The global aluminum perforated sheets market is experiencing robust growth, driven by increasing demand across construction, automotive, and industrial sectors. According to Grand View Research, the global perforated metal market size was valued at USD 5.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030, with aluminum variants gaining preference due to their lightweight, corrosion resistance, and recyclability. Mordor Intelligence further underscores this trend, projecting a CAGR of over 6% during the forecast period (2023–2028), fueled by rising infrastructure development and architectural applications in emerging economies. As sustainability and material efficiency become central to design and engineering decisions, aluminum perforated sheets are increasingly favored for facades, acoustic panels, filtration systems, and decorative elements. This growing demand has intensified competition among manufacturers, leading to advancements in precision perforation, customization, and eco-friendly production. In this evolving landscape, identifying the top 10 aluminum perforated sheets manufacturers offers critical insight for procurement professionals, architects, and project planners seeking reliable, high-performance suppliers.

Top 10 Aluminum Perforated Sheets Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Perforated Aluminum Manufacturers Suppliers

Domain Est. 2001

Website: perforated-metals.com

Key Highlights: Accurate Perforating is a one-stop shop for complete perforated metal solutions. We can perforate, fabricate and finish almost any metal for almost any use….

#2 Perforated Metal Manufacturer

Domain Est. 2015

Website: hendrickcorp.com

Key Highlights: We’re a top-rated perforated sheet metal manufacturer. We have a variety of perforation patterns and can create custom perforated sheet metal. Contact Us!…

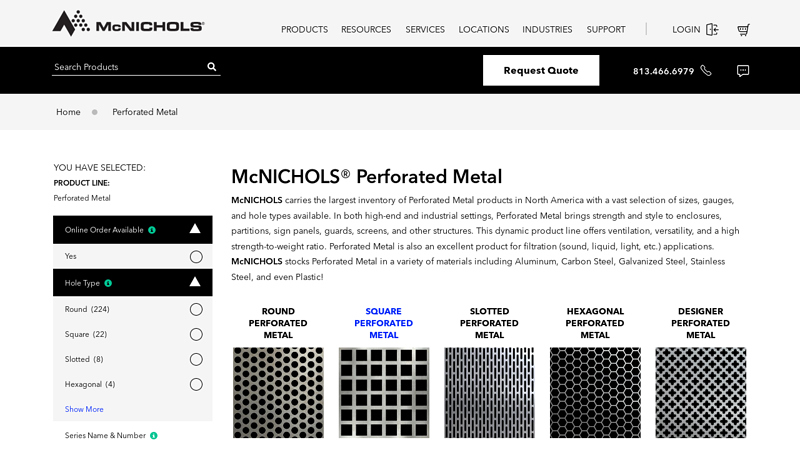

#3 Perforated Metal Sheets & Panels In-Stock

Domain Est. 1996

Website: mcnichols.com

Key Highlights: McNICHOLS carries the largest inventory of Perforated Metal products in North America with a vast selection of sizes, gauges, and hole types available….

#4 Perforated Metal Aluminum Wall Panels & Flat Sheet

Domain Est. 1996

Website: pac-clad.com

Key Highlights: Petersen offers perforation of select PAC-CLAD aluminum wall panels and flat sheet. Perforated aluminum can provide a contrasting look with any non-perforated ……

#5 Perforated

Domain Est. 1996

Website: ametco.com

Key Highlights: Ametco’s perforated sheet metal and plastic products have a wide variety of applications in construction projects, including acoustical wall and ceiling panels….

#6 Perforated Aluminum Sheet

Domain Est. 1997

Website: accurateperforating.com

Key Highlights: Accurate Perforating has the equipment and the capabilities to punch aluminum sheets with holes in a wide range of sizes, shapes, and patterns….

#7 Perforated Metal Sheet Products

Domain Est. 1998

Website: directmetals.com

Key Highlights: We carry perforated metal in many hole shapes, sizes, and materials. Perforated sheets are versatile and can be used for metal screens, diffusers, guards, ……

#8 Aluminum Perforated Sheet Supplier

Domain Est. 1999

#9 Perforated Metal Products & Fabrication Services

Domain Est. 1999

Website: marcospecialtysteel.com

Key Highlights: In stock – We stock & fabricate perforated metal with very different hole patterns & openings, each with its own benefits/applications. Contact us today!…

#10 Perforated Sheets Metal

Domain Est. 2014

Website: perforated-sheet.com

Key Highlights: Perforated aluminum sheet offers design flexibility, acoustic control, and sustainable performance for commercial and public ceiling projects….

Expert Sourcing Insights for Aluminum Perforated Sheets

2026 Market Trends for Aluminum Perforated Sheets

Growing Demand in Architectural and Construction Sectors

The architectural and construction industries are expected to be primary drivers of the aluminum perforated sheets market in 2026. With increasing emphasis on sustainable building practices and aesthetic design, architects are increasingly specifying aluminum perforated sheets for façades, sunshades, ceilings, and interior partitions. Their lightweight nature, corrosion resistance, and recyclability align with green building standards such as LEED and BREEAM. Urbanization and infrastructure development in emerging economies will further fuel demand, particularly in commercial and high-rise residential projects.

Expansion in Industrial and Acoustic Applications

Aluminum perforated sheets are witnessing rising adoption in industrial applications such as filtration, speaker grilles, machine guarding, and ventilation systems due to their durability and design flexibility. In 2026, advancements in manufacturing techniques will enable finer perforation patterns and custom hole configurations, broadening their use in precision equipment. Additionally, the growing focus on noise pollution control in urban and industrial environments will boost demand for perforated sheets in acoustic panels and sound barriers, where they provide effective sound absorption when combined with insulating materials.

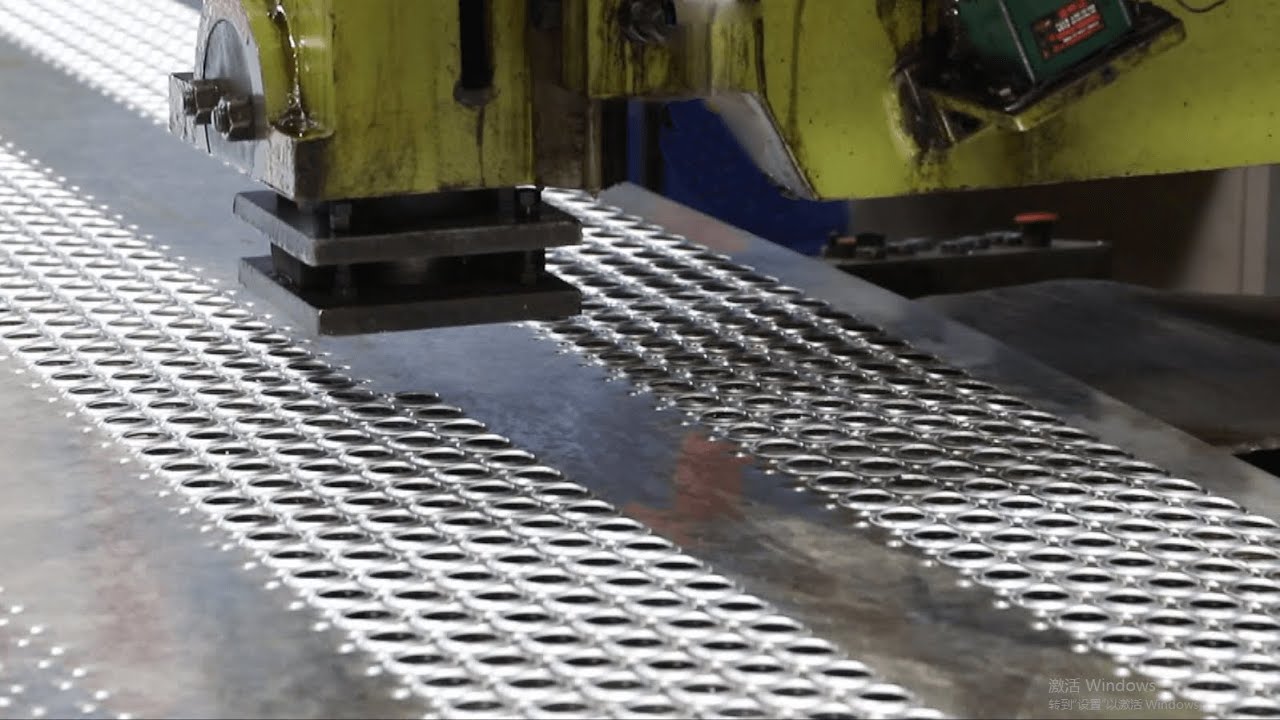

Technological Advancements and Customization

By 2026, digital manufacturing technologies, including CNC punching and laser cutting, will enhance the precision and customization capabilities of aluminum perforated sheets. This enables architects and designers to create complex geometric patterns, gradients, and artistic installations. Integration with Building Information Modeling (BIM) systems will streamline the design-to-production process, reducing lead times and waste. Manufacturers investing in automation and Industry 4.0 technologies will gain a competitive edge by offering rapid prototyping and just-in-time delivery.

Sustainability and Circular Economy Influence

Environmental regulations and corporate sustainability goals will shape the market landscape in 2026. Aluminum’s high recyclability—requiring only 5% of the energy to recycle versus primary production—positions perforated sheets as a preferred material in eco-conscious projects. Manufacturers are expected to increase the use of recycled aluminum and adopt low-carbon production methods to meet carbon neutrality targets. Transparency in supply chains and product lifecycle assessments will become critical differentiators.

Regional Market Dynamics and Supply Chain Resilience

Asia-Pacific, led by China, India, and Southeast Asia, will remain the largest market for aluminum perforated sheets due to rapid urbanization and industrial growth. North America and Europe will see steady demand driven by renovation projects and sustainable architecture. However, geopolitical tensions and supply chain disruptions will prompt companies to regionalize production and diversify sourcing. Nearshoring and investment in local manufacturing hubs will enhance resilience and reduce lead times.

Rising Competition and Price Volatility

The market will become increasingly competitive in 2026, with both established players and new entrants offering value-added services such as design support and finishing options (e.g., powder coating, anodizing). Price volatility in raw aluminum, influenced by energy costs and trade policies, may impact profit margins. Companies that optimize production efficiency and secure long-term supply agreements will be better positioned to navigate cost fluctuations and maintain profitability.

Conclusion

By 2026, the aluminum perforated sheets market will be characterized by innovation, sustainability, and design-driven demand. Growth will be propelled by architectural advancements, industrial diversification, and global infrastructure development. Success will depend on technological agility, environmental stewardship, and resilient supply chains, making aluminum perforated sheets a key material in the future of modern construction and industrial design.

Common Pitfalls When Sourcing Aluminum Perforated Sheets (Quality and Intellectual Property)

Sourcing aluminum perforated sheets requires careful attention to both material quality and intellectual property (IP) considerations. Overlooking these aspects can lead to substandard products, legal risks, and project delays. Below are common pitfalls in these two critical areas.

Quality-Related Pitfalls

Inconsistent Material Specifications

One of the most frequent quality issues is receiving aluminum perforated sheets that do not meet the specified alloy, thickness, or temper. Suppliers may substitute lower-grade materials (e.g., using 1050 instead of 5052 or 6063) to cut costs, resulting in reduced strength, corrosion resistance, or formability.

Poor Perforation Accuracy

Inaccurate hole patterns, inconsistent hole sizes, or misaligned perforations can affect both the aesthetic and functional performance of the sheets. This often stems from outdated or poorly maintained punching tools and lack of quality control during production.

Surface Defects and Finishing Issues

Scratches, dents, uneven coatings, or oxidation on the aluminum surface can compromise appearance and durability—especially in architectural or decorative applications. Improper handling, storage, or finishing processes (e.g., anodizing or powder coating) contribute to these defects.

Lack of Certifications and Testing

Reputable suppliers should provide material test reports (MTRs), mill certificates, or compliance documentation (e.g., ISO, ASTM, or EN standards). Sourcing from suppliers who cannot produce verifiable certifications increases the risk of receiving non-compliant or counterfeit materials.

Intellectual Property-Related Pitfalls

Unauthorized Use of Patented Designs

Some perforated patterns (e.g., specific acoustic or architectural designs) may be protected by patents or design rights. Using or sourcing sheets with such patterns without proper authorization can expose buyers to legal liability, especially in regulated markets.

Copying Proprietary Tooling

Suppliers may replicate custom perforation dies based on provided samples without permission, infringing on the original designer’s IP. This is particularly risky when working with niche or innovative patterns developed by third-party designers.

Ambiguous Contracts and IP Ownership

Contracts that fail to clarify ownership of custom tooling, designs, or patterns can lead to disputes. For example, if a buyer commissions a unique perforation layout, unclear terms may allow the supplier to reuse or resell the design to competitors.

Reverse Engineering by Suppliers

Some overseas manufacturers may reverse-engineer samples sent for quoting or production, creating knock-offs that violate IP laws. This is a growing concern when sharing physical or digital design files without non-disclosure agreements (NDAs) or safeguards.

Best Practices to Avoid Pitfalls

- Verify supplier credentials and request material certifications.

- Conduct factory audits or third-party inspections.

- Use NDAs and clearly define IP ownership in contracts.

- Work with trusted partners who respect design rights and international standards.

- Test samples thoroughly before placing bulk orders.

Avoiding these pitfalls ensures you receive high-quality, legally compliant aluminum perforated sheets suited for your application.

Logistics & Compliance Guide for Aluminum Perforated Sheets

Overview

Aluminum perforated sheets are widely used in architectural, industrial, and decorative applications due to their lightweight, corrosion resistance, and design flexibility. Safely and efficiently transporting these materials requires strict attention to logistics planning and compliance with international, national, and industry-specific regulations. This guide outlines key considerations for handling, packaging, transportation, documentation, and regulatory compliance.

Packaging and Handling

Proper packaging is essential to prevent damage during transit. Aluminum perforated sheets are susceptible to scratching, denting, and moisture exposure.

- Protective Wrapping: Use kraft paper, plastic film, or VCI (Vapor Corrosion Inhibitor) paper to protect sheet surfaces.

- Edge and Corner Protection: Apply cardboard or plastic edge protectors to prevent bending or chipping.

- Palletization: Secure sheets on wooden or metal pallets using stretch wrap or strapping. Ensure even weight distribution and avoid overhang.

- Stacking Limits: Adhere to manufacturer-recommended stacking heights to prevent crushing or deformation.

- Handling Equipment: Use forklifts with padded forks or vacuum lifters to minimize surface damage.

Transportation Requirements

Transportation methods vary based on shipment size, destination, and urgency. All modes—road, rail, sea, and air—have specific requirements.

- Containerized Shipping (Sea): Use dry freight containers with adequate dunnage to prevent shifting. Ensure containers are moisture-resistant and ventilated if needed.

- Overland Transport (Road/Rail): Secure loads with straps or load bars. Cover with waterproof tarpaulins when transporting uncovered.

- Air Freight: Reserved for urgent, high-value shipments. Comply with airline weight and dimension restrictions.

- Climate Considerations: Avoid exposure to extreme temperatures and humidity, which may cause condensation and corrosion. Use desiccants in enclosed containers if necessary.

Regulatory Compliance

Aluminum perforated sheets are subject to various trade, safety, and environmental regulations depending on origin, destination, and material composition.

- Customs Documentation: Provide accurate commercial invoices, packing lists, and bills of lading. Include HS Code (e.g., 7606.12 for non-alloy aluminum sheets).

- Export Controls: Verify compliance with export regulations (e.g., U.S. EAR or EU Dual-Use Regulations) if the sheets are used in sensitive industries.

- REACH & RoHS (EU): Ensure materials meet restrictions on hazardous substances, especially if coatings or alloys contain regulated elements.

- Country-Specific Standards: Confirm adherence to local building or safety codes (e.g., ASTM B209 in the U.S., EN 485 in Europe).

- ISPM 15 (Wood Packaging): Pallets and dunnage made of wood must be heat-treated and marked per ISPM 15 standards for international shipments.

Safety and Environmental Considerations

- Material Safety Data Sheets (MSDS/SDS): Provide SDS if the sheets are coated or treated with chemicals.

- Recyclability: Aluminum is 100% recyclable. Communicate recyclability to end-users to support sustainability initiatives.

- Waste Disposal: Follow local regulations for scrap metal disposal. Avoid landfilling where recycling is available.

Quality Assurance and Inspection

- Pre-Shipment Inspection: Verify dimensions, hole pattern accuracy, surface finish, and packaging integrity.

- Certifications: Supply mill test certificates (e.g., EN 10204 3.1) to confirm material compliance.

- Traceability: Maintain batch and heat traceability for quality control and recall preparedness.

Conclusion

Effective logistics and compliance management ensures that aluminum perforated sheets reach customers in optimal condition and in accordance with all applicable regulations. By implementing best practices in packaging, transportation, and documentation, suppliers and shippers can minimize risks, reduce costs, and maintain customer satisfaction.

Conclusion for Sourcing Aluminum Perforated Sheets

Sourcing aluminum perforated sheets requires a strategic approach that balances quality, cost, customization, and supplier reliability. These versatile materials offer numerous advantages, including lightweight strength, corrosion resistance, acoustic performance, and aesthetic appeal, making them ideal for applications in architecture, industrial filtration, acoustics, and decorative design.

To ensure optimal results, it is essential to partner with reputable suppliers who provide consistent product quality, precise perforation patterns, and compliance with relevant industry standards (such as ASTM or EN). Considerations such as alloy type (e.g., 3003, 5052, or 6061), thickness, hole size, open area percentage, and finishing options (e.g., anodizing or powder coating) should align with the specific project requirements.

Additionally, evaluating lead times, minimum order quantities, and logistical capabilities can significantly impact project timelines and overall costs. Leveraging supplier expertise for design consultation and prototyping can further enhance performance and efficiency.

In conclusion, successful sourcing of aluminum perforated sheets hinges on a thorough understanding of technical specifications, clear communication with suppliers, and a focus on long-term value rather than initial cost alone. By doing so, businesses can secure high-performing materials that meet functional and aesthetic goals while supporting sustainable and cost-effective operations.