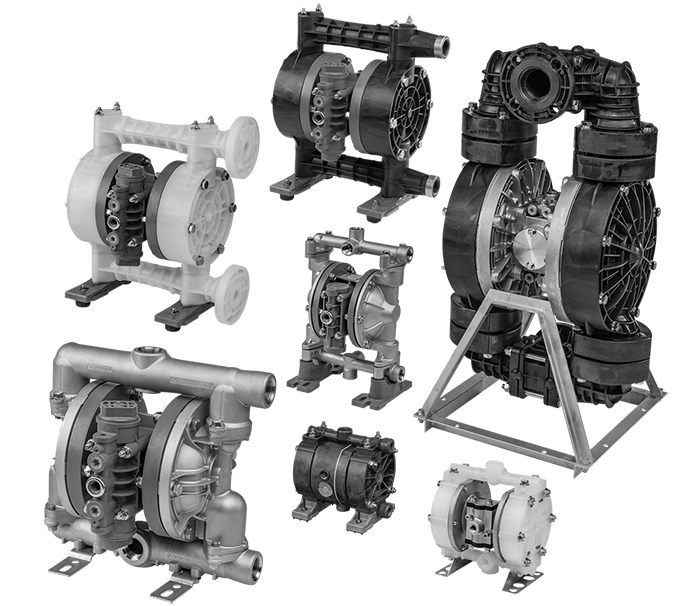

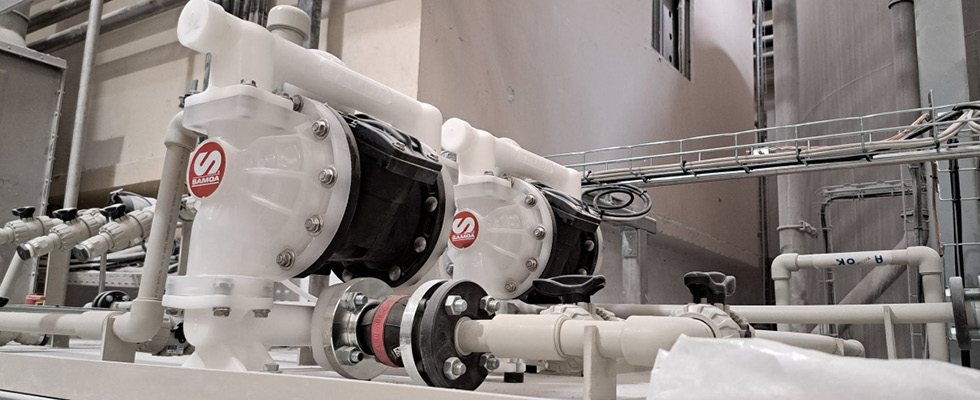

The global air-operated diaphragm (AODD) pump market is experiencing steady growth, driven by increasing demand across industries such as chemicals, pharmaceuticals, food and beverage, and wastewater treatment. According to Grand View Research, the global AODD pump market was valued at USD 1.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by the pumps’ reliability, ability to handle abrasive and shear-sensitive fluids, and minimal maintenance requirements. Mordor Intelligence also forecasts robust expansion, citing industrial automation and stricter environmental regulations as key drivers. As demand rises, manufacturers are enhancing pump efficiency, material compatibility, and energy performance. In this evolving landscape, nine leading companies have emerged as innovators and dominant suppliers, setting industry benchmarks for quality, durability, and application versatility.

Top 9 Air Operated Diaphragm Pump Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Double Diaphragm Pumps for Chemical Transfer

Domain Est. 1994

Website: graco.com

Key Highlights: Graco’s double diaphragm pumps are designed for chemical transfer applications. Our chemical transfer pumps come in pneumatic and electric options, ……

#2 AOD Centrifugal Pumps, MD, VC, VFD Stainless Steel, Aluminum …

Domain Est. 1996

Website: pricepump.com

Key Highlights: Price Pump Company is a premier manufacturer of Centrifugal and Air Operated Diaphragm (AOD) pumps. We specialize in addressing the needs of specialty ……

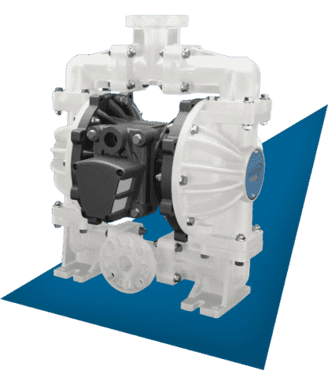

#3 Leading AODD Pump Manufacturer

Domain Est. 2000

Website: sandpiperpump.com

Key Highlights: With over 55 years delivering Air Operated Double Diaphragm pumping solutions and expertise, SANDPIPER is best-in-class for your most difficult and demanding ……

#4 Leading Manufacturer and Inventor of AODD Pumps

Domain Est. 2011

Website: psgdover.com

Key Highlights: In 1955, Jim Wilden revolutionized the pumping industry when he invented the air-operated double-diaphragm (AODD) pump….

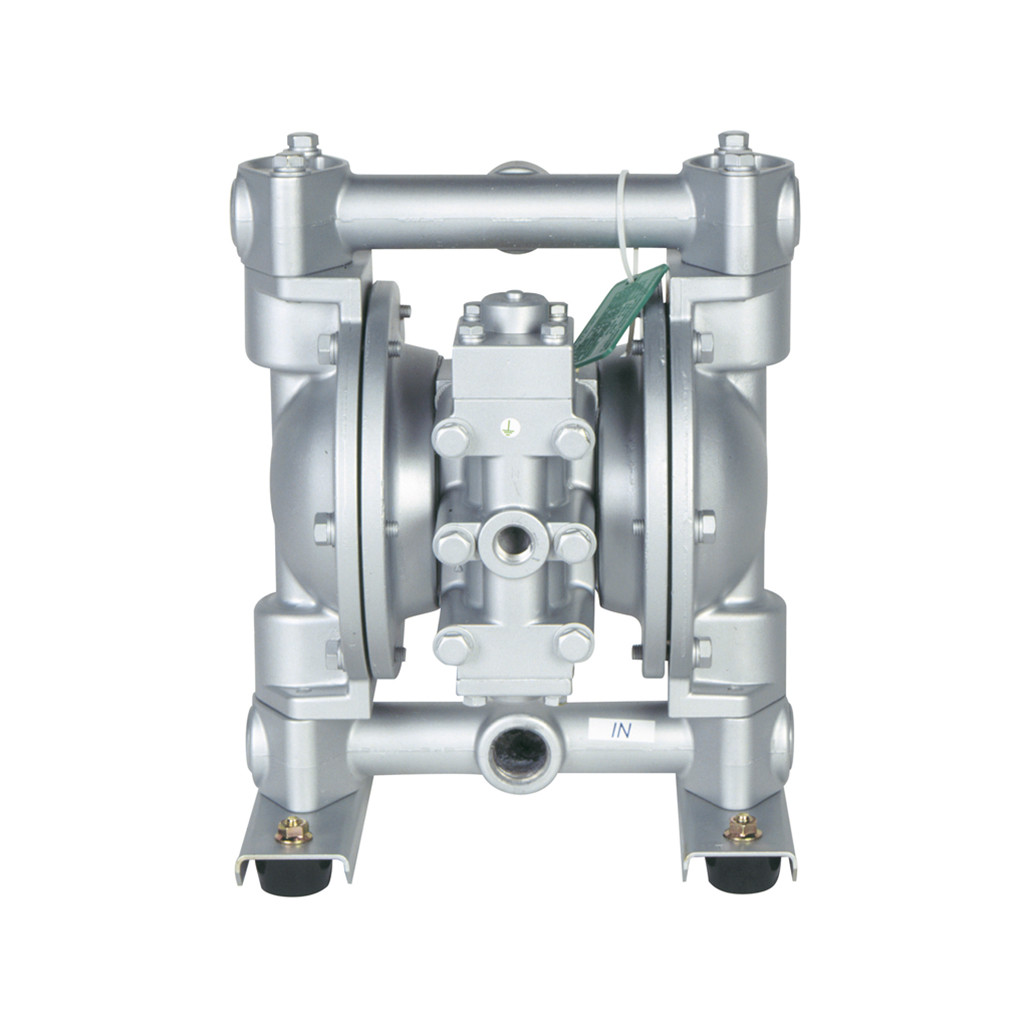

#5 Yamada Pump

Domain Est. 1996

Website: yamadapump.com

Key Highlights: Since its beginning in 1905, Yamada has been at the forefront in developing the most complete line of air operated double diaphragm pumps (AODD) in the world….

#6 Versamatic: Air

Domain Est. 1996

Website: versamatic.com

Key Highlights: Versamatic delivers quality, easy-to-use pumping solutions without compromising your budget. For over 30 years, our air-operated double-diaphragm (AODD) ……

#7 Air Dimensions

Domain Est. 1998

Website: airdimensions.com

Key Highlights: ADI’s precision gas diaphragm pumps offer corrosion-resistant, low-maintenance solutions for hazardous and safe areas across diverse industries….

#8 ARO Pumps

Domain Est. 2000

Website: arozone.com

Key Highlights: ARO air operated double diaphragm pumps can easily pump light to medium viscosity fluids. Our pneumatic diaphragm pumps provide stall-free, ice-free operation….

#9 Iwaki Air: AODD Pumps

Domain Est. 2014

Website: iwakiair.com

Key Highlights: Iwaki Air AODD pumps are engineered for maximum utility. These air operated diaphragm pumps are portable, as well as easy to install, operate, and maintain….

Expert Sourcing Insights for Air Operated Diaphragm Pump

2026 Market Trends for Air Operated Diaphragm (AODD) Pumps

The Air Operated Diaphragm (AODD) pump market is poised for significant evolution by 2026, driven by shifting industrial demands, technological advancements, and global sustainability initiatives. Key trends shaping the landscape include:

Rising Demand for Durability and Chemical Resistance in Harsh Environments

Industries such as mining, chemical processing, and wastewater treatment are increasingly requiring pumps capable of handling abrasive slurries, corrosive chemicals, and high-viscosity fluids. This is fueling demand for AODD pumps constructed with advanced materials like polytetrafluoroethylene (PTFE), polyvinylidene fluoride (PVDF), and reinforced elastomers. Manufacturers are focusing on enhancing diaphragm longevity and seal integrity to reduce downtime and maintenance costs, particularly in remote or hazardous locations where operational reliability is critical.

Growth in Sustainable and Energy-Efficient Pumping Solutions

With global emphasis on energy efficiency and carbon reduction, the AODD pump sector is responding through innovations that optimize compressed air usage—a historically inefficient aspect of AODD operation. By 2026, smart pneumatic control systems, adaptive air motors, and variable speed drives integrated with IoT sensors are expected to become standard in premium models. These technologies enable real-time monitoring of air consumption and automatic adjustment to flow requirements, significantly reducing compressed air waste and lowering the total cost of ownership.

Expansion in Emerging Economies and Infrastructure Development

Rapid industrialization in Asia-Pacific, Latin America, and parts of Africa is driving infrastructure and manufacturing growth, creating new demand for reliable fluid transfer solutions. AODD pumps, known for their portability, ease of installation, and versatility, are increasingly adopted in construction, dewatering, and municipal wastewater projects. Localized manufacturing and distribution networks are emerging to serve these regions, contributing to market expansion and competitive pricing.

Integration of Smart Technologies and Industry 4.0

The convergence of AODD pumps with digital technologies is accelerating. By 2026, predictive maintenance platforms powered by AI and machine learning will enable operators to anticipate diaphragm failure, detect leaks, and optimize pump performance remotely. Embedded sensors will collect data on stroke count, air pressure, and flow rates, feeding into centralized industrial IoT systems. This shift supports proactive maintenance strategies, enhances operational efficiency, and aligns with broader Industry 4.0 adoption across manufacturing and process industries.

Focus on Hygienic and Sanitary Pumping in Life Sciences and Food & Beverage

Stringent hygiene regulations in pharmaceuticals, biotechnology, and food processing are increasing the demand for AODD pumps with clean-in-place (CIP) and sterilize-in-place (SIP) capabilities. Manufacturers are developing compliant designs using FDA-approved materials, crevice-free housings, and fully drainable configurations. The trend toward modular and single-use pumping systems in biopharma applications is also expected to boost AODD adoption due to their simplicity and contamination control.

In summary, the 2026 AODD pump market will be characterized by innovation in materials, energy efficiency, digital integration, and application-specific engineering. Companies that invest in smart, sustainable, and durable solutions will be best positioned to capture growth across diverse industrial sectors.

Common Pitfalls When Sourcing Air Operated Diaphragm Pumps (Quality and IP)

Sourcing Air Operated Diaphragm (AODD) pumps requires careful consideration to ensure reliability, safety, and long-term performance. Overlooking key factors related to quality and Ingress Protection (IP) ratings can lead to premature failure, safety hazards, and operational downtime. Below are common pitfalls to avoid:

1. Prioritizing Low Cost Over Build Quality

One of the most frequent mistakes is selecting a pump based solely on the lowest price. Cheap AODD pumps often use inferior materials, such as low-grade plastics, substandard elastomers, or poor-quality metals, which degrade quickly when exposed to aggressive chemicals or abrasive media. This results in frequent maintenance, unplanned downtime, and higher total cost of ownership.

Avoid by: Evaluating total lifecycle costs, requesting material certifications, and opting for reputable manufacturers with proven track records in your industry.

2. Ignoring Material Compatibility of Wetted Parts

AODD pumps come into direct contact with the pumped fluid, making material compatibility critical. Using incompatible diaphragms, balls, seats, or manifolds can lead to swelling, cracking, or chemical degradation—especially with solvents, acids, or bases.

Avoid by: Reviewing chemical resistance charts for all wetted components and confirming compatibility with your specific fluid, including temperature and concentration.

3. Overlooking Diaphragm Design and Quality

The diaphragm is the heart of an AODD pump. Poorly designed or low-quality diaphragms (e.g., single-layer, thin membranes) are prone to fatigue, tearing, or delamination, especially under continuous operation or high pressures.

Avoid by: Selecting pumps with reinforced, multi-layer diaphragms (e.g., Teflon-coated, Santoprene, or PTFE) suited to your application’s pressure and chemical demands.

4. Misunderstanding or Ignoring IP Ratings

Ingress Protection (IP) ratings define a pump’s resistance to dust and water ingress. Selecting a pump with an insufficient IP rating for the environment (e.g., washdown areas, outdoor installations, or dusty facilities) can lead to motor or air valve damage, corrosion, and safety risks.

Avoid by: Matching the IP rating to the operating environment:

– IP65: Protected against dust and low-pressure water jets (suitable for washdown areas).

– IP66/IP67: Resistant to powerful water jets or temporary immersion (ideal for outdoor or high-moisture areas).

– IP68: Fully submersible (for specialized applications).

5. Assuming All “Stainless Steel” Pumps Are Equal

Not all stainless steel pumps offer the same corrosion resistance. Lower-cost pumps may use 304 SS instead of 316L SS, which is less resistant to chlorides and acidic environments. Castings may also have porosity or poor surface finishes that trap contaminants.

Avoid by: Verifying the grade of stainless steel used and requesting material test reports (MTRs) for critical components.

6. Neglecting Air Valve Reliability

The air valve controls pump cycling and is a common failure point in low-quality AODD pumps. Poor design or materials in the air distribution system can cause sticking, freezing, or excessive wear, especially in humid or dirty air supply conditions.

Avoid by: Choosing pumps with self-lubricating, non-stick air valves (e.g., PTFE or engineered plastics) and ensuring clean, dry air supply with proper filtration.

7. Failing to Verify Certification and Compliance

In regulated industries (e.g., food, pharmaceuticals, chemicals), using non-compliant pumps can result in safety issues or regulatory violations. Lack of certifications such as ATEX, UL, CE, FDA, or 3A can be a major pitfall.

Avoid by: Confirming that the pump meets all required industry standards and certifications for your application and region.

8. Not Considering Serviceability and Spare Parts Availability

Pumps that are difficult to disassemble or use proprietary parts increase maintenance time and cost. Limited spare parts availability can lead to extended downtime.

Avoid by: Choosing pumps with modular, field-serviceable designs and ensuring spare parts are readily available locally or through the supplier.

By addressing these pitfalls—particularly those related to material quality, diaphragm integrity, and appropriate IP protection—you can ensure a reliable, safe, and cost-effective AODD pump solution tailored to your operational needs.

Logistics & Compliance Guide for Air Operated Diaphragm Pumps

Product Overview

Air Operated Diaphragm (AODD) pumps are positive displacement pumps driven by compressed air, commonly used for transferring a wide range of fluids including corrosive, viscous, abrasive, and shear-sensitive media. Proper logistics planning and regulatory compliance are essential for safe handling, transport, and operation.

Packaging & Handling Requirements

Ensure AODD pumps are securely packaged in robust, moisture-resistant materials with protective wrapping to prevent damage during transit. Use palletized crates or containers with cushioning for mechanical shock absorption. Clearly label packages with “Fragile,” “This Side Up,” and “Protect from Moisture” indicators. Avoid stacking heavy items on top of pump packages. Handle with care using appropriate lifting equipment; never lift by hoses, fittings, or air motor components.

Transportation Guidelines

Transport AODD pumps via road, air, or sea in accordance with international freight standards (e.g., IMDG, IATA, ADR). Ensure vehicles are clean, dry, and secured against movement. For air freight, confirm compliance with IATA Dangerous Goods Regulations if pumps contain residual hazardous fluids. Declare pumps as non-hazardous unless contaminated. Use temperature-controlled transport when moving pumps with sensitive elastomers (e.g., EPDM, Teflon) in extreme climates.

Storage Conditions

Store pumps in a clean, dry, and well-ventilated area, away from direct sunlight and extreme temperatures (ideally 5°C to 40°C). Keep pumps in original packaging until deployment. Position horizontally with support to prevent stress on ports. Avoid contact with ozone-generating equipment or corrosive vapors. For long-term storage (>6 months), apply internal corrosion inhibitor and seal suction/discharge ports.

Regulatory Compliance

AODD pumps must comply with applicable regional and international standards:

– CE Marking: Required for sale in the EU; ensures conformity with Machinery Directive (2006/42/EC) and ATEX (2014/34/EU) if used in explosive atmospheres.

– ATEX / IECEx: Mandatory for pumps intended for use in hazardous (classified) locations; verify equipment group, category, and temperature class.

– RoHS & REACH: Comply with EU directives on restricted substances and chemical registration.

– UL / CSA: Required for pumps sold in North America; confirms electrical safety and performance standards.

– PED (Pressure Equipment Directive): Applies if the pump is designed for pressures exceeding 0.5 bar and meets volume/pressure thresholds.

Documentation & Labeling

Provide complete technical documentation, including:

– Manufacturer’s Declaration of Conformity (DoC)

– CE/UKCA marking (as applicable)

– Material Compatibility Charts

– Operating Instructions (in local language)

– Safety Data Sheets (SDS) for wetted materials

Ensure pumps are permanently labeled with:

– Manufacturer name and address

– Model and serial number

– Maximum air and discharge pressure

– Fluid compatibility and temperature limits

– CE/ATEX/UL marks (as applicable)

Import & Export Considerations

Verify country-specific import regulations for machinery and fluid-handling equipment. Ensure Harmonized System (HS) code classification (e.g., 8413.70 for diaphragm pumps). Comply with export control regulations (e.g., EAR in the U.S.) if technology involves controlled components. Retain records of compliance documentation for audit purposes.

Environmental & Safety Compliance

Dispose of packaging materials in accordance with local waste regulations. If pumps have handled hazardous fluids, clean and decontaminate before servicing or disposal per EPA, EEA, or local environmental standards. Follow OSHA or equivalent workplace safety guidelines during installation and operation.

Maintenance & Recertification

Follow manufacturer-recommended maintenance schedules. Recertify pumps used in hazardous areas per ATEX/IECEx requirements after major repairs. Keep service logs and compliance certificates on file for traceability.

Conclusion:

In conclusion, sourcing an air-operated double diaphragm (AODD) pump requires careful consideration of several key factors including material compatibility, flow rate requirements, pressure conditions, fluid characteristics, and the operating environment. These pumps offer distinct advantages such as self-priming capability, dry-run tolerance, portability, and the ability to handle abrasive, viscous, or shear-sensitive fluids, making them suitable for a wide range of industrial applications.

When selecting a supplier or manufacturer, reliability, technical support, compliance with industry standards (such as ANSI, ISO, or ATEX where applicable), and availability of spare parts are critical for ensuring long-term performance and reduced downtime. Additionally, evaluating total cost of ownership—beyond initial purchase price—to include energy efficiency, maintenance needs, and lifespan will lead to a more informed and cost-effective decision.

Ultimately, choosing the right AODD pump from a reputable source ensures operational efficiency, safety, and durability, supporting smooth and uninterrupted processes across sectors such as chemical processing, wastewater treatment, food and beverage, pharmaceuticals, and mining.