The global aluminum building components market is experiencing robust growth, driven by rising demand for durable, low-maintenance, and sustainable construction materials. According to Grand View Research, the global metal buildings market size was valued at USD 110.7 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030, with aluminum playing an increasingly pivotal role due to its corrosion resistance, lightweight properties, and recyclability. This upward trajectory is mirrored in the outdoor storage and shed sector, where aluminum shed doors are gaining preference over traditional wood and steel alternatives. As homeowners and commercial users alike prioritize longevity and aesthetic versatility, manufacturers specializing in aluminum shed doors are scaling innovation and production. Based on market presence, product quality, customer reviews, and manufacturing capabilities, the following nine companies have emerged as leading manufacturers shaping this growing niche.

Top 9 Aluminum Shed Doors Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Commercial Overhead Doors

Domain Est. 1998

Website: rytecdoors.com

Key Highlights: Rytec commercial overhead doors offer the highest value and day in, day out performance for a variety of applications and industries….

#2 DBCI: Steel, Metal Roll Up Doors

Domain Est. 1999

Website: dbci.com

Key Highlights: Light-duty roll-up doors that are ideal for recreational, agricultural and commercial storage uses. Multiple mounting material options for ease of use….

#3 Janus International

Domain Est. 2001

Website: janusintl.com

Key Highlights: We’re the leading global manufacturer and supplier of turn-key self-storage building solutions, roll up and swing doors, hallway systems and re-locatable ……

#4 ASTA America

Domain Est. 2020

Website: astaamerica.com

Key Highlights: ASTA AMERICA manufactures commercial roll up doors, insulated service doors, sheet doors, fire doors, and counter shutters. Request door pricing….

#5 Therma

Domain Est. 1995

Website: thermatru.com

Key Highlights: The Therma-Tru retractable screen door allows fresh air and natural light inside while keeping debris and insects out….

#6 C.H.I Overhead Doors

Domain Est. 1998

Website: chiohd.com

Key Highlights: C.H.I Overhead Doors provide high-quality garage doors for homes and businesses in a variety of styles and colors. Learn more….

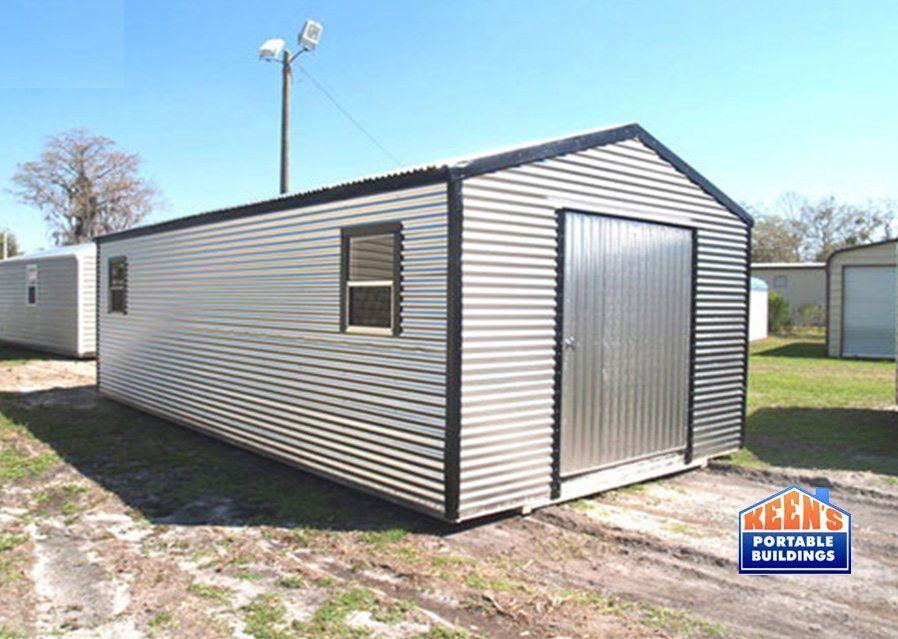

#7 Aluminum Storage Sheds and Building Products

Domain Est. 2002 | Founded: 1968

Website: unitedalum.com

Key Highlights: United Aluminum has supplied aluminum storage sheds and other residential and commercial aluminum products to the Phoenix market since 1968….

#8 Shed & Portable Building Doors

Domain Est. 2013

Website: midcoproducts.com

Key Highlights: MIDCO Building Products: Your shed door source. We carry Trac-rite roll-up, pre-hung, slab, custom doors & more!…

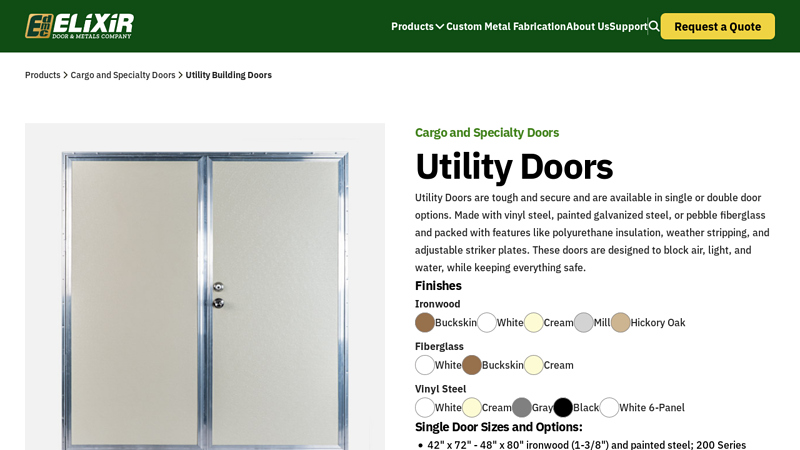

#9 Utility Doors

Domain Est. 2014

Website: elixirdoorandmetalscompany.com

Key Highlights: Utility Doors are tough and secure and are available in single or double door options. Made with vinyl steel, painted galvanized steel, or pebble fiberglass ……

Expert Sourcing Insights for Aluminum Shed Doors

H2: 2026 Market Trends for Aluminum Shed Doors

The market for aluminum shed doors is poised for notable evolution by 2026, driven by shifts in consumer preferences, technological advancements, and broader construction industry trends. As homeowners and commercial property managers increasingly prioritize durability, low maintenance, and energy efficiency, aluminum continues to emerge as a preferred material in outdoor storage solutions. Below is an in-depth analysis of key market trends shaping the aluminum shed door segment through 2026.

1. Rising Demand for Durable, Low-Maintenance Solutions

One of the dominant trends influencing the aluminum shed door market is the growing consumer preference for long-lasting, low-maintenance building materials. Aluminum is naturally resistant to rust, corrosion, and warping—qualities that make it ideal for outdoor applications. With climate change contributing to more extreme weather patterns, homeowners are investing in resilient structures. By 2026, this trend is expected to accelerate demand for aluminum doors, especially in coastal and high-humidity regions where steel and wood alternatives degrade more quickly.

2. Integration with Smart Home Technology

By 2026, the integration of smart technology into outdoor structures is anticipated to significantly impact the shed door market. Aluminum shed doors are increasingly being designed with smart locks, remote access via mobile apps, and built-in sensors for security and environmental monitoring. The structural integrity and customization potential of aluminum make it well-suited for embedding electronic components. As the Internet of Things (IoT) expands into outdoor living spaces, aluminum doors will be at the forefront of this smart shed movement.

3. Emphasis on Aesthetic Customization

Consumers in 2026 are expected to place a higher value on aesthetic integration between outdoor structures and primary residences. Aluminum offers superior versatility in finishes, colors, and styles—ranging from powder-coated matte textures to wood-grain laminates. This allows manufacturers to meet demand for doors that complement modern, minimalist, or traditional home designs. Customization options, including size, panel design, and hardware finishes, are becoming key differentiators in a competitive market.

4. Sustainability and Recyclability Trends

Environmental concerns are reshaping material choices in construction. Aluminum is 100% recyclable without loss of quality, and recycling requires only 5% of the energy needed for primary production. As sustainability certifications and green building standards (such as LEED) gain prominence, aluminum shed doors are likely to be favored over less eco-friendly alternatives. By 2026, manufacturers that highlight their use of recycled aluminum and sustainable production practices will gain a competitive edge.

5. Growth in DIY and Pre-Fabricated Shed Markets

The do-it-yourself (DIY) home improvement sector continues to expand, and aluminum shed doors are increasingly being offered as part of modular, pre-fabricated shed kits. These kits often feature lightweight yet sturdy aluminum doors that are easy to assemble and require minimal tools. The convenience and cost-effectiveness of such solutions are attracting urban and suburban homeowners with limited outdoor space. This trend is expected to drive volume growth in the aluminum shed door market through 2026.

6. Regional Market Expansion

While North America and Western Europe currently lead in aluminum shed door adoption, emerging markets in Asia-Pacific and Latin America are projected to experience significant growth by 2026. Rising urbanization, increasing disposable incomes, and growing awareness of durable building materials are contributing to this expansion. Localized manufacturing and distribution networks will be critical for companies aiming to capture market share in these regions.

7. Competitive Pricing and Material Innovation

Although aluminum has traditionally been more expensive than vinyl or wood, advancements in manufacturing processes are reducing production costs. Innovations such as alloy blending and improved extrusion techniques are enhancing strength while lowering material usage. By 2026, these developments are expected to narrow the price gap, making aluminum shed doors more accessible to a broader consumer base.

Conclusion

By 2026, the aluminum shed door market will be shaped by a confluence of durability demands, smart technology integration, aesthetic expectations, and environmental responsibility. Manufacturers that innovate in design, embrace sustainability, and align with digital trends will be best positioned to capitalize on these evolving dynamics. As outdoor living spaces become extensions of the home, aluminum shed doors will play an increasingly strategic role in both functionality and style.

Common Pitfalls When Sourcing Aluminum Shed Doors (Quality and Intellectual Property)

Sourcing aluminum shed doors, especially from overseas suppliers, presents several risks related to both product quality and intellectual property (IP) protection. Being aware of these pitfalls can help buyers make informed decisions and avoid costly issues down the line.

Quality Inconsistencies and Substandard Materials

One of the most frequent challenges is receiving aluminum shed doors that fail to meet promised specifications. Suppliers may substitute high-grade aluminum alloys (such as 6063-T5) with lower-quality or thinner materials to cut costs, resulting in doors that are less durable, prone to warping, or unable to withstand environmental stress. Surface finishes like powder coating may be uneven, too thin, or use inferior pigments, leading to premature fading, chipping, or corrosion. Additionally, poor welding, misaligned hinges, or faulty locking mechanisms are common quality control oversights that compromise functionality and safety.

Lack of Rigorous Quality Assurance Processes

Many suppliers, particularly smaller or less-established manufacturers, lack robust quality assurance (QA) protocols. Without in-process inspections, final product testing, or third-party verification, defects often go undetected until after shipment. Buyers may find themselves dealing with entire container loads of non-compliant doors, resulting in delays, return costs, or customer dissatisfaction. Relying solely on product samples without implementing ongoing audit procedures increases the risk of inconsistent batch quality.

Intellectual Property Infringement Risks

Sourcing aluminum shed doors carries a significant risk of IP violations, especially when dealing with generic or copycat designs. Some manufacturers may replicate patented door profiles, unique hardware systems, or branded aesthetic features without authorization. Purchasing such products—even unknowingly—can expose the buyer to legal liability, including cease-and-desist orders, customs seizures, or lawsuits from original equipment manufacturers (OEMs). This is particularly concerning in markets with strong IP enforcement, such as the EU or the United States.

Inadequate Documentation and Design Ownership

Suppliers may fail to provide clear documentation confirming design ownership or freedom to operate. Without proper licensing agreements or proof that the design is in the public domain, buyers assume all IP risk. In some cases, a supplier might claim the design is original, but it could be a derivative of a protected product. Ensuring that engineering drawings, CAD files, and product specifications are legally transferable and do not infringe on existing patents is critical but often overlooked during procurement.

Supply Chain Opacity and Hidden Subcontracting

Some suppliers outsource production to unauthorized subcontractors to meet demand or reduce costs, leading to a lack of control over both quality and IP compliance. These hidden tiers of manufacturing increase the risk of using counterfeit materials or replicating proprietary designs without consent. Without transparency into the full production chain, buyers cannot verify adherence to quality standards or confirm that IP rights are respected at every stage.

Conclusion

To mitigate these pitfalls, buyers should conduct thorough due diligence on suppliers, including factory audits, material certifications, and IP clearance checks. Contracts should explicitly address quality standards, inspection rights, and IP indemnification. Investing in trusted partners and proper verification processes upfront can prevent costly quality failures and legal complications later.

Logistics & Compliance Guide for Aluminum Shed Doors

Product Overview and Specifications

Aluminum shed doors are lightweight, durable, and corrosion-resistant solutions commonly used in residential and commercial storage structures. These doors typically feature extruded aluminum frames, tempered or polycarbonate glazing options, and weather-resistant finishes. Standard sizes vary, but common dimensions include 30″, 32″, or 36″ widths and 72″ or 80″ heights. Custom sizes may be available depending on the manufacturer.

Packaging and Handling Requirements

Aluminum shed doors must be packaged to prevent surface scratches, deformation, and moisture exposure during transit. Doors should be:

– Individually wrapped in protective plastic film or kraft paper.

– Secured between sturdy corrugated cardboard or foam edge protectors.

– Palletized with skids to allow for forklift handling.

– Banded or stretch-wrapped to prevent shifting.

– Labeled with “Fragile,” “This Side Up,” and handling instructions.

Avoid stacking loose doors or placing heavy items on top during storage and transport.

Transportation Guidelines

- Use enclosed trailers or containers to protect doors from weather and road debris.

- Secure pallets with straps or load locks to prevent movement during transit.

- Maintain dry, temperature-stable conditions to avoid condensation and thermal warping.

- For international shipments, ensure compliance with ISPM 15 standards for wooden pallets (if used).

- Avoid extreme temperature fluctuations during long-haul transport.

Storage Recommendations

- Store indoors in a dry, well-ventilated area.

- Keep doors palletized and off the ground to prevent moisture absorption.

- Protect from direct sunlight to prevent UV degradation of finishes and seals.

- Limit stack height to manufacturer specifications (typically no more than 4–5 pallets high).

- Rotate stock using a first-in, first-out (FIFO) system to prevent prolonged storage.

Regulatory Compliance

International Trade and Tariffs

- Harmonized System (HS) Code: 7610.90 (Other doors, windows, and their frames, of aluminum).

- Verify country-specific import duties and regulations (e.g., U.S. CBP, EU Customs).

- Be aware of anti-dumping or countervailing duties on aluminum products from certain countries.

- Ensure proper documentation: Commercial Invoice, Packing List, Bill of Lading, Certificate of Origin.

Safety and Environmental Standards

- Comply with local building codes (e.g., IRC, IBC in the U.S.) for structural integrity and wind load resistance.

- Confirm finishes meet environmental standards (e.g., AAMA 2604 for high-performance coatings).

- Ensure materials are REACH and RoHS compliant for shipments to the European Union.

- Avoid restricted substances such as lead or cadmium in coatings and hardware.

Installation and End-User Compliance

- Provide detailed installation instructions with torque specifications for hardware.

- Include safety warnings regarding glass or polycarbonate panels (if applicable).

- Recommend use of corrosion-resistant fasteners compatible with aluminum.

- Advise on proper clearance and leveling to ensure smooth operation and weather sealing.

Documentation and Traceability

- Maintain lot traceability for materials and components.

- Provide mill certificates for aluminum alloys upon request.

- Include product labeling with model number, size, manufacturing date, and compliance marks.

- Keep records of testing reports (e.g., wind load, corrosion resistance) for audits.

Returns and Damage Claims

- Establish a clear return policy for damaged or defective units.

- Require photographic evidence and packing condition documentation for damage claims.

- Train logistics partners to inspect and report damages at time of delivery.

- Process claims promptly with carriers using provided shipping documentation.

Sustainability and End-of-Life

- Encourage recycling of aluminum components (aluminum is 100% recyclable).

- Provide guidance on proper disposal of non-recyclable parts (e.g., seals, glazing).

- Consider offering take-back or recycling programs where feasible.

By adhering to this logistics and compliance guide, distributors, installers, and manufacturers can ensure the safe, legal, and efficient handling of aluminum shed doors across the supply chain.

In conclusion, sourcing aluminum shed doors requires careful consideration of several key factors including durability, weather resistance, cost, customization options, and supplier reliability. Aluminum is an excellent choice due to its lightweight nature, resistance to rust and corrosion, and low maintenance requirements, making it ideal for outdoor applications like sheds. When sourcing, it’s important to compare multiple suppliers, evaluate product quality and construction, and ensure compatibility with existing shed structures. Additionally, considering energy efficiency, security features, and aesthetic appeal can further enhance the value of the purchase. By conducting thorough research and opting for reputable suppliers, you can secure high-quality aluminum shed doors that offer long-term performance and satisfaction.