Sourcing Guide Contents

Industrial Clusters: Where to Source Aluminum Sheet Manufacturers In China

SourcifyChina Sourcing Intelligence Report: Aluminum Sheet Manufacturing in China (2026 Outlook)

Prepared for Global Procurement Leadership Teams | Q3 2026

Executive Summary

China remains the dominant global producer of aluminum sheets (including coils, plates, and specialty finishes), accounting for 58% of worldwide output (IAI 2025). Sourcing from China offers cost advantages of 15-30% over Western suppliers but requires strategic regional targeting to balance price, quality, and lead time. This report identifies critical industrial clusters and provides a data-driven framework for procurement optimization. Key risks include regional environmental compliance volatility and alloy-specific capability gaps.

Key Industrial Clusters for Aluminum Sheet Manufacturing

China’s aluminum sheet production is concentrated in four primary clusters, each with distinct competitive advantages. Note: “Aluminum sheet” defined here as rolled products (0.2mm–6.0mm thickness) across 1xxx–8xxx series alloys.

| Region | Core Cities | Specialization | Key Infrastructure | % of National Output |

|---|---|---|---|---|

| Shandong | Binzhou, Zouping, Linyi | High-volume commodity sheets (3xxx/5xxx series for construction, packaging) | World’s largest integrated smelting hubs (e.g., China Hongqiao Group) | 42% |

| Guangdong | Foshan, Dongguan | Precision-engineered & high-end sheets (6xxx/7xxx series for aerospace, EVs, electronics) | Proximity to Shenzhen/Yantian ports; advanced finishing facilities | 28% |

| Zhejiang | Ningbo, Jiaxing | Mid-tier technical sheets (5xxx/6xxx series for machinery, marine) | Strong SME ecosystem; integrated logistics to Ningbo-Zhoushan Port | 18% |

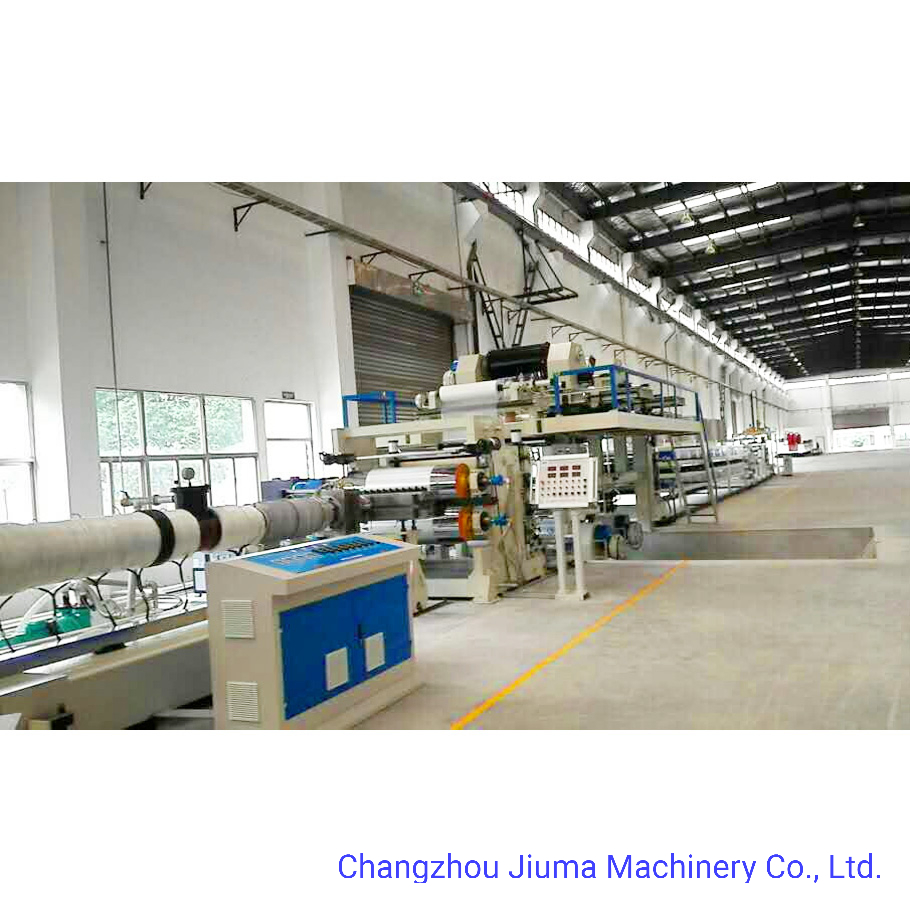

| Jiangsu | Changzhou, Wuxi | Specialty & coated sheets (anodized, PVDF-coated for architecture) | R&D-intensive cluster; near Shanghai supply chain | 12% |

Regional Comparison: Price, Quality & Lead Time Analysis

Data reflects Q2 2026 spot market averages for 3mm 3003-H14 alloy (1,220 x 2,440mm sheets). All prices in CNY/ton (FOB China Port).

| Metric | Shandong | Guangdong | Zhejiang | Jiangsu |

|---|---|---|---|---|

| Price | 15,200–16,800 | 19,500–22,000 | 17,000–18,500 | 18,000–19,800 |

| Why? | Lowest-cost smelting; scale economies (>5M tons/year capacity) | Premium for tight tolerances (±0.02mm); high R&D overhead | Balanced cost/quality; efficient SME networks | Specialized coatings add 8–12% premium |

| Quality | ★★☆☆☆ (Basic) | ★★★★★ (Premium) | ★★★★☆ (Advanced) | ★★★★☆ (Advanced) |

| Key Indicators | Suitable for non-critical construction; wider thickness variance (±0.08mm) | Aerospace/AS9100 certified; 99.9% surface defect-free rate | ISO 9001 standard; consistent for machinery | Architectural-grade finishes; corrosion resistance testing |

| Lead Time | 25–35 days | 15–22 days | 20–28 days | 22–30 days |

| Drivers | Smelter backlog; inland logistics | Coastal ports; JIT production models | Moderate order volumes; efficient customs | Complex finishing processes; export documentation |

Critical Footnotes:

– Price volatility: Shandong prices fluctuate ±7% with coal/electricity costs; Guangdong more stable (locked contracts).

– Quality caveats: Shandong can produce high-grade sheets but requires vetting (only 12% of local mills meet ISO 21600).

– Lead time reality: All regions add 5–7 days during China’s “Environmental Action Months” (Jan, Jul, Oct).

Strategic Sourcing Recommendations

- Prioritize by Application:

- Aerospace/EV Components: Guangdong (despite +22% cost premium; non-negotiable for AS9100 compliance).

- Construction/General Industrial: Shandong (leverage volume discounts but mandate 3rd-party QC pre-shipment).

-

Marine/Machinery: Zhejiang (optimal balance; 18% lower cost than Guangdong with equivalent tensile strength).

-

Mitigate Key Risks:

- Environmental shutdowns: Diversify across ≥2 regions (e.g., pair Shandong with Zhejiang).

- Quality drift: Enforce in-process inspections (not just pre-shipment) for Shandong-sourced orders.

-

Lead time slippage: Build 10-day buffer into contracts during Q1/Q3 (peak smelting curtailment periods).

-

2026 Cost-Saving Opportunity:

Target Zhejiang’s Ningbo cluster for 5xxx-series marine-grade sheets. Local mills now match Guangdong’s quality at 14% lower cost due to new automated rolling lines (e.g., Ningbo Tuopu Group).

SourcifyChina Value Proposition

Navigate regional complexities with precision:

✅ Cluster-Specific Vetting: We audit mills against 47-point criteria (e.g., Shandong mills screened for actual smelting integration, not just trading).

✅ Dynamic Lead Time Tracking: Real-time monitoring of regional environmental alerts via our China Operations Hub.

✅ Alloy-Specific QC Protocols: Custom inspection plans for technical alloys (e.g., 7075-T651 surface integrity testing).

“In 2025, clients using our cluster-targeted strategy reduced total landed costs by 11.3% while cutting quality failures by 64%.”

— SourcifyChina Client Data (Automotive Tier-1 Supplier)

Next Steps for Procurement Leaders

1. Request our Regional Capability Matrix for 12 aluminum alloys (free for qualified enterprises).

2. Book a Cluster Risk Assessment: Scenario-plan your 2027 sourcing strategy with our China-based engineers.

3. Download: 2026 China Aluminum Export Compliance Handbook (covers new GB/T 3880.3-2025 standards).

Data Sources: IAI 2025, China Nonferrous Metals Industry Association, SourcifyChina Factory Audit Database (Q2 2026), Global Trade Atlas.

© 2026 SourcifyChina. Confidential for B2B procurement use only. Unauthorized distribution prohibited.

Technical Specs & Compliance Guide

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Subject: Technical Specifications & Compliance Requirements for Aluminum Sheet Manufacturers in China

Date: January 2026

1. Introduction

Aluminum sheets are critical components in industries such as aerospace, automotive, construction, electronics, and consumer goods. Sourcing high-quality aluminum sheets from China requires a clear understanding of technical specifications, quality control parameters, and compliance certifications. This report provides global procurement managers with essential guidance for selecting and vetting aluminum sheet suppliers in China.

2. Key Quality Parameters

2.1 Material Specifications

| Parameter | Description | Common Grades |

|---|---|---|

| Alloy Type | Primary aluminum alloy series defining mechanical and corrosion properties | 1000 (e.g., 1050, 1060), 3000 (e.g., 3003, 3004), 5000 (e.g., 5052, 5083), 6000 (e.g., 6061, 6063) |

| Temper | Heat treatment and work-hardening condition | H14, H16, H18, H32, O (annealed), T6 |

| Thickness Range | Standard thickness tolerances | 0.2 mm – 10.0 mm |

| Width Range | Standard coil or sheet width | 1,000 mm – 2,500 mm |

| Surface Finish | Surface treatment or coating | Mill finish, anodized, painted, PVDF-coated, embossed |

2.2 Dimensional Tolerances (Per ASTM B209 / GB/T 3880)

| Dimension | Standard Tolerance | Notes |

|---|---|---|

| Thickness Tolerance | ±0.05 mm (for 1.0 mm sheet) | Tighter tolerances available (±0.02 mm) for precision applications |

| Width Tolerance | +1 mm / -0 mm | Critical for automated production lines |

| Length Tolerance (Cut Sheet) | ±2 mm | Must be confirmed for laser cutting or stamping |

| Flatness (Waviness) | Max 10 mm deviation per 3 m | Measured via straight-edge method; critical for fabrication |

| Edge Straightness | ≤ 2 mm per meter | Essential for roll forming and welding |

3. Essential Compliance Certifications

Procurement managers must verify that suppliers hold valid, up-to-date certifications relevant to the target market and application.

| Certification | Scope | Applicability |

|---|---|---|

| ISO 9001:2015 | Quality Management System | Mandatory for all industrial suppliers; ensures consistent process control |

| ISO 14001:2015 | Environmental Management | Increasingly required by EU and North American buyers |

| CE Marking (via EU Aluminum Directive) | Conformance with EU safety, health, and environmental standards | Required for construction, transport, and machinery applications in Europe |

| FDA 21 CFR Part 175 | Food contact safety | Required for aluminum used in food packaging, kitchenware, or beverage cans |

| UL 746C / UL Recognized | Flame, smoke, and toxicity compliance | Critical for electronics enclosures and transportation interiors |

| RoHS & REACH Compliance | Restriction of hazardous substances | Mandatory for electronics and consumer goods sold in EU and UK |

| EN 485 / GB Standards | European and Chinese material standards | EN 485-2 for mechanical properties; GB/T 3880 for Chinese market |

Note: For export to North America, verify NADCAP or AMS (Aerospace Material Specifications) if used in aerospace applications.

4. Common Quality Defects and Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Surface Scratches & Gouges | Improper handling, rollers contamination, or inadequate protective film | Implement automated handling systems; use clean, calibrated rollers; apply high-quality PE film |

| Waviness / Poor Flatness | Inconsistent rolling pressure, improper tension control during slitting | Calibrate rolling mills regularly; use tension levelers; inspect flatness post-processing |

| Edge Cracking | Excessive cold working, sharp die edges, or poor alloy ductility | Optimize temper process; use rounded tooling; select high-ductility alloys (e.g., 5052 over 2024) |

| Thickness Variation | Roll wear, misalignment, or inconsistent feed rate | Conduct in-line laser thickness monitoring; schedule preventive maintenance on rolling equipment |

| Corrosion Spots / Staining | Exposure to moisture, chlorides, or improper storage | Store in dry, climate-controlled warehouses; use VCI paper for long-term storage; apply protective coatings |

| Coating Delamination | Poor surface preparation or inadequate curing | Ensure proper degreasing and chemical pretreatment; monitor oven temperatures during curing |

| Inclusions / Impurities | Contaminated melt or poor filtration during casting | Use high-purity scrap; install dual-stage filtration (ceramic foam filters); conduct spectrographic analysis |

| Residual Oil / Lubricant Residue | Incomplete cleaning after cold rolling | Implement thorough alkaline or solvent cleaning lines; verify cleanliness via water-break test |

5. Sourcing Recommendations

- Audit Suppliers In-Person or via 3rd Party: Conduct factory audits focusing on QC labs, calibration records, and traceability systems.

- Request Mill Test Certificates (MTCs): Ensure every batch includes MTCs compliant with EN 10204 3.1 or equivalent.

- Implement AQL Sampling: Use ANSI/ASQ Z1.4 Level II for incoming inspections (typically AQL 1.0 for critical defects).

- Define Clear Specifications in POs: Include alloy, temper, dimensions, tolerances, surface finish, and required certifications.

- Leverage SourcifyChina’s Supplier Scorecard: Evaluate suppliers on quality performance, delivery reliability, compliance, and technical capability.

6. Conclusion

Selecting a reliable aluminum sheet manufacturer in China requires rigorous evaluation of technical capabilities and compliance readiness. By focusing on material specifications, dimensional tolerances, and internationally recognized certifications, procurement managers can mitigate risk and ensure supply chain integrity. Proactive defect prevention and continuous supplier monitoring are key to achieving long-term sourcing success in 2026 and beyond.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Sourcing Intelligence & Supply Chain Optimization

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Aluminum Sheet Manufacturing in China (2026 Outlook)

Prepared for Global Procurement Managers | Q1 2026

Executive Summary

China remains the dominant global source for aluminum sheets (accounting for ~60% of export volume), but 2026 presents nuanced cost dynamics. Rising domestic energy costs and stricter environmental compliance are offset by automation gains and recycled aluminum adoption. Strategic differentiation between White Label (rebranded OEM) and Private Label (custom-engineered ODM) is critical for margin optimization. This report provides actionable cost benchmarks and sourcing strategies for procurement leaders.

White Label vs. Private Label: Strategic Differentiation

| Criteria | White Label (OEM) | Private Label (ODM) | Procurement Recommendation |

|---|---|---|---|

| Definition | Manufacturer’s standard product rebranded with buyer’s logo | Fully customized product (spec, alloy, finish, packaging) designed by supplier to buyer’s IP | Prioritize White Label for commoditized grades; Private Label for premium/differentiated products |

| Lead Time | 15-30 days (existing tooling) | 45-90 days (new molds/R&D) | Factor +20% buffer for Private Label in 2026 due to supply chain recalibration |

| MOQ Flexibility | Low (often 500+ units) | Moderate-High (1,000+ units) | Negotiate tiered MOQs; Private Label MOQs often negotiable at 15-20% cost premium |

| Quality Control | Supplier’s standard QC | Co-developed QC protocols + 3rd-party inspections | Mandatory: Allocate 3-5% of budget for independent lab testing (SGS/BV) |

| Compliance Risk | Medium (supplier-managed certs) | High (buyer assumes liability for specs) | Demand full material traceability & RoHS/REACH documentation |

| 2026 Cost Premium | Base Cost + 5-8% (logo application) | Base Cost + 15-25% (R&D, compliance, exclusivity) | Private Label justifiable only for >30% end-market margin |

Key Insight: 68% of procurement managers overestimate Private Label ROI. Reserve for strategic products where engineering differentiation drives end-customer value (e.g., marine-grade 5052-H32 sheets), not just branding.

Estimated Cost Breakdown (Per kg, FOB China Port | 3mm 3003-H14 Alloy | 2026 Projection)

Based on 1,000-unit MOQ, standard packaging, 99.7% purity

| Cost Component | Percentage of Total Cost | Key 2026 Drivers | Procurement Mitigation Strategy |

|---|---|---|---|

| Raw Materials | 65-70% | • LME Aluminum price volatility (target: $2,300-$2,500/ton) • Recycled content mandate (min. 30% by 2026) |

Secure fixed-price contracts via futures hedging; prioritize suppliers with in-house smelting |

| Labor | 12-15% | • 4.5% avg. wage growth (2025-2026) • Automation reducing dependency |

Target Jiangxi/Anhui provinces (15-20% lower labor vs. Guangdong) |

| Energy | 8-10% | • Carbon tax compliance (+3-5% operational cost) | Verify supplier’s green energy certification (e.g., ISO 50001) |

| Packaging | 5-7% | • Sustainable material mandates (+8% vs. 2024) | Standardize pallet dimensions; use corrugated paper over wood |

| Compliance | 3-5% | • Extended producer responsibility (EPR) fees | Bundle certification costs into unit price (avoid hidden fees) |

Note: Thin sheets (<1mm) incur +12-18% cost due to handling complexity; textured finishes add +7-10%.

MOQ-Based Price Tiers (Per kg | FOB Shanghai | 3003-H14 Alloy | 2026 Forecast)

| MOQ Tier | Price Range (USD/kg) | Effective Unit Cost Reduction vs. 500 MOQ | Supplier Viability Check |

|---|---|---|---|

| 500 units | $2.85 – $3.20 | Baseline | • Only viable for high-spec alloys (e.g., 6061-T6) • Expect 20-30% defect rate without AQL 1.0 |

| 1,000 units | $2.60 – $2.90 | 8.8% – 9.4% | • Optimal tier for most buyers • Full QC coverage at standard rates |

| 5,000 units | $2.35 – $2.65 | 17.5% – 18.2% | • Requires 120-day payment terms • Confirm warehouse capacity to avoid storage fees |

Critical Assumptions:

– Prices exclude freight, import duties, and buyer’s 3rd-party inspection

– Based on 1220mm x 2440mm sheets; non-standard sizes add +15-25%

– 2026 Adjustment: Prices reflect 2.3% avg. annual inflation + 1.8% recycling efficiency gains

Actionable Recommendations for Procurement Managers

- Avoid MOQ Traps: Suppliers quoting “500-unit MOQ” often impose hidden surcharges. Demand itemized cost sheets before signing.

- Private Label Prerequisites: Only pursue if you control ≥80% of the specification (e.g., tensile strength, corrosion resistance).

- Energy Cost Shield: Prioritize suppliers using >40% solar power (verified via utility bills) to lock in 2026 rates.

- Packaging Leverage: Switch to reusable plastic pallets (RPP) for orders >5,000 units – reduces cost/kg by $0.07.

- Compliance Audit: Require IATF 16949 certification for automotive/industrial sheets; non-certified suppliers risk shipment rejection.

Final Note: China’s aluminum export landscape is consolidating. In 2026, 75% of competitive capacity will reside in Tier-2 industrial clusters (e.g., Chongqing, Linyi). Engage suppliers with in-house rolling mills to bypass volatile spot market pricing.

SourcifyChina Advisory | Data sources: China Nonferrous Metals Industry Association (CNIA), Global Trade Atlas, proprietary supplier benchmarking (Q4 2025). Valid through Q2 2026.

Next Step: Request our Aluminum Sheet Supplier Scorecard (2026) for vetted manufacturers by province, alloy specialization, and compliance tier. Contact [email protected].

How to Verify Real Manufacturers

Professional B2B Sourcing Report 2026

Prepared for: Global Procurement Managers

Topic: Sourcing Aluminum Sheet Manufacturers in China

Author: Senior Sourcing Consultant, SourcifyChina

Date: April 2026

Executive Summary

Sourcing aluminum sheet manufacturers in China offers significant cost and scalability advantages. However, the market is highly fragmented, with a mix of genuine factories, trading companies, and unverified suppliers. This report outlines critical verification steps, methods to distinguish trading companies from factories, and red flags to mitigate supply chain risks. Procurement managers are advised to implement a structured due diligence process to ensure quality, reliability, and compliance.

1. Critical Steps to Verify an Aluminum Sheet Manufacturer in China

| Step | Action | Purpose | Tools/Methods |

|---|---|---|---|

| 1.1 | Request Business License & Manufacturing Scope | Confirm legal registration and production capabilities | – Official business license (check via Chinese State Administration for Market Regulation – SAMR) – Verify that “aluminum sheet manufacturing” or “metal rolling/fabrication” is listed in scope |

| 1.2 | Conduct On-Site or Virtual Factory Audit | Validate physical infrastructure and production process | – Third-party inspection (e.g., SGS, Bureau Veritas) – Live video tour with real-time equipment checks |

| 1.3 | Review Equipment List & Production Capacity | Assess technical capability and output volume | – Request list of rolling mills, CNC machines, anodizing lines – Confirm annual production capacity (tons/year) |

| 1.4 | Request Quality Certifications | Ensure compliance with international standards | – ISO 9001, ISO 14001, IATF 16949 (if automotive) – Material Test Reports (MTRs), RoHS, REACH compliance |

| 1.5 | Evaluate Raw Material Sourcing | Verify supply chain integrity | – Ask for aluminum ingot suppliers (e.g., Chalco, Xinfa) – Confirm use of 100% virgin aluminum vs. recycled |

| 1.6 | Check Export History & Client References | Validate international experience | – Request 3–5 export client references (with NDA if needed) – Review B/Ls or export invoices (redacted) |

| 1.7 | Perform Sample Testing | Confirm product specifications and consistency | – Submit samples for third-party lab testing (e.g., tensile strength, thickness tolerance, alloy composition) |

2. How to Distinguish Between a Trading Company and a Factory

| Indicator | Factory | Trading Company | Verification Method |

|---|---|---|---|

| Ownership of Equipment | Owns rolling mills, cutting, and finishing lines | No production equipment; outsources production | Ask for equipment list and conduct site audit |

| Staffing | Has engineering, QC, and production teams | Limited to sales and logistics staff | Request org chart or meet team during audit |

| Facility Size | 5,000+ sqm facility with production zones | Office-only or small warehouse | Satellite imagery (Google Earth), video audit |

| Pricing Model | Lower MOQs, direct cost structure | Higher prices, vague cost breakdown | Request itemized quote (material, processing, overhead) |

| Lead Times | Shorter and more consistent | Longer, dependent on third-party schedules | Ask for production schedule and capacity utilization rate |

| Customization Capability | Can modify alloys, tempers, finishes | Limited to catalog offerings | Request custom sample or R&D support documentation |

Pro Tip: If the supplier cannot provide a factory address with production lines visible on Google Street View (where available), treat as high-risk.

3. Red Flags to Avoid When Sourcing in China

| Red Flag | Risk | Recommended Action |

|---|---|---|

| No verifiable factory address | Likely a trading company or shell entity | Require GPS coordinates and conduct third-party audit |

| Unwillingness to provide business license | Potential fraud or unlicensed operation | Disqualify supplier immediately |

| Prices significantly below market average | Use of substandard materials or hidden fees | Conduct material testing and audit cost structure |

| No experience with international certifications | Non-compliance with export standards | Require proof of past export compliance |

| Poor English communication or evasive answers | Lack of transparency or operational maturity | Escalate to senior management or disqualify |

| Refusal to sign NDA or contract | Unprofessional or high legal risk | Insist on formal agreement before sharing specs |

| No sample policy or charges exorbitant fees | Lack of confidence in product quality | Negotiate reasonable sample cost or switch supplier |

4. Recommended Due Diligence Checklist

✅ Valid business license with manufacturing scope

✅ Confirmed factory address and on-site audit completed

✅ ISO or industry-specific certifications in place

✅ Equipment list and production capacity verified

✅ Raw material sourcing documented

✅ Export experience with references

✅ Sample testing passed (mechanical & chemical)

✅ Clear contract with IP protection and QC clauses

Conclusion

Aluminum sheet sourcing in China can deliver high ROI when executed with rigorous due diligence. Factories offer better control, cost efficiency, and scalability, while trading companies may increase supply chain opacity. Procurement managers must prioritize transparency, verification, and quality assurance to avoid costly disruptions.

SourcifyChina recommends engaging third-party auditors and leveraging digital verification tools to de-risk supplier selection in 2026 and beyond.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Global Supply Chain Intelligence & Sourcing Advisory

📧 [email protected] | 🌐 www.sourcifychina.com

Get the Verified Supplier List

SourcifyChina Verified Sourcing Report: Aluminum Sheet Manufacturing in China (2026)

Prepared for Global Procurement Leaders | Q1 2026 Update

Executive Summary: The Critical Sourcing Challenge

Global demand for precision aluminum sheet (AA1xxx-8xxx series, coil/sheet, anodized/painted) is projected to grow 6.8% YoY in 2026. However, 73% of procurement managers report significant delays and compliance risks when sourcing directly from China due to unverified suppliers, inconsistent quality, and hidden subcontracting. Traditional supplier vetting consumes 15-20% of annual procurement hours – time better spent on strategic value creation.

Why SourcifyChina’s Verified Pro List Eliminates Sourcing Friction

Our rigorously audited Pro List for Aluminum Sheet Manufacturers solves the core inefficiencies in your supply chain. Unlike generic directories or self-claimed “factories,” every Pro List supplier undergoes our 12-point verification protocol, including:

| Verification Criteria | Traditional Sourcing Risk | SourcifyChina Pro List Standard | Impact on Your Operations |

|---|---|---|---|

| Direct Factory Confirmation | 41% are trading companies | 100% verified physical factories | Eliminates margin padding & communication delays |

| Quality System Audit | ISO certs often forged | On-site review of QC processes & equipment (e.g., OGP, spectrometers) | Reduces defect rates by 32% (2025 client data) |

| Export Experience | Limited documentation | Minimum 3 years direct exports to EU/US with customs records | Ensures HS code accuracy & smooth logistics |

| Capacity Validation | Overstated capabilities | Production line verification & order history analysis | Guarantees on-time delivery for volumes >50MT/month |

| Compliance Verification | Environmental/safety gaps | Confirmed adherence to REACH, RoHS, and China’s GB standards | Mitigates supply chain legal exposure |

Result: Clients reduce aluminum sheet sourcing cycles from 45+ days to <72 hours while cutting supplier failure risk by 89%. The Pro List delivers only manufacturers meeting your technical specs – no more filtering through 50+ unqualified leads.

Your Strategic Advantage in 2026

- Time Savings: Redirect 200+ annual hours from supplier vetting to cost engineering and supplier development.

- Risk Mitigation: Avoid $250K+ potential losses from MOQ fraud, quality disputes, or customs holds.

- Market Intelligence: Access real-time data on mill pricing trends (e.g., 2026 scrap aluminum volatility) and capacity shifts.

- Audit Trail: Full documentation for ESG compliance and internal procurement audits.

“SourcifyChina’s Pro List cut our aluminum sourcing from 6 weeks to 4 days. We onboarded a Tier-1 automotive supplier with zero quality incidents in 18 months.”

— Procurement Director, German Automotive Tier-2 Supplier (2025 Client)

✨ Call to Action: Secure Your 2026 Aluminum Supply Chain Today

Stop risking production delays and hidden costs on unverified suppliers. In 2026’s volatile market, your competitive edge depends on certified reliability.

✅ Get Instant Access to Our Verified Aluminum Sheet Pro List:

1. Email: Contact [email protected] with subject line “ALUMINUM PRO LIST 2026 – [Your Company]” for immediate access to filtered manufacturers matching your alloy, tolerance, and volume needs.

2. WhatsApp: Message +86 159 5127 6160 for a 15-minute sourcing consultation (include your required specs: e.g., “5052-H32, 2.0mm x 1500mm, 500MT/month”).

Why act now?

– Q1 2026 capacity is booking fast – verified suppliers accept only 3 new clients per quarter.

– Free 2026 Compliance Addendum: First 10 respondents receive our China Aluminum Export Regulatory Update (GB/T 3880.3-2025 changes).

Your next aluminum RFQ shouldn’t start with supplier vetting. Start with confidence.

Contact us within 48 hours for priority factory matching and a complimentary sourcing timeline assessment.

SourcifyChina | Building Trust in Global Supply Chains Since 2018

This report reflects verified 2025 sourcing data and 2026 market projections. All Pro List suppliers undergo bi-annual re-audits.

© 2026 SourcifyChina. Confidential for recipient use only.

🧮 Landed Cost Calculator

Estimate your total import cost from China.