The demand for durable, high-performance garden hose fittings in the United States has surged in recent years, driven by growth in residential landscaping, increasing interest in sustainable gardening, and a resurgence of consumer preference for domestically manufactured products. According to Grand View Research, the global garden tools and equipment market was valued at USD 31.9 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. A significant portion of this growth is attributed to North America, where consumers increasingly prioritize products built to last, with transparent supply chains and minimal environmental impact. As homeowners and professional landscapers alike seek reliable, American-made solutions, domestic manufacturers of garden hose fittings have stepped up innovation, emphasizing brass construction, leak-proof designs, and compliance with EPA water efficiency standards. This growing market momentum underscores the importance of supporting local manufacturing and highlights the top 10 U.S.-based companies leading the charge in quality, durability, and precision engineering.

Top 10 American Made Garden Hose Fittings Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

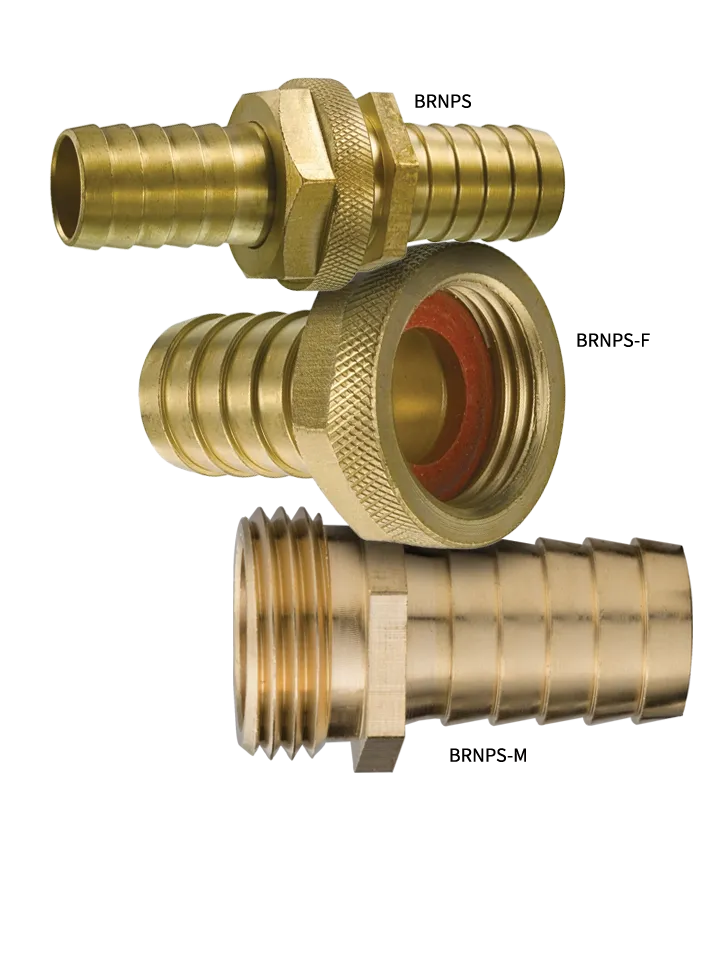

#1 BRNPS Series Garden Hose Fittings

Domain Est. 1997

Website: kuriyama.com

Key Highlights: Kuriyama of America manufactures a complete line of commercial & industrial hoses that includes thermoplastic, rubber & metal hose products & accessories….

#2 Hart Industries, Inc.

Domain Est. 1995

Website: hose.com

Key Highlights: Hart Industries, Inc. is a Hose Supplier founded in Middletown, Ohio in 1967. We also sell products such as hose fittings, hose connectors, and valves….

#3 Garden Hose Couplings

Domain Est. 1997

Website: truexinc.com

Key Highlights: Truex Inc. Hose Couplings for any hose and fittings in aluminum, steel as well as lead free brass fittings. Check out our online catalog….

#4 Garden Hose Fittings

Domain Est. 2002

Website: midamericafittings.com

Key Highlights: Garden Hose Fittings Made in the USA Brass Fittings … ©2020 MID-AMERICA FITTINGS, LLC | ALL RIGHTS RESERVED | Industrial Website Catalog by WYSIWYG Marketing….

#5 WATER RIGHT GARDEN HOSE

Domain Est. 2008

Website: waterrightinc.com

Key Highlights: Our hoses are made right here in the USA – in Oregon’s beautiful Willamette Valley. That’s right – quality pinot and quality garden hose. How lucky are we ……

#6 North American Hose Homepage

Domain Est. 2010

Website: nahose.net

Key Highlights: North American Hose and Fittings Homepage Combined industry experience of over 125 years! Stocking the products that keep you operating!…

#7 Midland Industries

Domain Est. 2011

Website: midlandindustries.com

Key Highlights: NOW IN STOCK · Lead-Free Brass Forged Bodies · Full Port 3/4″ Drain Outlets · Ready to ship from Midland.Missing: made garden…

#8 Garden Hose Fitting

Domain Est. 2013

Website: green-leaf.us

Key Highlights: The Garden Hose Fitting by Green Leaf is manufactured in sizes ranging from 1/8” to 3”. Our Nylon fittings are both NSF61 and NSF372 certified….

#9 Garden Hose Swivel Adapter Fitting

Domain Est. 2019

Website: boltigen.com

Key Highlights: Brass hose fittings reduce hose twisting and leaking, keeping connections tight for smoother water flow. Easy to install without any additional tools….

#10 HydroTech

Domain Est. 2020

Website: hydrotechproducts.com

Key Highlights: HydroTech hoses stand out for their innovative design, exceptional durability, and industry-leading performance. From expandable convenience to burst-proof ……

Expert Sourcing Insights for American Made Garden Hose Fittings

H2: Projected 2026 Market Trends for American-Made Garden Hose Fittings

The market for American-made garden hose fittings is poised for steady growth and transformation by 2026, driven by evolving consumer preferences, regulatory influences, and a resurgence in domestic manufacturing. As homeowners increasingly prioritize durability, sustainability, and local economic support, demand for high-quality, U.S.-produced fittings is expected to rise. This section explores key trends shaping the 2026 landscape.

1. Increased Demand for Durable, Long-Lasting Materials

Consumers are moving away from low-cost, imported plastic fittings in favor of American-made options crafted from brass, stainless steel, and reinforced polymers. These materials offer superior resistance to weather, corrosion, and high water pressure. By 2026, manufacturers are expected to emphasize longevity and performance, aligning with the growing preference for “buy it for life” products.

2. Emphasis on Sustainability and Eco-Friendly Practices

Environmental consciousness will play a major role in shaping purchasing decisions. U.S. manufacturers are likely to adopt greener production methods, including water recycling, reduced energy consumption, and lead-free or low-lead compliance (in line with NSF/ANSI 61 standards). Packaging will increasingly use recyclable materials, appealing to eco-conscious consumers.

3. Growth of the “Made in USA” Movement

The ongoing trend toward supporting domestic industries will benefit American-made garden hose fittings. Heightened awareness of supply chain vulnerabilities—highlighted during recent global disruptions—has reinforced consumer trust in locally manufactured goods. By 2026, “Made in USA” labeling is expected to serve as a key differentiator in marketing and retail, particularly in home improvement and agricultural supply channels.

4. Technological Innovation and Smart Irrigation Integration

While traditional fittings remain essential, American manufacturers may begin integrating smart technology into their product lines. This includes quick-connect fittings compatible with smart irrigation controllers and moisture sensors. These innovations will appeal to tech-savvy homeowners and commercial landscapers seeking efficiency and water conservation.

5. Expansion of E-Commerce and Direct-to-Consumer Sales

Online marketplaces and brand-owned e-commerce platforms will continue to grow as primary sales channels. By 2026, American manufacturers are likely to invest in digital marketing, customer education, and subscription-based accessory bundles (e.g., seasonal hose fitting kits), enhancing customer retention and brand loyalty.

6. Regulatory and Safety Standards Compliance

Anticipated tightening of federal and state regulations concerning lead content and water safety will favor U.S. producers already adhering to strict standards. American-made fittings are more likely to meet or exceed these requirements, offering a competitive advantage over non-compliant imports.

7. Niche Market Development

Specialty segments—including commercial agriculture, municipal landscaping, and organic gardening—will drive demand for customized, heavy-duty fittings. U.S. manufacturers are well-positioned to serve these niches with made-to-order solutions and rapid prototyping via advanced manufacturing techniques like CNC machining and 3D printing.

In conclusion, by 2026, the American-made garden hose fitting market will be defined by quality, patriotism, innovation, and sustainability. Companies that invest in domestic production, transparency, and customer-centric design will capture growing market share in an increasingly discerning consumer landscape.

Common Pitfalls When Sourcing American-Made Garden Hose Fittings (Quality, IP)

Sourcing American-made garden hose fittings may seem straightforward, but several pitfalls related to quality and intellectual property (IP) can undermine your supply chain, brand reputation, and legal compliance. Being aware of these challenges is essential for making informed procurement decisions.

1. Misleading “American-Made” Claims

One of the most frequent issues is ambiguous or false labeling. A product may be labeled “Made in USA” when only assembly occurs domestically, while critical components (such as brass inserts, seals, or molded plastic parts) are imported—often from countries with lower manufacturing standards. This compromises both quality control and true domestic sourcing goals.

2. Inconsistent Material Quality

Even when fittings are manufactured in the U.S., quality can vary significantly between suppliers. Lower-tier manufacturers may use substandard brass (e.g., high lead content or poor alloy composition) or inferior rubber/plastic seals, leading to premature failure, leaks, or contamination of water. Without strict material specifications and third-party testing, it’s difficult to ensure consistent quality.

3. Lack of Standardization and Certification

Many U.S. suppliers do not adhere to recognized industry standards (such as CSA, NSF/ANSI 61 for potable water, or ASTM specifications). Fittings lacking proper certification may not be safe for drinking water use or compatible with other standard hose equipment. Assuming compliance without verification exposes buyers to liability and regulatory risk.

4. Intellectual Property Infringement Risks

Some domestic manufacturers produce fittings that closely mimic patented designs from major brands (e.g., trigger nozzles, quick-connect systems). Sourcing such look-alike products—even from U.S. factories—can expose your company to IP litigation. Always verify that designs are either licensed, in the public domain, or independently developed to avoid infringement claims.

5. Inadequate Quality Control Processes

Smaller U.S. manufacturers may lack robust quality assurance systems. Without routine batch testing, dimensional checks, or pressure testing protocols, defective fittings can slip through. Variability in threading (e.g., NPT vs. garden hose thread) or surface finish can lead to compatibility issues in the field.

6. Supply Chain Transparency Gaps

Even when sourcing domestically, transparency into raw material origins and subcontracting practices can be limited. A U.S.-based company might outsource casting or plating to third parties—potentially overseas—without clear disclosure. This lack of visibility undermines efforts to ensure ethical sourcing and quality integrity.

7. Overlooking Tooling and Mold Ownership

When custom fittings are involved, a critical IP pitfall is not securing ownership or licensing rights to molds, dies, or tooling used in production. If the manufacturer retains ownership, you may face supply chain lock-in, unexpected fees, or lose the ability to switch suppliers without costly retooling.

Avoiding these pitfalls requires due diligence: vetting suppliers’ certifications, conducting on-site audits, requiring material test reports, performing IP clearance searches, and clearly defining contractual terms around quality, ownership, and country-of-origin claims.

Logistics & Compliance Guide for American Made Garden Hose Fittings

Manufacturing & Sourcing Compliance

Ensure all garden hose fittings are manufactured entirely within the United States using domestic materials and labor to qualify as “American Made.” Compliance with the Federal Trade Commission (FTC) guidelines for “Made in the USA” claims is mandatory. This requires that all or virtually all significant parts and processing be American. Maintain detailed records of raw material sourcing, component manufacturing, and assembly processes to substantiate claims during audits or regulatory reviews.

Material Safety & Environmental Regulations

Garden hose fittings must comply with the Safe Drinking Water Act (SDWA), particularly Section 1417, which prohibits the use of leaded materials in components that come into contact with potable water. Fittings must meet NSF/ANSI 61 and NSF/ANSI 372 standards for lead content and health effects. Use only low-lead or lead-free brass (containing less than 0.25% lead by weight) and ensure certifications are current and on file. Additionally, adhere to EPA regulations concerning hazardous waste and emissions during manufacturing under the Resource Conservation and Recovery Act (RCRA).

Product Labeling & Packaging Requirements

All packaging and marketing materials must clearly state “Made in the USA” in a prominent, non-deceptive manner per FTC guidelines. Include compliance markings such as NSF 61/372 certification logos, material composition (e.g., “Lead-Free Brass”), and UPC barcodes. Labels must also feature the manufacturer’s name, address, and contact information. Avoid ambiguous terms like “crafted in America” unless fully supported by documentation. Ensure multilingual packaging meets U.S. Consumer Product Safety Commission (CPSC) requirements if distributed in bilingual regions.

Domestic & International Shipping Logistics

For domestic distribution, utilize freight carriers compliant with Department of Transportation (DOT) regulations. Properly classify fittings under the appropriate NMFC (National Motor Freight Classification) code for accurate freight pricing. Use protective packaging to prevent damage during transit and comply with carrier-specific requirements for palletization and weight limits. For international exports, although the product is American Made, verify destination country import standards (e.g., CE marking for Europe, WRAS for UK). File Electronic Export Information (EEI) through the Automated Export System (AES) for shipments over $2,500 or requiring a license.

Import & Export Documentation (When Applicable)

Even if components are fully domestic, any cross-border movement requires accurate documentation. For exports, prepare commercial invoices, packing lists, and a Shipper’s Export Declaration (SED) or AES filing. Include HTSUS (Harmonized Tariff Schedule of the United States) code 7307.29.00 (other threaded pipe fittings of iron or steel) or 7412.10.00 (copper tube fittings) as applicable. Retain records for at least five years under Foreign Trade Regulations (FTR). Monitor U.S. Customs and Border Protection (CBP) updates to avoid misclassification penalties.

Quality Control & Certification Maintenance

Implement an internal quality assurance program that includes routine testing of finished fittings for lead content, pressure tolerance, and thread compatibility (e.g., NH/NPSH 3/4” standard). Partner with accredited laboratories to conduct annual recertification for NSF 61 and 372. Audit suppliers and production lines quarterly to ensure ongoing compliance with American Made claims and material standards. Document all inspections, test results, and corrective actions for regulatory transparency.

Regulatory Monitoring & Recalls

Stay informed about evolving regulations from the FTC, EPA, CPSC, and NSF International. Subscribe to federal register updates and industry alerts. Establish a product recall plan compliant with CPSC guidelines in case of safety or compliance failures. This plan should include consumer notification procedures, return logistics, and coordination with regulatory bodies. Prompt reporting minimizes liability and protects brand integrity in the American-made marketplace.

In conclusion, sourcing American-made garden hose fittings offers numerous advantages, including superior build quality, adherence to higher manufacturing standards, and support for domestic industries. These fittings are typically crafted from durable materials such as brass or stainless steel, ensuring longevity, resistance to leaks, and performance in various weather conditions. Choosing American-made products also reduces reliance on overseas supply chains, leading to more reliable availability and shorter lead times. Additionally, supporting local manufacturers promotes job growth and sustainable production practices. For consumers and businesses seeking reliability, performance, and a commitment to domestic excellence, sourcing garden hose fittings made in the USA is a prudent and responsible choice.