The global pneumatic tools market, which includes air-powered slide hammers, is experiencing steady growth driven by rising demand from automotive repair, industrial maintenance, and manufacturing sectors. According to Grand View Research, the global pneumatic tools market was valued at USD 7.96 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.8% from 2023 to 2030. This growth is fueled by the increasing preference for lightweight, high-efficiency tools that reduce manual labor and improve productivity in professional workshops. As air-powered slide hammers become essential in precision repair tasks—particularly in removing bearings, gears, and other press-fit components — manufacturers are investing in advanced engineering and durable materials to meet evolving industry standards. Against this backdrop, nine manufacturers have emerged as leaders, combining innovation, reliability, and performance to capture significant market share. These companies are shaping the future of pneumatic impact tools through rigorous testing, ergonomic design, and compliance with global safety regulations.

Top 9 Air Powered Slide Hammer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Air Hammers and Chisels

Domain Est. 1996

Website: kmstools.com

Key Highlights: 4.7 27 Air Hammers and Chisels ; Magnum Air Hammer Kit · Magnum Air Hammer Kit · 29.95 · 54.99 · MAG-AH901 ; Ingersoll Rand Super-Duty Air Hammer Kit….

#2 Bi

Domain Est. 1998

Website: steckmfg.com

Key Highlights: This Bi-Directional tool is not only an air hammer, it is also a powerful puller! Two tools in one. 3000 BPM air hammer. Smaller, allows access to tighter ……

#3 Slide Sledge

Domain Est. 2001

Website: slidesledge.com

Key Highlights: We carry a full range of tips and accessories for each hammer that allow you to accomplish every job safely and effectively….

#4 KCT855AH

Domain Est. 2001

Website: caseytool.com

Key Highlights: Bidirectional pound or pull air 2500 BMP air hammer. Snap air lock plug into front of gun to convert to pneumatic puller. Unlimited applications….

#5 LT855A

Domain Est. 2004

Website: miltonindustries.com

Key Highlights: Now you can convert your air hammer into a pneumatic slide hammer with the Texas Twister™ Pneumatic Slider Hammer Pulling Kit – 34 Pieces. Simply snap the Texas ……

#6 MZ75 Power Hammer

Domain Est. 2007

Website: kensiron.com

Key Highlights: The MZ75 operates just like a steam hammer. We use a mechanical linkage and a directional valve along with compressed air to operate and control the hammer….

#7 Sliding Hammer Pneumatic

Domain Est. 2011

Website: raeservice.com

Key Highlights: Sliding Hammer Pneumatic. $812.70. Please call for shipping information….

#8 HAZET 9098/24 Pneumatic sliding hammer injector (24 pcs.)

Domain Est. 2017

Website: misterworker.com

Key Highlights: 8-day delivery 14-day returnsYes, this pneumatic sliding hammer injector is suitable for heavy-duty use, making it ideal for professional mechanics and automotive applications. Wit…

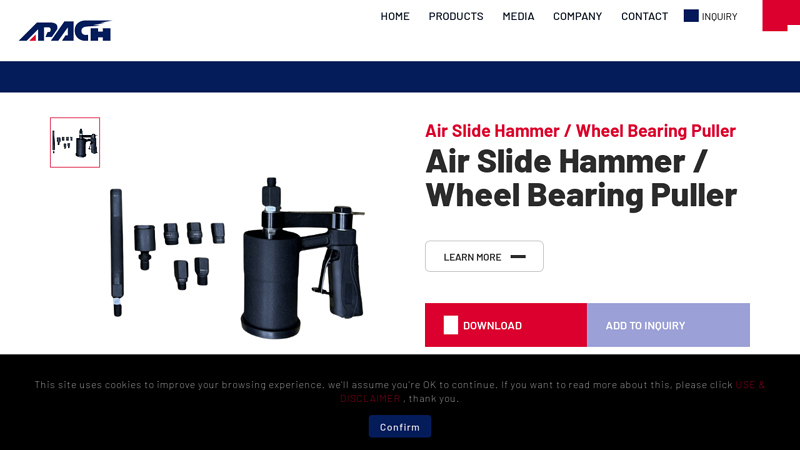

#9 Air Slide Hammer / Wheel Bearing Puller

Website: apach-tools.com

Key Highlights: Delivering up to 1200-1400 impact blows per minute with a simple trigger pull. Provides the pulling power of a 3.5-4.5 lb manual slide hammer on hard-to ……

Expert Sourcing Insights for Air Powered Slide Hammer

2026 Market Trends for Air Powered Slide Hammer

The air powered slide hammer market is poised for notable transformation by 2026, driven by advancements in pneumatic tool technology, increasing demand for efficient repair solutions in industrial and automotive sectors, and a growing emphasis on ergonomics and worker safety. This analysis explores key market trends expected to shape the industry over the coming years.

Rising Demand in Automotive and Industrial Maintenance

One of the primary drivers of growth in the air powered slide hammer market is the expanding need for rapid, reliable tools in vehicle and machinery repair. As automotive fleets become more complex—especially with the rise of electric and hybrid vehicles—technicians require robust tools capable of handling axle, bearing, and suspension removal tasks efficiently. Air powered slide hammers offer consistent power and controlled impact, reducing physical strain and service time. By 2026, the global automotive aftermarket is projected to grow significantly, directly boosting demand for specialized tools like pneumatic slide hammers.

Technological Advancements and Tool Optimization

Manufacturers are increasingly integrating smart features and improved materials into air powered slide hammers. Expect to see innovations such as adjustable impact force settings, noise-dampening systems, and lightweight composite housings by 2026. These enhancements improve usability, precision, and tool longevity. Additionally, compatibility with standard shop air systems and quick-connect fittings will further solidify their adoption in professional settings.

Shift Toward Ergonomic and Safety-Conscious Design

Workplace safety regulations and ergonomic concerns are influencing tool design. Traditional manual slide hammers can lead to repetitive strain injuries, whereas air-powered versions reduce operator fatigue through automated impact delivery. As industries prioritize worker well-being, tools that minimize physical exertion will gain favor. By 2026, air powered slide hammers with vibration-reduction technology and balanced weight distribution are expected to dominate premium segments.

Expansion in Emerging Markets

Growth in industrial infrastructure across Asia-Pacific, Latin America, and Africa will contribute significantly to market expansion. As these regions modernize their transportation and manufacturing sectors, demand for professional-grade pneumatic tools—including air powered slide hammers—will rise. Localized production and distribution partnerships are likely to emerge, improving accessibility and affordability.

Competitive Landscape and Brand Differentiation

The market is becoming increasingly competitive, with major tool manufacturers enhancing product lines to differentiate themselves. By 2026, brands offering comprehensive warranties, modular attachments, and IoT-enabled usage tracking (for maintenance analytics) may gain a strategic edge. Aftermarket support and compatibility with existing tool ecosystems will also play a crucial role in customer decisions.

Sustainability and Energy Efficiency Considerations

While air powered tools rely on compressed air systems, which have energy efficiency challenges, advancements in compressor technology are mitigating environmental concerns. Future air powered slide hammers may be marketed as part of “green workshop” initiatives, especially when paired with energy-efficient compressors and recyclable components. This alignment with sustainability goals could influence procurement decisions in environmentally conscious fleets and repair centers.

Conclusion

By 2026, the air powered slide hammer market will be shaped by technological innovation, ergonomic design, and expanding industrial applications. As demand for speed, safety, and reliability grows across global maintenance sectors, air powered variants are set to outpace manual alternatives. Stakeholders should focus on product differentiation, regional market penetration, and sustainability to capture emerging opportunities.

Common Pitfalls When Sourcing an Air Powered Slide Hammer (Quality & IP)

Sourcing an air-powered slide hammer requires careful consideration to avoid compromising on performance, durability, and legal compliance. Overlooking key aspects related to quality and intellectual property (IP) can lead to operational inefficiencies, safety risks, and potential legal issues. Below are critical pitfalls to watch for:

Poor Build Quality and Material Selection

Many low-cost air-powered slide hammers use substandard materials such as brittle aluminum alloys or low-grade steel, leading to premature wear, cracking, or failure under high-impact stress. Inferior internal components like seals and O-rings degrade quickly when exposed to compressed air contaminants, causing air leaks and loss of power. Always verify material specifications and look for models with hardened impact components and corrosion-resistant finishes.

Inadequate Air Motor Design

A poorly engineered air motor can result in inconsistent hammering action, reduced impact force, or excessive air consumption. Some budget models lack proper internal valving or balance, leading to vibration and operator fatigue. Ensure the tool uses a reciprocating vane or piston design proven for durability and efficiency, and confirm performance specifications (e.g., blows per minute, impact energy) are backed by testing.

Lack of Safety Features

Low-quality tools often omit essential safety mechanisms such as automatic shutoff under jamming conditions or secure chuck retention systems. This increases the risk of tool kickback or component ejection during use. Confirm the presence of safety certifications (e.g., CE, ANSI) and built-in safeguards like pressure relief valves.

Misrepresentation of Intellectual Property (IP)

A significant risk when sourcing from certain suppliers—especially in unregulated markets—is purchasing counterfeit or IP-infringing tools. Some manufacturers copy patented designs, branding, and performance specs from reputable brands without authorization. Using such tools can expose your business to legal liability, especially in regions with strict IP enforcement. Always source from authorized distributors and verify trademarks, patents, and design registrations.

Absence of Genuine Technical Documentation

Infringing or low-tier products often lack proper manuals, exploded diagrams, or service guidelines. This complicates maintenance and increases downtime. Additionally, missing or falsified documentation may indicate non-compliance with regional safety and emissions standards (e.g., EU PPE Regulation, OSHA guidelines).

No Warranty or After-Sales Support

Reputable manufacturers offer warranties and technical support, which are typically absent with counterfeit or poor-quality tools. Without access to replacement parts or expert service, tool lifespan is drastically reduced. Confirm warranty terms and availability of spare parts before procurement.

Final Recommendation

To mitigate these risks, prioritize suppliers with verifiable IP rights, third-party quality certifications, and transparent manufacturing practices. Conduct due diligence by requesting product test reports, patent numbers, and customer references. Investing in a genuine, high-quality air-powered slide hammer ensures long-term reliability, operator safety, and legal compliance.

Logistics & Compliance Guide for Air Powered Slide Hammer

This guide outlines the key logistics considerations and compliance requirements for the transportation, storage, and use of Air Powered Slide Hammers. Adherence to these guidelines ensures safety, regulatory compliance, and efficient operations.

Product Classification and Shipping Information

Air Powered Slide Hammers are classified as industrial tools powered by compressed air. They are typically non-hazardous for transport under international shipping regulations (e.g., IATA, IMDG, ADR) when shipped without pressurized components. Ensure units are depressurized and disconnected from air lines prior to packaging. Use durable, protective packaging to prevent damage during transit. Include appropriate labeling such as “Fragile” and “This Side Up” to safeguard equipment integrity.

Regulatory Compliance Standards

Air Powered Slide Hammers must comply with relevant safety and performance standards in target markets. In the United States, compliance with OSHA 29 CFR 1910.242 (Hand and portable powered tools) is required for workplace use. In the European Union, adherence to the Machinery Directive 2006/42/EC and CE marking is mandatory. Manufacturers should provide a Declaration of Conformity (DoC) and ensure equipment meets electromagnetic compatibility (EMC) and low voltage directives if applicable. Regular audits and certification documentation are recommended to maintain compliance.

Import and Export Documentation

When shipping internationally, complete all required customs documentation, including commercial invoices, packing lists, and certificates of origin. Depending on destination country regulations, an Export Control Classification Number (ECCN) may be required—typically, Air Powered Slide Hammers fall under EAR99 (no license required for most destinations). Verify local import duties, taxes, and any restrictions. Retain records for a minimum of five years in accordance with international trade compliance guidelines.

Storage and Handling Requirements

Store Air Powered Slide Hammers in a dry, temperature-controlled environment to prevent corrosion and damage to internal components. Keep units in their original packaging or protective cases when not in use. Avoid exposure to moisture, extreme temperatures, or corrosive chemicals. Ensure compressed air supply lines are clean, dry, and free of contaminants to maintain optimal tool performance and longevity.

Safety and End-Use Compliance

End users must follow manufacturer-operated guidelines and conduct routine maintenance to ensure safe operation. Operators should wear appropriate personal protective equipment (PPE), including safety glasses, hearing protection, and gloves. Compressed air systems must be equipped with pressure regulators and safety valves to prevent over-pressurization. Regular inspections for wear, air leaks, or damage are critical to maintaining compliance with workplace safety standards.

Environmental and Disposal Considerations

At end-of-life, dispose of Air Powered Slide Hammers in accordance with local waste electrical and electronic equipment (WEEE) regulations where applicable. Recycle metal components and dispose of any non-recyclable parts through authorized waste handlers. Avoid landfill disposal when recycling options are available to support environmental sustainability goals.

Conclusion:

Sourcing an air-powered slide hammer presents a valuable opportunity to enhance efficiency, productivity, and safety in automotive, industrial, or heavy equipment repair operations. By leveraging compressed air, these tools deliver consistent, high-impact force with minimal user fatigue, making them ideal for demanding extraction tasks such as removing axles, bearings, and bushings. After evaluating various suppliers, models, and specifications, it is evident that selecting the right air-powered slide hammer requires consideration of build quality, compatibility with existing air systems, ease of maintenance, and supplier reliability.

Prioritizing reputable manufacturers with strong customer support and warranties ensures long-term performance and return on investment. Additionally, comparing pricing, availability, and shipping logistics across suppliers can optimize procurement costs and reduce downtime. Ultimately, integrating a high-quality air-powered slide hammer into the toolkit supports faster job completion, reduces physical strain on technicians, and contributes to a more efficient and professional workshop environment.