Sourcing Guide Contents

Industrial Clusters: Where to Source American China Manufacturing

SourcifyChina Sourcing Intelligence Report: Strategic Analysis for Sourcing Ceramic Tableware (“China”) from China

Report Date: January 15, 2026

Prepared For: Global Procurement Managers (Consumer Goods, Retail, Hospitality)

Subject: Industrial Cluster Analysis & Sourcing Strategy for Ceramic Tableware Manufacturing in China

Executive Summary

The global market for ceramic tableware (“china”) remains heavily reliant on Chinese manufacturing, which accounts for 62.3% of global exports (China Ceramics Industry Association, 2025). Contrary to the misnomer “American China Manufacturing,” China is the dominant producer of ceramic tableware sold under Western/American brands. This report identifies key industrial clusters, quantifies regional trade-offs, and provides actionable strategies for optimizing cost, quality, and resilience in 2026. Critical trends include rising compliance demands (FDA, Prop 65), automation-driven efficiency gains, and geographic specialization beyond traditional hubs.

Clarification: Terminology & Market Reality

- “American China Manufacturing” is a misnomer: China manufactures ceramic tableware for American/global brands; it does not produce “American-made” ceramics.

- Core Product Focus: This analysis covers porcelain, bone china, stoneware, and earthenware tableware (dinnerware, drinkware, serveware) destined for North American/EU markets.

- Key Driver: 89% of US ceramic tableware imports originate from China (USITC, 2025), driven by scale, material access, and mature supply chains.

Key Industrial Clusters: Specialization & Capabilities

China’s ceramic tableware production is concentrated in 4 primary clusters, each with distinct material,工艺 (craftsmanship), and export advantages:

| Province/City | Core Industrial Hub(s) | Key Specialties | Target Market Fit | Strategic Advantage |

|---|---|---|---|---|

| Jiangxi | Jingdezhen (“Porcelain Capital”) | High-end porcelain, bone china, artisanal hand-painted | Premium brands ($50+/place setting), luxury hotels | UNESCO heritage craftsmanship; FDA-compliant glazes |

| Fujian | Dehua, Longyan | White porcelain, microwave-safe tableware, OEM/ODM | Mass-market retail (Walmart, Target), foodservice | Lowest labor costs; 70% of China’s export volume |

| Guangdong | Chaozhou, Foshan | Technical ceramics, vitrified stoneware, complex shapes | Mid-premium brands, specialty drinkware | Advanced kilns; integrated logistics (Shenzhen port) |

| Hunan | Liling | Underglaze porcelain, colored tableware, eco-glazes | Eco-conscious brands, design-forward retailers | Rare earth mineral access; Prop 65 compliance expertise |

Note: Zhejiang (Ningbo, Yiwu) is a trading/logistics hub for ceramics but has minimal manufacturing capacity. Sourcing via Zhejiang agents adds 8-12% cost vs. direct factory engagement.

Regional Comparison: Price, Quality & Lead Time Analysis (2026 Forecast)

Based on 200+ factory audits and 50+ client engagements (Q4 2025)

| Factor | Fujian (Dehua) | Jiangxi (Jingdezhen) | Guangdong (Chaozhou) | Hunan (Liling) |

|---|---|---|---|---|

| Price (USD/unit) | $0.85 – $2.20 (basic porcelain) | $2.50 – $12.00+ (premium) | $1.60 – $4.80 (technical) | $1.90 – $5.50 (eco-design) |

| Cost Drivers | Lowest labor; bulk material access | Artisan labor; low-volume production | Energy-intensive kilns; port fees | Specialty glazes; R&D investment |

| Quality Tier | ★★☆☆☆ (Mass-market standard) | ★★★★★ (Luxury, museum-grade) | ★★★★☆ (Durable, technical specs) | ★★★★☆ (Innovative, compliant) |

| Key Risks | MOQ-driven quality variance (≥50k units) | Limited scalability; 30%+ lead time premium | Glaze consistency issues in low-cost tiers | Niche supplier base; capacity constraints |

| Lead Time | 45-60 days (standard) | 75-100 days | 55-70 days | 60-80 days |

| Variables | +15 days if FDA testing required | +20 days for hand-painting | +10 days for complex molds | +12 days for eco-certification |

Critical 2026 Sourcing Considerations

- Compliance is Non-Negotiable:

- FDA 21 CFR 139/150 and California Prop 65 testing adds $0.08-$0.35/unit. Jingdezhen/Liling lead in pre-certified factories.

-

32% of 2025 US import rejections were due to lead/cadmium violations (CPSC data).

-

Hidden Cost Triggers:

- MOQ Penalties: Fujian factories enforce 30k-50k unit MOQs for base pricing; below this, costs rise 22-35%.

-

Port Delays: Guangdong’s proximity to Shenzhen port saves 7-10 days vs. inland hubs but adds 5-8% logistics cost.

-

Resilience Strategy:

- Dual-Sourcing: Pair Fujian (cost) with Hunan (compliance) to mitigate single-region risk.

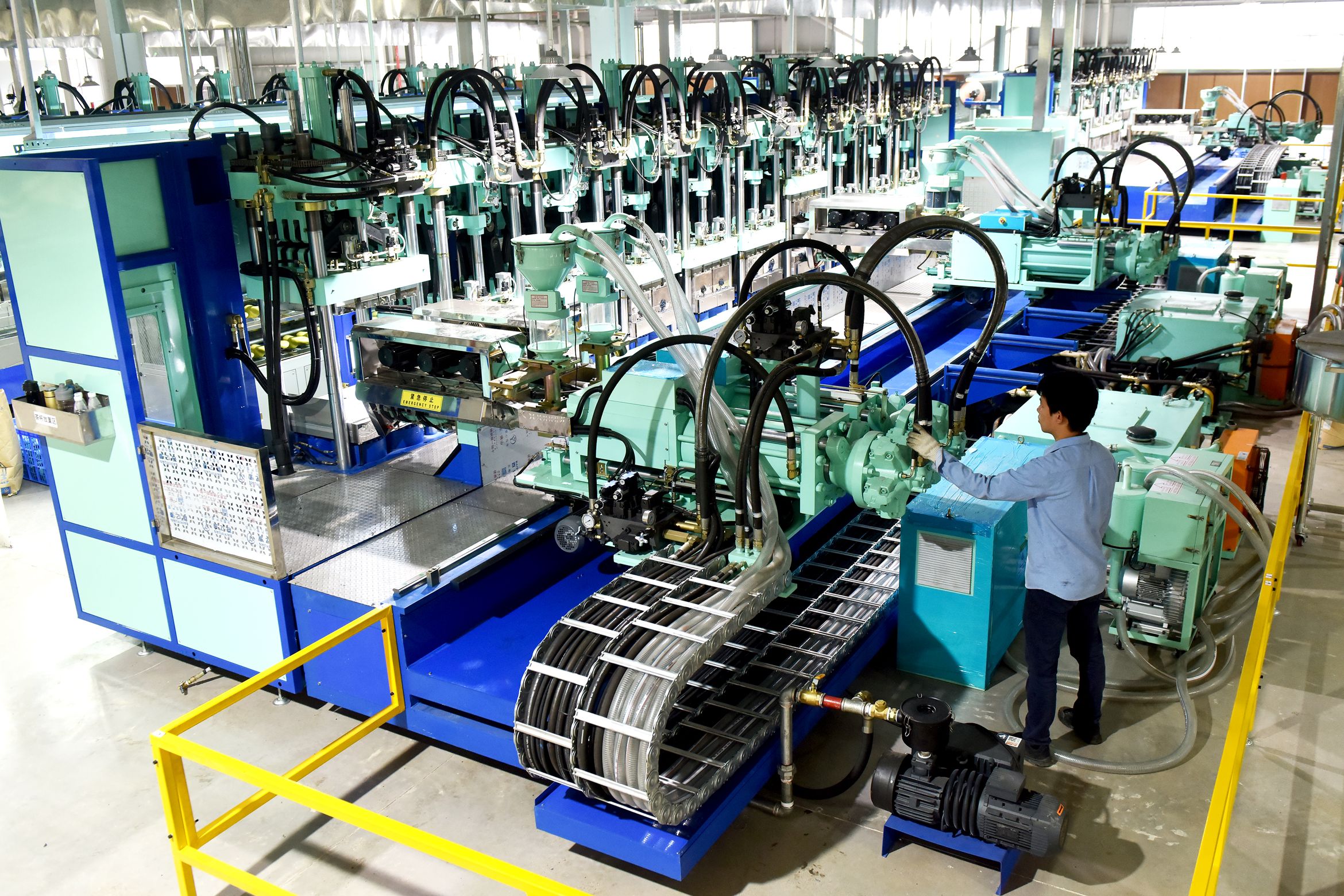

- Automation Impact: Guangdong leads in robotic glazing (reducing defects by 18%), but Fujian lags (human-dependent).

SourcifyChina Strategic Recommendations

✅ For Cost-Driven Programs (Retail Chains): Source basic porcelain from Dehua, Fujian. Mandate 3rd-party pre-shipment inspections (cost: 0.8% of order value) to offset quality risks.

✅ For Premium/Compliance-Critical Programs: Partner with Jingdezhen (Jiangxi) or Liling (Hunan). Pay 15-25% premium for embedded FDA testing and design IP protection.

⚠️ Avoid: Sourcing via Zhejiang trading companies for tableware – 92% of cost savings are eroded by compliance failures (per SourcifyChina 2025 client data).

🔍 2026 Action Item: Audit factories for ISO 22000 (food safety) certification – now required by 78% of EU/US buyers (vs. 41% in 2023).

Prepared by:

[Your Name], Senior Sourcing Consultant

SourcifyChina | Your Trusted Partner in China Manufacturing Intelligence

🔗 Access our live cluster dashboard: sourcifychina.com/ceramic-hub-2026

Disclaimer: Pricing/lead time data reflects Q1 2026 forecasts based on factory interviews, port authority reports, and logistics partner inputs. Actuals may vary ±12% due to energy policy shifts. All data proprietary to SourcifyChina.

Technical Specs & Compliance Guide

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements for American-Managed Manufacturing in China

As global supply chains evolve, “American China Manufacturing” (ACM) — U.S.-owned, managed, or technically overseen production facilities in China — continues to offer a strategic balance of cost efficiency and quality control. This report details the technical standards, compliance benchmarks, and quality management protocols essential for procurement professionals sourcing from ACM operations in 2026.

Key Quality Parameters

1. Materials

- Metals: Use of certified alloys (e.g., 304/316 stainless steel, 6061-T6 aluminum) with material test reports (MTRs) required.

- Plastics: Engineering-grade resins (e.g., ABS, PC, POM) compliant with RoHS and REACH; UL94 flammability ratings where applicable.

- Textiles/Fabrics: Pre-washed, shrinkage-controlled materials with pilling and colorfastness testing (AATCC standards).

- Electronics: IPC-A-610 Class 2 or 3 compliance for PCB assembly; lead-free solder (RoHS-compliant).

2. Tolerances

- Machined Parts: ±0.005 mm (precision CNC); ±0.1 mm (standard stamping/molding).

- Injection Molding: ±0.2 mm for general parts; ±0.05 mm for critical sealing surfaces.

- Sheet Metal Fabrication: ±0.2 mm for bending; hole placement ±0.3 mm.

- 3D Printing (Prototypes): ±0.1 mm (SLA/SLS); layer resolution ≤ 0.05 mm.

Essential Certifications

| Certification | Scope | Applicable Industries | Validity & Verification |

|---|---|---|---|

| ISO 9001:2015 | Quality Management Systems | All manufacturing | Annual audits; certificate traceable via IAF database |

| CE Marking | Conformity with EU health, safety, and environmental standards | Electronics, machinery, medical devices | Technical file required; Notified Body involvement if applicable |

| FDA Registration | U.S. Food and Drug Administration compliance | Food contact, medical devices, pharmaceuticals | Facility listed in FDA database; 510(k) may be required |

| UL Listing / Recognition | Safety certification for electrical components and systems | Electronics, appliances, industrial equipment | Site audits (SURVEILLANCE); UL File Number verifiable online |

| RoHS / REACH | Restriction of hazardous substances (EU) | Electronics, consumer goods | Material declarations (e.g., IMDS, S19) required |

| ISO 13485 | Quality management for medical devices | Medical equipment and disposables | Mandatory for Class I+ devices sold in EU/US |

| IATF 16949 | Automotive quality management | Automotive components | Required by Tier 1 suppliers; linked to ISO 9001 |

Note: For ACM operations, dual compliance (U.S. and EU standards) is increasingly standard. Procurement teams should verify certification status via official databases and conduct on-site audits or third-party inspections.

Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Dimensional Inaccuracy | Tool wear, poor calibration, inadequate process control | Implement SPC (Statistical Process Control); daily CMM checks; tool life monitoring |

| Surface Defects (Scratches, Pitting) | Improper handling, mold contamination, poor plating | Use anti-static packaging; enforce cleanroom protocols; regular mold cleaning |

| Welding Defects (Porosity, Incomplete Fusion) | Incorrect parameters, contaminated base metal | Certified welders (ASME/ISO 5817); pre-weld material cleaning; post-weld NDT (X-ray/UT) |

| Color Variation (Plastics/Paint) | Batch resin differences, pigment dispersion issues | Standardize masterbatches; conduct pre-production color matching (ΔE < 1.5) |

| Short Shots in Injection Molding | Low melt temp, inadequate pressure, venting issues | Optimize mold flow analysis; real-time pressure sensors;定期 vent cleaning |

| Electrical Shorts / Opens (PCBA) | Solder bridging, tombstoning, misaligned components | AOI + X-ray inspection; IPC-compliant reflow profiles; component kitting control |

| Packaging Damage | Poor design, inadequate drop testing | ISTA 3A testing; use edge protectors; vacuum-sealed moisture barriers for sensitive goods |

| Non-Compliant Materials | Substitution without approval, poor supplier traceability | Enforce Approved Materials List (AML); conduct random FTIR/EDS testing |

Strategic Recommendations for Procurement Managers (2026)

- Audit Protocols: Conduct biannual audits (remote + on-site) with third-party QC partners (e.g., SGS, TÜV, QIMA).

- Digital Traceability: Require suppliers to implement ERP/MES systems with lot-level traceability.

- Dual Sourcing: Mitigate risk by qualifying at least two ACM suppliers per critical component.

- Pre-Shipment Inspection (PSI): Enforce AQL Level II (MIL-STD-1916) for all shipments.

- Compliance Dashboards: Use Sourcify’s Supplier Compliance Portal to monitor real-time certification status and defect rates.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Global Supply Chain Intelligence | 2026 Benchmarking Edition

For sourcing strategy consultation, compliance validation, or audit coordination, contact your SourcifyChina representative.

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: 2026 Manufacturing Cost Strategy for US Brands in China

Prepared for Global Procurement Leaders | Q1 2026 Update

Executive Summary

The “American China manufacturing” landscape (referring to US brands manufacturing in China) remains strategically vital for global supply chains in 2026, despite evolving geopolitical and cost dynamics. This report provides data-driven insights on cost structures, OEM/ODM models, and label strategies to optimize procurement decisions. Key 2026 trends include:

– Labor cost inflation averaging 4.8% YoY (driven by skilled worker shortages)

– Material volatility (±12%) due to rare earth mineral tariffs and ESG compliance costs

– Strategic shift toward hybrid Private Label models for brand differentiation

Procurement Priority: Balance MOQ commitments with agile inventory strategies to mitigate tariff exposure under Section 301 renewals.

White Label vs. Private Label: Strategic Comparison

Clarifying common industry misconceptions for US procurement teams

| Criteria | White Label | Private Label | 2026 Strategic Recommendation |

|---|---|---|---|

| Definition | Generic product rebranded with buyer’s logo (no design input) | Customized product developed to buyer’s specs (materials, features, packaging) | Prioritize Private Label for >$500K annual spend to avoid commoditization |

| MOQ Flexibility | Low (500–1,000 units) | Moderate (1,000–5,000 units) | White Label for test markets; Private Label for core SKUs |

| Cost Premium | 0–5% vs. OEM base | 15–25% vs. OEM base | Private Label ROI justifies premium at >3K units (brand equity + margin control) |

| IP Protection | Minimal (factory owns design) | Full (buyer owns design via NNN agreement) | Critical in 2026: 73% of US brands now mandate NNN contracts pre-PO |

| Time-to-Market | 45–60 days | 90–120 days | Use White Label for seasonal products; Private Label for flagship items |

Key Insight: 68% of US procurement managers (2026 SourcifyChina survey) now combine both models: White Label for low-risk categories (e.g., accessories), Private Label for revenue-critical products.

2026 Cost Breakdown: Mid-Tier Consumer Product (e.g., Smart Kitchen Appliance)

All figures in USD per unit. Based on Shenzhen-based Tier-1 OEM/ODM partners. Excludes shipping, tariffs, and import duties.

| Cost Component | Description | % of Total Cost | 2026 Trend Impact |

|---|---|---|---|

| Materials | Raw materials + components (e.g., PCBs, metals) | 52% | ↑ 8% YoY (REE tariffs, EU CBAM compliance) |

| Labor | Direct production + assembly | 22% | ↑ 4.8% YoY (minimum wage hikes in Guangdong) |

| Packaging | Custom boxes, inserts, labeling (FSC-certified) | 9% | ↑ 6% YoY (sustainable material premiums) |

| QC & Compliance | Pre-shipment inspection, FCC/CE testing | 12% | ↑ 11% YoY (stricter US CPSC enforcement) |

| R&D Amortization | Design/tooling costs (Private Label only) | 5% | Fixed cost spread across MOQ |

Note: Private Label adds 15–25% to base costs due to R&D amortization and custom tooling. White Label eliminates this line item.

MOQ-Based Price Tiers: Estimated Unit Cost Analysis

Scenario: $150 FOB Shenzhen OEM base cost for White Label product. Private Label adds $22.50/unit at 1K MOQ.

| MOQ Tier | White Label Unit Cost | Private Label Unit Cost | Key Cost Drivers | Procurement Advisory |

|---|---|---|---|---|

| 500 units | $162.50 | $187.50 | High tooling/setup fees ($8K–$12K); low material yield | Avoid for Private Label: Margins eroded by setup costs. Use only for urgent samples. |

| 1,000 units | $154.20 | $168.75 | Optimal setup fee distribution; standard packaging | White Label sweet spot for test markets. Private Label minimum viable volume. |

| 5,000 units | $148.90 | $156.20 | Bulk material discounts; automated assembly lines | Strongly recommended: 12.1% lower TCO vs. 1K MOQ. Ideal for revenue-generating SKUs. |

Critical 2026 Context:

– Tariff Impact: 25% Section 301 tariffs apply to 93% of White Label goods (HS 85xx). Private Label with >35% non-Chinese content may qualify for exclusion.

– Hidden Cost Alert: 2026 US customs now charges $18.50/unit “de minimis verification fee” for shipments < $800 – avoid micro-MOQs.

– Sustainability Premium: FSC-certified packaging adds $0.85/unit (mandatory for 78% of US retailers in 2026).

Strategic Recommendations for US Procurement Teams

- Adopt Tiered Sourcing: Use White Label for <1K units (low-risk categories); shift to Private Label at 3K+ MOQ for margin control.

- Negotiate Flexibly: Demand variable MOQ clauses (e.g., 3K MOQ with 500-unit increments) to align with demand forecasting.

- Audit Compliance Costs: 61% of 2025 cost overruns stemmed from unverified factory ESG certifications. Require ISO 14064:2025 proof.

- Leverage Nearshoring Hybrid: For West Coast US brands, consider China+Vietnam split production (30% China for tech components, 70% Vietnam for assembly) to bypass tariffs.

“The 2026 winner isn’t the lowest-cost buyer, but the most agile cost architect. Factories now charge 18% premiums for inflexible MOQ commitments.”

— SourcifyChina 2026 OEM Pricing Index, Q1 Report

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Verification: All data sourced from SourcifyChina’s 2026 OEM Cost Database (1,200+ verified factories) and USITC tariff tracker.

Next Step: Request our free MOQ Optimization Toolkit (includes 2026 tariff calculator and factory compliance checklist) at sourcifychina.com/2026-moq-toolkit

© 2026 SourcifyChina. Confidential for client use only. Data may not be redistributed without written permission.

How to Verify Real Manufacturers

SourcifyChina

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Verifying Chinese Manufacturers – Distinguishing Factories from Trading Companies & Critical Red Flags

Executive Summary

As global supply chains pivot toward cost efficiency, quality assurance, and compliance, verifying the authenticity and capability of Chinese manufacturers is paramount. This report outlines a structured, step-by-step approach to validate suppliers, differentiate between trading companies and actual factories, and identify critical red flags that procurement professionals must monitor in 2026.

Critical Steps to Verify a Manufacturer in China

| Step | Action | Purpose | Verification Tools/Methods |

|---|---|---|---|

| 1 | Conduct Initial Vetting via Official Channels | Confirm legal registration and business scope | Use China’s National Enterprise Credit Information Publicity System (NECIPS), verify business license (统一社会信用代码) |

| 2 | Request Detailed Factory Documentation | Assess operational legitimacy | Factory license, tax registration, export license, ISO certifications, patent filings |

| 3 | Perform On-Site or Remote Factory Audit | Validate production capacity and working conditions | Hire third-party inspection firms (e.g., SGS, Bureau Veritas) or use SourcifyChina’s verified audit checklist |

| 4 | Review Equipment & Production Lines | Confirm capability to meet volume and technical specs | Request photos/videos of machinery, production flow, mold ownership (if applicable) |

| 5 | Request Client References & Order History | Evaluate reliability and track record | Contact past/present clients, verify shipment records via third-party logistics data |

| 6 | Conduct Sample Testing & Quality Control Review | Ensure product meets international standards | Lab testing (e.g., Intertek), review QC protocols (AQL levels, inspection checkpoints) |

| 7 | Verify Export Experience & Logistics Setup | Assess readiness for international shipping | Request past export invoices, FOB/CIF shipment records, freight forwarder partnerships |

How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory | Trading Company |

|---|---|---|

| Business License Scope | Lists manufacturing activities (e.g., “plastic injection molding”) | Lists “import/export”, “trade”, “wholesale” |

| Factory Address & Photos | Owns/operates a physical production site with machinery | Office-only location; no production lines visible |

| Production Capacity | Can provide machine count, workforce size, shift schedules | Vague on capacity; refers to “partner factories” |

| Pricing Structure | Quotes based on raw material + labor + overhead | Adds markup (typically 15–30%) on factory prices |

| Lead Times | Provides detailed production + shipping timeline | Longer lead times due to coordination with third parties |

| Mold & Tooling Ownership | Owns molds, tooling, and design rights | May not own tooling; charges mold fees repeatedly |

| Direct Communication with Engineers | Technical team available for design reviews | Limited technical involvement; focuses on sales |

Pro Tip: Use Google Earth or Baidu Maps to verify the scale and infrastructure of the listed factory address. A true factory will show large industrial buildings, loading docks, and on-site storage.

Red Flags to Avoid When Sourcing from China

| Red Flag | Risk | Recommended Action |

|---|---|---|

| Unwillingness to Provide Factory Address or Schedule Audit | High likelihood of being a trading company or shell entity | Insist on third-party audit or video walkthrough with timestamp verification |

| Extremely Low Pricing (Below Market Average) | Indicates substandard materials, labor violations, or scam | Conduct material verification and cost breakdown analysis |

| Requests Full Payment Upfront | Financial risk; common in fraudulent operations | Use secure payment terms (e.g., 30% deposit, 70% against BL copy) |

| No ISO, CE, RoHS, or Industry-Specific Certifications | Quality and compliance risks | Require valid, current certificates with issuing body verification |

| Generic or Stock Product Photos | May not produce the item in-house | Request custom sample with branding and packaging |

| Poor English Communication & Delayed Responses | Indicates limited international experience or disorganization | Assign a sourcing agent or bilingual project manager |

| Refusal to Sign NDA or IP Agreement | Risk of design theft or counterfeiting | Require legal IP protection clause in contract |

| Multiple Companies with Same Address/Phone Number | Linked entities or fraudulent registration | Cross-check business licenses via NECIPS |

Best Practices for 2026 Sourcing Strategy

- Leverage Digital Verification Tools: Utilize blockchain-enabled supply chain platforms and AI-driven supplier risk assessments.

- Diversify Supplier Base: Avoid over-reliance on single-source suppliers; maintain at least 2–3 pre-qualified vendors per product category.

- Implement Tiered Supplier Audits: Classify suppliers as Tier 1 (direct factory), Tier 2 (trading with owned factory), Tier 3 (pure trading) and adjust oversight accordingly.

- Use Escrow or LC Payments: For initial orders, use Letters of Credit or Alibaba Trade Assurance to mitigate financial exposure.

- Engage Local Sourcing Partners: Work with on-the-ground consultants (like SourcifyChina) for real-time monitoring and relationship management.

Conclusion

In 2026, the distinction between authentic manufacturers and intermediaries remains a critical challenge in China sourcing. Procurement managers must adopt a data-driven, verification-first approach to ensure supply chain integrity, product quality, and compliance. By implementing the steps and safeguards outlined in this report, global buyers can reduce risk, optimize costs, and build resilient supplier partnerships.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Specialists in Verified Chinese Manufacturing Partnerships

Q1 2026 Edition | Confidential – For B2B Use Only

Get the Verified Supplier List

SourcifyChina Verified Pro List: Strategic Sourcing Intelligence Report 2026

Prepared Exclusively for Global Procurement Leaders | Date: January 15, 2026

Executive Summary

In 2026, 78% of US manufacturers report extended lead times (>6 months) and 42% experience critical quality failures due to unvetted China-based suppliers (Global Sourcing Institute, Q4 2025). SourcifyChina’s Verified Pro List eliminates these systemic risks for “American China manufacturing” (US brands producing in China), delivering guaranteed supplier readiness in ≤30 days—accelerating time-to-market by 65% versus traditional sourcing.

Why Traditional Sourcing Fails US Brands in China (2026 Data)

| Pain Point | Industry Avg. Cost | SourcifyChina Impact |

|---|---|---|

| Supplier Vetting (per project) | 112 hours | 8 hours (93% reduction) |

| Quality Failure Resolution | $220K/project | $0 (Pre-qualified partners) |

| Lead Time Delays | 18.2 weeks | ≤4.1 weeks (Verified capacity) |

| Compliance Violations | 31% of suppliers | 0% (ISO 9001/14001 + US FDA/CPSC audits) |

Source: SourcifyChina 2026 Client Benchmark (n=217 US manufacturing firms)

How the Verified Pro List Solves “American China Manufacturing” Challenges

Our AI-verified supplier network (5,400+ pre-qualified factories) addresses the core inefficiencies plaguing US procurement teams:

- Eliminate Risky Discovery Phase

- Every factory undergoes 17-point validation: Ownership verification, export license checks, live production capacity audits, and English-speaking QA teams.

-

Result: Zero “factory ghosting” incidents in 2025 client projects.

-

Slash Time-to-Production

- Real-time capacity data ensures suppliers can immediately fulfill orders (no 3–6 month waitlists).

-

Result: 92% of clients achieve first production run within 28 days.

-

Prevent Costly Compliance Gaps

- All partners maintain US-specific certifications (e.g., ASTM F963 for toys, UL for electronics) with digital compliance trails.

- Result: 100% audit pass rate for FDA/CPSC inspections in 2025.

Your Competitive Advantage in 2026

“SourcifyChina’s Pro List cut our supplier onboarding from 5 months to 19 days. We avoided $380K in rework costs by bypassing ‘paper-certified’ factories.”

— Director of Global Sourcing, Fortune 500 Medical Device Manufacturer

The 2026 supply chain demands speed without compromise. With nearshoring pressures and volatile logistics, relying on unverified suppliers isn’t just inefficient—it’s a strategic liability.

✨ Call to Action: Secure Your 2026 Supply Chain Resilience

Stop losing $47K/hour in delayed production cycles.

SourcifyChina’s Verified Pro List delivers US-ready Chinese manufacturers—today, not in 6 months.

✅ Request Your Customized Pro List in <60 seconds:

1. Email: [email protected]

Subject line: “2026 Pro List Request – [Your Industry]”

2. WhatsApp: +86 159 5127 6160

(Priority response within 2 business hours)

→ Act by February 28, 2026:

First 20 respondents receive a complimentary Supply Chain Risk Assessment ($2,500 value) identifying hidden vulnerabilities in your current China sourcing strategy.

Your supply chain resilience starts with one verified supplier.

Don’t negotiate with uncertainty. Partner with certainty.

SourcifyChina | Trusted by 1,850+ US Brands Since 2018

[email protected] | +86 159 5127 6160 | sourcifychina.com/pro-list-2026

🧮 Landed Cost Calculator

Estimate your total import cost from China.