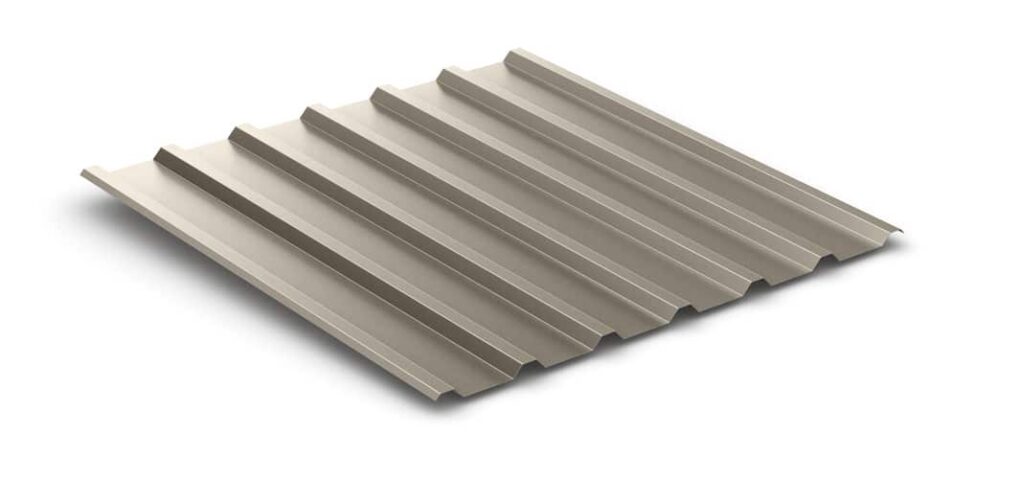

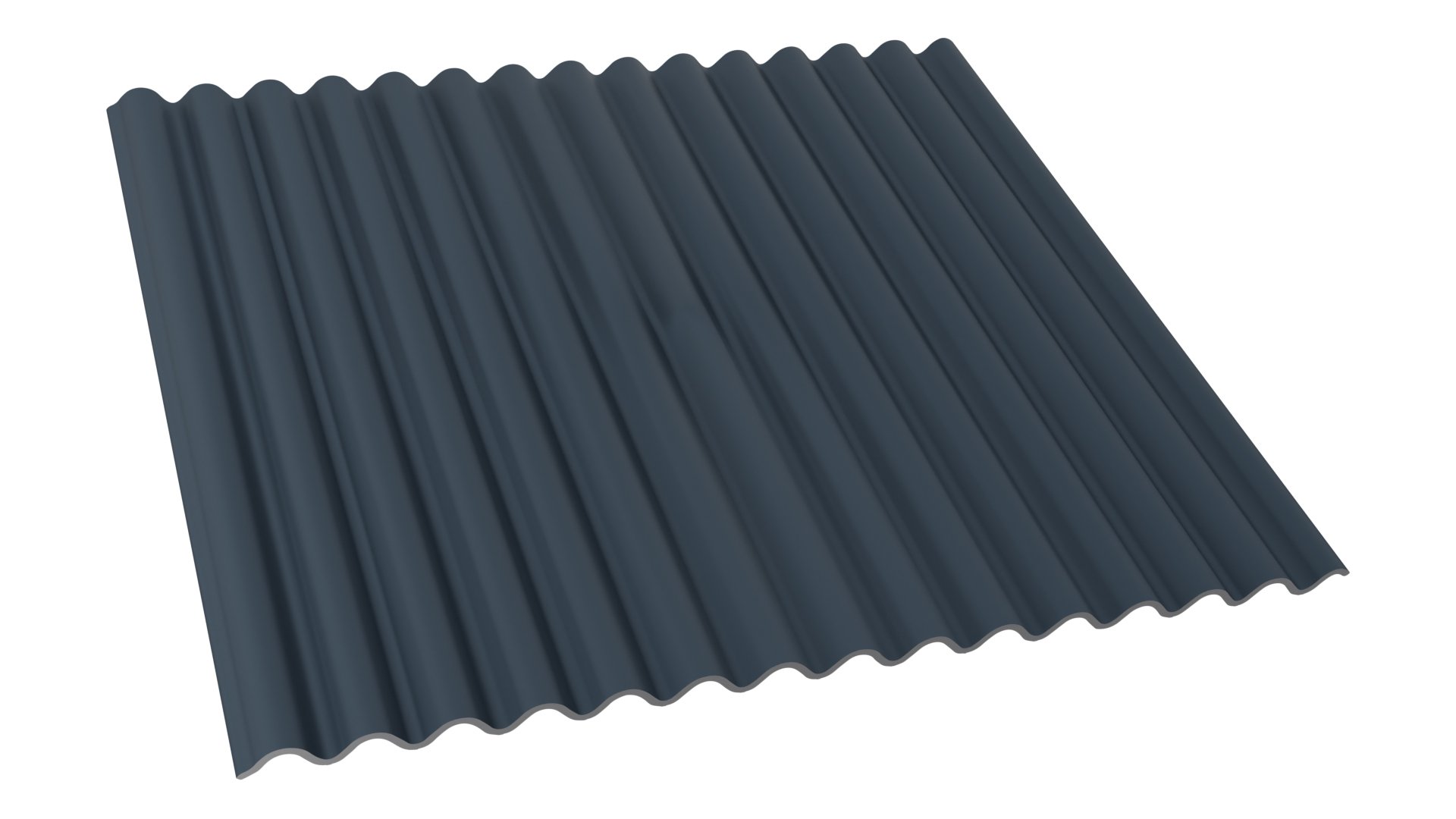

The global aluminum corrugated metal roofing market is experiencing robust growth, driven by increasing demand for durable, lightweight, and corrosion-resistant roofing solutions across residential, commercial, and industrial sectors. According to a report by Mordor Intelligence, the global metal roofing market was valued at USD 24.8 billion in 2023 and is projected to grow at a CAGR of 6.3% from 2024 to 2029, with aluminum-based systems gaining traction due to their sustainability and energy efficiency. Similarly, Grand View Research highlights that the rising adoption of green building practices and government initiatives promoting energy-efficient construction are accelerating demand for aluminum roofing products. As urbanization expands and climate resilience becomes a priority, aluminum corrugated metal roofing stands out for its long lifespan, recyclability, and low maintenance. In this evolving landscape, a select group of manufacturers are leading innovation, scalability, and product performance. Here’s a data-informed look at the top 10 aluminum corrugated metal roofing manufacturers shaping the future of modern construction.

Top 10 Aluminum Corrugated Metal Roofing Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Berridge Manufacturing Co.

Domain Est. 1996

Website: berridge.com

Key Highlights: For over 50 years Berridge has worked to set the standard by designing, developing and manufacturing superior architectural metal products and technology….

#2 Corrugated Metal Roofing and Siding Manufacturers

Domain Est. 2000

Website: corrugated-metals.com

Key Highlights: Explore Corrugated Metals, Inc.’s extensive range as a metal roofing and siding manufacturers, including custom roll forming services. Contact us today!…

#3 McElroy Metal

Domain Est. 1996

Website: mcelroymetal.com

Key Highlights: McElroy Metal is the leading manufacturer of metal roofing, metal siding, and substructural components with locations across the United States. Learn more….

#4 Metal Roofing Manufacturer

Domain Est. 1997

Website: mbci.com

Key Highlights: MBCI manufactures the highest quality metal roofing & wall panels to meet your project’s aesthetic & structural standards. Request a quote today!…

#5 Metal Roofing Manufacturers

Domain Est. 1999

Website: unioncorrugating.com

Key Highlights: Union Corrugating Company provides commercial and residential metal roofing to fit your requirements. To learn more about our metal roofing manufacturers ……

#6 Western States Metal Roofing

Domain Est. 2015

Website: westernstatesmetalroofing.com

Key Highlights: Manufacturer of Metal Roof Panels and Metal Siding Panels. Buy Direct And Save Money. Corrugated, Standing Seam, Flats, Coil. Delivery throughout the USA….

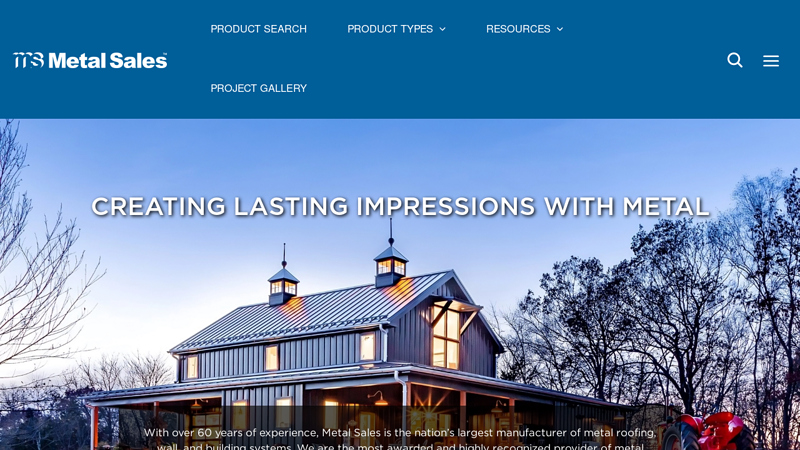

#7

Website: metalsales.us.com

Key Highlights: Metal Sales is the nation’s largest manufacturer of metal roofing, wall, and building systems. We are the most awarded and highly recognized provider of metal ……

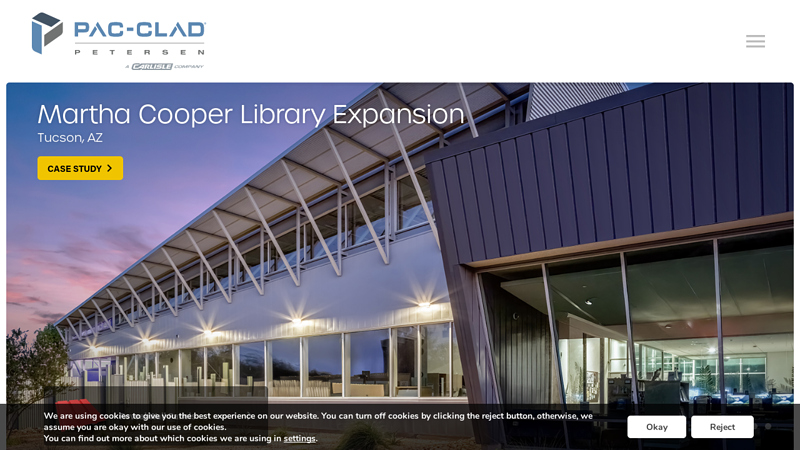

#8 PAC-CLAD

Domain Est. 1996

Website: pac-clad.com

Key Highlights: Made from high-quality steel and aluminum, PAC-CLAD panels are engineered for long service life, durability, and superior performance. PAC-CLAD architectural ……

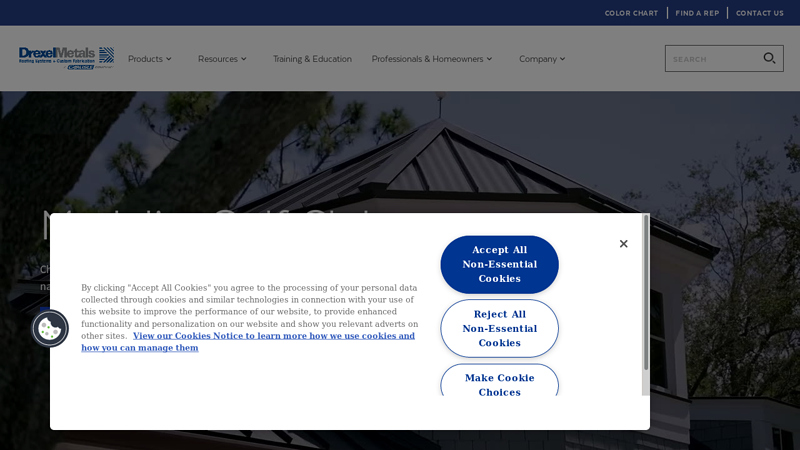

#9 Drexel Metals

Domain Est. 1996 | Founded: 1985

Website: drexmet.com

Key Highlights: Founded in 1985, Drexel Metals Corporation grew to become a leader in the distribution of painted metal for the roofing, architectural sheet metal, military and…

#10 Sheffield Metals

Domain Est. 1998

Website: sheffieldmetals.com

Key Highlights: Sheffield Metals is a leader in the distribution of coated and bare metal products, as well as engineered standing seam metal roof (SSMR) & wall systems….

Expert Sourcing Insights for Aluminum Corrugated Metal Roofing

2026 Market Trends for Aluminum Corrugated Metal Roofing

The aluminum corrugated metal roofing market is poised for significant evolution by 2026, driven by a confluence of sustainability demands, technological advancements, and shifting construction dynamics. Here’s a breakdown of the key trends expected to shape the industry:

H2: Rising Demand Driven by Sustainability and Resilience

Environmental consciousness and climate change adaptation will be paramount drivers. Aluminum corrugated roofing excels in sustainability metrics: it’s highly recyclable (often containing significant post-consumer content), has a long lifespan (50+ years), and requires minimal maintenance, reducing lifecycle environmental impact. Its reflective properties contribute to energy efficiency by lowering cooling loads in buildings (reducing the urban heat island effect). Simultaneously, increasing frequency of extreme weather events (hurricanes, wildfires, hail) will boost demand for resilient building materials. Aluminum’s inherent strength, fire resistance (Class A rating), and ability to withstand high winds make it a preferred choice for climate-resilient construction, particularly in vulnerable regions.

H2: Technological Advancements and Aesthetic Innovation

The market will see a shift beyond basic functionality. Manufacturers will invest heavily in advanced coatings (e.g., PVDF, SMP) offering superior durability, color retention, and self-cleaning properties. Integration of solar-ready systems (pre-configured mounting points for PV panels) into the roofing profile will become more common, simplifying solar adoption. Aesthetics will be a major differentiator; expect a wider range of colors, textures (e.g., matte, wood-grain finishes), and profile designs to cater to diverse architectural styles, moving beyond industrial looks to appeal to residential and commercial high-design projects.

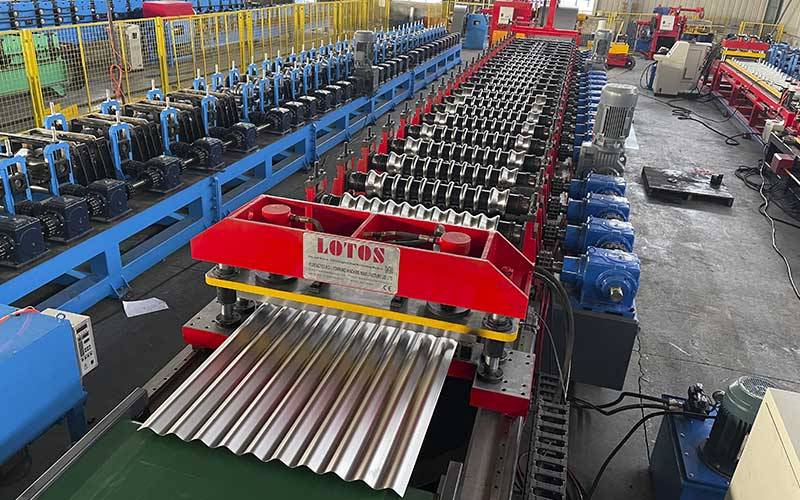

H2: Supply Chain Optimization and Regionalization

Ongoing global supply chain volatility will push players towards greater resilience. This includes strategic stockpiling of key raw materials (primary and recycled aluminum), increased investment in regional manufacturing hubs to reduce dependence on long-distance shipping, and enhanced logistics planning. The push for sustainability will also drive greater transparency and scrutiny of supply chains, with emphasis on ethically sourced aluminum and reduced carbon footprint in production and transportation. Nearshoring, particularly in North America and Europe, may accelerate to meet local demand and reduce geopolitical risks.

H2: Regulatory Tailwinds and Energy Code Adoption

Government policies and stricter building codes will act as strong tailwinds. Incentives for energy-efficient and sustainable building materials (like tax credits or rebates) will directly boost aluminum roofing adoption. Mandatory energy codes, increasingly requiring high Solar Reflectance Index (SRI) values and cool roofing standards, will favor reflective aluminum roofs, especially in hot climates. Regulations promoting circular economy principles and higher recycled content requirements in construction materials will further benefit aluminum, given its established recycling infrastructure.

H2: Competitive Landscape and Consolidation

The market will likely see increased competition and potential consolidation. Established metal roofing manufacturers will expand their aluminum corrugated offerings, while specialized players innovate on niche products. Competition will intensify on price, performance (warranty length, coating technology), and value-added services (design support, installation training, digital tools). Larger players may acquire smaller, innovative firms to gain technology or market share. Distributors and contractors will play a crucial role, requiring enhanced training on proper aluminum installation techniques to ensure system performance and longevity.

In conclusion, the 2026 aluminum corrugated metal roofing market will be characterized by a strong emphasis on sustainability, resilience, and innovation. Success will depend on manufacturers’ ability to deliver high-performance, aesthetically pleasing, and sustainably produced products through resilient supply chains, while navigating evolving regulations and competitive pressures.

Common Pitfalls When Sourcing Aluminum Corrugated Metal Roofing (Quality and Intellectual Property)

Sourcing aluminum corrugated metal roofing can be a cost-effective and durable solution for construction projects. However, buyers often encounter challenges related to product quality and intellectual property (IP) infringement. Being aware of these pitfalls helps ensure that you receive a reliable, compliant, and legally sound product.

Poor Material Quality and Specifications

One of the most frequent issues when sourcing aluminum corrugated roofing is receiving substandard materials. Some suppliers may use lower-grade aluminum alloys (e.g., non-marine or non-ceramic-coated) that lack corrosion resistance, leading to premature degradation. Buyers should verify alloy type (e.g., 3003, 3004, or 5052), thickness (typically 0.4mm–0.7mm), and coating specifications (e.g., PVDF or polyester coatings) to meet project requirements.

Inconsistent Coating and Finish

Inconsistent or low-quality surface coatings can result in uneven color, chalking, or peeling over time. Inferior finishes reduce both aesthetic appeal and longevity, especially in harsh climates. It’s essential to request coating test reports (e.g., ASTM B117 salt spray tests) and inspect samples before placing bulk orders.

Lack of Certification and Compliance

Many suppliers, particularly from less-regulated markets, may not provide proper certifications. Reputable roofing materials should comply with international standards such as ASTM, ISO, or EN. Missing or falsified documentation can lead to non-compliant installations, voided warranties, or safety risks.

Counterfeit or IP-Infringing Products

Some manufacturers replicate patented profiles, branding, or coating technologies without authorization. Using such products may expose buyers to legal liability, especially in commercial or government projects. Always verify the supplier’s right to produce and sell the design, and request proof of IP ownership or licensing agreements.

Inaccurate Profile Dimensions and Tolerances

Minor deviations in corrugation height, pitch, or flat width can lead to installation issues, leaks, or reduced structural performance. Suppliers may cut corners on tooling precision. Request dimensional inspection reports and physical samples to confirm conformance with technical drawings.

Inadequate Packaging and Handling

Poor packaging can cause deformation or surface damage during transit. Aluminum sheets are prone to scratching and bending if not properly interleaved and secured. Confirm packaging standards with the supplier and inspect goods upon arrival to document any damage.

Hidden Costs and Misleading Quotations

Some suppliers quote low prices but omit critical costs such as export packaging, testing, or shipping. Others may substitute materials without notice. Ensure transparency by requiring a detailed bill of materials and fixed specifications in the contract.

Limited After-Sales Support and Warranty

Many low-cost suppliers offer little to no technical support or warranty coverage. Without proper documentation and service, addressing defects or performance issues becomes difficult. Prioritize suppliers with clear warranty terms and accessible customer service.

By carefully vetting suppliers, verifying product specifications, and protecting against IP risks, buyers can avoid these common pitfalls and ensure a successful procurement of aluminum corrugated metal roofing.

Logistics & Compliance Guide for Aluminum Corrugated Metal Roofing

Product Overview and Handling Requirements

Aluminum corrugated metal roofing is a lightweight, corrosion-resistant material commonly used in residential, commercial, and industrial applications. Due to its malleable nature and susceptibility to surface damage, proper handling and storage are critical. Panels must be lifted using spreader bars or vacuum lifts to prevent bending or deformation. Direct dragging across surfaces should be avoided to minimize scratching or coating damage.

Packaging and Transportation

Panels are typically bundled with protective interlacing paper or plastic film and secured with non-abrasive strapping. Wooden skids or edge protectors are used to prevent edge damage during transit. Transport vehicles must be clean, flat, and free of debris. Loads must be securely fastened using straps or tiedowns to prevent shifting. When transporting vertically, racks with rubber padding should be used to avoid abrasion. Ensure coverage with waterproof tarps to protect against moisture during transit.

Storage Guidelines

Store aluminum roofing panels indoors whenever possible in a dry, well-ventilated area. If outdoor storage is necessary, elevate bundles at least 6 inches off the ground using wooden blocking and cover completely with UV-resistant, waterproof tarps—avoiding direct plastic-to-panel contact to prevent moisture trapping. Keep panels flat and avoid stacking beyond manufacturer-recommended heights to prevent deformation. Limit exposure to rain, snow, and high humidity to reduce the risk of staining or oxidation.

Import and Export Compliance

Verify compliance with international trade regulations based on origin and destination countries. Aluminum corrugated roofing may be subject to anti-dumping or countervailing duties, particularly when sourced from certain regions (e.g., China, India). Ensure Harmonized System (HS) code classification is accurate—typically 7306.30 for corrugated steel, but 7610.10 for aluminum panels. Provide complete documentation, including commercial invoices, packing lists, and certificates of origin.

Environmental and Safety Regulations

Aluminum production and processing are subject to environmental standards such as EPA regulations (in the U.S.) and REACH (in the EU). Ensure suppliers comply with environmental management systems (e.g., ISO 14001). During installation, follow OSHA (or local equivalent) safety protocols, including fall protection, PPE use, and safe lifting practices. Recyclability of aluminum must be communicated; most corrugated aluminum roofing is 100% recyclable, supporting LEED and other green building certifications.

Building Code and Certification Requirements

Aluminum corrugated roofing must meet regional building codes for wind uplift, snow load, fire resistance, and structural integrity. In the U.S., compliance with International Building Code (IBC) and International Residential Code (IRC) is required. Panels should carry third-party certifications such as UL (Underwriters Laboratories), FM Global approval, or Miami-Dade County NOA for high-wind areas. Verify paint and finish systems meet ASTM standards (e.g., ASTM D3795 for coil coating).

Quality Assurance and Documentation

Maintain a complete chain of custody and quality documentation throughout the supply chain. Required documents include mill test reports (MTRs), material certifications (e.g., ASTM B209 for aluminum alloy), and finish warranty information. Conduct pre-shipment inspections to verify panel dimensions, coating integrity, and packaging compliance. Address discrepancies before shipment to avoid delays or rejections upon delivery.

End-of-Life and Recycling Compliance

Aluminum roofing contributes to sustainable construction due to its high scrap value and recyclability. Ensure end-of-life handling follows local recycling regulations. Provide customers with recycling guidelines and support take-back programs where available. Document recycling rates and material recovery to support environmental reporting and green building compliance (e.g., LEED MR credits).

In conclusion, sourcing aluminum corrugated metal roofing offers a durable, lightweight, and corrosion-resistant solution ideal for both residential and commercial applications. Its longevity, low maintenance requirements, and energy efficiency make it a cost-effective choice over time, especially in harsh weather environments. When sourcing, it is essential to consider factors such as material gauge, panel profile, coating type, and supplier reliability to ensure quality and performance. By selecting reputable suppliers and verifying product certifications, buyers can secure high-performing roofing systems that meet structural and aesthetic needs. Overall, aluminum corrugated roofing represents a sustainable and resilient option that aligns with modern construction demands.