The global gantry crane market is experiencing robust growth, driven by rising demand across manufacturing, logistics, and shipbuilding sectors. According to a report by Grand View Research, the global overhead and gantry crane market size was valued at USD 6.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. The increasing adoption of lightweight materials such as aluminum in crane construction—due to their corrosion resistance, low maintenance, and portability—is a key trend shaping industry dynamics. Mordor Intelligence further projects steady growth in the material handling equipment sector, with Asia-Pacific leading in both production and consumption, fueled by rapid industrialization and infrastructure development. As operational efficiency and sustainability become critical priorities, aluminum gantry cranes are emerging as preferred solutions for indoor and outdoor lifting applications. In this evolving landscape, a select group of manufacturers are leading innovation, delivering high-performance, customizable, and energy-efficient systems. Here are the top 8 aluminum gantry crane manufacturers making a significant impact in the global market.

Top 8 Aluminium Gantry Crane Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 American Crane & Equipment Corporation

Domain Est. 1996

Website: americancrane.com

Key Highlights: As a member of the Crane Manufacturers Association of America (CMAA), our crane experts can help find the right solution for your project’s specifications….

#2 REID Lifting Inc

Domain Est. 1999

Website: us.reidlifting.com

Key Highlights: REID Lifting Inc are a leading manufacturer of lightweight, portable lifting products for materials and personnel, including aluminum gantry and davit cranes….

#3 High

Domain Est. 1999 | Founded: 1954

Website: wallacecranes.com

Key Highlights: We’ve been manufacturing high-quality, low-cost industrial cranes since 1954. Thanks to a friendly team of experts, dozens of patents and faster shipping times….

#4 Crane Rail Designer, Manufacturerer and Installer Worldwide …

Domain Est. 2008

Website: gantrail.com

Key Highlights: We are Gantrail a crane rail company who design, install, manufacture and support crane rail interfaces worldwide. From rail clips and other supplies we ……

#5 Aluminum Gantry Cranes

Domain Est. 1996

Website: gorbel.com

Key Highlights: Gorbel’s Aluminum Gantry Cranes are lightweight, adjustable, and collapsible for storage. Made from extruded aluminum, with a capacity of 1000 lbs to 4000 ……

#6 Unified Gantry Crane

Domain Est. 1997

Website: cmco.com

Key Highlights: The Unified Enclosed Track Aluminum gantry crane has a capacity up to 2200 lbs and is an excellent mobile lifting workstation solution. Get a quote!…

#7 Adjustable Height Aluminum Gantry Cranes (AHA)

Domain Est. 1998

Website: vestil.com

Key Highlights: The adjustable height Aluminum Gantry crane combines lightweight and rigid, sturdy construction into one unit. The all aluminum construction of this gantry ……

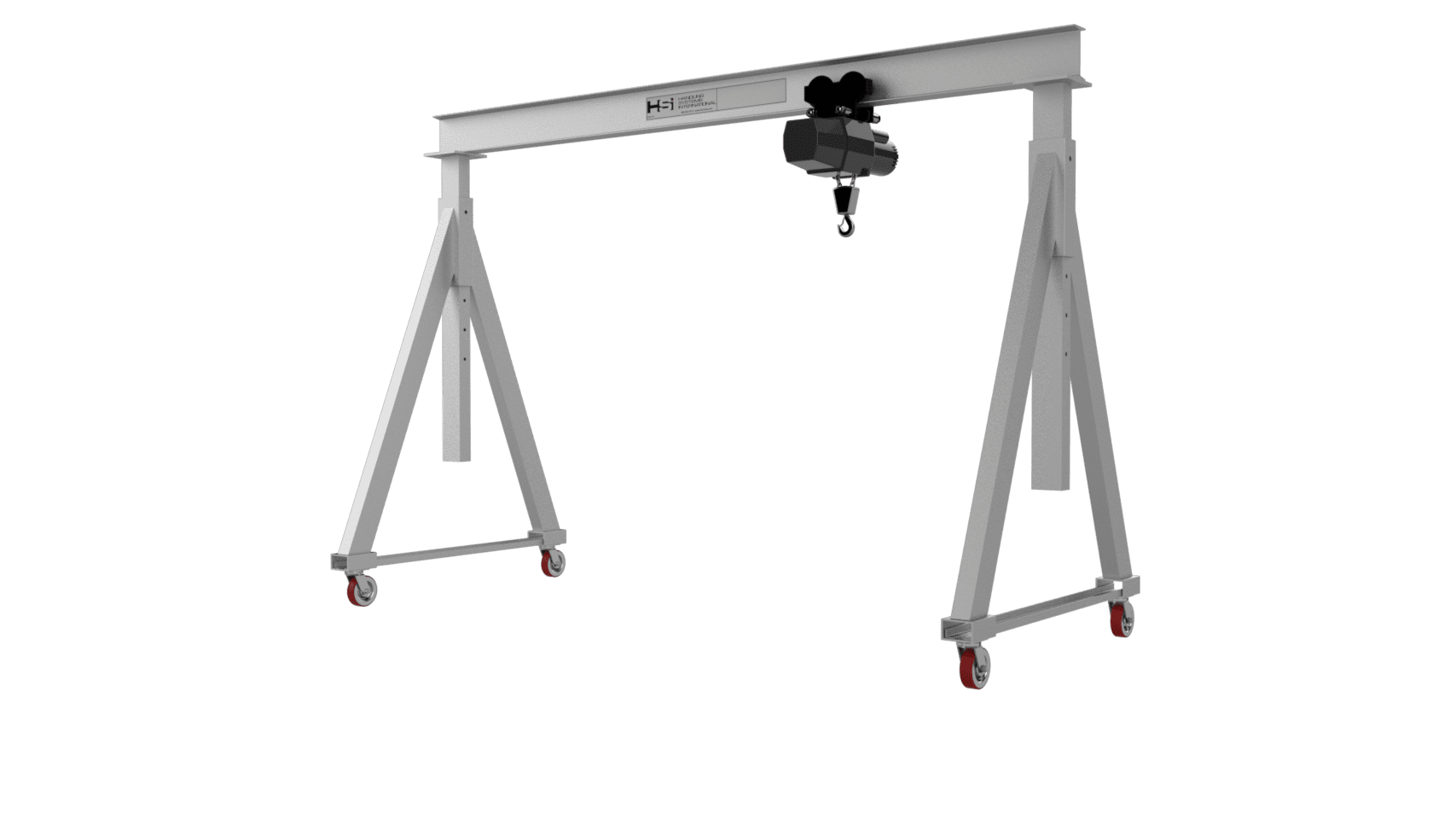

#8 Handling Systems International (HSI Cranes)

Domain Est. 2013

Website: hsicrane.com

Key Highlights: With our full line of jib cranes, gantry cranes, bridge cranes, and hoists, we provide comprehensive solutions to meet your unique lifting needs. Our jib cranes ……

Expert Sourcing Insights for Aluminium Gantry Crane

H2: 2026 Market Trends for Aluminium Gantry Crane

The global market for aluminium gantry cranes is poised for significant evolution by 2026, driven by technological advancements, growing demand for lightweight and corrosion-resistant material handling solutions, and shifting industrial priorities. These trends reflect broader movements in manufacturing, logistics, and sustainability goals across key end-user sectors.

1. Rising Demand for Lightweight and Portable Cranes

A major trend shaping the 2026 market is the increasing preference for lightweight material handling equipment. Aluminium gantry cranes, known for their high strength-to-weight ratio, are gaining traction in industries requiring portability and ease of relocation—such as construction sites, workshops, and maintenance facilities. As modular and reconfigurable manufacturing systems become more common, the demand for lightweight cranes that can be assembled and disassembled quickly is expected to grow.

2. Expansion in Renewable Energy and Infrastructure Sectors

The renewable energy sector—including solar panel installations, wind turbine maintenance, and battery manufacturing—is emerging as a key growth driver. Aluminium gantry cranes are ideal for cleanroom environments and outdoor installations due to their corrosion resistance and low maintenance requirements. With governments worldwide investing heavily in green infrastructure through 2026, the need for durable, non-rusting lifting equipment in these applications will continue to rise.

3. Focus on Corrosion Resistance and Sustainability

Aluminium’s natural resistance to rust and corrosion makes it a preferred material in humid, coastal, or chemically aggressive environments. This characteristic is increasingly valued in industries such as marine engineering, food processing, and pharmaceuticals. Moreover, aluminium is 100% recyclable, aligning with corporate sustainability targets and tightening environmental regulations. By 2026, eco-conscious procurement policies are expected to favor aluminium-based equipment over traditional steel alternatives.

4. Technological Integration and Smart Features

The integration of smart technologies—such as IoT-enabled load monitoring, remote control operation, and predictive maintenance—is transforming aluminium gantry cranes into intelligent lifting systems. Manufacturers are enhancing product offerings with digital interfaces and automation compatibility to meet Industry 4.0 standards. These advancements improve safety, efficiency, and operational data transparency, making aluminium gantry cranes more attractive to tech-forward industries.

5. Regional Market Growth and Manufacturing Shifts

Asia-Pacific is anticipated to dominate the aluminium gantry crane market by 2026, fueled by rapid industrialization in countries like China, India, and Vietnam. North America and Europe will also see steady growth, driven by infrastructure modernization and a shift toward energy-efficient machinery. Localized production and supply chain resilience are becoming priorities, encouraging manufacturers to establish regional assembly units to reduce lead times and logistics costs.

6. Competitive Landscape and Customization Trends

Market competition is intensifying, with key players focusing on product differentiation through customization. Customers increasingly demand cranes tailored to specific load capacities, span widths, and operational environments. Modular aluminium systems that allow for easy scalability are becoming a selling point. Additionally, rental and leasing models are gaining popularity, especially among SMEs seeking cost-effective access to high-performance equipment.

In conclusion, the 2026 market for aluminium gantry cranes will be shaped by a confluence of material advantages, technological innovation, and sustainability imperatives. As industries prioritize efficiency, environmental compliance, and operational flexibility, aluminium gantry cranes are well-positioned to capture a larger share of the material handling equipment market.

Common Pitfalls When Sourcing Aluminium Gantry Cranes (Quality and IP)

Sourcing aluminium gantry cranes offers advantages like lightweight portability and corrosion resistance, but buyers must navigate several critical pitfalls—particularly concerning quality and intellectual property (IP)—to avoid costly failures and legal risks.

Poor Material Quality and Structural Integrity

One of the most frequent issues is substandard aluminium alloy composition or improper fabrication. Some suppliers use lower-grade alloys (e.g., non-6000 series) that lack the necessary strength-to-weight ratio, leading to deformation or failure under load. Inadequate welding techniques or lack of proper heat treatment can further compromise structural integrity, especially in critical joints and beam connections.

Inaccurate Load Capacity Claims and Certification

Suppliers may exaggerate load ratings without providing third-party testing or certification (e.g., CE, ISO, or local regulatory compliance). Without verified documentation, users risk overloading the crane, which can result in collapse, injury, or equipment damage. Always demand test reports and ensure the crane meets recognized safety standards.

Lack of Traceability and Material Documentation

Reputable suppliers provide mill test certificates (MTCs) confirming the aluminium alloy grade and mechanical properties. Sourcing from vendors who cannot supply such documentation increases the risk of receiving counterfeit or recycled material that fails to meet safety and performance standards.

Intellectual Property (IP) Infringement

Aluminium gantry crane designs—especially modular or patented systems—may be protected by IP rights. Sourcing from manufacturers that replicate branded designs without licensing exposes buyers to legal liability, shipment seizures, or forced discontinuation of use. Always verify that the supplier owns or has rights to the design, especially when purchasing from low-cost offshore vendors.

Inadequate Design for Intended Application

Generic or poorly engineered designs may not suit specific operational needs (e.g., indoor vs. outdoor use, frequent relocation, or integration with hoists). Using a crane outside its designed parameters due to insufficient customization or misrepresentation by the supplier can lead to premature wear or safety hazards.

Opaque Supply Chain and Lack of OEM Transparency

Some distributors resell cranes without disclosing the original equipment manufacturer (OEM), making it difficult to verify quality control processes or obtain spare parts and technical support. This lack of transparency complicates maintenance and increases downtime risks.

Insufficient After-Sales Support and Spare Parts Availability

Even high-quality cranes require maintenance. Sourcing from suppliers without local support or a clear spare parts supply chain can render the crane unusable during breakdowns. Verify service network access and parts availability before purchase.

Conclusion

To avoid these pitfalls, conduct thorough due diligence: request material certifications, verify load testing reports, confirm IP legitimacy, and audit the supplier’s manufacturing and quality processes. Investing time upfront ensures a safe, compliant, and durable aluminium gantry crane solution.

Logistics & Compliance Guide for Aluminium Gantry Crane

Overview

An Aluminium Gantry Crane is a lightweight, mobile lifting solution commonly used in industrial, warehouse, and manufacturing environments. Due to its portability and reduced weight compared to steel counterparts, it requires specific handling, transport, and compliance considerations. This guide outlines key logistics and regulatory requirements to ensure safe, legal, and efficient operations.

Transportation and Handling

- Disassembly Requirements: Most aluminium gantry cranes are modular and require partial or full disassembly for transport. Follow manufacturer instructions for safe breakdown and reassembly.

- Packaging and Protection: Use protective covers and padding to prevent scratches, dents, or corrosion during transit. Secure components in crates or on pallets to avoid shifting.

- Weight and Dimensions: Confirm the total weight and folded/assembled dimensions for accurate freight classification. Aluminium cranes are lighter but may still exceed vehicle or elevator load limits.

- Loading/Unloading: Use appropriate lifting equipment (e.g., forklifts, hoists) with soft slings to avoid damaging extruded aluminium beams. Ensure a level, stable surface during setup.

Regulatory Compliance

- OSHA Standards (USA): Comply with OSHA 29 CFR 1910.179 (Overhead and Gantry Cranes). Ensure load testing, operator training, and routine inspections are documented.

- EU Machinery Directive (2006/42/EC): Cranes placed in the EU market must bear CE marking and include a Declaration of Conformity, technical file, and risk assessment.

- Lifting Equipment Regulations (LOLER – UK): Requires thorough examination every 6 to 12 months by a competent person, depending on usage.

- National Standards: Verify compliance with local codes (e.g., AS 1418 in Australia, CSA B167 in Canada).

Load Capacity and Certification

- Rated Capacity: Never exceed the manufacturer’s specified load limit. Clearly mark the safe working load (SWL) on visible labels.

- Load Testing: Perform proof-load testing (typically 125% of SWL) after initial installation or major repairs. Retain test certificates for audit purposes.

- Calibration and Inspection: Calibrate load-limiting devices annually. Conduct daily pre-use visual checks for cracks, loose bolts, or wheel damage.

Site Requirements and Installation

- Floor Load Capacity: Ensure flooring can support point loads, especially on casters or outriggers. Use load-distribution mats if necessary.

- Clearance and Obstacles: Maintain minimum clearance above and around the crane path. Avoid power lines, racks, or overhead obstructions.

- Stability and Anchoring: Use outriggers or stabilizers on uneven surfaces. Consider temporary anchoring in high-traffic or windy environments.

Operator Training and Safety

- Certification: Operators must be trained and certified in crane safety, including load handling, emergency stops, and hazard awareness.

- PPE and Signage: Provide high-visibility vests, hard hats, and safety barriers. Post warning signs in crane operation zones.

- Lifting Procedures: Use appropriate slings and rigging gear. Ensure loads are balanced and secured before lifting.

Maintenance and Documentation

- Scheduled Maintenance: Follow the manufacturer’s maintenance schedule for lubrication, bolt tightening, and wear inspection.

- Record Keeping: Maintain logs for inspections, repairs, load tests, and operator certifications. Retain records for a minimum of 5 years or per local regulation.

- Spare Parts: Keep critical spare parts (e.g., casters, pins, bolts) on-site to minimize downtime.

Import/Export Considerations (International Shipments)

- Customs Documentation: Prepare commercial invoices, packing lists, and certificates of origin. Include HS code for aluminium structures (e.g., 7610.90).

- Material Compliance: Confirm the aluminium alloy used meets REACH (EU) or TSCA (USA) chemical regulations if applicable.

- Packaging Standards: Use ISPM 15-compliant wooden crates if required. Avoid restricted materials in packaging.

Environmental and Disposal Guidelines

- Recyclability: Aluminium is 100% recyclable. At end-of-life, dispose of or recycle through certified metal recyclers.

- Hazardous Components: Remove and dispose of any electrical or hydraulic parts per local e-waste or hazardous waste rules.

Emergency Procedures

- Crane Failure: Establish protocols for load suspension, evacuation, and reporting.

- Incident Reporting: Document any accidents or near-misses and report to relevant authorities if required by law.

Adhering to this logistics and compliance guide ensures the safe, legal, and efficient deployment of aluminium gantry cranes across diverse operational environments. Always consult the manufacturer’s manual and local regulatory bodies for site-specific requirements.

Conclusion for Sourcing an Aluminium Gantry Crane

Sourcing an aluminium gantry crane presents a strategic advantage for businesses seeking a lightweight, corrosion-resistant, and easily transportable lifting solution. The choice of aluminium offers significant benefits over traditional steel cranes, including reduced fatigue during manual handling, resistance to harsh environments, and lower maintenance costs over the crane’s lifecycle.

When sourcing, it is essential to evaluate suppliers based on material quality, engineering standards, load capacity requirements, customization options, and compliance with safety regulations such as OSHA or CE marking. Additionally, considering after-sales support, warranty, and lead times ensures long-term reliability and operational efficiency.

Investing in a high-quality aluminium gantry crane from a reputable supplier not only enhances workplace safety and productivity but also contributes to cost savings through durability and energy efficiency. As industries continue to prioritize mobility and sustainability, aluminium gantry cranes represent a forward-thinking solution for dynamic lifting needs. Therefore, careful vendor selection and thorough specification alignment are key to achieving optimal performance and return on investment.