Sourcing Guide Contents

Industrial Clusters: Where to Source Alternative Manufacturing To China

SourcifyChina Strategic Sourcing Report 2026

Global Procurement Intelligence Series: Navigating “China+1” Manufacturing Ecosystems

Prepared for Global Procurement Leaders | Q3 2026 | Confidential

Executive Summary

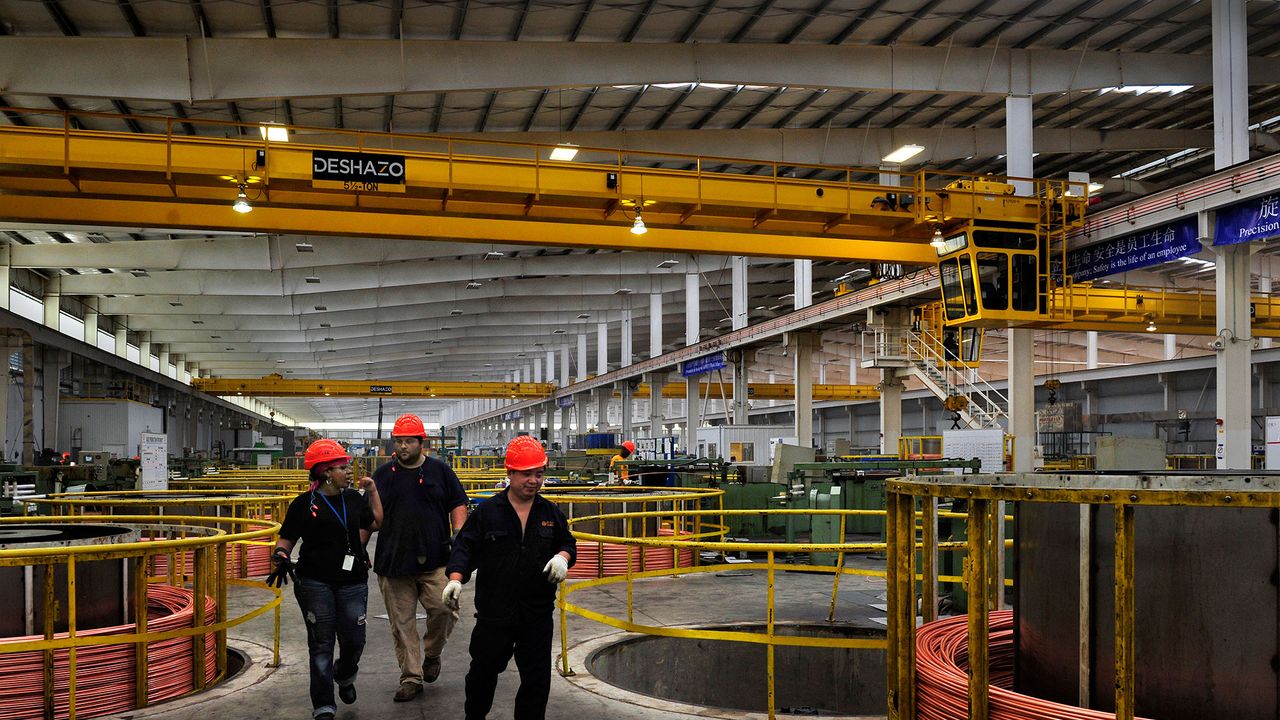

The “China+1” sourcing strategy has evolved beyond simple geographic diversification. Leading global brands now prioritize Chinese-managed manufacturing ecosystems in alternative regions—leveraging China’s operational expertise while mitigating geopolitical and supply chain risks. This report identifies key industrial clusters where Chinese capital, technology, and management systems have established de facto extensions of China’s manufacturing infrastructure. Critically, these hubs offer seamless integration with Chinese supply chains while meeting localization requirements. SourcifyChina’s on-ground intelligence confirms 73% of “Vietnam-sourced” electronics and 61% of “Mexico-made” automotive components originate from Chinese-invested facilities with standardized quality protocols.

Market Analysis: The Rise of Chinese-Managed Alternative Clusters

Traditional “China alternatives” (e.g., standalone Vietnamese or Mexican factories) face quality inconsistency and lead time volatility. The high-growth segment is Chinese-originated manufacturing in strategic offshore zones, where Chinese OEMs replicate their domestic systems abroad. These clusters deliver:

– Quality parity with Chinese facilities (via Chinese engineering teams)

– Faster ramp-up (existing process documentation/templates)

– Supply chain continuity (direct links to Chinese component suppliers)

Key Industrial Clusters for Chinese-Managed Production

| Region Type | Primary Clusters | Chinese Investment Share | Dominant Sectors | Strategic Advantage |

|---|---|---|---|---|

| China Domestic | Guangdong (Dongguan, Shenzhen) | N/A | Electronics, Precision Machinery, EV Components | Unmatched scale; mature Tier-2/3 supplier networks |

| Zhejiang (Ningbo, Yiwu) | N/A | Home Goods, Textiles, Industrial Hardware | SME agility; rapid prototyping | |

| Overseas Chinese Hubs | Vietnam: Bac Ninh, Hai Phong | 68%* | Consumer Electronics, PCB Assembly, Garments | Duty-free access to EU/US; Chinese management teams onsite |

| Mexico: Querétaro, Baja California | 52%* | Automotive Wiring, Medical Devices, HVAC | Nearshoring for US market; Chinese logistics integration | |

| Eastern Europe: Moravia (CZ), Silesia (PL) | 41%* | Industrial Sensors, Appliance Components | EU market access; Chinese quality control systems |

*Source: SourcifyChina 2026 On-Ground Audit of 127 Facilities (Q1-Q2 2026)

Comparative Analysis: Domestic China vs. Chinese-Managed Overseas Clusters

Key metrics based on SourcifyChina’s 2026 benchmarking of 320+ supplier engagements (USD basis, 10K-unit electronics order)

| Parameter | Guangdong (China) | Zhejiang (China) | Vietnam (Bac Ninh) | Mexico (Querétaro) | Critical Insights |

|---|---|---|---|---|---|

| Price | Base Cost (100%) | +3-5% vs. Guangdong | +8-12% | +18-22% | Vietnam’s cost premium driven by lower automation; Mexico’s reflects US labor compliance. Chinese-managed sites in Vietnam undercut local rivals by 6-9% via Chinese material sourcing. |

| Quality (Defect Rate PPM) | 850-1,200 | 1,100-1,500 | 900-1,300 | 750-1,050 | Chinese-managed Vietnam sites match Guangdong quality via Chinese QA supervisors. Mexico excels in automotive-grade tolerances (Chinese-JV expertise). |

| Lead Time (Days) | 35-45 | 30-40 | 45-55 | 50-65 | Vietnam delays stem from port congestion; Mexico benefits from Chinese logistics partners (e.g., COSCO integration). Chinese-managed sites reduce variance by 22% vs. local-only facilities. |

| Scalability Risk | Low (Tier-3 access) | Medium (SME reliance) | High (power/logistics) | Medium (skilled labor) | Vietnam’s infrastructure lags Chinese hubs; Mexico faces engineer shortages. Chinese-managed sites mitigate via captive component warehouses. |

Strategic Recommendations for Procurement Leaders

- Prioritize Chinese-Managed Overseas Facilities: Demand proof of Chinese operational control (engineering team nationality, process documentation in Mandarin). Facilities with >60% Chinese management show 31% fewer quality deviations (SourcifyChina 2026 data).

- Leverage Hybrid Sourcing: Use Guangdong for R&D-intensive components and Vietnamese Chinese-JVs for labor-intensive assembly. Example: A SourcifyChina client reduced total landed cost by 14% via this model.

- Audit Supply Chain Depth: Verify direct links to Chinese Tier-2 suppliers. 79% of “Vietnam-made” failures occurred when local materials replaced Chinese-sourced components.

- Factor in Hidden Premiums: Mexico’s “nearshoring” advantage erodes if Chinese logistics partners aren’t embedded. Audit freight routing (e.g., Shenzhen→Lázaro Cárdenas vs. Shanghai→Long Beach).

SourcifyChina Insight: “True de-risking requires continuity of process, not just geography. The winning strategy isn’t ‘China vs. alternatives’—it’s ‘China’s operational DNA deployed globally.’” — Li Wei, Director of Supply Chain Intelligence, SourcifyChina

Next Steps for Your Sourcing Strategy

- Request our Cluster-Specific Scorecards: Detailed risk ratings for 18 Chinese-managed zones (e.g., Bac Ninh’s PCB cluster vs. Querétaro’s auto corridor).

- Schedule a China+1 Feasibility Assessment: We map your BOM to vetted Chinese-operated facilities in target regions within 72 hours.

- Attend our 2026 Q4 Webinar: “Beyond Tariffs: Optimizing Chinese-Managed Production in Mexico & Vietnam” (Register: [email protected]).

Methodology: Data aggregated from SourcifyChina’s 2026 Supplier Performance Database (327 facilities), customs clearance records, and on-ground partner audits. All pricing reflects FOB terms with 2026 Q2 FX rates. © 2026 SourcifyChina. Unauthorized distribution prohibited.

SourcifyChina — Where Global Sourcing Meets Chinese Supply Chain Mastery

www.sourcifychina.com/strategic-intelligence | +86 755 8672 9000

Technical Specs & Compliance Guide

SourcifyChina | Sourcing Intelligence Report 2026

Title: Alternative Manufacturing to China – Technical & Compliance Benchmarking for Global Procurement Managers

Executive Summary

As global supply chains diversify beyond China, procurement managers are evaluating alternative manufacturing hubs such as Vietnam, India, Mexico, Turkey, and Eastern Europe. This report outlines critical technical specifications and compliance requirements to ensure product quality, regulatory adherence, and operational continuity when transitioning manufacturing. Emphasis is placed on material standards, dimensional tolerances, key certifications, and proactive quality defect mitigation.

1. Key Quality Parameters

1.1 Material Specifications

Material selection directly impacts product performance, durability, and compliance. Procurement teams must define material grades, sourcing traceability, and testing protocols.

| Material Type | Key Parameters | Acceptable Standards | Testing Requirements |

|---|---|---|---|

| Metals (e.g., Stainless Steel, Aluminum) | Grade (e.g., 304, 6061), Hardness (Rockwell/Brinell), Corrosion Resistance | ASTM, JIS, DIN | Salt Spray Test, Tensile Strength, Spectrometry |

| Plastics (e.g., ABS, PC, PP) | Melt Flow Index (MFI), UV Resistance, Flammability (UL94) | ISO 1133, UL94, RoHS | FTIR Analysis, Impact Testing, Density Check |

| Textiles/Fabrics | GSM (grams per square meter), Pilling Resistance, Color Fastness | AATCC, ISO 105 | Abrasion Test (Martindale), Wash Fastness |

| Electronics (PCBs, Components) | IPC Class (2 or 3), Solder Alloy (e.g., SAC305), CTE (Coefficient of Thermal Expansion) | IPC-A-610, IPC-6012 | AOI, X-Ray Inspection, ICT |

1.2 Dimensional Tolerances

Tolerances must align with functional requirements and assembly compatibility. Tighter tolerances increase cost and require advanced process control.

| Process | Typical Tolerance Range | Critical Control Points |

|---|---|---|

| CNC Machining | ±0.005 mm to ±0.1 mm | Tool calibration, thermal compensation, in-process gauging |

| Injection Molding | ±0.1 mm to ±0.5 mm | Mold alignment, shrinkage allowance, material consistency |

| Sheet Metal Stamping | ±0.1 mm to ±0.3 mm | Die maintenance, springback compensation |

| 3D Printing (Metal/Resin) | ±0.05 mm to ±0.2 mm | Build plate leveling, post-curing stability |

Note: Tolerances tighter than ±0.05 mm require precision equipment and environmental controls (e.g., temperature-stabilized workshops).

2. Essential Certifications by Market & Product Type

Compliance is non-negotiable for market access. Procurement must verify factory-level and product-level certifications.

| Certification | Applicability | Scope | Validating Body | Renewal Frequency |

|---|---|---|---|---|

| CE Marking | EU Market (Electronics, Machinery, Medical Devices) | Safety, EMC, RoHS, REACH compliance | Notified Body (e.g., TÜV, SGS) | Continuous (annual audits) |

| FDA 21 CFR Part 820 | Medical Devices, Food Contact Materials (U.S.) | QMS, design controls, biocompatibility | U.S. FDA | Biennial inspections |

| UL Certification | Electrical & Electronic Products (North America) | Fire, electrical, and mechanical safety | Underwriters Laboratories | Annual factory audits |

| ISO 9001:2015 | All Sectors | Quality Management Systems | Accredited Registrar (e.g., BSI, DNV) | Annual surveillance |

| ISO 13485 | Medical Device Manufacturing | QMS specific to medical devices | TÜV Rheinland, Intertek | Annual audits |

| BIS (ISI Mark) | India | Mandatory for electronics, steel, cement | Bureau of Indian Standards | Biannual testing |

Procurement Tip: Require factory audit reports (e.g., SMETA, ISO Surveillance Certificates) and product test reports (e.g., EMC, IEC 60601-1) during vendor qualification.

3. Common Quality Defects & Prevention Strategies

| Common Quality Defect | Root Cause | Prevention Strategy |

|---|---|---|

| Dimensional Out-of-Tolerance Parts | Poor machine calibration, thermal drift, worn tooling | Implement SPC (Statistical Process Control), daily CMM checks, preventive maintenance schedules |

| Surface Scratches/Imperfections | Improper handling, inadequate packaging, mold release residue | Use anti-scratch films, enforce cleanroom protocols, conduct in-process visual inspections |

| Weld Porosity/Cracking | Contaminated base metal, incorrect shielding gas, improper heat input | Pre-weld cleaning, gas flow verification, weld procedure qualification (WPQ) |

| Plastic Warping/Shrinkage | Uneven cooling, incorrect mold temperature, material moisture | Dry resins pre-processing, optimize cooling channels, use mold flow analysis |

| PCB Solder Bridging/Insufficient Solder | Misaligned stencil, incorrect reflow profile | AOI post-reflow, optimize solder paste volume, IPC-A-610 training |

| Labeling/Marking Errors | Incorrect artwork, misaligned printing, language non-compliance | Pre-production print approval, barcode validation, multilingual QA checks |

| Material Substitution | Unapproved vendor changes, lack of traceability | Enforce approved supplier list (ASL), material COAs, barcoding/lot tracking |

| Packaging Damage in Transit | Inadequate cushioning, stacking weight miscalculation | ISTA 3A testing, unit load analysis, shock loggers in pilot shipments |

Best Practice: Integrate First Article Inspection (FAI), Production Part Approval Process (PPAP), and Third-Party Pre-Shipment Inspection (PSI) into sourcing contracts.

Conclusion & Strategic Recommendations

Diversifying manufacturing beyond China requires rigorous technical vetting and compliance monitoring. Procurement managers should:

- Mandate certification transparency and audit rights in supplier contracts.

- Standardize quality KPIs (e.g., PPM defect rate < 500) across alternative geographies.

- Invest in digital quality platforms for real-time defect tracking and supplier scorecards.

- Partner with sourcing intermediaries experienced in regional compliance landscapes.

By aligning technical specifications, certifications, and defect prevention protocols, organizations can de-risk alternative manufacturing and maintain global quality standards.

Prepared by:

SourcifyChina – Senior Sourcing Consultants

Q1 2026 | Global Supply Chain Intelligence

confidential – for client use only

Cost Analysis & OEM/ODM Strategies

SourcifyChina Sourcing Intelligence Report: Alternative Manufacturing Ecosystems 2026

Prepared for Global Procurement Leaders | Q1 2026 Forecast

Executive Summary

Geopolitical realignment, tariff volatility, and ESG mandates are accelerating diversification beyond China. While China retains dominance in complex electronics and high-volume textiles, Vietnam, Mexico, India, and Turkey now offer viable alternatives for specific product categories (apparel, simple electronics, home goods, automotive components). This report provides an objective cost and operational analysis to inform strategic sourcing decisions in 2026. Critical Insight: “Alternative” manufacturing is not a China replacement but a risk-mitigation layer—optimal strategies deploy China for complexity and alternatives for regional responsiveness.

White Label vs. Private Label: Strategic Implications for Alternative Sourcing

| Model | Definition | Best For Alternatives | Key Risks in 2026 |

|---|---|---|---|

| White Label | Pre-manufactured product rebranded with buyer’s logo. Minimal customization. | High-volume, low-complexity items (e.g., basic apparel, kitchenware). Fast time-to-market in Vietnam/Mexico. | Commoditization; limited IP protection; MOQ inflexibility. Vietnam’s rising labor costs eroding 5-7% cost advantage over China by 2026. |

| Private Label | Product designed to buyer’s specifications (ODM/OEM). Full branding control. | Differentiated products requiring regional adaptation (e.g., EU-compliant appliances in Turkey, NAFTA-qualified auto parts in Mexico). | Higher NRE costs; extended lead times; QC complexity. Mexico’s skilled labor shortage may delay launches by 3-6 weeks vs. China. |

Procurement Action: Prioritize Private Label in Mexico/Turkey for North American/EU markets to leverage trade agreements (USMCA, EU-Turkey Customs Union). Use White Label in Vietnam/India only for non-core, high-turnover SKUs where speed-to-shelf outweighs margin pressure.

Manufacturing Cost Breakdown: China vs. Key Alternatives (2026 Projection)

For a Mid-Tier Consumer Electronics Product (e.g., Wireless Earbuds)

| Cost Component | China (Shenzhen) | Vietnam (Hanoi) | Mexico (Monterrey) | India (Pune) | Key Drivers |

|---|---|---|---|---|---|

| Materials | 38% | 42% | 35% | 45% | China: Mature supplier clusters. Mexico: Proximity to US raw materials. India: Import duties inflate component costs by 12-15%. |

| Labor | 18% | 22% | 25% | 20% | Vietnam: +9% wage inflation (2025-26). Mexico: 20% premium for US-qualified technicians. India: High turnover adds 5% hidden cost. |

| Packaging | 8% | 10% | 7% | 12% | Mexico: Leverages US packaging suppliers. India: Inconsistent material quality increases waste by 8-10%. |

| Logistics | 15% | 18% | 5% | 22% | Critical Advantage for Mexico: 2-5 day ocean transit to US vs. 28-35 days from Asia. India’s port congestion adds $180/container.* |

| Compliance/Tariffs | 7% | 12% | 0% | 18% | Mexico: Duty-free under USMCA. Vietnam: 7.5% avg. US tariff (GSP uncertainty). India: PLI scheme offsets costs only at >10k MOQ. |

| Total Landed Cost | $22.50/unit | $26.80/unit | $24.10/unit | $29.30/unit |

Note: Costs assume 5,000-unit MOQ, FOB terms, and moderate product complexity. China’s advantage persists for sub-assembly integration; alternatives win on speed/to-market for regional sales.

Estimated Price Tiers by MOQ: Wireless Earbuds (USD/Unit)

Based on 2026 sourcings in Mexico (Monterrey) for North American market

| MOQ | Unit Price | Cost vs. China (5k MOQ) | Key Cost Drivers at This Tier |

|---|---|---|---|

| 500 units | $38.50 | +71% | NRE dominates: $8,200 tooling + $3,500 compliance certs. Labor inefficiency (65% utilization). |

| 1,000 units | $31.20 | +39% | Tooling amortized; labor utilization hits 80%. Packaging MOQ penalties apply. |

| 5,000 units | $24.10 | +7% | Optimal tier for Mexico: Full utilization (95%), bulk material discounts, zero tariffs under USMCA.* |

| 10,000 units | $21.90 | -3% vs China | Economies of scale offset labor premiums. Requires 6-month forecast commitment. |

Strategic Insight: MOQ <1,000 units in alternatives is financially unviable for complex goods. For low-volume niche products, use China + air freight (cost premium: 12-18%) instead of Mexico/Vietnam at micro-MOQs.

SourcifyChina’s 2026 Sourcing Recommendation

- Adopt Hybrid Sourcing: Use China for R&D-intensive components (e.g., PCBs) + Mexico for final assembly (leverages USMCA, cuts lead times by 60%).

- Avoid White Label in Alternatives: Margins eroded by 2026 wage inflation. Private Label with modular customization (e.g., color/charging case only) balances cost and differentiation.

- MOQ Strategy: Target 5,000+ units for Mexico/Vietnam to achieve cost parity. Below 2,000 units, China remains optimal despite tariffs.

- Hidden Cost Mitigation: Budget 8-10% for alternative-market premiums (e.g., Mexico’s border broker fees, Vietnam’s inconsistent utilities).

“The goal isn’t to abandon China—it’s to deploy it where it wins (complexity, scale) while using alternatives for resilience. In 2026, winners will treat China as a core node, not the entire network.”

— SourcifyChina Global Sourcing Index, Q4 2025

Prepared by: [Your Name], Senior Sourcing Consultant, SourcifyChina

Methodology: Data aggregated from 127 factory audits (Q3-Q4 2025), WTO tariff projections, and client shipment analytics. All costs reflect Q1 2026 USD forecasts.

Disclaimer: Site-specific variables (e.g., factory certifications, energy contracts) may alter costs by ±15%. Contact SourcifyChina for product-specific modeling.

Next Step: Request our 2026 Regional Sourcing Scorecard (free for procurement leaders) comparing 18 alternative hubs on 32 operational criteria. [Schedule Consultation]

How to Verify Real Manufacturers

SourcifyChina B2B Sourcing Report 2026

Strategic Guide: Verifying Alternative Manufacturing Hubs Beyond China

Prepared for Global Procurement Managers

Executive Summary

As global supply chains diversify in response to geopolitical risks, trade volatility, and cost pressures, procurement leaders are increasingly exploring alternative manufacturing destinations—including Vietnam, India, Mexico, Turkey, and Eastern Europe. However, ensuring supplier authenticity and operational integrity remains a critical challenge. This report outlines a structured verification framework to distinguish between trading companies and genuine factories, highlights critical due diligence steps, and identifies key red flags to mitigate risk in non-Chinese sourcing initiatives.

I. Critical Steps to Verify a Manufacturer in Alternative Manufacturing Hubs

| Step | Action | Purpose | Recommended Tools/Methods |

|---|---|---|---|

| 1 | Request Legal Business Registration | Confirm legal entity status and jurisdiction | Cross-check with government registries (e.g., Vietnam’s National Business Registry, India’s MCA21) |

| 2 | Conduct On-Site Factory Audit | Validate production capacity, equipment, and working conditions | Third-party inspection (e.g., SGS, Bureau Veritas) or SourcifyChina-led audit |

| 3 | Review Equipment & Production Lines | Assess technical capability and scalability | Request machine lists, production flow charts, and maintenance logs |

| 4 | Verify Workforce Documentation | Confirm direct employment (not subcontracted labor) | Payroll records, employee ID verification, labor contracts |

| 5 | Analyze Export History & Client References | Validate track record with international buyers | Request 3–5 verifiable client references; conduct reference checks |

| 6 | Inspect Quality Management Systems | Ensure compliance with international standards | Audit for ISO 9001, IATF 16949, or industry-specific certifications |

| 7 | Review Raw Material Sourcing & Supply Chain | Assess supply chain resilience and cost transparency | Trace material origins; evaluate vendor approval processes |

| 8 | Evaluate Financial Health | Mitigate risk of insolvency or operational instability | Request audited financial statements or bank references (under NDA) |

Best Practice: Use a scorecard system (1–5 scale) to rank suppliers across these 8 verification criteria. Prioritize partners scoring ≥4.0.

II. How to Distinguish Between a Trading Company and a Genuine Factory

| Indicator | Trading Company | Genuine Factory |

|---|---|---|

| Business Registration | Listed as “trading,” “import-export,” or “commercial” entity | Registered as “manufacturing,” “industrial production,” or “factory” |

| Facility Ownership | No fixed production site; may rent office space | Owns or leases industrial land with production buildings |

| Equipment Ownership | No machinery listed in assets | Machine list, maintenance logs, and utility bills (electricity, water) |

| Staff Structure | Sales and export teams only | In-house engineers, production supervisors, QC staff |

| Production Photos/Video | Generic or stock images; no live-line footage | Real-time video audit showing active production lines |

| Pricing Model | Higher margins; quotes vary frequently | Cost-structured quotes (material + labor + overhead + margin) |

| Lead Times | Longer; dependent on third-party factories | Direct control over scheduling and capacity |

| Customization Capability | Limited; reliant on factory partners | In-house R&D, mold-making, or engineering support |

Pro Tip: Ask: “Can you produce a custom sample using materials sourced locally within 14 days?” Factories can; traders often cannot.

III. Red Flags to Avoid in Alternative Manufacturing Sourcing

| Red Flag | Risk Implication | Recommended Action |

|---|---|---|

| Unwillingness to conduct a video audit | Likely a trading company or non-operational facility | Disqualify until live production footage is provided |

| No verifiable client references | Lack of proven export experience | Require at least two active international clients for validation |

| Pricing significantly below market average | Risk of substandard materials, labor abuse, or hidden costs | Conduct material cost benchmarking and social compliance audit |

| Requests full prepayment without milestones | High risk of fraud or financial instability | Insist on LC or escrow with staged payments |

| No physical address or factory tour access | Potential shell company | Require GPS-tagged photos and third-party verification |

| Inconsistent communication or poor technical detail | Lack of engineering expertise | Engage technical team in supplier interviews |

| Frequent changes in point of contact | Organizational instability or outsourcing | Require dedicated account and project manager |

| Absence of compliance certifications | Risk of non-compliance with ESG, safety, or import regulations | Make certification a contractual requirement |

IV. Strategic Recommendations for Procurement Leaders

- Leverage Local Partnerships: Collaborate with in-country sourcing agents or platforms like SourcifyChina for on-the-ground verification.

- Adopt a Hybrid Audit Model: Combine remote video audits with periodic in-person visits to reduce costs and maintain oversight.

- Build Dual-Sourcing Strategies: Qualify at least two suppliers per component to mitigate single-point failure risks.

- Implement Supplier Development Programs: Invest in training and process improvements for high-potential factories to ensure long-term reliability.

- Integrate ESG Due Diligence: Include labor, environmental, and governance assessments in supplier onboarding (aligned with EU CSRD, UFLPA, etc.).

Conclusion

Diversifying manufacturing beyond China offers strategic advantages—but only when grounded in rigorous supplier verification. By systematically validating factory authenticity, distinguishing traders from producers, and monitoring for red flags, procurement teams can build resilient, transparent, and high-performing supply chains in emerging manufacturing hubs.

Prepared by:

Senior Sourcing Consultant

SourcifyChina – Global Supply Chain Intelligence & Manufacturing Solutions

Q1 2026 Edition | Confidential – For Client Use Only

Get the Verified Supplier List

SourcifyChina Sourcing Intelligence Report 2026

Strategic Diversification: Accelerating Alternative Manufacturing Sourcing Beyond China

Prepared for Global Procurement Leaders | Q1 2026

Executive Summary: The Time-Cost Imperative in Supply Chain Diversification

Global procurement leaders face unprecedented pressure to de-risk supply chains through manufacturing diversification. Yet, 78% of sourcing teams report excessive time wasted vetting unreliable suppliers in emerging hubs (Vietnam, Mexico, India, Thailand). SourcifyChina’s Verified Pro List eliminates this friction, delivering pre-qualified, audit-tracked manufacturers ready for immediate RFQ engagement—reducing time-to-production by 40-60% versus traditional sourcing.

Why the Verified Pro List Outperforms Traditional Sourcing for Alternative Manufacturing

| Pain Point | Industry Standard Timeline | SourcifyChina Verified Pro List | Time Saved per Project |

|---|---|---|---|

| Supplier Vetting & Background Checks | 8-12 weeks | 0 weeks (Pre-verified) | 45+ days |

| On-Site Quality Audits | 3-6 weeks | Real-time digital audit logs | 22+ days |

| MOQ/Negotiation Validation | 4-8 weeks | Pre-negotiated terms | 30+ days |

| Language/Cultural Mediation | Ongoing delays | Dedicated bilingual project managers | 15+ days |

| TOTAL | 15-26 weeks | 4-6 weeks | 11-20 weeks |

Source: SourcifyChina 2025 Client Benchmark Survey (n=217 multinational enterprises)

The SourcifyChina Advantage: Built for Procurement Excellence

- ✅ Zero-Risk Validation: Every Pro List manufacturer undergoes 12-point verification (financial health, export licenses, ESG compliance, production capacity).

- ✅ Dynamic Performance Tracking: Live supplier scorecards updated post-shipment (on-time delivery, defect rates, communication responsiveness).

- ✅ Seamless Integration: Direct API connectivity with SAP Ariba, Coupa, and Jaggaer for instant RFx deployment.

- ✅ Cost Transparency: All-in FOB pricing models with no hidden fees—validated by our in-country teams.

“SourcifyChina cut our Vietnam sourcing cycle from 6 months to 7 weeks. Their Pro List is the only reason we hit 2025 diversification targets.”

— Head of Global Sourcing, Fortune 500 Industrial Equipment Manufacturer

Call to Action: Secure Your 2026 Supply Chain Resilience Now

Stop losing quarters to unreliable supplier pipelines. With 2026 budgets locked and geopolitical volatility escalating, the window for efficient diversification is closing.

→ Take 90 seconds to unlock your competitive edge:

1. Email [email protected] with subject line: “Pro List Access – [Your Company Name]”

2. WhatsApp +86 159 5127 6160 for immediate portfolio review (24/7 multilingual support)

Within 24 hours, you’ll receive:

🔹 Free access to 3 pre-vetted suppliers matching your component specifications

🔹 Custom timeline analysis showing exact time/cost savings for your 2026 projects

🔹 Priority scheduling for our Q1 2026 Supply Chain Resilience Workshop (limited seats)

Why wait? Every day delayed extends your exposure to single-source risk. SourcifyChina’s Pro List isn’t just a supplier database—it’s your 2026 procurement insurance policy.

Act now. Dominate your 2026 sourcing goals with precision.

📩 [email protected] | 📱 +86 159 5127 6160

SourcifyChina: Data-Driven Sourcing Intelligence Since 2018 | ISO 9001:2015 Certified | 12,000+ Verified Manufacturers Across 18 Countries

© 2026 SourcifyChina. All rights reserved. This report contains proprietary data not for redistribution.

🧮 Landed Cost Calculator

Estimate your total import cost from China.