The global air conditioning micrometer gauge market is experiencing steady growth, driven by increasing demand for precision measurement tools in HVAC-R (Heating, Ventilation, Air Conditioning, and Refrigeration) systems. According to Grand View Research, the global HVAC market size was valued at USD 167.1 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030, fueled by rising energy efficiency standards and infrastructure development. As critical instruments for measuring refrigerant pressure and system performance, micrometer gauges are becoming essential across residential, commercial, and industrial HVAC applications. This growth trajectory is further supported by advancements in climate control technologies and the expansion of smart building ecosystems. In this evolving landscape, a select group of manufacturers has emerged as leaders, combining engineering precision with technological innovation to meet the rising global demand for reliable and accurate air conditioning measurement solutions.

Top 8 Air Conditioning Micrometer Gauge Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 SHIMADZU CORPORATION

Domain Est. 1994

Website: shimadzu.com

Key Highlights: Shimadzu provides a variety of industrial and testing equipment for the advancement of industrial fields such as semiconductors….

#2 Vacuum gauge for safe evacuation

Domain Est. 1996

Website: testo.com

Key Highlights: Vacuum gauge. High-precision vacuum measurement is an absolute must when it comes to the evacuation of heat pumps, air conditioning, and refrigeration systems.Missing: micrometer …

#3 Pfeiffer Vacuum+Fab Solutions

Domain Est. 1996

Website: pfeiffer-vacuum.com

Key Highlights: Vacuum pumps, systems and leak detectors for high and ultra-high vacuum applications. Trusted by leaders in semiconductor industry, research, and science….

#4 Digital Micron Vacuum Gauge

Domain Est. 1996

Website: robinair.com

Key Highlights: The RAVG-1 measures vacuum from Atmosphere to 10 microns in 6 different scales, and can withstand overpressure beyond 30 bar….

#5 Refrigeration Vacuum Gauges

Domain Est. 1996

Website: cpsproducts.com

Key Highlights: Choose from our selection of refrigeration vacuum gauges, including digital & wireless gauges. Buy precise technician tools from a CPS Products distributor!…

#6 Correctly Use Your Vacuum Gauge

Domain Est. 1997

Website: fieldpiece.com

Key Highlights: A vacuum gauge is the best tool to measure deep vacuum and “see” what’s going on with the system. Slow micron rise indicates moisture still burning off….

#7 HVAC

Domain Est. 1998

#8 Micron & Vacuum Gauges

Domain Est. 2007

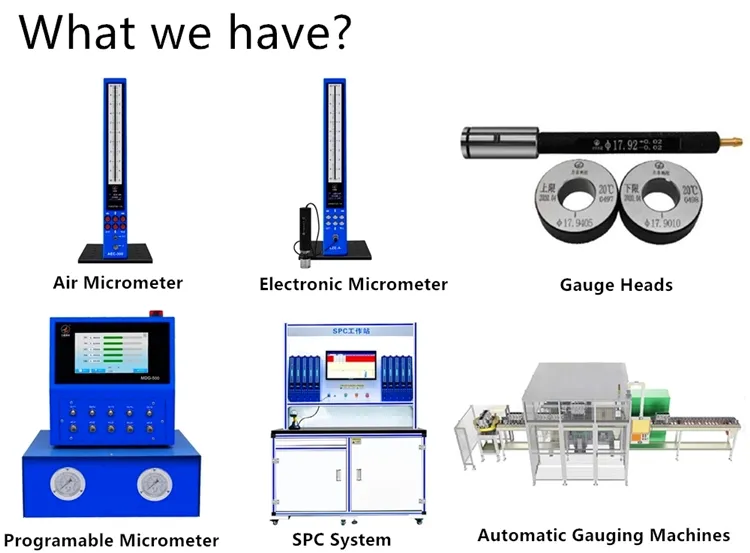

Expert Sourcing Insights for Air Conditioning Micrometer Gauge

H2: 2026 Market Trends for Air Conditioning Micrometer Gauge

The global market for air conditioning micrometer gauges is poised for steady growth and transformation by 2026, driven by technological advancements, increasing demand for HVAC system precision, and expanding regulatory standards for energy efficiency. These specialized tools, essential for accurate refrigerant pressure and temperature measurement in HVAC/R systems, are experiencing shifts influenced by several key trends.

1. Rising Demand in HVAC/R Maintenance and Diagnostics

With the growing complexity of modern air conditioning systems, especially in commercial and industrial applications, technicians increasingly rely on high-precision instruments like micrometer gauges. The expansion of smart HVAC systems and the need for accurate diagnostics to ensure optimal performance are fueling demand. The global push toward reducing system downtime and improving energy efficiency further supports the adoption of precision measurement tools.

2. Integration with Digital and Smart Technologies

By 2026, digital micrometer gauges equipped with Bluetooth connectivity, mobile app integration, and real-time data logging capabilities are expected to dominate the market. These enhancements allow HVAC professionals to record, analyze, and share system performance data seamlessly. The shift from analog to digital formats improves accuracy and reduces human error, aligning with the broader trend of digitization in the HVAC industry.

3. Focus on Energy Efficiency and Environmental Regulations

Stringent environmental regulations, such as the Kigali Amendment to the Montreal Protocol, are driving the phase-down of high-GWP refrigerants. This regulatory landscape demands precise refrigerant handling and leak detection—tasks that micrometer gauges support effectively. As HVAC systems transition to eco-friendly refrigerants, the need for accurate pressure and temperature measurement becomes even more critical, boosting demand for high-precision gauges.

4. Growth in Emerging Markets

Asia-Pacific, Latin America, and parts of Africa are witnessing rapid urbanization and rising demand for air conditioning, particularly in residential and commercial sectors. This growth is creating new opportunities for HVAC tools, including micrometer gauges. Local manufacturing and distribution networks are expanding to meet demand, while training initiatives are improving technician proficiency in using precision instruments.

5. Emphasis on Calibration and Quality Standards

By 2026, industry standards and certifications related to measurement accuracy (e.g., ISO 9001, NIST traceability) will play a greater role in product selection. Manufacturers are responding by offering gauges with improved durability, enhanced calibration features, and longer service life. This focus on reliability ensures consistent performance in field conditions and supports compliance with quality assurance protocols.

6. Competitive Landscape and Innovation

The market is becoming increasingly competitive, with established brands like Fieldpiece, GaugeTek, and Extech investing in R&D to offer multifunctional, rugged, and user-friendly micrometer gauges. Innovation in materials (e.g., corrosion-resistant components) and ergonomic design is enhancing product appeal. Additionally, bundled service packages—including calibration services and technical support—are becoming common value-added offerings.

In conclusion, the air conditioning micrometer gauge market in 2026 will be shaped by digital transformation, regulatory pressures, and global HVAC expansion. Manufacturers and service providers that prioritize precision, connectivity, and compliance will be best positioned to capitalize on emerging opportunities in this evolving sector.

Common Pitfalls When Sourcing Air Conditioning Micrometer Gauges (Quality, IP)

Sourcing air conditioning micrometer gauges—often referred to as manifold gauge sets or HVAC refrigerant gauges—requires careful attention to both quality and Ingress Protection (IP) ratings. Overlooking these aspects can lead to inaccurate readings, safety hazards, and equipment failure. Below are key pitfalls to avoid:

Poor Build Quality and Material Selection

Low-cost gauges often use inferior materials such as plastic components, thin metal housings, or low-grade brass. These can degrade quickly under high pressure, exposure to refrigerants, or frequent use. Poor sealing mechanisms and weak hose connections increase the risk of leaks and inaccuracies. Always verify that gauges are constructed with durable, refrigerant-compatible materials like brass, stainless steel, and reinforced rubber hoses.

Inaccurate or Unreliable Pressure Readings

A major quality concern is gauge calibration. Cheap or counterfeit gauges may have inconsistent or uncalibrated dials, leading to incorrect system diagnostics and improper refrigerant charging. Look for gauges that are NIST-traceable or come with a calibration certificate to ensure measurement accuracy.

Lack of Proper Ingress Protection (IP Rating)

Many HVAC technicians work in dusty, damp, or outdoor environments. Sourcing gauges without an appropriate IP rating (e.g., IP54 or higher) exposes internal components to moisture and debris, potentially damaging the gauge mechanism and electronics (if digital). An inadequate IP rating reduces lifespan and reliability—ensure the gauge housing is sealed against water splashes and dust ingress.

Misleading or Missing IP Certification

Some suppliers claim “water-resistant” without providing a valid IP rating. Always verify the IP rating through product documentation or third-party testing reports. Avoid products with vague or unsubstantiated claims about durability.

Incompatibility with Modern Refrigerants

Lower-quality gauges may not be compatible with newer, high-pressure refrigerants like R-32 or R-410A. This can result in gauge failure or safety risks. Confirm that the gauge set is rated for the specific refrigerants used in modern HVAC systems.

Poor Hose and Fitting Quality

Low-quality hoses can crack, leak, or burst under pressure. Similarly, poorly machined Schrader fittings may not seat properly, causing refrigerant leaks or contamination. Inspect hoses for thickness, flexibility, and UV resistance, and ensure fittings are precisely threaded and leak-tested.

Skipping Safety and Compliance Verification

Avoid gauges that lack safety certifications (e.g., CE, UL, or regional HVAC standards). These certifications indicate the product has undergone testing for pressure integrity, material safety, and environmental resistance—critical for both performance and user safety.

By addressing these pitfalls during procurement, HVAC professionals can ensure reliable, accurate, and long-lasting performance from their micrometer gauge sets.

Logistics & Compliance Guide for Air Conditioning Micrometer Gauge

Product Classification and HS Code

The Air Conditioning Micrometer Gauge is an HVAC diagnostic tool used to measure refrigerant pressure and system performance. It typically falls under the Harmonized System (HS) Code 9026.20 – Instruments and apparatus for measuring or checking pressure. However, classification may vary by country; always confirm with local customs authorities. Accurate classification ensures correct duty assessment and avoids shipment delays.

Import/Export Regulations

Micrometer gauges are generally not restricted items, but export controls may apply if the device contains sensitive measurement technology or dual-use components (e.g., high-precision sensors). Check compliance with export regulations such as the U.S. Export Administration Regulations (EAR) or EU Dual-Use Regulation. Ensure no sanctions apply to the destination country, especially for regions under trade restrictions.

Packaging and Shipping Requirements

Use durable, shock-resistant packaging with internal cushioning (e.g., foam inserts) to protect gauges during transit. Include moisture barriers if shipping to humid environments. Label packages with “Fragile” and “Do Not Stack” indicators. For air freight, comply with IATA packaging standards. For sea freight, ensure containers are waterproof and palletized appropriately.

Safety and Certification Compliance

Ensure micrometer gauges meet relevant safety and metrology standards, such as:

– CE Marking (European Economic Area) – meets EU health, safety, and environmental requirements.

– UL/CSA Certification (North America) – for electrical safety if gauge includes electronic components.

– ISO 9001 – quality management for manufacturing processes.

– NIST Traceability – for calibration accuracy, especially important in professional HVAC applications.

Documentation Requirements

Prepare the following documents for smooth customs clearance:

– Commercial Invoice (with product description, value, and HS code)

– Packing List

– Certificate of Origin

– Bill of Lading or Air Waybill

– Calibration Certificate (if applicable)

– Test Reports or Compliance Certifications (CE, UL, etc.)

Environmental and RoHS Compliance

Ensure the micrometer gauge complies with the EU’s Restriction of Hazardous Substances (RoHS) Directive 2011/65/EU. Verify that components do not contain prohibited substances such as lead, mercury, cadmium, or hexavalent chromium above threshold limits. Provide a RoHS compliance declaration upon request.

Battery and Hazardous Materials Consideration

If the gauge includes a lithium battery (e.g., for digital displays), follow IATA Dangerous Goods Regulations (DGR) for air transport. Batteries must be properly installed, protected from short circuits, and declared on shipping documents. Include UN38.3 test certification for lithium batteries.

Customs Clearance and Duties

Anticipate potential import duties and VAT based on the destination country’s tariff schedule. Provide accurate valuation to prevent customs audits. Use an experienced customs broker to facilitate clearance, especially in regions with complex regulatory environments (e.g., Brazil, India, or China).

Labeling and Language Requirements

Product labels must include:

– Manufacturer name and address

– Model number and serial number

– Measurement units (PSI, bar, etc.)

– Safety warnings in the local language (e.g., Spanish in Latin America, French in Canada)

– Compliance marks (CE, UKCA, etc.)

After-Sales and Warranty Logistics

Plan for reverse logistics in case of returns or repairs. Clearly state warranty terms and service procedures. Ensure spare parts and technical support are accessible in key markets to meet customer expectations and regulatory service requirements.

Summary

Proper logistics and compliance planning ensures timely delivery, avoids penalties, and supports market access. Always verify requirements with local regulatory bodies and stay updated on trade regulation changes affecting HVAC diagnostic tools.

Conclusion:

Sourcing a high-quality air conditioning micrometer gauge is essential for ensuring accurate pressure and temperature measurements in HVAC/R systems, which directly impacts system performance, efficiency, and reliability. When selecting a micrometer gauge, key factors such as precision, durability, ease of use, calibration standards, and compatibility with refrigerants must be carefully evaluated. Opting for reputable suppliers and trusted brands helps guarantee product accuracy and long-term service life. Additionally, considering after-sales support, warranty, and calibration services contributes to sustained operational effectiveness. Ultimately, investing in a reliable micrometer gauge from a verified source not only enhances diagnostic accuracy but also supports safe and efficient HVAC system maintenance and troubleshooting.