The global demand for airtight bulk storage containers has surged in recent years, driven by increasing emphasis on food safety, shelf-life extension, and efficient supply chain logistics across the food & beverage, pharmaceutical, and agricultural sectors. According to Mordor Intelligence, the global food storage containers market was valued at USD 9.8 billion in 2023 and is projected to grow at a CAGR of 5.2% from 2024 to 2029. This growth is further supported by rising consumer awareness about contamination prevention and moisture control, particularly in emerging economies. With stringent regulatory standards and evolving industrial needs, manufacturers are innovating to deliver high-capacity, durable, and hermetically sealed storage solutions. As the market expands, a select group of manufacturers have emerged as leaders, combining advanced materials, scalable production, and compliance with international safety standards to meet escalating global demand. The following analysis identifies the top 10 airtight bulk storage container manufacturers shaping this growing industry.

Top 10 Airtight Bulk Storage Containers Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial Container

Domain Est. 1997

Website: industrialcontainer.com

Key Highlights: Browse Industrial Container and Supply Company Products. Plastic Bottles, Glass Bottles, Lids & Closures, Buckets & Pails, Specialty Items, Food Storage….

#2 Airtight

Domain Est. 2011

Website: onyxcontainers.com

Key Highlights: This is a wholesale order only site. To shop please click here · login … Manufacturer and wholesaler of non-plastic storage containers….

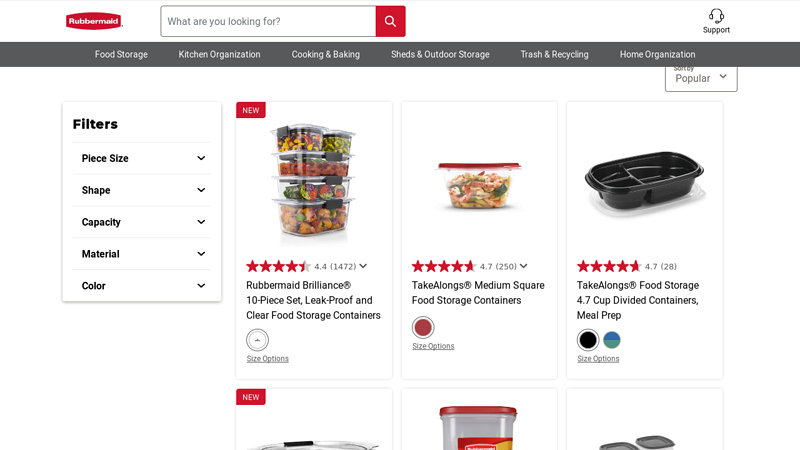

#3 Food Storage Containers

Domain Est. 1994

Website: rubbermaid.com

Key Highlights: Organize your kitchen, pantry, and cabinets with Rubbermaid® air-tight food containers perfect for meal prep, snacks, and more. From everyday containers to meal ……

#4 Plastic Storage and Measuring

Domain Est. 1997

#5 Food containers

Domain Est. 1997

Website: araven.com

Key Highlights: If you are looking for food containers, you will find a wide range of these products for the hotel and catering industry. Come in!…

#6 Container Supply Co.

Domain Est. 2000

Website: containersupplycompany.com

Key Highlights: Container Supply Co. provides quality food-grade storage containers in plastic and metal for all of your food storage needs….

#7 Flexcon

Domain Est. 2004

Website: flexcontainer.com

Key Highlights: Flexcon engineers material handling solutions for any application. We supply totes, ASRS bins, and custom systems to solve your specific workflow ……

#8 Airtight Food Storage Containers

Domain Est. 2005

Website: tightvac.com

Key Highlights: Free delivery over $25 14-day returnsTightvac airtight food storage containers are great to keep your food items fresh, organized, and within reach. Available in many colors and si…

#9 Dalcini Stainless

Domain Est. 2015

Website: dalcinistainless.com

Key Highlights: 30-day returnsOur products are made with the highest quality of FDA-compliant, food-grade stainless steel without any plastic, paints, dyes or coatings….

#10 page

Domain Est. 2018

Website: vtopmart.net

Key Highlights: Free deliveryAirtight Food Storage Containers with Lids, Vtopmart 24 pcs Plastic Kitchen and Pantry Organization Canisters for Cereal, Dry Food, Flour and Sugar, BPA ……

Expert Sourcing Insights for Airtight Bulk Storage Containers

H2: 2026 Market Trends for Airtight Bulk Storage Containers

The global market for airtight bulk storage containers is poised for significant transformation and expansion by 2026, driven by evolving consumer demands, technological advancements, and increasing regulatory focus on food safety and sustainability. These containers, essential in food processing, pharmaceuticals, agriculture, and industrial chemical storage, are witnessing a shift toward smarter, more eco-conscious, and efficient solutions.

-

Growing Demand in Food and Agriculture Sectors

By 2026, the food and agriculture industries will remain primary growth drivers for airtight bulk storage containers. Rising awareness about food preservation, shelf-life extension, and reduction of post-harvest losses is accelerating adoption—particularly in emerging economies. Innovations such as UV-resistant polymers and oxygen-barrier materials are enhancing container performance, reducing spoilage and maintaining nutritional quality. -

Expansion of E-Commerce and Home Storage Solutions

The surge in e-commerce and direct-to-consumer food delivery models is fueling demand for consumer-grade airtight bulk storage containers. By 2026, households are expected to increasingly invest in modular, stackable, and smart-labeled containers for pantry organization, driven by minimalist lifestyles and zero-waste movements. This trend is supported by the rise of bulk grocery shopping and refill stations in retail. -

Sustainability and Circular Economy Initiatives

Environmental regulations and consumer preference for sustainable packaging will shape material innovation. By 2026, manufacturers are projected to adopt biodegradable polymers, recycled plastics, and reusable container systems. Major players are investing in closed-loop recycling programs and designing containers for durability and repeated use, aligning with global circular economy goals. -

Smart and IoT-Integrated Containers

A key technological trend by 2026 is the integration of IoT sensors and RFID tags into airtight storage systems. These smart containers monitor internal conditions such as humidity, temperature, and gas composition in real time—critical for pharmaceutical cold chains and precision agriculture. Data from these systems enable predictive maintenance, inventory management, and enhanced traceability. -

Regional Market Growth and Industrialization

Asia-Pacific is expected to dominate market growth by 2026, led by rapid industrialization, urbanization, and government investments in food infrastructure in countries like India, China, and Indonesia. Meanwhile, North America and Europe will emphasize premium, high-barrier containers compliant with FDA and EU safety standards, particularly for organic and specialty foods. -

Consolidation and Innovation Among Suppliers

The competitive landscape will see increased mergers and acquisitions as companies aim to broaden product portfolios and geographic reach. Innovation in sealing technologies—such as vacuum locks, silicone gaskets, and automated closure systems—will differentiate market leaders. Customization for niche applications (e.g., cannabis storage, medical-grade dry goods) will also rise.

In conclusion, by 2026, the airtight bulk storage container market will be characterized by intelligent design, sustainability, and digital integration. Stakeholders who prioritize innovation, regulatory compliance, and eco-friendly practices will be best positioned to capture value in this dynamic and expanding sector.

Common Pitfalls When Sourcing Airtight Bulk Storage Containers (Quality & Intellectual Property)

Sourcing airtight bulk storage containers—especially for food, pharmaceuticals, or sensitive materials—requires careful attention to both quality and intellectual property (IP) considerations. Overlooking these aspects can lead to product spoilage, regulatory non-compliance, legal disputes, and reputational damage. Below are key pitfalls to avoid:

Poor Material Quality and Construction

One of the most frequent issues is selecting containers made from substandard materials or with weak construction. Low-grade plastics may degrade over time, leach chemicals, or fail under pressure or temperature fluctuations. Thin seams or poorly sealed lids compromise airtight integrity, leading to contamination, moisture ingress, or loss of product freshness.

Avoidance Tip: Source from suppliers who provide material certifications (e.g., FDA, NSF, or EU food-contact compliance) and conduct independent testing for airtight performance (e.g., vacuum or pressure retention tests).

Inconsistent Manufacturing Tolerances

Even with quality materials, inconsistent molding or assembly can result in containers that don’t seal uniformly. Variations in lid fit, gasket alignment, or thread precision can render the container non-airtight when scaled across large orders.

Avoidance Tip: Request production samples from multiple batches and perform dimensional checks and seal integrity tests before full-scale production.

Lack of Intellectual Property Due Diligence

Many airtight container designs—especially patented closure systems, gasket configurations, or unique structural features—are protected by IP rights. Sourcing generic copies of patented designs, even unintentionally, can expose your business to infringement lawsuits, customs seizures, or forced product recalls.

Avoidance Tip: Conduct a patent landscape search before finalizing designs. Work with suppliers who can provide freedom-to-operate assurances or develop proprietary, licensed, or non-infringing alternatives.

Misrepresentation of IP Ownership by Suppliers

Some manufacturers may claim to own the design of a container when they do not. They might be reselling or copying a third party’s IP, leaving the buyer liable if legal action arises. This is common with OEM suppliers in competitive markets.

Avoidance Tip: Include IP indemnification clauses in contracts and require suppliers to disclose any third-party design rights associated with the product.

Inadequate Regulatory Compliance Documentation

Containers used in regulated industries must meet specific standards (e.g., ISO 22000, GMP, or USP Class VI). Suppliers may claim compliance without proper documentation, putting end users at risk during audits or inspections.

Avoidance Tip: Request and verify actual test reports, compliance certificates, and manufacturing facility audit records before procurement.

Overlooking Long-Term Performance and Durability

Some containers perform well initially but degrade after repeated use, UV exposure, or stacking under load. This can lead to seal failure or container collapse during transport or storage.

Avoidance Tip: Evaluate accelerated aging tests and real-world durability data, especially if containers will be reused or stored long-term.

Failure to Secure Custom Design Rights

If you commission a custom container design, failing to formally assign IP ownership in writing means the supplier may retain rights to sell the same design to competitors.

Avoidance Tip: Use a clear development agreement that transfers all IP rights to your company upon payment, including design files, molds, and tooling.

By proactively addressing these quality and IP-related pitfalls, businesses can ensure reliable, compliant, and legally secure sourcing of airtight bulk storage containers.

Logistics & Compliance Guide for Airtight Bulk Storage Containers

This guide outlines best practices and regulatory considerations for the safe and compliant transportation, handling, storage, and use of airtight bulk storage containers. These containers are commonly used across industries such as food, pharmaceuticals, chemicals, and agriculture to preserve product integrity by preventing moisture ingress, oxygen exposure, contamination, and spoilage.

Transportation & Handling

Ensure containers are properly secured during transit to prevent damage, tipping, or leakage. Use pallets, straps, or containers with integrated stacking features to maintain stability. Always follow manufacturer guidelines for maximum stacking height and load capacity. Avoid dropping or impacting containers, as structural damage can compromise airtight seals. When handling with forklifts or pallet jacks, ensure forks are centered and level to prevent deformation.

Loading & Sealing Procedures

Before loading, inspect each container for cracks, warping, or damaged gaskets. Clean and dry the container thoroughly if reused. Load materials carefully to avoid overfilling—maintain the recommended headspace to allow for thermal expansion and ensure proper lid closure. Use calibrated torque tools when applying bolted or clamp-style lids to achieve manufacturer-specified sealing pressure. For twist-seal or bayonet closures, confirm audible or tactile feedback indicating a complete seal.

Storage Conditions

Store containers in a clean, dry, temperature-controlled environment whenever possible. Avoid direct sunlight and extreme temperatures that may degrade materials (e.g., UV exposure for polyethylene containers). Elevate containers off the floor using pallets to prevent moisture absorption and facilitate cleaning. Segregate containers by content type to prevent cross-contamination, especially when storing food-grade vs. chemical materials.

Regulatory Compliance

Adhere to relevant regulations based on the stored material:

-

Food-Grade Applications: Ensure containers comply with FDA 21 CFR standards for food contact materials. Use only containers certified as food-safe with appropriate labeling (e.g., NSF, FDA-compliant). Maintain records of supplier certifications and material safety data sheets (MSDS/SDS).

-

Pharmaceutical & Medical Use: Follow cGMP (current Good Manufacturing Practices) and applicable ISO standards (e.g., ISO 9001, ISO 13485). Containers must support traceability and prevent contamination. Documentation of cleaning and sterilization procedures is required.

-

Hazardous Materials: For chemical storage, comply with OSHA HAZCOM, DOT 49 CFR (for transport), and local environmental regulations. Use UN-certified containers where required, clearly label contents with GHS-compliant hazard pictograms, and ensure vapor-tight seals for volatile substances.

Cleaning & Reuse Protocols

When reusing containers, implement a documented cleaning and inspection process. Clean with food-safe or industry-appropriate detergents, rinse thoroughly, and dry completely before reuse. Inspect gaskets and seals regularly for wear or deformation—replace as needed. Maintain logs of cleaning cycles and container usage to support audit readiness.

Inspection & Maintenance

Perform routine visual and functional inspections of containers. Check for signs of stress cracking, seal degradation, or warping. Test seal integrity periodically using pressure decay tests or vacuum checks, especially in critical applications. Remove damaged containers from service immediately.

Documentation & Traceability

Keep detailed records including container batch numbers, filling dates, contents, storage conditions, and handling history. This supports compliance during audits and enables effective product recalls if necessary. Use barcodes or RFID tags for efficient tracking in large-scale operations.

By following this guide, organizations can ensure the safe, compliant, and efficient use of airtight bulk storage containers, protecting product quality and meeting regulatory requirements across the supply chain.

In conclusion, sourcing airtight bulk storage containers is a strategic investment that enhances product preservation, extends shelf life, and maintains quality—especially for food, grains, supplements, and moisture-sensitive materials. By prioritizing factors such as material durability (e.g., food-grade plastic, stainless steel), sealing mechanisms (e.g., gasket lids, vacuum seals), capacity requirements, and ease of use, businesses and households can ensure long-term cost savings, reduce waste, and improve inventory management. Additionally, choosing suppliers that offer certifications (e.g., BPA-free, FDA-compliant) and sustainable options contributes to safety and environmental responsibility. With the right selection criteria and reliable sourcing partners, airtight bulk storage solutions provide a practical, efficient, and scalable answer to modern storage challenges.