The global aluminum market is experiencing robust expansion, driven by rising demand for lightweight, corrosion-resistant materials across aerospace, automotive, and construction sectors. According to Grand View Research, the global aluminum market size was valued at USD 202.1 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is further amplified by increasing adoption of aluminum extrusions—particularly those with custom profiles such as inside radii—for enhanced structural performance and design flexibility. As industries prioritize precision engineering and material efficiency, the demand for specialized aluminum angle components with custom inside radii has surged. This rising need has positioned a select group of manufacturers at the forefront of innovation, combining advanced extrusion capabilities, strict quality controls, and engineering expertise to meet exacting application requirements. Based on production capacity, technical capability, and market reach, the following three manufacturers have emerged as leaders in aluminum angle custom inside radius solutions.

Top 3 Aluminum Angle Custom Inside Radius Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

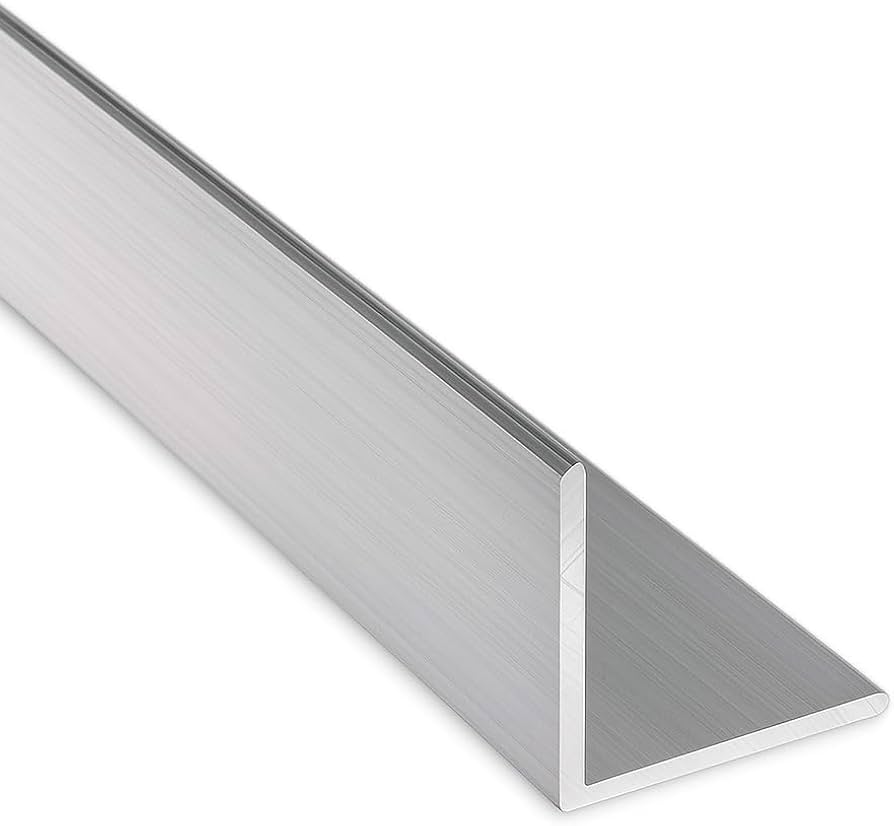

#1 Aluminum Angles

Domain Est. 1998

Website: extrude-a-trim.com

Key Highlights: Extrude-a-trim stocks aluminum angles in a square or round corner for decorative or structural use. Available in various lengths and finishes….

#2 Aluminum Angle

Domain Est. 2000

Website: alcobrametals.com

Key Highlights: Aluminum angle stands out as a remarkably versatile solution perfect for building shelves, brackets, protective edges, and corner pieces….

#3 Aluminum Angle

Domain Est. 2001

Website: thewarrencompany.com

Key Highlights: Buy aluminum angles from The Warren Company. Choose from a variety of shapes and sizes. Can’t find your size? We can cut to your exact needs….

Expert Sourcing Insights for Aluminum Angle Custom Inside Radius

H2: 2026 Market Trends for Aluminum Angle with Custom Inside Radius

The global market for aluminum angle with custom inside radius is poised for significant transformation by 2026, driven by advancements in manufacturing technologies, rising demand from key end-use industries, and an increased focus on lightweight, corrosion-resistant materials. This specialized aluminum product—characterized by its L-shaped cross-section and tailored internal curvature—offers enhanced structural integrity and design flexibility, making it highly desirable in precision-critical applications.

One of the primary drivers shaping the 2026 market landscape is the aerospace and defense sector’s growing reliance on custom-radius aluminum angles. These components are essential in airframe construction, where stress distribution and aerodynamic efficiency are paramount. As aircraft manufacturers push for fuel efficiency and reduced emissions, demand for lightweight, durable aluminum profiles with customized geometries will continue to rise.

Similarly, the automotive industry—particularly electric vehicle (EV) manufacturers—is increasingly adopting aluminum angle with custom inside radius for chassis, battery enclosures, and interior structural supports. The trend toward vehicle lightweighting to extend battery range supports this shift. By 2026, it is expected that aluminum fabrication will play a central role in modular EV platforms, further boosting demand for custom-designed angles.

In the architectural and construction sector, aesthetic and functional design innovations are fueling demand. Architects are incorporating custom-radius aluminum angles into curtain walls, façade systems, and interior design elements to achieve smooth transitions and modern, curved profiles. The ability to anodize or powder-coat these angles enhances their appeal in high-end commercial and residential projects.

Technological advancements in extrusion and CNC bending processes are enabling manufacturers to produce aluminum angles with tighter tolerances and complex internal radii more efficiently. Automation and digital twin technologies are also improving prototyping and customization lead times, making low-volume, high-precision orders more economically viable.

Regionally, North America and Europe are expected to maintain strong demand due to stringent environmental regulations and robust aerospace sectors. Meanwhile, the Asia-Pacific region—led by China, Japan, and India—is projected to witness the highest growth rate, driven by industrial expansion, infrastructure development, and rising investments in high-tech manufacturing.

Sustainability initiatives will also influence the 2026 market. Aluminum’s recyclability and low lifecycle emissions align with global decarbonization goals. As industries prioritize circular economy models, recycled aluminum use in custom angle production is expected to grow, supported by improved sorting and remelting technologies.

In summary, by 2026, the market for aluminum angle with custom inside radius will be shaped by innovation in materials engineering, expanding applications in high-growth industries, and a global shift toward sustainable, precision manufacturing. Companies that invest in flexible production capabilities and value-added services such as design consultation and rapid prototyping will be best positioned to capitalize on emerging opportunities.

Common Pitfalls Sourcing Aluminum Angle with Custom Inside Radius (Quality, IP)

Sourcing aluminum angles with a custom inside radius introduces specific challenges that can impact both product quality and intellectual property (IP) protection. Being aware of these pitfalls helps ensure a successful procurement process.

Quality-Related Pitfalls

Inconsistent Radius Tolerances

Manufacturers may struggle to maintain tight tolerances on custom inside radii, especially with complex tooling or varying material batches. This can lead to parts that don’t fit properly in assemblies, causing downstream production delays or rework.

Material Defects at the Bend

The bending process required to form a custom inside radius can induce micro-cracks, surface tearing, or thinning on the inside of the curve—particularly if improper tooling or techniques are used. These defects compromise structural integrity and surface finish.

Tooling Wear and Process Drift

Custom tooling degrades over time, especially during high-volume production. Without regular maintenance or monitoring, the inside radius may gradually deviate from specifications, resulting in non-conforming parts later in the production run.

Improper Alloy or Temper Selection

Not all aluminum alloys or tempers perform well during tight-radius bending. Using an unsuitable material can lead to cracking or springback issues. Suppliers may substitute materials without consultation, affecting final performance.

Inadequate Quality Control Documentation

Suppliers might lack robust inspection processes or fail to provide detailed reports (e.g., radius measurements, bend angle checks, material certifications), making it difficult to verify compliance with specifications.

IP-Related Pitfalls

Lack of IP Ownership Clarity

If custom tooling is developed for the radius, ownership rights may be ambiguous. Without a clear agreement, the supplier could retain rights to the tooling or reuse it for other customers, undermining competitive advantage.

Insufficient NDA Coverage

Standard NDAs might not explicitly cover design specifics like custom radii or dimensional tolerances. This leaves the door open for suppliers to reverse-engineer or share design details with third parties.

Tooling Replication by Supplier or Third Parties

A supplier may replicate the custom tooling for resale or use in competing products, especially in regions with weak IP enforcement. This risk increases if tooling is left in the supplier’s possession post-production.

Design Leakage Through Subcontractors

If the supplier outsources bending or fabrication, your custom design could be exposed to additional parties not bound by your original IP agreements, increasing the risk of unauthorized duplication.

Absence of IP Clauses in Contracts

Procurement contracts that don’t include specific clauses assigning IP rights, restricting tooling use, or governing post-contract tooling disposition leave your design vulnerable to misuse.

Mitigation Strategies

To avoid these pitfalls, ensure:

– Detailed technical specifications with tolerances

– Clear contracts defining IP ownership and tooling rights

– Robust NDAs covering all design elements

– Approved supplier audits and QC protocols

– Retention or destruction clauses for custom tooling

– Regular inspection and first-article testing

Proactively addressing these issues minimizes risk and ensures consistent quality and IP protection when sourcing custom aluminum angles.

Logistics & Compliance Guide for Aluminum Angle with Custom Inside Radius

Material Specifications and Compliance

Ensure that the aluminum alloy used for the custom inside radius aluminum angle complies with international and regional standards such as ASTM B221 (Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes) or EN 755 (European standard for aluminum and aluminum alloy extruded rods, bars, tubes, profiles, and wires). Verify the alloy grade (e.g., 6061-T6, 6063-T5) and temper designation to meet mechanical and chemical property requirements.

Certification documentation, including Mill Test Certificates (MTCs) or Material Test Reports (MTRs), must accompany shipments to confirm compliance. These documents should detail chemical composition, mechanical properties, and quality control testing results.

Custom Inside Radius Design and Tolerances

Design specifications for the custom inside radius must be clearly defined in technical drawings, including dimensional tolerances per standards such as ISO 2768 (General Tolerances) or ANSI H35.2 (American National Standard for Aluminum Dimensional Tolerances). The inside radius tolerance directly affects formability, fit, and function in end-use applications.

Collaborate with the supplier to ensure tooling is calibrated for the specified radius, minimizing springback and deformation. Confirm that the extrusion or bending process maintains wall thickness uniformity and avoids cracking at the bend.

Manufacturing and Processing Compliance

The manufacturing process—whether extruded with a custom die or post-formed via bending—must adhere to environmental, safety, and quality regulations. Facilities should be ISO 9001 (Quality Management) and ISO 14001 (Environmental Management) certified where applicable.

For anodized or coated finishes, ensure compliance with RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations, especially if parts are destined for the European market. Surface treatments must not contain restricted substances such as lead, cadmium, or hexavalent chromium.

Packaging and Handling Requirements

Aluminum angles with custom inside radii are prone to surface damage and deformation during transit. Use protective packaging such as edge protectors, V-board separators, or foam padding to prevent scratching, denting, or warping.

Bundle materials securely using non-corrosive strapping and place in moisture-resistant wrapping or crates to prevent oxidation. Clearly label packages with handling instructions (e.g., “Fragile,” “Do Not Stack,” “This Side Up”) and include product identification tags with alloy type, dimensions, radius specification, and heat number.

International Shipping and Documentation

Prepare complete shipping documentation, including commercial invoice, packing list, bill of lading, and certificate of origin. For exports, ensure Harmonized System (HS) code classification is accurate—typically 7604.29 (aluminum angles, shapes, and sections) under the HTSUS or equivalent national tariff code.

For shipments to countries with specific import regulations (e.g., U.S. CBP, EU customs), verify anti-dumping or countervailing duty (AD/CVD) status for aluminum extrusions. Maintain up-to-date records to facilitate customs clearance and avoid delays.

Regulatory and Industry-Specific Compliance

Depending on the application (e.g., aerospace, construction, transportation), additional certifications may be required:

- Aerospace: Nadcap or AS9100 compliance for quality systems.

- Construction: Compliance with local building codes; in the U.S., ICC-ES evaluation reports may be needed.

- Transportation: FMVSS (Federal Motor Vehicle Safety Standards) or AAR (Association of American Railroads) standards as applicable.

Ensure traceability throughout the supply chain, from raw material sourcing to final delivery, to support audit readiness and compliance with industry regulations.

Environmental and Sustainability Considerations

Aluminum is recyclable, and suppliers should demonstrate responsible sourcing practices. Encourage use of recycled aluminum content and verify compliance with initiatives such as the Aluminium Stewardship Initiative (ASI) for sustainable production.

Carbon footprint disclosures and Environmental Product Declarations (EPDs) may be required for green building certifications like LEED or BREEAM, particularly in architectural applications.

Quality Assurance and Inspection

Implement incoming inspection procedures to verify dimensional accuracy, surface finish, and radius conformity using calibrated tools such as radius gauges, coordinate measuring machines (CMM), or optical comparators.

Perform periodic audits of supplier facilities to ensure ongoing compliance with quality, safety, and environmental standards. Retain inspection records for traceability and regulatory purposes.

Conclusion: Sourcing Aluminum Angle with Custom Inside Radius

Sourcing aluminum angle with a custom inside radius requires careful coordination between design specifications, material capabilities, and manufacturing expertise. Standard aluminum angles typically come with fixed inside corner radii determined by extrusion tooling, but custom inside radii are achievable through specialized die design, precision extrusion processes, or secondary machining operations.

To successfully procure aluminum angles with a custom inside radius, it is essential to partner with an experienced extruder or metal fabricator capable of accommodating tight tolerances and specific geometric requirements. Early engagement with suppliers during the design phase allows for optimization of the profile for manufacturability, cost-efficiency, and performance. Key considerations include alloy selection, minimum bend radius limitations, tooling costs for custom dies, lead times, and volume requirements.

In summary, while custom inside radii add complexity to the sourcing process, they are feasible with the right supplier collaboration and engineering support. By clearly defining requirements and leveraging supplier expertise, businesses can obtain aluminum angle components that meet both functional and aesthetic demands, enhancing the overall quality and performance of the final product.