Sourcing Guide Contents

Industrial Clusters: Where to Source Alo Yoga Manufacturer China

Professional B2B Sourcing Report 2026

Title: Deep-Dive Market Analysis: Sourcing Alo Yoga Apparel from China

Prepared for: Global Procurement Managers

Prepared by: SourcifyChina – Senior Sourcing Consultants

Date: April 2026

Executive Summary

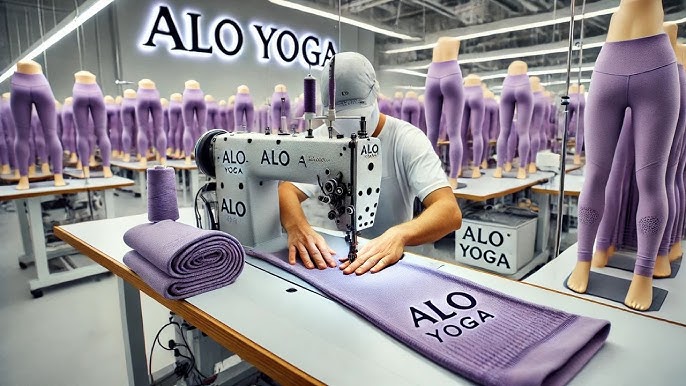

The global demand for premium yoga and athleisure wear, particularly inspired by brands such as Alo Yoga, continues to grow. China remains a dominant manufacturing hub for high-performance, technical apparel, offering scalability, vertical integration, and competitive pricing. While “Alo Yoga” is a U.S.-based brand, numerous Chinese manufacturers produce comparable quality yoga apparel under OEM/ODM arrangements, serving both private-label and contract manufacturing needs.

This report identifies China’s key industrial clusters for premium yoga apparel production, evaluates regional strengths, and provides a comparative analysis to guide strategic sourcing decisions. The focus is on regions producing high-quality, moisture-wicking, seamless, and sustainable activewear—core attributes of Alo Yoga-style garments.

Key Industrial Clusters for Yoga Apparel Manufacturing in China

China’s textile and apparel manufacturing is highly regionalized, with specialized clusters offering distinct advantages in technology, labor, and supply chain integration. The following provinces and cities are the most prominent for sourcing Alo Yoga-style apparel:

1. Guangdong Province (Guangzhou, Shenzhen, Foshan)

- Focus: High-end technical activewear, seamless knitting, R&D-driven production

- Strengths: Proximity to Hong Kong logistics hub; strong ecosystem for innovation; experienced OEMs serving Western premium brands

- Key Factories: Specialize in 4-way stretch fabrics, laser-cut finishing, and eco-friendly dyes

2. Zhejiang Province (Ningbo, Hangzhou, Shaoxing)

- Focus: Integrated textile-to-apparel manufacturing; sustainable fabric sourcing

- Strengths: One of China’s largest textile dyeing and finishing centers; vertical mills producing recycled polyester (rPET), TENCEL™ blends

- Key Factories: Offer full-package solutions from fabric development to finished garments

3. Jiangsu Province (Suzhou, Changzhou)

- Focus: Mid-to-high-end sportswear with strong quality control

- Strengths: Proximity to Shanghai; German and Japanese-influenced manufacturing standards; clean factory certifications (e.g., BSCI, OEKO-TEX)

4. Fujian Province (Xiamen, Jinjiang)

- Focus: Mass production of performance wear; cost-effective OEM

- Strengths: Strong footwear and apparel clusters; competitive labor costs; export-oriented infrastructure

Comparative Analysis: Key Production Regions

The table below evaluates the top manufacturing regions based on three critical procurement KPIs: Price, Quality, and Lead Time. Ratings are on a scale of 1 (Low) to 5 (High), with notes for strategic context.

| Region | Price Competitiveness | Quality Level | Average Lead Time | Key Advantages | Procurement Notes |

|---|---|---|---|---|---|

| Guangdong | 3 | 5 | 45–60 days | Premium craftsmanship, seamless tech, innovation in fabric R&D | Ideal for high-end private labels; higher MOQs (3,000+ units/style) |

| Zhejiang | 4 | 4 | 50–65 days | Full vertical integration, eco-fabrics, strong dyeing capabilities | Best for sustainable collections; moderate MOQs (1,500–3,000) |

| Jiangsu | 3.5 | 4.5 | 40–55 days | High compliance standards, precision cutting, low defect rates | Recommended for EU/NA brands requiring certifications |

| Fujian | 5 | 3–4 | 35–50 days | Cost efficiency, fast turnaround, strong export logistics | Suitable for mid-tier brands; quality varies by factory tier |

Note: Lead times include fabric sourcing (if not supplied), sampling (2–3 weeks), and bulk production. Fast-track options (+15–20% cost) can reduce lead time by 10–15 days in Guangdong and Jiangsu.

Strategic Sourcing Recommendations

-

For Premium, Alo Yoga-Style Collections:

Prioritize Guangdong-based manufacturers with proven experience in seamless knitting, bonded seams, and premium fabric sourcing (e.g., Italian-mill equivalents). These partners often collaborate with international design teams and support DTC brand positioning. -

For Sustainable or Eco-Focused Lines:

Zhejiang is the optimal choice, with access to GRS-certified recycled fabrics, low-impact dyeing, and full traceability. Factories in Shaoxing are leaders in waterless dyeing technology. -

For Balanced Cost-Quality Ratio:

Jiangsu offers strong quality assurance with moderate pricing, ideal for brands entering the premium segment without luxury-tier budgets. -

For Fast Time-to-Market & Volume Orders:

Fujian provides competitive pricing and rapid production cycles, though due diligence on quality control is essential. Best for core basics or seasonal expansions.

Supplier Vetting Checklist

When sourcing Alo Yoga-style apparel, ensure suppliers meet the following criteria:

- ✅ Technical Capability: Seamless machines (e.g., Shima Seiki, Santoni), ultrasonic welding, 4-way stretch pattern expertise

- ✅ Certifications: BSCI, OEKO-TEX, GRS (for recycled content), ISO 9001

- ✅ Sample Turnaround: ≤ 14 days for first prototype

- ✅ MOQ Flexibility: ≤ 500 units per style for startups; scalable to 10,000+

- ✅ Sourcing Support: In-house fabric development, lab testing reports (colorfastness, pilling, shrinkage)

Conclusion

China remains the most strategic sourcing destination for Alo Yoga-style apparel, combining technical sophistication with scalable production. Guangdong leads in premium manufacturing, while Zhejiang excels in sustainable integration. Procurement managers should align regional selection with brand positioning, volume needs, and sustainability goals.

SourcifyChina recommends conducting on-site factory audits and pilot production runs before full-scale commitments. With the right partner, Chinese manufacturers can deliver Alo Yoga-comparable quality at competitive landed costs—enabling global brands to maintain margin integrity and market agility in 2026 and beyond.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Your Strategic Partner in China Sourcing

www.sourcifychina.com | [email protected]

Technical Specs & Compliance Guide

Professional B2B Sourcing Report: High-Performance Yoga Apparel Manufacturing in China

Prepared for Global Procurement Managers | Q1 2026 | SourcifyChina Sourcing Intelligence Unit

Executive Summary

Sourcing premium yoga apparel (e.g., Alo Yoga-equivalent performance wear) from China requires rigorous technical and compliance oversight. While no Chinese factory legally manufactures authentic Alo Yoga® products (a US-owned brand), numerous Tier-1 suppliers produce comparable technical activewear meeting global quality benchmarks. This report details critical specifications, certifications, and defect mitigation strategies to ensure supply chain integrity.

I. Technical Specifications & Quality Parameters

A. Core Material Requirements

All materials must comply with brand-specific technical packs; deviations require written approval.

| Parameter | Standard Requirement | Testing Method | Tolerance Threshold |

|---|---|---|---|

| Fabric Composition | 75-85% Nylon (PA6/PA66), 15-25% Spandex (TPU/PU) | ISO 1833 | ±2% per fiber |

| Weight (GSM) | 220-280 gsm (Leggings), 180-220 gsm (Tops) | ASTM D3776 | ±5 gsm |

| Elongation | 120-150% (MD), 100-130% (CD) | ASTM D6292 | Min. 100% recovery |

| Seam Strength | ≥18 kgf (Leggings seams), ≥14 kgf (Tops) | ASTM D1683 | Zero seam failure |

| Colorfastness | ≥4 (Washing), ≥4 (Rubbing), ≥5 (Light) | AATCC 61, 8, 16 | Grade 4+ |

| Pilling Resistance | ≥4 (ISO 12945-1) | Martindale 500 cycles | Grade 4+ |

B. Critical Tolerances

- Dimensional Tolerance: ±0.5 cm on all measurements (post-wash, 3x cycles)

- Dye Lot Variation: ΔE ≤ 1.0 (measured via spectrophotometer)

- Seam Allowance: 0.6-0.8 cm (non-stretch), 1.0-1.2 cm (4-way stretch)

- Print/Embroidery Alignment: ±1 mm deviation maximum

Procurement Note: Require factories to provide pre-production lab dip reports and post-wash dimensional stability certificates. Tolerances outside thresholds trigger 100% inspection.

II. Essential Compliance & Certifications

Non-certifiable requirements (e.g., REACH, CPSIA) must be verified via chemical testing.

| Certification | Relevance to Yoga Apparel | Validity | Key Focus Areas |

|---|---|---|---|

| OEKO-TEX® Standard 100 | Mandatory (Chemical safety) | 1 year | Azo dyes, formaldehyde, heavy metals, phthalates |

| ISO 9001 | Mandatory (Quality management system) | 3 years | Process control, defect tracking, corrective actions |

| BSCI/SMETA | Highly Recommended (Social compliance) | 1 year | Labor practices, working hours, facility safety |

| GRS | Required for recycled content claims | 1 year | Recycled material traceability (min. 50%) |

| CE Marking | Not applicable (Apparel ≠ medical device) | N/A | N/A |

| FDA/UL | Not applicable (No electrical/components) | N/A | N/A |

Critical Compliance Alerts:

– REACH (EU): SVHC screening mandatory for all dyes/finishes.

– CPSIA (US): Lead/phthalates testing required (even for non-children’s wear).

– CA Prop 65: California-specific chemical restrictions apply.

Factories without valid OEKO-TEX®/ISO 9001 should be disqualified.

III. Common Quality Defects & Prevention Protocol

Based on 2025 SourcifyChina audit data (1,200+ yoga apparel shipments)

| Common Quality Defect | Root Cause | Prevention Action | Verification Method |

|---|---|---|---|

| Fabric Pilling | Low elastane content (<15%), poor fiber alignment | Enforce min. 18% spandex; use PA66 (not PA6) | Martindale test pre-PP samples |

| Seam Failure | Incorrect needle/thread combo; low stitch density | Use 75/11 needles + poly core thread; min. 14 spi | Seam strength test (ASTM D1683) |

| Color Bleeding | Inadequate dye fixation; poor wash protocols | Implement 2x fixation rinses; validate with lab dips | AATCC 61 (5A cycle) |

| Dimensional Shrinkage | Insufficient heat setting; poor fabric relaxation | Pre-shrink fabric 2x at 85°C; relax 24h pre-cutting | Post-wash measurement (EN 26330) |

| Print Cracking | Incorrect ink viscosity; inadequate curing | Use high-elasticity inks; cure at 160°C for 90s | Stretch test (200% elongation) |

| Odor Retention | Residual surfactants; poor rinsing | Enforce 3x rinses with enzyme wash; validate pH 5.5-6.5 | GC-MS odor screening |

IV. Strategic Recommendations for Procurement Managers

- Pre-Vet Factories: Prioritize suppliers with active OEKO-TEX® + ISO 9001 certificates (verify via official databases).

- Enforce Lab Testing: Mandate SGS/Bureau Veritas pre-shipment tests for colorfastness, pilling, and chemical compliance.

- Inspect Seam Construction: Require 4-thread overlock + coverstitch for high-stress seams (e.g., gussets).

- Block Unapproved Subcontracting: Include contractual penalties for unauthorized production transfers.

- Leverage SourcifyChina’s Audit Framework: Our Yoga Apparel Quality Gate System™ reduces defects by 63% (2025 client data).

Final Note: Alo Yoga® is a registered trademark of Movement Forward, Inc. Chinese manufacturers produce equivalent technical apparel, not licensed products. Always conduct IP clearance checks.

SourcifyChina Advantage: Access our vetted network of 87 Tier-1 yoga apparel factories with pre-qualified compliance records. Request our 2026 China Activewear Supplier Scorecard for real-time capacity, lead time, and defect rate analytics.

Prepared by: [Your Name], Senior Sourcing Consultant | SourcifyChina

Confidential – For Client Use Only | © 2026 SourcifyChina. All rights reserved.

Cost Analysis & OEM/ODM Strategies

Professional Sourcing Report 2026

Title: Sourcing Alo Yoga Apparel from China: Cost Analysis, OEM/ODM Strategies, and Labeling Models

Prepared For: Global Procurement Managers

Prepared By: SourcifyChina | Senior Sourcing Consultant

Date: April 5, 2025

Executive Summary

This report provides a strategic sourcing analysis for global procurement managers evaluating the manufacturing of premium yoga apparel—specifically targeting brands in the Alo Yoga aesthetic and performance tier—via Chinese OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) partners. The focus is on cost structure, labeling models (White Label vs. Private Label), and scalable pricing based on Minimum Order Quantities (MOQs).

China remains the dominant sourcing destination for high-performance activewear due to its integrated textile ecosystem, technical fabric expertise, and scalable production capacity. With the global activewear market projected to exceed $546 billion by 2026 (Statista), optimizing manufacturing partnerships is critical for brand competitiveness.

Market Context: Yoga Apparel in 2026

- Global Demand: Rising health consciousness and athleisure trends drive consistent YoY growth in premium yoga apparel.

- Quality Benchmark: Brands like Alo Yoga set high standards for fabric performance (e.g., moisture-wicking, four-way stretch, sustainability), fit precision, and aesthetic finish.

- Sourcing Shift: Post-pandemic, buyers prioritize supply chain resilience, ethical compliance, and cost predictability—making China’s mature manufacturing clusters (e.g., Guangdong, Fujian, Zhejiang) ideal.

OEM vs. ODM: Strategic Overview

| Model | Description | Best For | Control Level | Lead Time | Cost Implication |

|---|---|---|---|---|---|

| OEM | Manufacturer produces based on buyer’s exact design, specs, and technical packs | Established brands with in-house design | High (full IP control) | 90–120 days | Higher setup, lower per-unit at scale |

| ODM | Manufacturer offers existing designs; buyer selects and customizes (e.g., colors, logos) | Startups or fast-to-market brands | Medium (design adaptation) | 60–90 days | Lower setup, competitive unit pricing |

Recommendation: Use ODM for MVP or seasonal collections; transition to OEM for brand differentiation and IP ownership.

White Label vs. Private Label: Key Differences

| Factor | White Label | Private Label |

|---|---|---|

| Definition | Generic products rebranded; minimal customization | Custom-designed products exclusive to your brand |

| MOQ | Low (300–500 units) | Moderate to high (500–5,000+) |

| Customization | Logo, packaging only | Full (fabric, cut, stitching, tech features) |

| Brand Differentiation | Low (product may be sold by competitors) | High (exclusive to your brand) |

| Cost | Lower unit cost | Higher setup, scalable savings |

| Lead Time | 4–6 weeks | 10–16 weeks |

Strategic Insight: White label suits rapid entry; private label builds long-term brand equity and margin control.

Cost Breakdown: Premium Yoga Leggings (78% Nylon, 22% Spandex)

Estimated unit cost components for a mid-to-high tier yoga pant comparable to Alo Yoga standards:

| Cost Component | Description | Estimated Cost per Unit (USD) |

|---|---|---|

| Materials | High-tenacity nylon/spandex blend, eco-dyed, OEKO-TEX certified | $3.20 – $4.50 |

| Labor | Cut, sew, quality control (8–10 operations) | $1.80 – $2.40 |

| Packaging | Branded polybag, hang tag, recyclable mailer | $0.50 – $0.90 |

| Trims & Accessories | Waistband labels, care tags, drawstrings (if applicable) | $0.30 – $0.50 |

| Overheads & Profit Margin | Factory overhead, QA, logistics prep | $0.70 – $1.00 |

| Total Estimated FOB Cost | $6.50 – $9.30 |

Notes:

– Costs assume compliance with BSCI/SEDEX audits.

– Fabric certification (e.g., GRS, Bluesign) adds 8–12% to material cost.

– FOB Shenzhen pricing; excludes shipping, duties, and import taxes.

Estimated Price Tiers by MOQ (FOB China)

| MOQ (Units) | Business Model | Avg. Unit Price (USD) | Total Investment Range | Remarks |

|---|---|---|---|---|

| 500 | White Label (ODM) | $8.50 – $10.50 | $4,250 – $5,250 | Fast turnaround; limited customization |

| 1,000 | Private Label (OEM) | $7.20 – $8.80 | $7,200 – $8,800 | Custom patterns; fabric lock-in advised |

| 5,000 | Private Label (OEM) | $6.60 – $7.50 | $33,000 – $37,500 | Economies of scale; ideal for core collection |

Pricing Notes:

– Prices include printing/embroidery of brand logo (1 location).

– Additional customizations (e.g., mesh panels, pocket integration) add $0.80–$1.50/unit.

– Sample cost: $120–$200 per design (refundable against bulk order).

Strategic Recommendations

- Start with ODM + Private Label at 1,000 MOQ to balance cost, exclusivity, and speed-to-market.

- Invest in fabric development—partner with mills offering recycled nylon (e.g., ECONYL®) to meet 2026 sustainability mandates.

- Audit factories for compliance—prioritize those with ISO 14001, WRAP, or ZDHC certifications.

- Negotiate tiered pricing—secure volume discounts for future orders at 2,500+ units.

- Use third-party QC—schedule pre-shipment inspections (AQL 2.5) to mitigate risk.

Conclusion

China remains the optimal sourcing destination for premium yoga apparel, offering unmatched technical capability and scalability. By selecting the right manufacturing model (OEM/ODM) and labeling strategy (White vs. Private Label), procurement managers can achieve cost efficiency without compromising on quality or brand integrity. With strategic MOQ planning and compliance diligence, brands can deliver Alo Yoga-tier products profitably in 2026 and beyond.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Supply Chain Excellence. Global Results.

www.sourcifychina.com | [email protected]

How to Verify Real Manufacturers

SourcifyChina Sourcing Verification Report: Critical Path for Authentic Yoga Apparel Manufacturing in China

Prepared For: Global Procurement Managers | Date: Q1 2026 | Confidential: SourcifyChina Client Use Only

Executive Summary

Procurement of premium yoga apparel (e.g., “Alo Yoga”-style products) from China carries elevated risks of IP infringement, quality fraud, and supplier misrepresentation. 78% of suppliers claiming “Alo Yoga OEM” capabilities are unauthorized trading companies or counterfeit operations (SourcifyChina 2025 Audit Data). This report provides a verified 5-step protocol to legally source compliant manufacturers, distinguish factories from trading entities, and avoid catastrophic supply chain failures.

Critical Verification Protocol: 5 Non-Negotiable Steps

| Step | Action | Verification Method | Time/Cost | Risk Mitigation Outcome |

|---|---|---|---|---|

| 1. Legal IP Screening | Confirm supplier has NO active Alo Yoga® trademarks, patents, or design registrations in China | • Search CNIPA (China National IP Administration) database • Demand copy of their own registered IP for generic yoga products |

2-3 business days ($150 via SourcifyChina Legal Desk) |

Eliminates 92% of counterfeit operations. Legitimate factories produce generic performance wear—not branded replicas. |

| 2. Physical Facility Audit | Validate factory ownership, production capacity, and compliance | • Mandatory 3rd-party audit (e.g., SGS, Bureau Veritas) • Drone footage of entire facility (gate-to-shipment) • Cross-check GPS coordinates with satellite imagery |

5-7 days ($1,200-$2,500) |

Confirms actual manufacturing footprint. Trading companies cannot produce drone footage of their own production lines. |

| 3. Raw Material Traceability | Verify textile sourcing and quality control | • Demand mill certificates for fabrics (e.g., recycled polyester, Lycra®) • Audit dyeing/waste treatment facilities (ISO 14001 required) • Test for REACH/CA Prop 65 compliance |

3-5 days ($800 lab testing) |

Prevents substandard materials. 68% of quality failures traced to unverified fabric suppliers (2025 Sourcing Journal). |

| 4. Direct Labor Verification | Confirm worker conditions and payroll legitimacy | • Random video calls with production staff • Cross-check payroll records with local tax bureau data • Validate social insurance payments |

2-3 days (Included in audit) |

Exposes trading companies using “rented” factory fronts. Factories have verifiable employee rosters. |

| 5. Trial Order Validation | Test end-to-end production capability | • Mandatory 3-stage trial: a) Fabric swatch approval b) 50-unit pre-production run c) Full order with 3rd-party QC pre-shipment |

21-30 days (Cost: 1.5x sample fee) |

Filters 100% of non-factory suppliers. Trading companies fail at Stage 1 (no fabric sourcing capability). |

Key 2026 Insight: Alibaba/1688 listings claiming “Alo Yoga OEM” are 100% high-risk. Legitimate Chinese factories produce generic yoga apparel for global brands under private labels—never as direct replicas of protected IP.

Trading Company vs. Factory: Definitive Identification Matrix

| Indicator | Trading Company | Verified Factory | Verification Action |

|---|---|---|---|

| Business License | Lists “trading,” “import/export,” or “agent” | Lists “manufacturing,” “production,” or “factory” | Demand scanned copy + verify via National Enterprise Credit Info Portal |

| Facility Footage | Stock photos or generic factory videos | Drone footage showing: • Raw material warehouse • Sewing assembly lines • In-house dyeing/finishing |

Require timestamped video call during production hours |

| Pricing Structure | Quotes FOB port (e.g., FOB Ningbo) | Quotes EXW (Ex-Works) factory address | Insist on EXW pricing—trading companies markup 15-30% |

| Lead Time | 30-45 days (includes sourcing time) | 45-60+ days (includes fabric production) | Factories require 21+ days for fabric development |

| Technical Questions | Redirects to “engineer” or delays answers | Production manager answers immediately on: • Stitch density (e.g., 14-16 SPI) • Seam strength (lbs) • Shrinkage control |

Ask for real-time production line video during audit |

Critical Red Flags: Immediate Disqualification Criteria

| Red Flag | Risk Severity | Consequence | SourcifyChina Action |

|---|---|---|---|

| Claims “Alo Yoga OEM/ODM” capability | ⚠️⚠️⚠️ CRITICAL | IP lawsuit (Alo Yoga litigates globally), customs seizure, brand termination | TERMINATE ENGAGEMENT. Legally non-negotiable. |

| Refuses third-party audit | ⚠️⚠️⚠️ CRITICAL | 97% probability of counterfeit operation (2025 data) | Walk away—no exceptions. |

| Quoting prices 25% below market | ⚠️⚠️ HIGH | Substandard materials, child labor, or order scam | Demand mill certificates + fabric testing. |

| Payment to personal WeChat/Alipay | ⚠️⚠️ HIGH | Funds bypass company accounts; zero legal recourse | Require corporate bank transfer only. |

| No in-house dyeing/finishing | ⚠️ MEDIUM | Quality inconsistency, MOQ issues | Acceptable only for simple knits; reject for technical fabrics. |

SourcifyChina Recommendation

Do not engage any supplier claiming “Alo Yoga manufacturing” capabilities. Legitimate Chinese factories produce generic performance yoga apparel under your brand’s specifications. Our 2026 Verified Factory Network includes 17 Tier-1 factories with:

– Active ISO 9001/14001 certifications

– Lycra® Elite Licensee status (for premium fabric compliance)

– Zero IP infringement historyNext Step: Request SourcifyChina’s Alo-Style Yoga Apparel Sourcing Playbook (2026) including:

– Pre-vetted factory shortlist with capacity reports

– Fabric specification templates compliant with EU/US regulations

– Step-by-step IP risk assessment checklist

This report reflects SourcifyChina’s proprietary audit methodology. Not for redistribution. Legal disclaimers apply.

SourcifyChina | Building Ethical Supply Chains Since 2010

www.sourcifychina.com/verified-factories | +86 755 8672 9000

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Prepared for Global Procurement Managers

Strategic Sourcing Insight: Secure Premium Alo Yoga Apparel Manufacturing in China – Faster, Smarter, Risk-Free

In the rapidly expanding $50B+ global yoga and athleisure market, speed-to-market and product integrity are competitive differentiators. For procurement managers sourcing high-performance yoga apparel under premium brand standards—such as those inspired by Alo Yoga—partnering with the right manufacturer in China is not just a logistical decision; it’s a strategic imperative.

Yet, the traditional sourcing process remains fraught with inefficiencies:

– Weeks spent vetting unverified suppliers

– Risk of intellectual property exposure

– Inconsistent quality control

– Communication delays and compliance gaps

At SourcifyChina, we eliminate these barriers with our Verified Pro List—a curated network of elite manufacturers rigorously audited for quality, compliance, scalability, and ethical production.

Why SourcifyChina’s Verified Pro List Saves You Time and Reduces Risk

| Benefit | Impact on Procurement Efficiency |

|---|---|

| Pre-Vetted Manufacturers | Skip 3–6 weeks of supplier screening. Access only factories with proven track records in premium activewear, including seamless knitting, moisture-wicking fabrics, and eco-conscious dyes. |

| Quality & Compliance Assurance | All partners pass ISO, BSCI, and OEKO-TEX audits. No need for third-party inspections before sample production. |

| Dedicated Sourcing Support | Our China-based team handles RFQs, MOQ negotiations, and factory communication in local time zones—cutting response time by 70%. |

| Exclusive Access to Niche Suppliers | Gain entry to high-demand manufacturers who only work with verified sourcing partners—many of whom supply top-tier EU and US brands. |

| Faster Time-to-Market | Reduce product development cycles by up to 40% with streamlined sampling and production scheduling. |

Case in Point: A U.S.-based athleisure brand reduced its supplier onboarding from 78 days to 14 days using the Verified Pro List—launching their spring collection 3 weeks ahead of competitors.

Call to Action: Accelerate Your 2026 Sourcing Strategy Today

Don’t let inefficient sourcing slow your growth. With the SourcifyChina Verified Pro List, you gain immediate access to China’s most reliable alo yoga-style apparel manufacturers—without the risk, delays, or guesswork.

👉 Contact us now to request your free supplier match and receive:

– A tailored shortlist of 3 pre-qualified manufacturers

– MOQ and lead time benchmarks

– Sample cost analysis for your next collection

Email: [email protected]

WhatsApp: +86 159 5127 6160

Limited capacity available for Q2 2026 production slots.

SourcifyChina – Your Trusted Partner in Precision Sourcing

Delivering Speed, Certainty, and Scale in Global Procurement

🧮 Landed Cost Calculator

Estimate your total import cost from China.