The global metal forming machinery market, which includes aluminum siding brake equipment, is witnessing steady expansion driven by growth in construction, manufacturing, and infrastructure development. According to Grand View Research, the global sheet metal machinery market size was valued at USD 21.3 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. Contributing to this trend, rising demand for energy-efficient buildings and durable exterior cladding solutions has amplified the need for precision tools like aluminum siding brakes. As manufacturers increasingly focus on efficiency and customization, the North American and European markets—key adopters of aluminum siding—have seen a surge in demand for high-performance braking systems. This growing industry momentum underscores the importance of identifying leading manufacturers capable of delivering reliability, innovation, and scalability. Based on market share, technological advancements, and customer feedback, the following nine companies represent the top aluminum siding brake manufacturers shaping the future of architectural metal fabrication.

Top 9 Aluminum Siding Brake Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Brakes

Domain Est. 1998

Website: buchnermfg.com

Key Highlights: Buchner Manufacturing Inc. offers a wide range of Brakes products. Call 1.800.461.6455 today to learn more about this fantastic product….

#2

Website: metalsales.us.com

Key Highlights: Metal Sales is the nation’s largest manufacturer of metal roofing, wall, and building systems. We are the most awarded and highly recognized provider of metal ……

#3 SAF

Domain Est. 1992

Website: saf.com

Key Highlights: SAF is the leader in metals fabrication, finishing, and distribution around the world. Learn more about how we can turn your ideas into reality….

#4 Durable Siding or Sheet Metal Brakes

Domain Est. 1996

Website: mittlerbros.com

Key Highlights: A siding brake is used commonly for creating cuts and bends in aluminum sheet metal (or mild steels). Brakes are used for various applications….

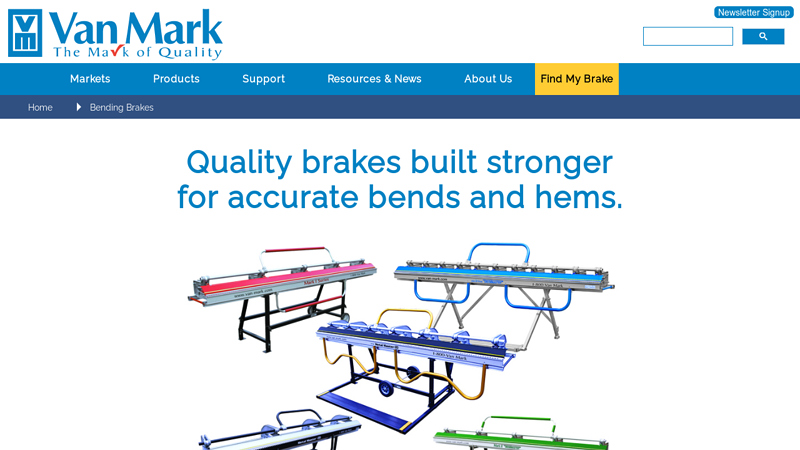

#5 Our Bending Brakes

Domain Est. 1997

Website: van-mark.com

Key Highlights: Engineered to repeatedly bend common trim around windows, doors, fascia and siding with soft aluminum with ease, accuracy and consistency. Mark I Series ……

#6 Aluminum Siding Brakes by Alum

Domain Est. 1998

Website: alumapole.com

Key Highlights: Pro-Trim is easy to clean and work with. Bendable on any brake. Many shapes can now be bent that would be impossible using aluminum. For example, porch columns ……

#7 Innovatools Inc: Innovatools International

Domain Est. 1999

Website: innovatools.com

Key Highlights: InnovaTools manufactures & sells modular aluminum siding brakes, bending brake accessories for all benders in the United States of America and worldwide….

#8 Aluminum Brakes For Sale

Domain Est. 2000

Website: associated-scaffolding.com

Key Highlights: Offering a wide selection of Van-Mark Aluminum bending brakes including the Mark I Series, Mark II Trimmaster, Metal Master and more. Order Online today!…

#9 Siding Benders/Brakes

Domain Est. 2006

Website: arcanaluminium.com

Key Highlights: They are lightweight, versatile and proudly made in the USA. With thousands sold, Arcan is your siding bender/brake expert! Call us now!…

Expert Sourcing Insights for Aluminum Siding Brake

H2: Projected Market Trends for Aluminum Siding Brake in 2026

The aluminum siding brake market is poised for notable shifts and growth by 2026, driven by advancements in construction technology, evolving building regulations, and increasing demand for energy-efficient and durable building materials. The aluminum siding brake—a specialized tool used to bend and shape aluminum siding panels during installation—is benefiting from rising residential and commercial construction activities, particularly in North America and parts of Europe and Asia-Pacific.

One key trend shaping the 2026 outlook is the growing emphasis on sustainable construction. Aluminum, being 100% recyclable and lightweight, aligns with green building standards, boosting its adoption in siding applications. As a result, demand for precision tools like aluminum siding brakes is increasing, especially among contractors seeking efficient, waste-reducing installation methods. Automation and digital integration are also influencing product development, with manufacturers introducing ergonomic, adjustable, and portable brake models equipped with digital readouts for improved accuracy.

Additionally, the expansion of the repair and remodeling sector—fueled by aging infrastructure and homeowner upgrades—will support steady demand for aluminum siding and associated tools. The DIY (do-it-yourself) movement, particularly in the U.S., is also contributing to market growth, as more consumers invest in high-quality, user-friendly tools for home improvement projects.

Regionally, North America is expected to maintain dominance in the aluminum siding brake market due to widespread use of aluminum siding in residential construction and favorable climatic conditions that necessitate durable exterior materials. Meanwhile, emerging economies in Asia-Pacific may experience accelerated growth as urbanization and modern construction practices gain traction.

In summary, by 2026, the aluminum siding brake market will likely be shaped by sustainability trends, technological innovation, and robust construction activity, positioning it for moderate but steady expansion across key global markets.

Common Pitfalls When Sourcing Aluminum Siding Brake (Quality, IP)

Sourcing aluminum siding brakes—especially with considerations around quality and intellectual property (IP)—can present several challenges. Being aware of these common pitfalls helps ensure you procure reliable equipment that meets performance standards and avoids legal complications.

Poor Material Quality and Construction

One of the most frequent issues is receiving aluminum siding brakes made from substandard materials. Lower-quality units may use thin-gauge steel or inferior aluminum alloys in critical load-bearing components, leading to warping, misalignment, or premature failure under repeated use. Poor welding, inadequate powder coating, or lack of rust protection can further reduce durability, especially in outdoor or high-humidity environments.

Inaccurate Bending Precision and Calibration

Low-cost or counterfeit brakes often suffer from inconsistent bending angles and poor calibration. This results in uneven seams, misaligned panels, and increased material waste. Precision is critical in siding installation—deviations of even a few degrees can compromise weather resistance and aesthetics. Without proper quality control during manufacturing, these inconsistencies are difficult to correct in the field.

Lack of Intellectual Property Compliance

Sourcing from manufacturers that replicate patented designs without authorization poses significant IP risks. Many reputable aluminum siding brake models are protected by patents covering their unique mechanisms, handle designs, or clamping systems. Purchasing from suppliers using such infringing designs—even unknowingly—can expose your business to legal liability, shipment seizures, or forced equipment removal.

Inadequate Documentation and Certification

Reputable equipment should come with clear technical documentation, safety certifications (e.g., CE, ANSI), and traceable manufacturing details. Suppliers offering brakes without proper documentation may be cutting corners or selling unverified copies. This lack of transparency complicates maintenance, warranty claims, and compliance with industry or regulatory standards.

Hidden Costs from Short-Term Reliability Issues

While lower-priced brakes may seem cost-effective initially, frequent breakdowns, replacement parts scarcity, or the need for constant recalibration can lead to higher total cost of ownership. Downtime and repair labor often outweigh initial savings, especially for contractors relying on consistent tool performance.

Risk of Counterfeit or “Knock-Off” Products

In global supply chains, especially via online marketplaces, counterfeit siding brakes mimicking well-known brands are common. These copies may use similar branding or packaging but deliver poor performance and lack IP licensing. Verifying supplier authenticity and requesting proof of IP rights or OEM partnerships is essential to avoid legal and operational risks.

Avoiding these pitfalls requires due diligence: vetting suppliers, requesting product certifications, inspecting units before bulk orders, and prioritizing long-term reliability over upfront cost savings.

Logistics & Compliance Guide for Aluminum Siding Brake

Product Classification and Regulatory Overview

Aluminum siding brakes are classified as industrial tools used in metal fabrication, primarily for bending aluminum siding panels during installation or manufacturing. While the tool itself is not a regulated product in the same way as consumer goods or hazardous materials, its transportation, import/export, and workplace use are subject to various logistical and compliance requirements depending on jurisdiction and application.

Transportation and Shipping Requirements

When shipping aluminum siding brakes domestically or internationally, standard freight regulations apply. The equipment should be securely packaged to prevent damage, typically crated or palletized. For international shipments, ensure compliance with International Maritime Dangerous Goods (IMDG) Code or International Air Transport Association (IATA) regulations if applicable—though aluminum siding brakes are generally non-hazardous. Accurate commercial invoices, packing lists, and Harmonized System (HS) codes (e.g., 8462.21 for metal-bending machinery) must accompany shipments to avoid customs delays.

Import and Export Compliance

Importers and exporters must verify country-specific regulations. In the United States, aluminum siding brakes may be subject to tariffs under HTSUS code 8462.21.00. Ensure compliance with U.S. Customs and Border Protection (CBP) documentation and potential anti-dumping or countervailing duties if sourced from certain countries. Export controls under the Export Administration Regulations (EAR) typically do not apply unless the brake contains controlled technology, which is uncommon.

Environmental and Safety Standards

Aluminum siding brakes must comply with relevant workplace safety standards. In the U.S., the Occupational Safety and Health Administration (OSHA) requires that industrial machinery be equipped with appropriate guards and emergency stop mechanisms. Employers must provide operator training and maintain equipment in safe working condition. Additionally, the product should meet electrical safety standards (e.g., UL or CSA certification) if it includes powered components.

Packaging and Handling Guidelines

Use durable wooden crates or reinforced pallets to protect the brake during transit. Clearly label packages with handling instructions such as “Fragile,” “This Side Up,” and weight specifications. Include safety warnings if applicable, especially for moving parts. For海运, ensure moisture protection using desiccants or vapor barriers to prevent corrosion during long voyages.

End-of-Life and Recycling Considerations

At end-of-life, aluminum siding brakes—composed primarily of steel and aluminum—should be recycled in accordance with local waste management regulations. Disassemble components where possible, separating ferrous and non-ferrous metals. Adhere to Environmental Protection Agency (EPA) guidelines or equivalent regional standards for proper disposal of any electrical or hydraulic parts.

Documentation and Recordkeeping

Maintain comprehensive records including bills of lading, customs documentation, safety data sheets (if applicable), and compliance certifications. For businesses, retain records for a minimum of five years to support audits or regulatory inquiries. Provide users with an operations manual that includes safety warnings, maintenance procedures, and compliance statements.

Regional Compliance Variations

Compliance requirements may vary by region. In the European Union, machinery must meet the EU Machinery Directive (2006/42/EC) and carry the CE marking. Canada requires compliance with the Canadian Standards Association (CSA) Z432 for machinery safety. Always verify local regulations before distribution to ensure full compliance.

In conclusion, sourcing an aluminum siding brake requires careful consideration of factors such as durability, precision, portability, and cost-effectiveness. Whether opting for a manual, electric, or hydraulic model, it’s essential to select a brake that aligns with your production needs, material thickness requirements, and workshop capabilities. Sourcing from reputable suppliers or manufacturers ensures quality craftsmanship and reliable after-sales support. Additionally, evaluating customer reviews, warranty options, and compatibility with existing tools can further streamline the decision-making process. By investing in the right aluminum siding brake, contractors and fabricators can enhance efficiency, achieve clean and consistent bends, and improve the overall quality of their siding projects.