The global tailgate cylinder market is experiencing steady growth, driven by increasing demand for efficient loading and unloading solutions in commercial vehicles and industrial applications. According to Grand View Research, the global hydraulic cylinders market—of which air-operated tailgate cylinders are a key segment—was valued at USD 7.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030. This growth is fueled by rising e-commerce activity, expanding logistics networks, and evolving safety regulations that favor automated material handling systems. Air-operated tailgate cylinders, known for their reliability, lower maintenance, and compatibility with pneumatic systems, are increasingly preferred in light- and medium-duty truck applications. As demand surges across North America, Europe, and Asia-Pacific, a select group of manufacturers are leading innovation in durability, sealing technology, and performance efficiency. Based on market presence, product breadth, and technological advancement, the following eight companies represent the top air-operated tailgate cylinder manufacturers shaping the industry’s future.

Top 8 Air Operated Tailgate Cylinders Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

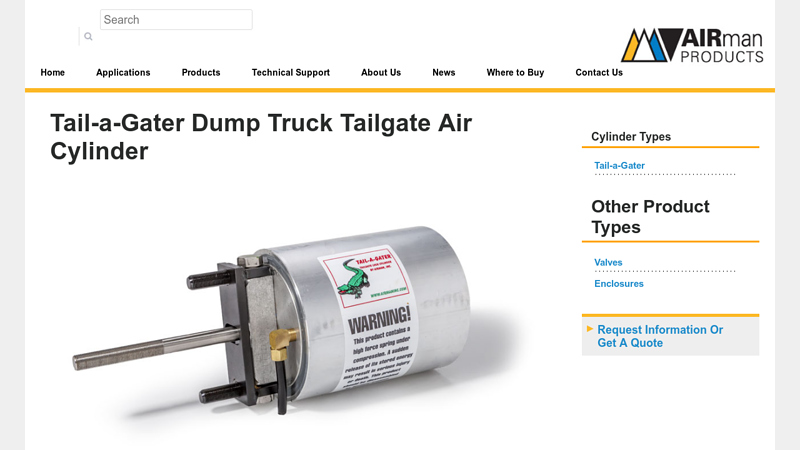

#1 Tail

Domain Est. 2016

Website: airmanproducts.com

Key Highlights: Product Description. Dump truck tailgate air cylinder. Heavy duty aluminum thick wall tubing with pivoting trunnion flange. Model Number, Bore Size, Stroke …Missing: operated ma…

#2 EconoMAX

Domain Est. 2021

Website: onetoughcylinder.com

Key Highlights: As a result of over six decades of R&D, we have become the leading manufacturer of air tarp, tailgate latch, high lift and belly dump cylinders. EconoMAX is ……

#3 Tailgate and Belly Dump Systems

Domain Est. 1997

Website: alkoncorp.com

Key Highlights: High-quality cylinders and control valves. Pneumatic components built to be tough, dependable, and will stand up to road and field contaminants….

#4 Tailgate Control

Domain Est. 1997

Website: buyersproducts.com

Key Highlights: Tailgate Cylinders are ideal for dump truck operators to engage and disengage tailgate latches from inside their vehicle….

#5 3

Domain Est. 1997

Website: velvac.com

Key Highlights: 300 service stainless steel cylinder shafts provide excellent corrosion resistance and extended cycle life -cylinders tested to over 500000 cycles….

#6 Dump Body and Tailgate Air System Components

Domain Est. 1999

#7 Tailgate and dolly lock air cylinder kits

Domain Est. 2000

Website: hydreco.com

Key Highlights: Air operated tailgate and dolly lock cylinder and valve combination kits are now available from Hydreco. Made to the common industry size of ……

#8 Cylinders

Domain Est. 2007

Website: apscopower.com

Key Highlights: APSCO air cylinders offer a variety of solutions for your dump trailer or dump body’s high lift tailgate needs. APSC-Product-Photo-Bellydump.png. Belly Dump….

Expert Sourcing Insights for Air Operated Tailgate Cylinders

H2: Market Trends for Air Operated Tailgate Cylinders in 2026

The global market for air operated tailgate cylinders is poised for notable transformation and growth by 2026, driven by advancements in commercial vehicle technology, increased focus on operational efficiency, and evolving regulatory landscapes. These hydraulic-pneumatic components, essential in tailgate lift systems for delivery vans, waste management trucks, and utility vehicles, are expected to benefit from several key trends.

-

Rise in Last-Mile Delivery Demand

The rapid expansion of e-commerce continues to fuel the need for efficient urban logistics. Delivery fleets are increasingly adopting vehicles equipped with automated tailgate systems, where air operated cylinders provide reliable, low-maintenance actuation. By 2026, the demand for quick, ergonomic loading and unloading solutions will drive integration of these cylinders in last-mile delivery vans, especially in emerging and developed urban markets alike. -

Focus on Lightweight and Durable Materials

Manufacturers are shifting toward composite materials and high-strength aluminum alloys to reduce cylinder weight without compromising durability. This trend supports broader industry goals of vehicle weight reduction to improve fuel efficiency and reduce emissions. Air operated tailgate cylinders designed with corrosion-resistant coatings and sealed pneumatic systems will gain preference, particularly in harsh operating environments. -

Integration with Smart Fleet Systems

By 2026, connectivity and telematics are expected to play a larger role in commercial vehicle maintenance and performance monitoring. Air operated cylinders may increasingly be integrated with sensors that monitor actuation cycles, pressure levels, and wear indicators. This enables predictive maintenance, reducing downtime and extending operational life—key selling points for fleet operators. -

Growth in Waste and Recycling Segments

The global push toward sustainable waste management is leading to increased deployment of automated side-loading and rear-loading refuse trucks. Air operated tailgate cylinders are critical in these systems due to their robustness and compatibility with pneumatic controls. Government infrastructure investments in smart cities and waste collection modernization will further boost demand in this sector. -

Regional Market Expansion

While North America and Europe remain mature markets with steady demand due to aging vehicle fleets and replacement cycles, growth in Asia-Pacific—particularly in China, India, and Southeast Asia—is expected to accelerate. Urbanization, rising e-commerce penetration, and government support for modern logistics infrastructure will drive adoption of advanced tailgate systems incorporating air operated cylinders. -

Regulatory and Safety Standards

Stricter occupational health and safety regulations are pushing companies to adopt automated loading systems to reduce manual handling injuries. Air operated cylinders, known for their smooth and controlled operation, align well with these safety mandates. By 2026, compliance with ISO and regional safety standards will be a competitive differentiator for cylinder manufacturers. -

Sustainability and Energy Efficiency

Although pneumatic systems traditionally consume compressed air (which requires energy to generate), manufacturers are optimizing cylinder designs for lower air consumption and improved energy efficiency. Combined with the rise of electric and hybrid commercial vehicles, innovations in energy recovery and low-power actuation will enhance the sustainability profile of air operated systems.

In summary, the 2026 market for air operated tailgate cylinders will be shaped by increased automation in logistics, material innovation, digital integration, and sustainability imperatives. Manufacturers who align with these trends—offering reliable, smart, and eco-conscious solutions—are likely to capture significant market share in this evolving landscape.

Common Pitfalls When Sourcing Air Operated Tailgate Cylinders (Quality, IP)

Sourcing air operated tailgate cylinders involves several potential pitfalls, especially concerning product quality and intellectual property (IP) protection. Being aware of these risks helps ensure reliable performance, legal compliance, and long-term cost efficiency.

Substandard Quality and Performance Issues

One of the most frequent challenges is receiving cylinders that fail to meet required performance or durability standards. Low-quality units often use inferior seals, subpar plating on piston rods, or poorly machined components, leading to premature failure, air leaks, or inconsistent operation. These defects increase maintenance costs and downtime. Buyers may also encounter misleading specifications—such as inflated pressure ratings or stroke length—due to lack of independent testing or certification.

Inadequate IP Protection and Counterfeit Risk

Air operated tailgate cylinder designs may be protected by patents, trademarks, or technical know-how. Sourcing from unauthorized or unverified suppliers increases the risk of IP infringement, especially when dealing with OEM-equivalent or “compatible” products. Some manufacturers reverse-engineer proprietary designs without licensing, exposing buyers to legal liability. Additionally, counterfeit cylinders that mimic reputable brands can infiltrate supply chains, compromising safety and voiding warranties.

Lack of IP65/IP67 Certification Verification

Many applications require tailgate cylinders to have a minimum ingress protection (IP) rating—typically IP65 or IP67—to withstand dust, moisture, and washdown environments. A key pitfall is assuming a supplier’s claim of IP compliance without verified test reports or third-party certification. Some suppliers may self-certify without rigorous testing, resulting in failures in harsh conditions. Always request documentation such as test certificates from accredited labs to confirm compliance.

Inconsistent Manufacturing Standards Across Suppliers

Suppliers, particularly overseas manufacturers, may follow inconsistent quality control processes. Without proper auditing or ISO certification (e.g., ISO 9001), there’s a higher risk of batch-to-batch variability. This inconsistency affects sealing performance, corrosion resistance, and dimensional accuracy, ultimately impacting integration with existing tailgate systems.

Hidden Costs from Poor Warranty and After-Sales Support

Low initial pricing can be deceptive if the supplier offers limited or no warranty, or lacks technical support. When cylinders fail, the absence of responsive after-sales service or spare parts availability leads to operational delays. Poor IP management may also mean that replacement parts are incompatible or unavailable over time.

Mitigation Strategies

To avoid these pitfalls:

– Source from reputable suppliers with proven track records and certifications.

– Request test reports for IP ratings and pressure performance.

– Conduct factory audits or use third-party inspection services.

– Verify IP rights and ensure components are legally licensed or designed to be non-infringing.

– Include quality and compliance clauses in procurement contracts.

By addressing quality and IP concerns proactively, buyers can ensure reliable, compliant, and cost-effective sourcing of air operated tailgate cylinders.

Logistics & Compliance Guide for Air Operated Tailgate Cylinders

1. Product Overview and Classification

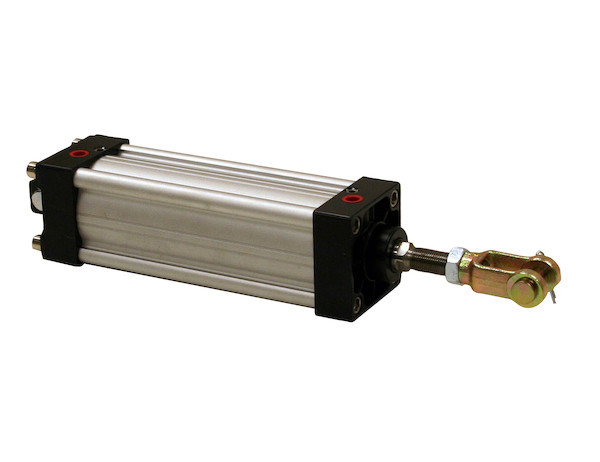

Air operated tailgate cylinders are pneumatic devices used primarily in commercial vehicles to assist in the opening and closing of tailgates. These components are typically classified under specific Harmonized System (HS) codes depending on the destination country. Common classifications include:

- HS Code 8412.21 – Pneumatic engines and motors (applicable in many jurisdictions).

- HS Code 8708.29 – Parts and accessories of motor vehicles (if classified as vehicle components).

Ensure accurate classification for customs clearance, as misclassification may result in delays, penalties, or incorrect duty assessments.

2. Packaging and Handling Requirements

Proper packaging is essential to prevent damage during transit:

- Cylinders must be sealed to prevent contamination of internal components.

- Use moisture-resistant wrapping and desiccants if shipping in humid environments.

- Secure in rigid, shock-absorbent packaging with adequate padding.

- Clearly label packages with “Fragile,” “This Side Up,” and handling instructions.

- Include protective end caps on cylinder rods to avoid dents or scratches.

3. Shipping and Transportation

Air operated cylinders are generally non-hazardous but require careful logistics planning:

- Mode of Transport: Suitable for air, sea, and ground freight. Air freight is recommended for time-sensitive deliveries.

- Stacking: Do not stack heavy items on top of packaged cylinders.

- Temperature Control: Avoid exposure to extreme temperatures during transit (below -20°C or above 80°C).

- Documentation: Include commercial invoice, packing list, bill of lading/air waybill, and certificate of origin.

4. Import/Export Compliance

Ensure adherence to international trade regulations:

- Export Controls: Verify whether cylinders are subject to export restrictions (e.g., EAR in the U.S., dual-use considerations).

- Import Duties and Taxes: Research local tariffs, VAT, and import licensing requirements.

- Customs Declarations: Provide accurate product descriptions, HS codes, country of origin, and value.

- Incoterms®: Clearly define responsibilities using Incoterms (e.g., FOB, EXW, DDP).

5. Regulatory and Safety Standards

Air operated tailgate cylinders must meet relevant safety and performance standards:

- ISO 6953: Pneumatic fluid power – Rod couplings for cylinders – Metric series.

- ISO 15552: Pneumatic fluid power – Cylinders – Bore diameter series.

- CE Marking: Required for EU market; indicates conformity with health, safety, and environmental protection standards.

- RoHS Compliance: Ensure restriction of hazardous substances if selling in EU or similar regulated markets.

- DOT/CMVSS: May apply if integrated into vehicles in North America.

6. Labeling and Documentation

All units must be correctly labeled and accompanied by compliant documentation:

- Product label with model number, bore size, stroke, pressure rating, and manufacturer details.

- User manual or installation guide (multilingual if required by destination market).

- Compliance certificates (CE, ISO, etc.) available upon request.

- Safety warnings in local language where required.

7. After-Sales and Warranty Logistics

Plan for reverse logistics and service support:

- Define warranty terms (typically 12–24 months).

- Establish return material authorization (RMA) process for defective units.

- Provide spare parts availability and technical support documentation.

- Ensure compliance with WEEE (Waste Electrical and Electronic Equipment) directives where applicable.

8. Country-Specific Requirements

Check for regional variations:

- United States: FCC compliance not required (non-electric), but NTEP or OIML may apply if used in weighing systems.

- European Union: CE, RoHS, REACH compliance mandatory.

- Canada: May require CSA certification or CMVSS compliance.

- Australia/NZ: Check AS/NZS standards; import permits may be needed.

Adhering to this logistics and compliance guide ensures smooth international distribution, minimizes customs delays, and supports product safety and legal conformity for air operated tailgate cylinders.

Conclusion: Sourcing Air-Operated Tailgate Cylinders

After a thorough evaluation of suppliers, product specifications, cost considerations, and reliability, sourcing air-operated tailgate cylinders requires a strategic approach focused on quality, durability, and compatibility with existing hydraulic or pneumatic systems. These cylinders play a critical role in the efficient and safe operation of tailgate lifts, particularly in demanding commercial and industrial applications.

Key factors such as build quality, corrosion resistance, operating pressure compatibility, and seal integrity must be prioritized to ensure long-term performance and minimize maintenance downtime. Engaging with reputable suppliers offering proven track records, technical support, and warranty coverage is essential. Additionally, considering total cost of ownership—beyond initial purchase price—helps identify the most cost-effective solution over time.

In conclusion, successful sourcing involves balancing performance requirements with supplier reliability and service. By selecting air-operated tailgate cylinders from trusted manufacturers with robust engineering and responsive support, organizations can enhance operational efficiency, improve safety, and reduce lifecycle costs across their fleet or equipment.