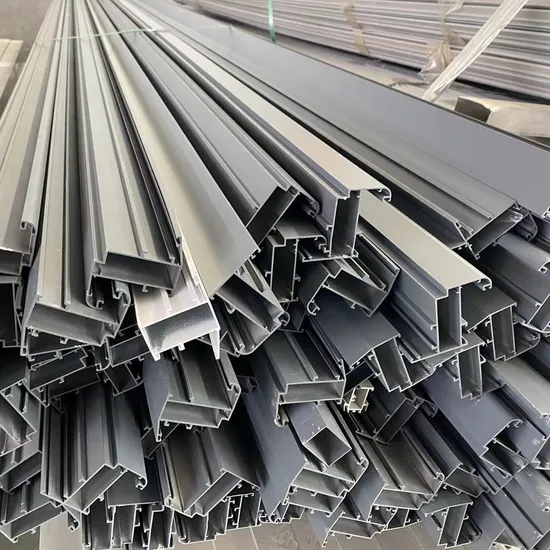

The global aluminum products market continues to expand at a robust pace, driven by increasing demand across industries such as construction, automotive, packaging, and renewable energy. According to a report by Grand View Research, the global aluminum market size was valued at USD 233.5 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. This growth is fueled by aluminum’s lightweight properties, recyclability, and rising adoption in electric vehicles and sustainable infrastructure. With manufacturing hubs concentrated in regions like Asia-Pacific—particularly China, India, and Southeast Asia—wholesale aluminum product suppliers are playing a pivotal role in meeting international demand. As competition intensifies and buyers prioritize cost-efficiency and quality, identifying the top-performing wholesale manufacturers becomes critical for distributors, OEMs, and procurement professionals aiming to optimize supply chain performance.

Top 10 Aluminum Products Wholesale Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 TW Metals: Specialty Metals Suppliers

Domain Est. 1997

Website: twmetals.com

Key Highlights: TW Metals stocks and processes Tube, Pipe, Bar, Extrusions, Sheet, and Plate in stainless, aluminum, nickel, titanium, and carbon alloy….

#2 New England Wholesale Building Materials Distributor

Domain Est. 2004

Website: raffertyaluminum.com

Key Highlights: Rafferty Aluminum & Steel Co., Inc. is a wholesale building materials distributor based in Sterling Massachusetts. We serve retail lumber yards, hardware ……

#3

Domain Est. 2011

Website: reynoldsconsumerproducts.com

Key Highlights: These new scented trash bags combine trusted strength, effective odor control technology, and six-in-one protection with the sweet scent of watermelon….

#4 Eastern Metal Supply

Domain Est. 1996

Website: easternmetal.com

Key Highlights: EMS offers nationwide supplier of quality aluminum components which include custom aluminum extrusions manufacturing as well as complete custom aluminum ……

#5 Superior Aluminum Products

Domain Est. 1997

Website: superioraluminum.com

Key Highlights: Superior Aluminum Products designs and manufactures aluminum railing, columns, and fence customized for your project….

#6 Aluminum Metal Supplier

Domain Est. 1998

Website: ryerson.com

Key Highlights: Find a comprehensive aluminum supply from Ryerson, a trusted aluminum supplier. Browse our extensive aluminum stock for various applications and industries….

#7 Pierce Aluminum

Domain Est. 1998

Website: piercealuminum.com

Key Highlights: Pierce Aluminum is your nationwide source for aluminum supply and value-added operations. From raw aluminum to finished parts, Pierce delivers it all….

#8 Aluminum Metal Products

Domain Est. 1999

Website: industrialmetalsupply.com

Key Highlights: Need aluminum metal? As your aluminum supplier, we offer a vast selection of products, including sheets, plates, tubes, and custom solutions tailored for ……

#9 Tri

Domain Est. 2001

Website: tri-stateal.com

Key Highlights: At Tri-State Aluminum, we specialize in producing custom 6000 series aluminum extrusions tailored to the specific needs of our customers. Contact us today!…

#10 Aluminum Wholesalers

Domain Est. 2011

Website: aluminumwholesalers.com

Key Highlights: A team of professionals dedicated to outstanding customer service, providing high grade quality aluminum sheets, extrusions and marine products….

Expert Sourcing Insights for Aluminum Products Wholesale

H2: 2026 Market Trends for Aluminum Products Wholesale

The global wholesale market for aluminum products is poised for significant transformation by 2026, driven by evolving industrial demands, sustainability imperatives, and technological advancements. As one of the most versatile and recyclable metals, aluminum continues to gain traction across construction, automotive, packaging, and renewable energy sectors. The following analysis outlines key market trends expected to shape the aluminum wholesale landscape in 2026.

-

Rising Demand from the Automotive and Transportation Sectors

The shift toward lightweight, fuel-efficient, and electric vehicles (EVs) remains a primary growth driver. Aluminum’s high strength-to-weight ratio makes it ideal for reducing vehicle mass and improving energy efficiency. By 2026, automakers are expected to increase aluminum content in EVs and hybrid models, boosting wholesale demand. Governments’ emissions regulations and consumer preferences for greener transport will further accelerate this trend. -

Expansion in Renewable Energy Infrastructure

Aluminum is essential in solar panel frames, wind turbine components, and energy storage systems. With global commitments to net-zero emissions, investment in renewable infrastructure is projected to surge through 2026. This growth will translate into increased wholesale procurement of aluminum extrusions, sheets, and structural components for solar farms and grid systems. -

Sustainability and Circular Economy Momentum

Environmental concerns are reshaping supply chains. The aluminum industry is responding with a stronger focus on recycled aluminum, which uses up to 95% less energy than primary production. By 2026, many wholesale buyers—especially in Europe and North America—will prioritize suppliers with certified low-carbon or recycled content. Aluminum’s infinite recyclability supports circular economy models, making it a preferred material in sustainable construction and packaging. -

Geopolitical and Supply Chain Realignments

Trade dynamics, energy costs, and regional production shifts will influence wholesale pricing and sourcing strategies. Countries with access to low-cost, renewable energy—such as Canada, Norway, and parts of the Middle East—are becoming preferred hubs for low-carbon aluminum production. Meanwhile, import tariffs, carbon border adjustments (e.g., the EU’s CBAM), and reshoring initiatives may redirect global aluminum flows, affecting wholesale distribution networks. -

Technological Advancements in Manufacturing

Innovations in extrusion, coating, and alloy development are enhancing aluminum’s performance and expanding its applications. By 2026, digitalization and Industry 4.0 technologies will streamline wholesale operations, enabling real-time inventory tracking, predictive logistics, and customized product offerings. Smart contracts and blockchain may also improve transparency in aluminum sourcing and certification. -

Growth in Emerging Markets

Urbanization and infrastructure development in Asia-Pacific, Latin America, and Africa are increasing demand for aluminum in construction and consumer goods. Countries like India and Vietnam are expected to emerge as major consumers and secondary producers, creating new opportunities for wholesale distributors to expand regional networks.

Conclusion

By 2026, the wholesale aluminum market will be shaped by sustainability mandates, technological innovation, and shifting global demand patterns. Wholesalers who adapt to low-carbon sourcing, embrace digital tools, and align with high-growth sectors like EVs and renewables will be best positioned for long-term success. As aluminum continues to underpin the green transition, its wholesale market is set for resilient and strategic expansion.

Common Pitfalls Sourcing Aluminum Products Wholesale (Quality, IP)

Sourcing aluminum products wholesale offers cost advantages, but it comes with significant risks, particularly concerning quality consistency and intellectual property (IP) protection. Being aware of these common pitfalls is crucial for making informed decisions and safeguarding your business.

Inconsistent Material Quality and Specifications

One of the most prevalent issues is receiving aluminum products that do not meet the required alloy grades, temper conditions, or dimensional tolerances. Suppliers may substitute lower-grade materials (e.g., using 6063 instead of 6061) or fail to adhere to industry standards like ASTM or ISO, leading to performance failures in end applications. Always request material test reports (MTRs) and conduct third-party inspections to verify compliance.

Lack of Certification and Traceability

Many wholesale suppliers, especially those in less regulated markets, cannot provide proper certification (e.g., mill test certificates, RoHS, REACH compliance). Without traceability, it becomes difficult to ensure the aluminum is sourced ethically and meets environmental or safety regulations—potentially exposing your business to legal and reputational risks.

Poor Surface Finishes and Workmanship

Wholesale aluminum products often exhibit defects such as uneven anodizing, scratches, warping, or inconsistent powder coating. These flaws arise from inadequate processing controls or cost-cutting measures. Such imperfections may be unacceptable for visible or precision applications, resulting in customer dissatisfaction or rework costs.

Intellectual Property Infringement Risks

Sourcing from overseas or unverified suppliers increases the risk of inadvertently purchasing counterfeit or IP-infringing products. Some manufacturers replicate patented designs, logos, or proprietary profiles without authorization. If your company distributes these items, you could face legal action, product seizures, or damage to your brand reputation.

Hidden Costs from Re-Work and Rejection

Low upfront prices can be misleading. Defective or non-compliant products often require sorting, rework, or complete rejection, leading to hidden expenses, project delays, and increased logistics costs. Factor in the total cost of ownership—not just the unit price—when evaluating suppliers.

Inadequate Communication and Technical Support

Wholesale suppliers may lack responsive customer service or technical expertise, making it difficult to resolve issues or customize orders. Poor communication can lead to misunderstandings about specifications, packaging, or delivery timelines, disrupting your supply chain.

Supply Chain and Delivery Delays

Reliability is a major concern. Some wholesale suppliers overcommit or face production bottlenecks, resulting in delayed shipments. Without robust logistics planning or backup suppliers, these delays can halt your manufacturing or distribution operations.

Conclusion

To mitigate these risks, conduct thorough due diligence on suppliers, request samples, audit facilities when possible, and use legally binding contracts that specify quality standards and IP protections. Partnering with reputable, certified suppliers—even at a slightly higher cost—can save significant expenses and liabilities in the long term.

Logistics & Compliance Guide for Aluminum Products Wholesale

Product Classification and HS Codes

Accurately classifying aluminum products is critical for international trade compliance. Common Harmonized System (HS) codes include:

– 7606: Aluminum plates, sheets, and strip (non-alloyed or alloyed)

– 7608: Aluminum tubes and pipes

– 7610: Aluminum structures and structural components

– 7616: Other fabricated aluminum articles

Ensure correct classification to determine applicable tariffs, import quotas, and regulatory requirements. Consult local customs authorities or a licensed customs broker when in doubt.

International Shipping and Transportation

Aluminum products are typically shipped via containerized ocean freight, flatbed trucks, or rail, depending on volume and destination. Key logistics considerations:

– Use moisture-resistant packaging and desiccants to prevent oxidation during transit

– Securely bundle sheets, coils, and extrusions to prevent shifting

– Comply with International Maritime Dangerous Goods (IMDG) Code if transporting aluminum powder or scrap (Class 4.3, Dangerous When Wet)

– Optimize load distribution to prevent deformation of lightweight products

Import and Export Regulations

Wholesalers must adhere to customs regulations in both origin and destination countries:

– Obtain an Export License if required (e.g., for dual-use items or strategic materials)

– Prepare accurate commercial invoices, packing lists, and certificates of origin

– Comply with U.S. Customs and Border Protection (CBP), EU Customs, or other regional authorities’ documentation standards

– Monitor trade remedies such as anti-dumping (AD) or countervailing duties (CVD) on aluminum from specific countries

Environmental and Safety Compliance

Aluminum manufacturing and distribution are subject to environmental regulations:

– Follow OSHA guidelines for safe material handling (e.g., PPE for cutting edges, lifting equipment use)

– Comply with EPA regulations regarding dust control (especially with scrap or powder)

– Adhere to REACH (EU) and TSCA (U.S.) chemical substance reporting requirements, if applicable

– Recycle aluminum scrap in accordance with local environmental laws

Trade Agreements and Tariff Preferences

Leverage free trade agreements (FTAs) to reduce or eliminate tariffs:

– USMCA: Duty-free treatment for qualifying aluminum products traded between the U.S., Canada, and Mexico

– EU-South Korea FTA: Preferential access for aluminum components meeting rules of origin

– Ensure proper Certificate of Origin (e.g., USMCA Certificate of Origin) is completed and retained

Recordkeeping and Audit Preparedness

Maintain detailed records for a minimum of five years, including:

– Product specifications and sourcing documentation

– Customs filings, duty payments, and exemption claims

– Compliance certifications (e.g., ISO, REACH, conflict minerals, if applicable)

Regular internal audits help ensure ongoing compliance and readiness for customs inspections.

Quality Assurance and Standards Compliance

Ensure aluminum products meet industry standards:

– ASTM B209 (standard specification for aluminum and aluminum-alloy sheet and plate)

– EN 573 (European standard for chemical composition of wrought aluminum)

– Provide Material Test Reports (MTRs) to customers upon request

– Implement traceability systems for batch tracking and recalls, if necessary

Sanctions and Restricted Party Screening

Conduct due diligence on all trading partners:

– Screen customers, suppliers, and freight forwarders against OFAC, EU, and UN sanctions lists

– Avoid transactions with entities in embargoed countries (e.g., Iran, North Korea)

– Maintain an internal compliance program with regular screening protocols

Insurance and Risk Management

Protect against logistical risks with comprehensive coverage:

– Marine cargo insurance for international shipments

– General liability and warehouse insurance for stored inventory

– Consider freight loss/damage clauses (e.g., FOB, CIF) in contracts to clarify responsibility

Sustainability and ESG Reporting

Increasingly important for B2B aluminum wholesalers:

– Track and report carbon footprint of transportation and supply chain

– Source from suppliers with certified sustainable practices (e.g., ASI – Aluminium Stewardship Initiative)

– Prepare for upcoming regulations such as the EU Carbon Border Adjustment Mechanism (CBAM) for metal imports

Staying compliant and efficient in aluminum wholesale logistics requires proactive planning, accurate documentation, and adherence to evolving global regulations. Partner with experienced logistics providers and legal advisors to mitigate risks and ensure smooth operations.

In conclusion, sourcing aluminum products wholesale offers numerous advantages for businesses seeking cost-effective, durable, and versatile materials for manufacturing, construction, or distribution. By partnering with reliable suppliers, companies can benefit from competitive pricing, consistent quality, and large-volume availability, supporting scalability and operational efficiency. However, success in wholesale sourcing depends on thorough due diligence—evaluating supplier credibility, understanding product specifications, considering logistics and lead times, and staying informed about market trends and pricing fluctuations. With strategic planning and strong supplier relationships, businesses can secure high-quality aluminum products that meet industry standards and contribute to long-term profitability and sustainability.