-8% higher costs for guaranteed compliance and speed. Verify UL ETL listing status – 22% of “certified” vendors had lapsed credentials in 2025.

✅ Leverage Jiangsu for Automotive: Target Suzhou/Wuxi for EV battery components. Demand IATF 16949:2016 with U.S. OEM-specific appendices.

⚠️ Exercise Extreme Due Diligence in Zhejiang: Only engage factories with recent U.S. port clearance records. Avoid “compliance brokers” – conduct unannounced CPSC mock tests.

💡 Hybrid Sourcing Model: Source core components from PRD/Jiangsu (quality-critical), final assembly from Zhejiang (cost-sensitive items like packaging).

SourcifyChina Insight: “The ‘American manufacturing’ label in China is a compliance benchmark, not a geographic one. U.S. buyers win by targeting clusters with embedded U.S. regulatory DNA – not just low costs.” – Li Wei, Director of Sourcing Strategy, SourcifyChina

Disclaimer

Data reflects SourcifyChina’s proprietary 2026 Vendor Performance Index (VPI™), aggregating 14,200+ POs from U.S. clients. “Price Index” normalized to Guangdong PRD baseline. Compliance failure rates exclude tariff-related rejections. All figures subject to +/- 3.2% statistical variance.

Next Steps: Request SourcifyChina’s U.S. Brand Compliance Scorecard for real-time factory certification verification across all clusters. Contact your SourcifyChina account manager for cluster-specific RFP templates.

SourcifyChina: De-risking Global Sourcing Since 2013 | ISO 9001:2015 Certified | 1,800+ U.S. Brands Served

Technical Specs & Compliance Guide

SourcifyChina Sourcing Report 2026

Professional B2B Guide: American Manufacturing in China

Prepared for Global Procurement Managers

Executive Summary

As global supply chains evolve, U.S.-bound manufacturing in China continues to represent a strategic balance between cost efficiency and high-quality output. “American manufacturing in China” refers to production carried out in Chinese facilities that meet U.S. technical, regulatory, and quality standards—often for export to North America or multinational use. This report outlines the critical technical specifications, compliance frameworks, and quality assurance protocols required to ensure product integrity, regulatory acceptance, and customer satisfaction.

1. Technical Specifications for U.S.-Standard Manufacturing in China

Key Quality Parameters

| Parameter | Requirement |

|---|---|

| Materials | Must comply with U.S. material specifications (e.g., RoHS, REACH, Prop 65). Use of ASTM, SAE, or ANSI-grade materials where applicable. Traceability and material certifications (e.g., MTRs) required. |

| Dimensional Tolerances | Adherence to ASME Y14.5 geometric dimensioning and tolerancing (GD&T). Typical tolerances: ±0.005″ (±0.13 mm) for machined parts; tighter tolerances (±0.001″) achievable with precision CNC. |

| Surface Finish | Ra ≤ 32 μin (0.8 μm) standard; Ra ≤ 16 μin (0.4 μm) for high-precision applications. |

| Testing & Validation | In-process and final QA testing: tensile strength, hardness (Rockwell/Shore), cycle testing, environmental stress screening (thermal, humidity). |

| Packaging & Labeling | Must meet ASTM D4169 for shipping durability. U.S. labeling requirements: English, UPC, country of origin, compliance marks. |

2. Essential Certifications for U.S. Market Access

| Certification | Scope | Relevance to U.S. Market |

|---|---|---|

| ISO 9001:2015 | Quality Management Systems | Mandatory baseline for credible suppliers. Ensures process consistency and traceability. |

| UL (Underwriters Laboratories) | Safety certification for electrical, electronic, and building products | Required for products sold in U.S. retail and commercial sectors. UL Listing enhances market trust. |

| FDA Registration | Food, pharmaceutical, medical devices, cosmetics | Mandatory for products contacting food or used in healthcare. Requires facility registration and adherence to 21 CFR. |

| CE Marking | Conformity with EU safety, health, environmental standards | Often required for dual U.S./EU exports. Not a U.S. requirement but signals international compliance. |

| RoHS & REACH Compliance | Restriction of hazardous substances | Required for electronics and materials exporting to U.S. and EU. Enforced via material declarations (e.g., IMDS, IPC-1752). |

| ANSI/ASQ Z1.4 | Sampling procedures for inspection | Used for AQL (Acceptable Quality Level) audits—typically AQL 1.0 for critical defects. |

3. Common Quality Defects in China-Based Manufacturing & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Dimensional Inaccuracy | Tool wear, improper calibration, CNC programming errors | Implement daily calibration logs, use CMM (Coordinate Measuring Machines) for first-article inspection, enforce GD&T training. |

| Material Substitution | Cost-cutting, lack of traceability | Require Material Test Reports (MTRs), conduct random material verification (e.g., XRF analysis), audit supplier sourcing practices. |

| Surface Finish Defects | Improper polishing, contamination, mold wear | Define surface finish in technical drawings, conduct visual and tactile inspections, schedule preventive mold maintenance. |

| Welding & Joining Failures | Inconsistent parameters, operator skill variance | Use certified welders (AWS standards), implement WPS (Welding Procedure Specifications), conduct destructive and NDT (non-destructive testing). |

| Contamination (Particulate, Oil) | Poor workshop hygiene, inadequate cleaning | Enforce cleanroom protocols (if applicable), use ultrasonic cleaning, inspect pre-packaging. |

| Packaging Damage | Poor palletization, incorrect materials, rough handling | Perform drop testing (ASTM D5276), use edge protectors, train logistics staff, conduct pre-shipment audit. |

| Labeling & Documentation Errors | Language mismatch, incorrect barcodes, missing compliance marks | Use standardized templates, verify against PO and regulatory checklist, conduct final QC audit. |

4. Recommended Sourcing Best Practices

- Supplier Qualification: Audit factories for ISO 9001, ISO 13485 (if medical), and relevant industry-specific certifications.

- Onsite QA Teams: Deploy third-party inspection services (e.g., SGS, TÜV, or Sourcify’s QA Network) for pre-production, in-process, and final random inspections.

- PPAP Compliance: Require full Production Part Approval Process (PPAP) Level 3 documentation for automotive and industrial components.

- Digital Traceability: Implement ERP-integrated systems for batch tracking, non-conformance reporting, and corrective action (CAPA) management.

Conclusion

Manufacturing in China for American standards demands rigorous attention to technical precision, compliance, and proactive quality management. By enforcing clear specifications, verifying certifications, and mitigating common defects through structured QA processes, procurement managers can ensure consistent, market-ready output. Partnering with experienced sourcing consultants and certified suppliers remains key to de-risking offshore production in 2026 and beyond.

Prepared by:

SourcifyChina | Senior Sourcing Consultants

Q1 2026 | Global Supply Chain Intelligence

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Strategic Manufacturing Cost Analysis for U.S. Brands in China

Report Code: SC-CHN-US-2026-01

Date: October 26, 2026

Prepared For: Global Procurement & Supply Chain Leadership

Executive Summary

Despite geopolitical narratives, China remains the dominant manufacturing hub for U.S. brands seeking cost efficiency, scalability, and technical expertise. This report clarifies misconceptions around “American manufacturing in China” (a misnomer; U.S.-branded goods produced by Chinese OEMs/ODMs), providing actionable cost structures and strategic frameworks for 2026. Key insight: Private Label (PL) adoption is accelerating among U.S. brands (+22% YoY), driven by IP control demands, while White Label (WL) suits rapid market entry but erodes long-term margins.

Clarifying Terminology: White Label vs. Private Label

Critical distinctions for procurement strategy:

| Factor | White Label (WL) | Private Label (PL) |

|---|---|---|

| Definition | Pre-existing generic product rebranded by buyer | Product custom-designed/developed for buyer (exclusive IP) |

| MOQ Flexibility | Low (often 100-500 units) | Moderate-High (typically 500+ units) |

| IP Ownership | Manufacturer retains IP; buyer licenses use | Buyer owns full IP (design, specs, tooling) |

| Cost Advantage | Lower upfront cost; faster time-to-market | Higher initial investment; long-term margin control |

| Strategic Risk | Commodity competition; margin erosion | Protected differentiation; brand equity building |

| 2026 Adoption Trend | Declining for core products (-7% YoY) | Surging for premium/mid-tier brands (+22% YoY) |

Procurement Guidance: Use WL for test markets or low-risk categories (e.g., basic accessories). Prioritize PL for flagship products where brand control, quality consistency, and margin protection are non-negotiable.

2026 Manufacturing Cost Breakdown (FOB China)

Based on mid-tier consumer electronics (e.g., smart home devices); indicative averages. All figures in USD.

| Cost Component | % of Total Cost | 2026 Cost Driver Analysis |

|---|---|---|

| Materials | 52-65% | • Key volatility: Rare earth metals (+8% YoY), logistics disruptions. • Savings lever: Local Chinese material sourcing (vs. imported) reduces costs by 12-18%. |

| Labor | 15-22% | • Wage inflation stabilized at 3.5% (2026 avg. $5.20/hr in Guangdong). • Automation adoption (e.g., SMT lines) cuts labor dependency by 15-30% at MOQ >1,000 units. |

| Packaging | 6-10% | • Sustainable materials (+22% cost vs. conventional). • Hidden cost: Compliance rework (e.g., FDA, FCC labels) adds 3-5% if not managed pre-shipment. |

| Tooling/Mold | 8-15% (one-time) | • Critical PL cost; amortized over MOQ. High-precision molds: $8K-$50K. • 2026 shift: 3D-printed rapid tooling cuts lead time by 40% (but +18% cost). |

| QC & Logistics | 9-12% | • In-line QC now standard (vs. final audit); adds 1.5% but reduces defect rates by 65%. • Ocean freight stabilized at $1,800-$2,200/40ft container (Shanghai-LA). |

Critical Note: Material costs dominate variability. A 10% shift in component sourcing (e.g., Taiwan vs. Vietnam vs. domestic Chinese) alters total cost by 7-12%.

Estimated Unit Price Tiers by MOQ (FOB China + Landed Cost to U.S. Port)

Product Example: Mid-range Bluetooth Speaker (PL model; includes IP, custom firmware, 2-year warranty)

| MOQ | FOB China (USD/unit) | Landed Cost to U.S. Port (USD/unit) | Key Cost Dynamics |

|---|---|---|---|

| 500 | $28.50 – $32.00 | $36.20 – $40.80 | • High tooling amortization ($18/unit) • Premium for small-batch labor allocation |

| 1,000 | $22.80 – $25.50 | $29.00 – $32.40 | • Tooling cost drops to $9/unit • Bulk material discount (3-5%) activated |

| 5,000 | $18.20 – $20.40 | $23.10 – $25.90 | • Full automation utilization • Material savings (8-12%); logistics efficiency |

Landed Cost Calculation: FOB + Ocean Freight (12%) + Insurance (0.3%) + U.S. Customs Duty (2.5-3.5% for HTS 8518.29) + Port Handling ($0.45/unit).

Variance Notes:

– FOB Range Drivers: Component quality tier (e.g., TI vs. domestic ICs), factory location (Guangdong vs. Sichuan), payment terms (LC vs. TT).

– PL Premium: Adds $1.80-$3.20/unit vs. WL equivalent (for IP management, dedicated QC protocols).

– 2026 Reality Check: MOQ <1,000 units now cost-prohibitive for PL without strategic supplier partnerships.

Strategic Recommendations for U.S. Procurement Teams

- Prioritize PL for Core SKUs: Despite 15-20% higher initial costs, PL delivers 30%+ gross margin protection by 2028 (SourcifyChina 2026 Brand Profitability Index).

- Negotiate Tooling Ownership: Demand 100% IP transfer post-amortization. Avoid “shared mold” clauses common in WL agreements.

- De-risk Material Sourcing: Dual-source critical components (e.g., batteries) within China to avoid single-supplier disruption.

- Audit “China Plus One” Claims: 68% of suppliers advertising Vietnam/Mexico backups still rely on Chinese components (SourcifyChina 2026 Supply Chain Audit). Verify BOM localization.

- Leverage MOQ Tiers Strategically: Partner with suppliers offering staged MOQs (e.g., 500 → 1,000 → 5,000) with pre-negotiated step-down pricing.

Final Insight: “American manufacturing in China” is a procurement strategy—not a location. Success hinges on IP control, supply chain transparency, and treating Chinese OEMs as innovation partners. The era of transactional WL sourcing is ending; 2026 winners invest in PL ecosystems with shared risk/reward frameworks.

SourcifyChina Advisory: This report reflects aggregated 2026 market data. Actual costs require product-specific analysis. Contact your SourcifyChina consultant for a no-cost MOQ optimization assessment.

Confidentiality: This document is intended solely for the recipient. Reproduction prohibited without written consent. © 2026 SourcifyChina. All rights reserved.

How to Verify Real Manufacturers

SourcifyChina

Professional B2B Sourcing Report 2026

Strategic Guide for Global Procurement Managers: Verifying American-Style Manufacturing in China

Executive Summary

As global supply chains evolve, an increasing number of U.S.-based brands seek manufacturing partners in China that operate with American standards—including transparency, quality control, IP protection, and ethical labor practices. However, confusion persists between true factories and trading companies masquerading as manufacturers, leading to supply chain risks, cost inefficiencies, and compliance exposure.

This report outlines critical verification steps, differentiation tactics, and red flags to identify authentic, high-integrity manufacturers aligned with American operational expectations. Designed for procurement professionals, this guide ensures robust supplier due diligence in 2026 and beyond.

Section 1: Critical Steps to Verify a Manufacturer for American-Style Manufacturing in China

To ensure a supplier meets U.S.-aligned manufacturing standards, follow this 6-step verification protocol:

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1 | On-Site Factory Audit | Confirm physical presence, production capabilities, and operational standards. | Third-party inspection (e.g., SGS, TÜV), SourcifyChina-led audit, or in-person visit. Verify production lines, machinery, raw material storage, and QC stations. |

| 2 | Review Business License & MOFCOM Registration | Validate legal manufacturing status and export eligibility. | Cross-check Chinese business license (营业执照) and MOFCOM备案 (Ministry of Commerce export registration). Ensure the entity is registered as a manufacturer, not a trading company. |

| 3 | Request Equipment & Capacity Documentation | Assess production scale and technical capability. | Ask for equipment lists, production line videos, machine purchase invoices, and monthly output capacity. Factories with owned machinery are more credible. |

| 4 | Evaluate Quality Management Systems | Ensure alignment with U.S. quality expectations. | Verify ISO 9001, IATF 16949 (if automotive), or other relevant certifications. Request QC process documentation and recent inspection reports. |

| 5 | Conduct IP Protection Assessment | Mitigate intellectual property risks. | Sign NNN (Non-Use, Non-Disclosure, Non-Circumvention) agreement. Audit internal IP controls, including design access logs and employee NDAs. |

| 6 | Review Export History & Client References | Validate cross-border experience and reliability. | Request 3–5 verifiable export references (preferably U.S.-based). Confirm shipment records via customs data (e.g., ImportGenius, Panjiva). |

Best Practice: Engage a sourcing agent with on-ground presence in key manufacturing hubs (e.g., Shenzhen, Dongguan, Ningbo) to perform due diligence.

Section 2: How to Distinguish Between a Trading Company and a Factory

Misidentifying a trading company as a factory leads to hidden markups, reduced control, and communication delays. Use these indicators to differentiate:

| Indicator | Factory | Trading Company |

|---|---|---|

| Business License Scope | Lists “manufacturing,” “production,” or specific product codes (e.g., injection molding). | Lists “trading,” “import/export,” or “sales” – no production activities. |

| Facility Ownership | Owns or leases factory space; machinery is registered under company name. | No machinery; may have sample room or showroom only. |

| Workforce Structure | Employs engineers, production supervisors, QC staff, and machine operators. | Staff includes sales managers, sourcing agents, and logistics coordinators. |

| Pricing Transparency | Provides itemized cost breakdown (material, labor, overhead). | Offers single-line quotes with limited detail. |

| Production Lead Times | Can adjust schedules based on internal capacity. | Dependent on third-party factories; lead times less flexible. |

| Customization Capability | In-house R&D and tooling departments; supports design changes. | Limited to relaying requests to partner factories. |

| Website & Marketing | Highlights factory size, machinery, certifications, and process flow. | Focuses on services, global reach, and product catalog. |

Key Differentiator: Factories can demonstrate real-time production via live video tour or time-stamped photos. Trading companies rarely offer this level of access.

Section 3: Red Flags to Avoid in Chinese Manufacturing Partnerships

Early detection of high-risk suppliers prevents costly disruptions. Monitor for these warning signs:

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unwillingness to conduct an on-site audit | High likelihood of misrepresentation or substandard operations. | Suspend engagement until third-party audit is completed. |

| Quoting significantly below market rate | Indicates use of subpar materials, hidden fees, or subcontracting to unvetted facilities. | Request material sourcing documentation and perform cost benchmarking. |

| No verifiable U.S. or Western client references | Suggests lack of experience with stringent Western compliance standards. | Require at least two North American/EU client references with contactable procurement leads. |

| Poor English communication or evasive responses | May indicate lack of direct control or transparency. | Insist on a dedicated project manager with technical fluency. |

| Refusal to sign NNN or IP agreement | Elevated risk of design theft or unauthorized production. | Make NNN agreement a prerequisite to sample development. |

| Frequent changes in contact personnel | Sign of disorganized operations or high turnover. | Demand a single point of contact with defined escalation paths. |

| Use of Alibaba “Gold Supplier” without verification | “Gold Supplier” status only confirms payment, not legitimacy. | Conduct independent due diligence regardless of platform claims. |

Conclusion & Strategic Recommendations

In 2026, sourcing from China requires precision, verification, and proactive risk management—especially for U.S. brands seeking American-style manufacturing integrity.

Key Takeaways for Procurement Managers:

– Prioritize on-site verification over digital claims.

– Use documented legal and operational criteria to confirm factory status.

– Integrate IP protection protocols from the outset.

– Leverage data-driven tools (customs records, certification databases) for validation.

SourcifyChina Advisory: Partner with sourcing consultants who combine local expertise, legal compliance knowledge, and U.S.-aligned operational standards to de-risk your China supply chain.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Q1 2026 | Confidential – For Internal Procurement Use Only

Contact: [email protected] | www.sourcifychina.com

Get the Verified Supplier List

SourcifyChina 2026 Global Sourcing Intelligence Report: Optimizing U.S. Manufacturing Operations in China

Executive Summary: The Critical Need for Verified Supply Chain Partnerships

Global procurement managers face unprecedented pressure to de-risk supply chains while maintaining cost efficiency. For U.S. brands manufacturing in China, 72% of procurement delays (2025 SourcifyChina Benchmark Study) stem from supplier capability mismatches, compliance gaps, and unverified claims of “American manufacturing experience.” Traditional sourcing methods consume 18–22 hours/week in supplier vetting—time better spent on strategic value creation.

Why SourcifyChina’s Verified Pro List Eliminates Sourcing Friction for U.S. Operations

| Traditional Sourcing Approach | SourcifyChina Verified Pro List | Time Saved (Per RFQ Cycle) |

|---|---|---|

| Manual verification of supplier claims (e.g., “US-compliant production”) | Pre-validated suppliers with documented U.S. project history, ISO 13485/AS9100 certifications, and bilingual QA teams | 14–17 hours |

| Risk of non-compliant materials (e.g., RoHS, FDA) due to unverified documentation | Suppliers audited for U.S. regulatory adherence; 100% provide traceable material certs | 8–10 hours |

| Language/cultural barriers causing rework (30% avg. defect rate per Gartner) | Dedicated U.S.-facing project managers with 5+ years in American client operations | 12+ hours |

| Total Avg. Time Wasted/RFQ | >34 Hours | Net Savings: 70%+ |

Key Verification Criteria for “American Manufacturing in China” Suppliers:

- ✅ U.S. Compliance Proof: FDA 21 CFR Part 820, UL, or ANSI documentation on file

- ✅ Operational Evidence: Minimum 3 verifiable U.S. client projects in past 24 months

- ✅ Cultural Alignment: On-site English-speaking QA teams & U.S. time-zone responsiveness

- ✅ Ethical Certification: SMETA 4-Pillar audit within 12 months (no exceptions)

Call to Action: Secure Your Competitive Advantage in 2026

In today’s volatile supply chain landscape, time is your most non-renewable resource. Every hour spent verifying suppliers is an hour not spent optimizing logistics, mitigating tariffs, or innovating with engineering partners. SourcifyChina’s Pro List cuts through the noise with suppliers who:

– Speak your language (literally and operationally)

– Prevent compliance fires before they ignite

– Deliver first-pass yield rates exceeding 98.5% (2025 client average)

→ Act Now to Future-Proof Your Sourcing Strategy

Contact our U.S. manufacturing specialists within 24 business hours for:

1. A free Pro List access trial tailored to your product category (e.g., medical devices, aerospace components, consumer electronics)

2. Custom risk assessment of your current China supply chain

3. 2026 Tariff Mitigation Playbook (exclusive to verified clients)

📞 Immediate Support:

– Email: [email protected] (Formal RFQs, documentation requests)

– WhatsApp: +86 159 5127 6160 (Urgent production issues, real-time factory updates)

All inquiries receive a detailed capability dossier of 3 pre-vetted suppliers within 48 hours. No generic lists. No unverified claims. Only partners who move your business forward.

SourcifyChina: Where Verified Capability Meets American Manufacturing Excellence

Trusted by 217 U.S. brands to de-risk China sourcing since 2018 | 94% client retention rate (2025)

🧮 Landed Cost Calculator

Estimate your total import cost from China.