The global barbed wire (alambre de púas) market is experiencing steady expansion, driven by rising demand for perimeter security across industrial, agricultural, and residential sectors. According to a 2023 report by Mordor Intelligence, the global barbed wire market was valued at approximately USD 3.2 billion and is projected to grow at a CAGR of 5.1% from 2023 to 2028. This growth is fueled by increasing infrastructure development, urbanization, and heightened focus on border and asset protection, particularly in emerging economies. As demand rises, manufacturers are scaling production, enhancing corrosion resistance through galvanization and PVC coating technologies, and complying with international safety standards. In this competitive landscape, a handful of key players have distinguished themselves through innovation, global distribution networks, and consistent product quality—setting the benchmark in the alambre de púas industry.

Top 5 Alambre De Puas Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Alambre De Púas Inchalam

Domain Est. 2009

Website: common-nails.com

Key Highlights: Alambre De Púas Inchalam Manufacturers, Factory, Suppliers From China, Special emphasis around the packaging of merchandise to avoid any damage during ……

#2 Alambre De Puas $ 70

Domain Est. 2024

Website: almagroup-sa.com

Key Highlights: Manufacturer site is here Open in new window Find furniture and interior items easily! Click here for Askul’s general furniture homepage. Open in new window ……

#3 Alambre de púas Cebu

Domain Est. 1993

Website: proalco.bekaert.com

Key Highlights: Es un alambre de púas de tradición para los ganaderos colombianos. Beneficios: Resistencia a la rotura. Puntas afiladas. Apariencia brillante. Torsión constante ……

#4 ALAMBRE DE PÚAS

Domain Est. 2012

Website: magnacero.com

Key Highlights: El alambre de púas de Magnacero está conformado por dos alambres galvanizados trenzados longitudinalmente y sujetados con otros dos alambres torcidos que ……

#5 Alambre de Púas Motto Ganadero E

Website: inchalam.cl

Key Highlights: Motto Livestock Barbed Wire is a triple galvanized and high resistance wire. Its alternating twist direction acts as a spring. It has 4 tip barbs….

Expert Sourcing Insights for Alambre De Puas

2026 Market Trends for Alambre De Puas

The global market for alambre de púas, commonly known as barbed wire, is expected to experience steady growth and notable shifts by 2026, driven by evolving security needs, infrastructure development, and regional economic dynamics. This analysis explores the key trends shaping the alambre de púas market in the lead-up to 2026.

Rising Demand in Security and Perimeter Protection

One of the primary drivers of the alambre de púas market is the increasing need for physical security across residential, commercial, industrial, and governmental sectors. With rising concerns over theft, trespassing, and border control, especially in regions with political instability or high crime rates, demand for cost-effective and durable fencing solutions like barbed wire continues to grow. By 2026, integration with smart surveillance systems may enhance the appeal of traditional barbed wire installations, particularly in hybrid security perimeters.

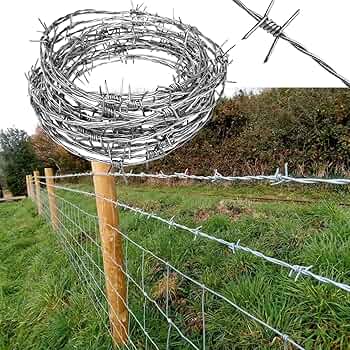

Infrastructure and Agricultural Applications

In developing economies, infrastructure expansion—including roads, railways, and utility corridors—requires extensive boundary demarcation and protection. Similarly, the agricultural sector, especially in Latin America, Africa, and parts of Asia, relies heavily on alambre de púas for livestock containment and farm boundary control. As rural development initiatives gain momentum, demand for durable and affordable fencing materials like barbed wire is projected to rise through 2026.

Regional Market Dynamics

Latin America remains a significant consumer and producer of alambre de púas, with countries like Mexico, Brazil, and Colombia showing consistent demand due to agricultural activity and security concerns. In Africa, growing urbanization and land privatization are increasing the need for fencing solutions. Meanwhile, in North America and Europe, usage is more regulated and often limited to agricultural or military applications, but replacement demand and border security projects (e.g., U.S.-Mexico border) sustain market activity.

Material and Environmental Considerations

By 2026, environmental and regulatory standards may influence the production of alambre de púas. Galvanized steel remains the dominant material due to its durability and corrosion resistance, but there is growing interest in eco-friendly coatings and recyclable materials. Manufacturers are expected to adopt more sustainable practices to comply with environmental regulations, particularly in Europe.

Technological Innovations and Market Competition

Although alambre de púas is a traditional product, innovations such as barbed tape (razor wire), anti-climb variants, and integration with electronic detection systems are expanding its functionality. Competition among manufacturers is intensifying, with price, quality, and customization becoming key differentiators. Chinese and Indian producers continue to dominate the global supply chain due to cost advantages, but regional manufacturers are gaining ground through localized production and faster delivery.

Conclusion

By 2026, the alambre de púas market will remain resilient due to persistent demand in security and agriculture. While it faces competition from high-tech alternatives, its affordability, simplicity, and effectiveness ensure continued relevance. Market growth will be most pronounced in emerging economies, supported by infrastructure development and rising security needs. Producers who adapt to environmental standards and offer value-added variants are likely to capture greater market share in the coming years.

Common Pitfalls When Sourcing Alambre De Puas (Barbed Wire)

Sourcing Alambre De Puas, commonly known as barbed wire, can be a complex process, especially when balancing cost, quality, and compliance. Buyers often encounter several recurring issues that can compromise safety, durability, and legal compliance. Below are some of the most common pitfalls to watch for.

1. Compromised Material Quality

One of the most frequent issues is receiving barbed wire made from substandard steel or with inadequate galvanization. Low-quality wire may use thin-gauge steel or insufficient zinc coating, leading to premature rust and structural failure. This is particularly problematic in high-moisture or coastal environments.

- Red Flags: Uneven coating, flaking zinc, visible rust spots upon delivery.

- Best Practice: Specify minimum wire gauge (e.g., 12–14 gauge) and galvanization standards (e.g., ASTM A641 or G60 coating weight).

2. Inconsistent Barbing Pattern and Spacing

Poorly manufactured barbed wire often features irregular barb spacing or weak barb attachment. This reduces effectiveness for security or livestock containment and increases injury risk during installation.

- Red Flags: Missing barbs, barbs that rotate easily, inconsistent spacing (should typically be 4–6 inches apart).

- Best Practice: Request sample reels and conduct visual and tactile inspections before bulk ordering.

3. Lack of Compliance with International Standards

Many suppliers, especially from regions with lax manufacturing regulations, may not adhere to recognized international standards such as ISO, ASTM, or EN norms. This can lead to legal or liability issues, particularly in government or infrastructure projects.

- Red Flags: Vague or missing certifications, refusal to provide test reports.

- Best Practice: Require documentation of compliance with relevant standards and verify through third-party testing if necessary.

4. Intellectual Property and Brand Infringement

Some suppliers falsely label their products as branded (e.g., claiming “Heck Barbed Wire” or other trademarks) when they are counterfeit. This not only violates intellectual property rights but also misleads buyers about quality expectations.

- Red Flags: Suspiciously low prices for well-known brands, packaging that mimics but doesn’t match authentic branding.

- Best Practice: Source directly from authorized distributors or verify trademark registration and licensing with the supplier.

5. Inadequate Packaging and Corrosion During Transit

Barbed wire is often shipped in harsh conditions. Poor packaging—such as lack of protective wrapping or exposure to moisture—can result in corrosion before the product even reaches the site.

- Red Flags: Unwrapped coils, visible moisture damage upon arrival.

- Best Practice: Require weather-resistant packaging and moisture barriers, especially for ocean freight.

6. Unreliable Supply Chain and Lead Time Delays

Sourcing from distant or unverified suppliers can lead to unpredictable delivery times, inventory shortages, or order cancellations.

- Red Flags: Vague delivery timelines, no track record or verifiable references.

- Best Practice: Conduct due diligence on suppliers, start with small trial orders, and use contracts with clear delivery terms.

7. Misrepresentation of Product Specifications

Some suppliers may exaggerate wire thickness, zinc coating weight, or tensile strength in their product descriptions. This misrepresentation can lead to performance failures in the field.

- Red Flags: Spec sheets without verifiable test data, reluctance to provide mill certificates.

- Best Practice: Request mill test certificates (MTCs) and consider independent lab testing for critical applications.

By being aware of these common pitfalls and implementing strict quality control and supplier vetting processes, buyers can ensure they source reliable, safe, and compliant Alambre De Puas for their projects.

Logistics & Compliance Guide for Alambre De Puas (Barbed Wire)

Overview of Alambre De Puas

Alambre De Puas, commonly known as barbed wire, is a type of steel fencing wire with sharp edges or points arranged at intervals along the strand. It is widely used in agriculture, security perimeters, and industrial applications. Due to its nature as a sharp, potentially hazardous material, the logistics and compliance handling of barbed wire require careful attention to safety, transportation regulations, and local laws.

Regulatory Classification and Documentation

Barbed wire is typically classified as a controlled or regulated item in many jurisdictions due to its potential use as a weapon or security hazard. Proper classification under the Harmonized System (HS Code) is essential for international shipping. Common HS codes include 7313.00 (barbed wire, whether or not in coils) or country-specific variations. Accurate documentation, including commercial invoices, packing lists, and certificates of origin, must reflect this classification. Some countries may require import permits or declarations for security-related goods.

Transportation and Packaging Requirements

Barbed wire must be securely packaged to prevent injuries during handling and transit. Standard practices include:

– Coiling and wrapping in protective plastic or cardboard

– Securing with steel or plastic strapping

– Marking packages with hazard labels (e.g., “Sharp Edges,” “Handle with Care”)

– Using pallets for bulk shipments to ensure stability

Transport vehicles should be inspected to ensure secure loading and weather protection, especially for ocean freight. Mismanagement during transport can lead to damage, liability, or customs delays.

Safety Handling and Worker Protection

All personnel involved in the handling, loading, or unloading of barbed wire must be trained in safety protocols. Mandatory protective equipment includes:

– Cut-resistant gloves

– Safety goggles

– Long-sleeve clothing and steel-toed boots

Work areas should be clearly marked, and first aid kits with treatments for puncture wounds must be readily available. Employers must comply with OSHA (or equivalent) safety standards in their region.

Import and Export Compliance

Exporters and importers must verify compliance with both origin and destination country regulations. Key considerations include:

– Prohibited or restricted end-uses (e.g., use in prisons, military zones)

– End-user certification requirements

– Embargoes or sanctions on certain countries

Certain governments may regulate barbed wire under dual-use or strategic goods legislation. Always consult local customs authorities or a licensed customs broker before shipping.

Storage and Inventory Management

Stored barbed wire should be kept in a dry, secure area to prevent rust and unauthorized access. Coils should be elevated off the ground and segregated from other inventory to avoid accidental contact. Access should be restricted to authorized personnel only, particularly in sensitive locations.

Environmental and Disposal Considerations

Barbed wire is typically made from galvanized steel, which is recyclable. At end-of-life, it should be disposed of in accordance with local environmental regulations. Do not abandon or leave barbed wire in natural areas, as it poses risks to wildlife and public safety.

Country-Specific Restrictions

Regulations vary significantly by country:

– Mexico: Barbed wire is legal but may require documentation for bulk purchases; some states monitor sales for security reasons.

– European Union: Subject to REACH and general product safety directives; use in public spaces may be restricted.

– Australia: Classified as a security item; importers may need to comply with state-based fencing regulations.

– United States: Generally unrestricted for agricultural use, but local zoning laws may limit installation.

Always research and comply with local laws before shipping or deploying barbed wire.

Conclusion

Proper logistics and compliance for Alambre De Puas involve careful attention to packaging, documentation, safety, and legal requirements. By following this guide, businesses can ensure safe transport, avoid regulatory penalties, and maintain responsible supply chain practices. Regular audits and updates to compliance procedures are recommended to adapt to changing regulations.

In conclusion, sourcing alambre de puas (barbed wire) requires careful consideration of quality, supplier reliability, compliance with local regulations, and cost-effectiveness. Whether for agricultural fencing, security applications, or construction projects, it is essential to evaluate suppliers based on material specifications—such as gauge, zinc coating (e.g., galvanized steel), and strand count—to ensure durability and performance in the intended environment. Additionally, establishing partnerships with reputable manufacturers or distributors, both locally and internationally, can enhance supply chain efficiency and product consistency. By prioritizing safety standards, ethical sourcing practices, and long-term value over initial cost, businesses can effectively secure high-quality barbed wire that meets technical requirements and project demands.