The global automotive testing equipment market is experiencing robust growth, driven by increasing vehicle production, stricter emission regulations, and the rising complexity of automotive electrical systems. According to a report by Mordor Intelligence, the automotive diagnostic and testing equipment market was valued at USD 18.5 billion in 2022 and is projected to grow at a CAGR of over 6.8% from 2023 to 2028. A critical segment within this market is alternator testing tools—essential for ensuring the reliability and performance of vehicle charging systems. As demand for preventive maintenance and accurate fault diagnostics rises across OEMs and aftermarket service providers, manufacturers of alternator testing equipment are innovating rapidly to meet evolving technical standards. This growing ecosystem has led to increased competition and specialization among key players worldwide. Based on market presence, product innovation, and technological capabilities, here are the top 10 alternator testing tool manufacturers shaping the industry today.

Top 10 Alternator Testing Tool Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Process safety, automation, test and measurement

Domain Est. 1996

Website: eaton.com

Key Highlights: Comprehensive solutions for intrinsic safety, fieldbus, signal conditioning, industrial networking, surge protection and HMI that control, operate and protect ……

#2 ALT

Domain Est. 1997

Website: dvelectronics.com

Key Highlights: The ALT-72 is designed to provide manufacturers with a detailed test of the alternator’s performance and endurance under varied temperatures and thermal ……

#3 Alternator Testing

Domain Est. 2000

Website: aeimich.com

Key Highlights: Final End-of-line Finished Product Alternator Tester. The ALT-98 is designed to provide remanufacturers with a detailed test of the alternators under heavy ……

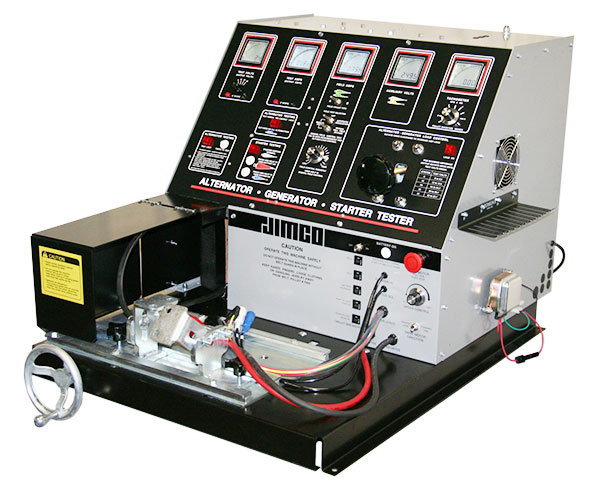

#4 to JIMCO

Domain Est. 2002

Website: jimcotest.com

Key Highlights: JIMCO console alternator test benches provide safe, quick and accurate testing of alternators, generators and starters….

#5 Balmar

Domain Est. 1999

Website: balmar.net

Key Highlights: Balmar has been serving the Recreational Marine Industry for over 30 years. We supplying Alternators, DC Charging Products, and Battery Monitors….

#6 Voltmeter/Alternator Tester

Domain Est. 1999

#7 Associated Equipment 6031

Domain Est. 2008

Website: autotoolworld.com

Key Highlights: In stock Rating 5.0 (1) Tests for defective alternator diodes including GM trio test; Performs complete battery test; 125 Amp load checks state of charge; Searches for excess ……

#8 STAMFORD

Domain Est. 2009

Website: stamford-avk.com

Key Highlights: We are STAMFORD | AvK: your global leader in power generation. Explore reliable alternators, superior engineering, and worldwide support for every ……

#9 Wakespeed Charge Smarter

Domain Est. 2012

Website: wakespeed.com

Key Highlights: Wakespeed’s advanced alternator regulator, the WS500, is the first of its kind and delivers unsurpassed quality and performance, allowing you to charge smarter….

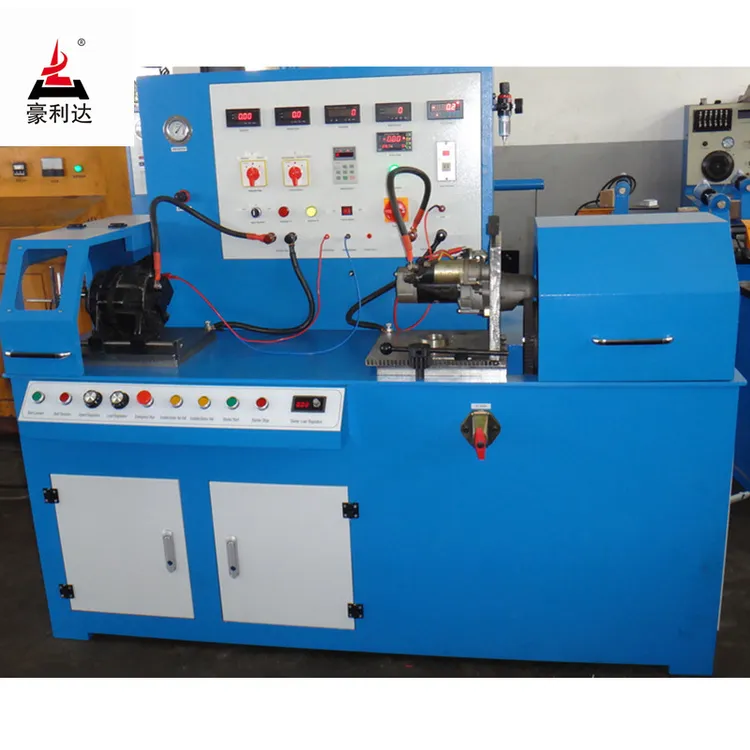

#10 Starter and Alternator Diagnostic Equipment

Website: msg.equipment

Key Highlights: Professional test benches and testers for automotive starters, alternators, and voltage regulators. Precise malfunction identification and repair ……

Expert Sourcing Insights for Alternator Testing Tool

2026 Market Trends for Alternator Testing Tools

Rising Demand Driven by Vehicle Electrification and Complexity

Despite the growth of electric vehicles (EVs), the internal combustion engine (ICE) and hybrid vehicle market will remain substantial through 2026, sustaining demand for alternator testing tools. Modern vehicles incorporate increasingly sophisticated electrical systems, including start-stop technology, regenerative braking, and advanced driver-assistance systems (ADAS), all placing higher loads on alternators. This complexity necessitates more precise and intelligent diagnostic tools. As a result, alternator testing tools are evolving from basic voltage checkers to multifunctional diagnostic platforms capable of evaluating ripple voltage, diode performance, and alternator load under real-world conditions. The aftermarket and repair shops are investing in advanced tools to reduce diagnostic errors and service time, driving market growth.

Shift Toward Smart, Connected, and Data-Centric Testing Solutions

By 2026, alternator testing tools are expected to integrate more deeply with digital workshop ecosystems. Bluetooth and Wi-Fi connectivity are becoming standard, enabling tools to sync with mobile apps and cloud-based diagnostic software. This allows technicians to store test results, generate service reports, and compare readings against OEM specifications in real time. Artificial intelligence (AI) and machine learning are beginning to play a role in predictive maintenance, where tools analyze historical performance data to flag potential alternator failures before breakdowns occur. These smart features not only improve accuracy but also enhance productivity, making them highly attractive to professional repair facilities.

Growth in Aftermarket and DIY Segments Fuels Product Innovation

The global automotive aftermarket is expanding, supported by aging vehicle fleets and increasing vehicle ownership in emerging economies. This trend benefits the alternator testing tool market, as both professional mechanics and do-it-yourself (DIY) users seek affordable, user-friendly diagnostic devices. Manufacturers are responding with intuitive interfaces, step-by-step guidance, and multilingual support to cater to a broader user base. Compact, handheld testers with smartphone integration are particularly popular in the DIY segment, while professional-grade tools emphasize durability, precision, and compatibility with a wide range of vehicle makes and models.

Regional Market Dynamics and Regulatory Influences

North America and Europe will continue to lead in the adoption of high-end alternator testing equipment due to stringent emission standards and advanced service infrastructure. In contrast, Asia-Pacific—especially China, India, and Southeast Asia—is expected to witness the fastest market growth, driven by rising vehicle production, expanding service networks, and government support for automotive repair standardization. Regulatory requirements for vehicle maintenance, particularly for commercial fleets, are also encouraging the use of certified diagnostic tools, further boosting market demand.

Competitive Landscape and Technological Convergence

The alternator testing tool market is becoming increasingly competitive, with established players like Bosch, Fluke, and UView competing against innovative startups offering cost-effective, feature-rich alternatives. There is a noticeable trend toward convergence, where alternator testers are bundled within broader battery and electrical system diagnostic kits. This integration reflects the interdependence of vehicle electrical components and enables comprehensive system health assessments. As a result, standalone alternator testers are giving way to modular platforms that can expand functionality via software updates or add-on modules.

Sustainability and Calibration Standards

Environmental concerns are prompting manufacturers to focus on energy efficiency and recyclable materials in tool production. Additionally, calibration and accuracy standards are gaining importance, with industry bodies and repair networks demanding ISO-compliant testing equipment. By 2026, tools featuring self-calibration functions and traceable certification will be preferred in professional environments, ensuring reliability and compliance with quality assurance protocols.

Common Pitfalls When Sourcing an Alternator Testing Tool (Quality, IP)

When sourcing an alternator testing tool, organizations often face challenges that can compromise performance, reliability, and long-term value. Two critical areas where pitfalls frequently occur are product quality and intellectual property (IP) protection.

Poor Quality Components and Inconsistent Performance

One of the most prevalent issues in sourcing alternator testing tools is receiving products made with substandard materials or lacking rigorous quality control. Low-cost suppliers may cut corners by using inferior electrical components, leading to inaccurate voltage, current, or ripple measurements. Inconsistent calibration across units can result in unreliable diagnostics, increasing the risk of misdiagnosing vehicle issues. Additionally, inadequate build quality—such as weak connectors, fragile housings, or insufficient heat dissipation—can reduce tool lifespan, especially in demanding workshop environments. Without proper certifications (e.g., CE, RoHS) or verifiable testing protocols, buyers may unknowingly integrate unreliable tools into their operations.

Intellectual Property Risks and Lack of Innovation Protection

Sourcing from manufacturers in regions with weak IP enforcement can expose buyers to significant legal and reputational risks. Counterfeit or cloned testing tools—often reverse-engineered from established brands—may infringe on patents, software copyrights, or proprietary algorithms. Using such tools can inadvertently involve the buyer in IP violations, potentially leading to litigation or supply chain disruptions. Moreover, reliance on copied technology stifles innovation and limits access to advanced features like automated diagnostics, firmware updates, or integration with digital service platforms. Without clear IP agreements and due diligence in the supply chain, companies may lose control over product differentiation and future development.

Logistics & Compliance Guide for Alternator Testing Tool

This guide outlines the logistics procedures and compliance requirements for the safe, efficient, and lawful handling, transportation, and use of the Alternator Testing Tool.

Product Overview

The Alternator Testing Tool is a diagnostic device used to evaluate the performance and electrical output of vehicle alternators. It includes electronic components, wiring harnesses, and a display interface. Proper handling is essential to maintain functionality and ensure user safety.

Regulatory Compliance

The Alternator Testing Tool must comply with the following standards and regulations:

- Electromagnetic Compatibility (EMC): Complies with FCC Part 15 (USA) and CE-EMC (EU) directives to prevent interference with other electronic devices.

- Electrical Safety: Meets IEC 61010-1 standards for safety requirements for electrical equipment used in measurement, control, and laboratory use.

- RoHS Compliance: Adheres to the Restriction of Hazardous Substances Directive (2011/65/EU), ensuring the product contains no restricted materials such as lead, mercury, or cadmium above permitted levels.

- REACH: Complies with Regulation (EC) No 1907/2006 concerning the Registration, Evaluation, Authorization, and Restriction of Chemicals.

Certification marks (CE, FCC, RoHS) are displayed on product labels and packaging.

Packaging and Labeling

Each unit must be packaged in anti-static, shock-resistant material to protect sensitive electronics during transit. Packaging must include:

- Product name and model number

- Manufacturer details and contact information

- Compliance markings (CE, FCC, RoHS)

- Handling symbols (e.g., “Fragile,” “Do Not Stack,” “This Side Up”)

- Language-specific user instructions and safety warnings (as applicable per region)

Barcodes and serial numbers must be clearly visible for inventory tracking.

Shipping and Transportation

- Domestic (USA): Ship via certified carriers (e.g., FedEx, UPS) using ground or air services as needed. Ensure packages meet carrier size and weight limits.

- International: Use freight forwarders experienced in shipping electronic diagnostic tools. Provide commercial invoices, packing lists, and certificates of compliance (CE, FCC) for customs clearance.

- Hazardous Materials: The tool is not classified as hazardous under IATA, IMDG, or 49 CFR regulations. No special hazardous labeling is required.

- Temperature Considerations: Avoid prolonged exposure to extreme temperatures (>60°C or <–10°C) during storage and transit.

Import/Export Documentation

For international shipments, ensure the following documents are prepared:

- Commercial Invoice (with Harmonized System [HS] code 9030.89 for electrical measuring instruments)

- Packing List

- Certificate of Origin

- FCC Declaration of Conformity (for exports to the U.S.)

- EU Declaration of Conformity (for intra-EU shipments or imports into the EU)

Verify tariff classifications and import duties with local customs authorities.

Storage Requirements

- Store in a dry, climate-controlled environment with temperatures between 10°C and 35°C and relative humidity below 80%.

- Keep away from direct sunlight, magnetic fields, and sources of electrical interference.

- Stack packages only as high as recommended on the packaging label to prevent damage.

End-of-Life and Recycling

The Alternator Testing Tool must be disposed of in accordance with WEEE (Waste Electrical and Electronic Equipment) Directive 2012/19/EU. Users should return end-of-life units to authorized electronic waste collection points. Do not dispose of in household waste.

Quality and Audit Compliance

- Maintain records of compliance certifications, shipping documents, and test reports for a minimum of five years.

- Conduct annual internal audits to verify adherence to logistics and compliance protocols.

- Report any non-conformities or safety incidents immediately to the Quality Assurance department.

For questions or updates to this guide, contact: [email protected].

Conclusion: Sourcing an Alternator Testing Tool

In conclusion, sourcing a reliable alternator testing tool is essential for ensuring accurate diagnostics, improving repair efficiency, and maintaining the integrity of vehicle electrical systems. When selecting a tool, key considerations such as compatibility with various vehicle models, measurement accuracy, ease of use, durability, and cost-effectiveness must be carefully evaluated. Whether opting for handheld testers, bench-style models, or multi-function diagnostic devices, choosing a tool from reputable suppliers—with proven technical support and calibration options—enhances long-term reliability.

Additionally, assessing total cost of ownership, including maintenance, training, and potential downtime, contributes to a more informed procurement decision. For businesses focused on quality service and operational efficiency, investing in a high-performance alternator testing tool not only streamlines diagnostic processes but also strengthens customer trust and reduces unnecessary component replacements.

Ultimately, the right alternator testing tool—strategically sourced based on technical specifications and operational needs—serves as a valuable asset in any automotive repair or maintenance environment.