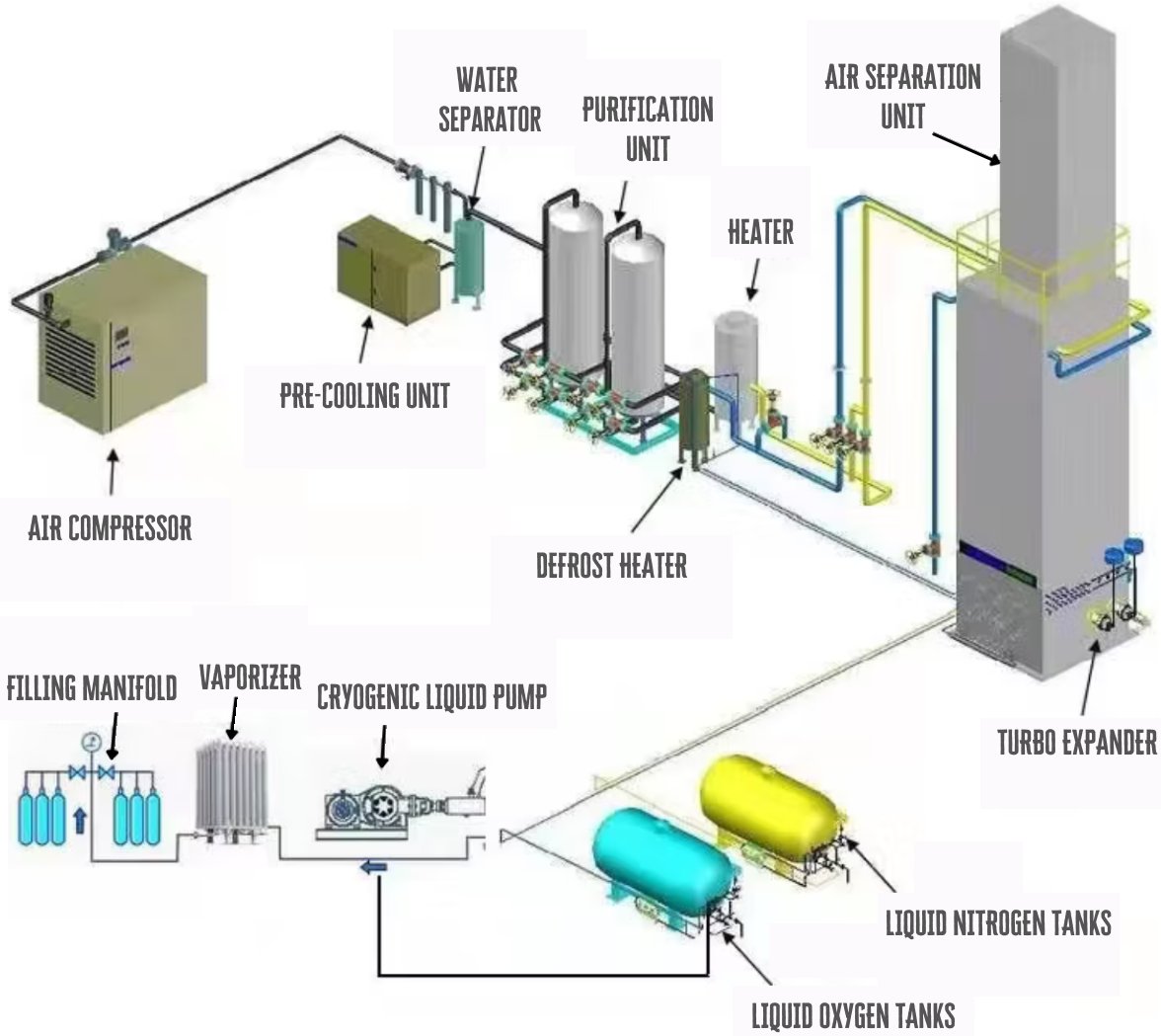

The global aviation industry is undergoing rapid transformation, driven by increasing air travel demand, fleet modernization, and a strong focus on aircraft safety and efficiency. A critical yet often overlooked component in this ecosystem is the air line water separator, which plays a vital role in removing moisture from pneumatic systems to prevent icing, corrosion, and system failure in commercial and military aircraft. According to Mordor Intelligence, the Aircraft Pneumatic System Market—which includes water separation technology—is projected to grow at a CAGR of over 4.8% from 2023 to 2028, driven by rising aircraft deliveries and stringent regulatory standards for system reliability. Similarly, Grand View Research valued the broader aircraft environmental control systems market at USD 9.4 billion in 2022, forecasting continued growth fueled by advancements in next-generation aircraft platforms such as the Boeing 787 and Airbus A350. As demand for lightweight, high-efficiency components increases, manufacturers of air line water separators are expanding their innovation and global footprint. Below is a data-informed overview of the top nine manufacturers leading this niche but essential segment of aviation technology.

Top 9 Air Line Water Separator Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Engine and Industrial Air, Oil and Liquid Filtration

Domain Est. 1995

Website: donaldson.com

Key Highlights: Donaldson Company, Inc. is a global leader in providing engine and industrial air, oil and liquid filtration solutions….

#2 High Efficiency Air & Dirt Separators

Domain Est. 1995

Website: spirotherm.com

Key Highlights: Spirotherm, Inc. manufactures the industry leading high efficiency Spirovent® coalescing type air elimination products and its extended line of Spirotrap® dirt ……

#3 Compressed Air and Gas Water Separators

Domain Est. 1995

Website: ph.parker.com

Key Highlights: Parker compressed air and gas water separators enable the efficient removal of liquid contaminants from air supplies. These compressed air and gas water ……

#4 Pall Corporation

Domain Est. 1995

Website: pall.com

Key Highlights: A global leader providing a complete set of technologies from consumables & customizations to new inventions for the purification & filtration needs of ……

#5 Automatic Drain Filter Separator

Domain Est. 1995

Website: exair.com

Key Highlights: In stock 30-day returnsEXAIR’s Filter Separators remove water, dirt and rust from compressed air systems. They prevent these contaminants from plugging or damaging compressed air ….

#6 Water droplet filtration for compressed air systems

Domain Est. 1995

Website: atlascopco.com

Key Highlights: Atlas Copco’s WSD cyclone-based separators effectively remove water aerosols. Made entirely of corrosion-proof material, they increase the reliability of your ……

#7 Arrow Pneumatics

Domain Est. 1997

Website: arrowpneumatics.com

Key Highlights: Free delivery 15-day returnsThe Arrow Pneumatics F300-02 Mini Particulate and Water Removing Filter ensures critical protection for compressed air systems by removing harmful ……

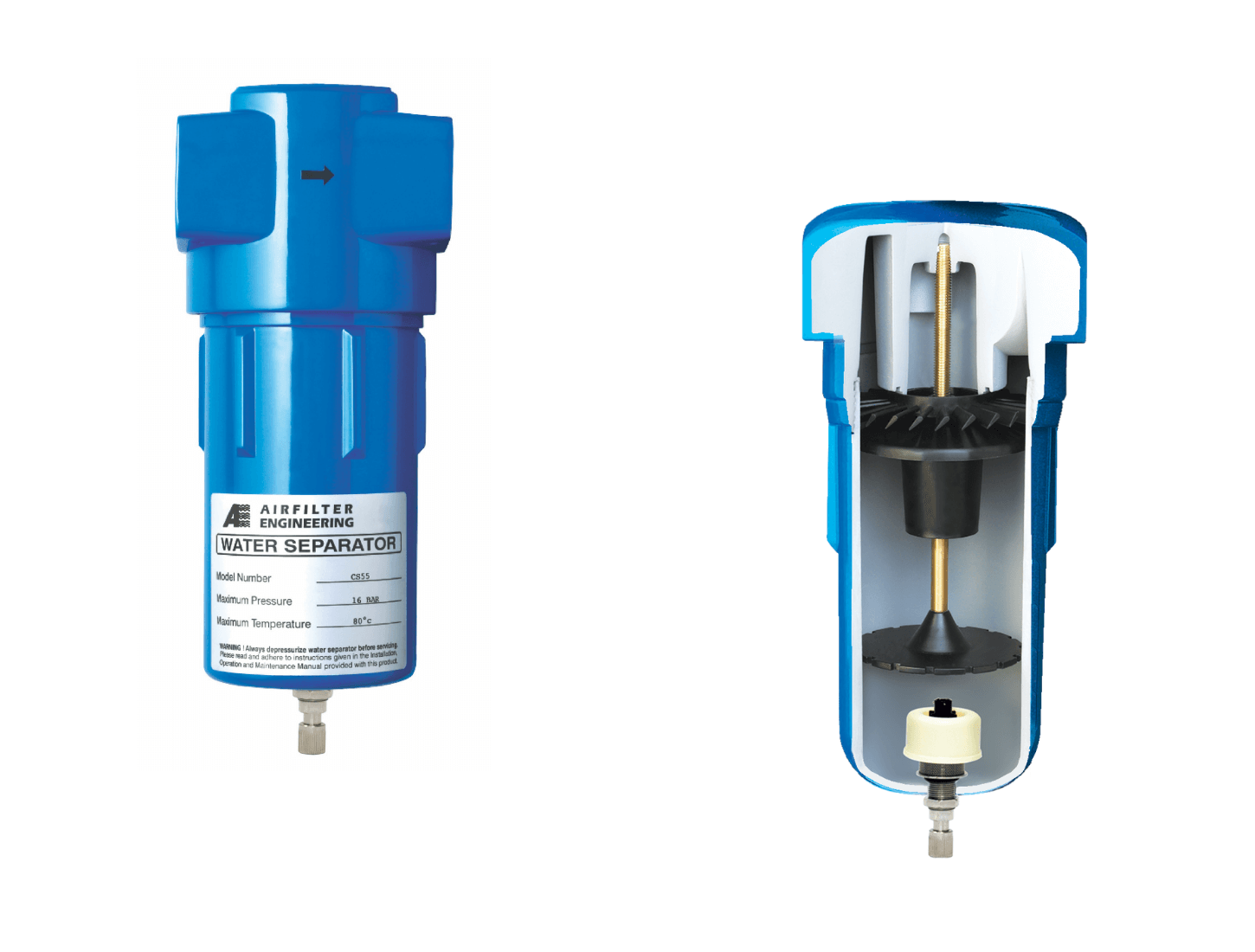

#8 Water Separators Remove Water from Air Lines

Domain Est. 1998

Website: airengineering.com

Key Highlights: Water separators remove the liquid water before it enters your machine. Buy from the Official Site AirEngineering.com….

#9 Water Separators

Domain Est. 1999

Website: compressorworld.com

Key Highlights: Free delivery over $1,000 · 30-day returns…

Expert Sourcing Insights for Air Line Water Separator

H2: Market Trends for Air Line Water Separators in 2026

As industries continue to prioritize efficiency, reliability, and sustainability in compressed air systems, the air line water separator market is poised for significant evolution by 2026. Driven by technological advancements, regulatory developments, and shifting industrial demands, several key trends are expected to shape the landscape of this sector.

-

Increased Demand from Manufacturing and Industrial Automation

The expansion of smart manufacturing and Industry 4.0 initiatives is fueling the need for clean, dry compressed air. Water-laden air can damage pneumatic tools, reduce equipment lifespan, and compromise product quality—especially in sectors like automotive, food and beverage, pharmaceuticals, and electronics. By 2026, heightened investment in automation will drive higher adoption of high-efficiency air line water separators to maintain optimal system performance. -

Growth in Energy-Efficient and Zero-Loss Drain Technologies

A major trend shaping the market is the shift toward energy-efficient and intelligent drainage systems. Traditional timed or manual drains waste compressed air and energy. In response, manufacturers are increasingly offering zero-loss automatic drain valves with sensors and IoT integration. By 2026, these smart drains—often paired with water separators—are expected to dominate new installations, especially in energy-conscious regions like Europe and North America. -

Stringent Air Quality Standards and Regulatory Compliance

Global standards such as ISO 8573-1, which define acceptable levels of contaminants in compressed air, are becoming more rigorously enforced. Industries like pharmaceuticals and food processing require Class 0 or Class 1 air quality, necessitating advanced multi-stage filtration and separation systems. As regulatory compliance becomes non-negotiable, demand for high-performance air line water separators will rise through 2026. -

Rise of Compact and Modular Designs

With space optimization being a priority in industrial facilities, manufacturers are focusing on compact, modular, and easy-to-install water separator units. These designs allow for flexible integration into existing compressed air systems and reduce maintenance downtime. The trend toward modular systems will be especially prominent in retrofit projects and small-to-medium enterprises (SMEs) seeking cost-effective upgrades. -

Expansion in Emerging Markets

Countries in Asia-Pacific (particularly India, Vietnam, and Indonesia), the Middle East, and Latin America are experiencing rapid industrialization. As new manufacturing plants and infrastructure projects come online, demand for compressed air treatment equipment—including water separators—is accelerating. Local production and distribution partnerships are expected to grow, making these regions key growth drivers by 2026. -

Integration with Digital Monitoring and Predictive Maintenance

The convergence of industrial IoT (IIoT) and predictive maintenance is transforming air treatment systems. By 2026, advanced water separators will increasingly feature built-in sensors for moisture detection, pressure monitoring, and performance analytics. These data-enabled systems allow for remote diagnostics and proactive maintenance, reducing downtime and improving operational efficiency—especially in large-scale industrial settings. -

Sustainability and Environmental Compliance

As global sustainability goals intensify, industries are under pressure to reduce waste and improve resource efficiency. Water separators that enable condensate management and oil-water separation (especially in oil-lubricated compressors) will be in higher demand. Eco-friendly designs that facilitate safe condensate disposal and reduce environmental impact will gain market traction by 2026.

In summary, the air line water separator market in 2026 will be characterized by technological innovation, regulatory influence, and growing demand across both developed and emerging economies. Companies that invest in smart, energy-efficient, and modular solutions will be best positioned to capitalize on these trends.

H2: Common Pitfalls When Sourcing Air Line Water Separators (Quality and Intellectual Property)

Sourcing Air Line Water Separators—critical components in pneumatic systems for removing moisture from compressed air—can be fraught with challenges, particularly concerning product quality and intellectual property (IP) risks. Below are common pitfalls to avoid:

1. Compromised Quality Due to Substandard Materials

– Pitfall: Suppliers, especially low-cost manufacturers, may use inferior materials (e.g., non-anodized aluminum, low-grade seals) that degrade quickly under pressure or temperature fluctuations.

– Risk: Reduced separation efficiency, premature failure, contamination of downstream equipment.

– Mitigation: Require material certifications (e.g., ISO 9001), conduct third-party testing, and inspect samples before bulk orders.

2. Inaccurate or Inflated Performance Specifications

– Pitfall: Suppliers may exaggerate efficiency ratings (e.g., claiming 99% moisture removal without independent validation) or misrepresent flow capacity (CFM/LPM).

– Risk: System inefficiency, increased maintenance, and equipment damage due to residual moisture.

– Mitigation: Request test reports from accredited labs and verify specifications against industry standards (e.g., ISO 8573 for air purity).

3. Lack of Compliance with International Standards (IP Rating Misrepresentation)

– Pitfall: Mislabeling of Ingress Protection (IP) ratings—e.g., claiming IP65 (dust-tight and protected against water jets) when the product only meets IP54.

– Risk: Equipment failure in harsh environments, safety hazards, and non-compliance in regulated industries.

– Mitigation: Audit manufacturing facilities, demand certified test documentation, and perform spot checks using standardized IP test methods.

4. Intellectual Property (IP) Infringement Risks

– Pitfall: Sourcing from suppliers who replicate patented designs (e.g., proprietary baffle systems, automatic drain mechanisms) without licensing.

– Risk: Legal liability for buyers, shipment seizures, reputational damage, and forced redesigns.

– Mitigation: Conduct IP due diligence, require suppliers to provide proof of design ownership or licensing agreements, and include IP indemnification clauses in contracts.

5. Inadequate or Missing Certifications

– Pitfall: Absence of necessary certifications such as CE, UKCA, or ATEX (for hazardous environments), even when claimed.

– Risk: Non-compliance with regional safety regulations, operational shutdowns.

– Mitigation: Verify certifications via official databases and insist on original documentation.

6. Poor After-Sales Support and Spare Parts Availability

– Pitfall: Suppliers offering no technical support or unavailability of replacement elements (e.g., filter cartridges, drain valves).

– Risk: Extended downtime and increased total cost of ownership.

– Mitigation: Evaluate supplier service history, request spare parts catalogs, and include support terms in procurement agreements.

7. Counterfeit or Gray Market Products

– Pitfall: Rebranded or fake versions of well-known brands sold at suspiciously low prices.

– Risk: Unreliable performance, warranty voidance, safety issues.

– Mitigation: Source only through authorized distributors and verify batch authenticity using manufacturer traceability tools.

Conclusion

To mitigate risks in sourcing Air Line Water Separators, adopt a due diligence framework that validates both quality claims and IP integrity. Prioritize transparent suppliers with verifiable track records, enforce contractual safeguards, and invest in pre-shipment inspections and certification audits. Doing so ensures reliable performance, regulatory compliance, and protection against legal exposure.

Logistics & Compliance Guide for Air Line Water Separator

Overview

An Air Line Water Separator is a critical component in compressed air systems, designed to remove moisture, oil, and particulates from compressed air lines. Ensuring proper logistics handling and compliance with relevant regulations is essential for safe transportation, storage, and end-use. This guide outlines key logistics considerations and compliance requirements for the shipment, handling, and deployment of Air Line Water Separators.

Regulatory Compliance

International Shipping & Customs

- HS Code Classification: Air Line Water Separators typically fall under HS Code 8421.39 (Other gas filters and purifiers, including for compressed air systems). Confirm the exact classification with local customs authorities, as variations exist by country and construction materials.

- Export Controls: Verify if the product contains materials or components subject to export restrictions (e.g., dual-use technologies). Most standard water separators are not controlled, but verify with the Export Administration Regulations (EAR) or equivalent.

- Country-Specific Requirements: Some countries require product certification (e.g., CE marking for the EU, UKCA for the UK, CCC for China). Ensure units are labeled accordingly prior to shipment.

Environmental & Safety Regulations

- REACH & RoHS Compliance (EU/UK): Confirm that materials used (e.g., metals, seals, coatings) comply with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives.

- Proposition 65 (California, USA): If selling in California, ensure no components contain chemicals listed under Prop 65 without appropriate warning labels.

- Waste Electrical and Electronic Equipment (WEEE): Although not typically classified as electronic equipment, if the separator includes sensors or electronic drains, WEEE compliance may apply in the EU.

Packaging & Handling

Packaging Standards

- Use robust, moisture-resistant packaging to prevent corrosion during transit.

- Include protective wrapping (e.g., VCI paper) for metal components to prevent rust.

- Secure internal components to prevent movement (e.g., foam inserts, cardboard dividers).

- Label packages with:

- “Fragile”

- “This Side Up”

- Product model and serial number

- Weight and dimensions

Handling Instructions

- Avoid dropping or impact during loading/unloading.

- Store in a dry, climate-controlled environment (ideally 10°C to 30°C, <70% RH).

- Do not stack packages beyond the manufacturer’s recommended limit.

Transportation

Mode of Transport

- Air Freight: Compliant with IATA Dangerous Goods Regulations if no hazardous materials are present (standard separators are non-hazardous). Declare as “Machinery Components – Not Restricted.”

- Sea Freight: Use moisture-barrier packaging and silica gel desiccants in containers to prevent condensation. Follow IMDG Code for general cargo.

- Ground Transport: Ensure secure strapping and load distribution. Use pallets with skid-resistant surfaces.

Documentation

- Commercial Invoice

- Packing List (itemizing quantity, weight, dimensions per package)

- Certificate of Origin (if required for customs duty reduction)

- Material Compliance Certificates (RoHS, REACH, etc.)

- Warranty and Installation Manual (included or shipped separately)

Storage & Inventory Management

- Store in original packaging until installation.

- Rotate stock using FIFO (First In, First Out) to prevent obsolescence.

- Maintain records of batch numbers and manufacturing dates for traceability.

- Inspect for damage or corrosion upon receipt and before dispatch.

End-of-Life & Recycling

- Inform customers of proper disposal procedures based on local regulations.

- For units with electronic components, advise recycling through WEEE or equivalent programs.

- Provide take-back or recycling options if required by regional law (e.g., EU Producer Responsibility).

Summary

Proper logistics and compliance management for Air Line Water Separators ensures regulatory adherence, protects product integrity, and supports environmental sustainability. Always verify region-specific requirements and maintain thorough documentation throughout the supply chain.

Conclusion for Sourcing Air Line Water Separator:

Sourcing a suitable air line water separator is a critical step in ensuring the efficiency, reliability, and longevity of pneumatic systems. After evaluating technical specifications, environmental conditions, required flow rates, material compatibility, and maintenance needs, it becomes evident that selecting the right separator enhances air quality, protects downstream equipment, and reduces operational downtime.

Cost-effectiveness should not be the sole deciding factor; instead, priority should be given to performance, durability, and compliance with industry standards. Suppliers with a proven track record, quality certifications, and responsive technical support offer added value. In conclusion, a well-informed sourcing decision—balancing quality, performance, and total cost of ownership—will lead to improved system performance and reduced maintenance costs, ultimately supporting smooth and efficient operations across industrial applications.