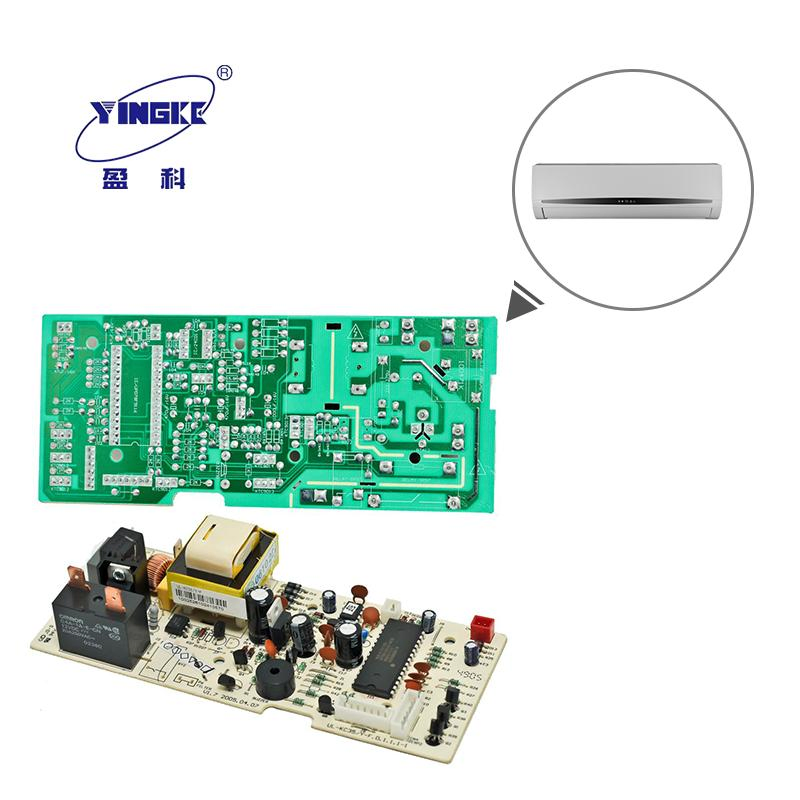

The global air conditioner circuit board market is experiencing robust growth, driven by rising demand for energy-efficient cooling systems, advancements in smart HVAC technologies, and expanding residential and commercial construction in emerging economies. According to Grand View Research, the global HVAC market size was valued at USD 157.8 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 7.6% from 2024 to 2030—directly fueling demand for reliable, high-performance circuit boards that control modern air conditioning units. Similarly, Mordor Intelligence projects the HVAC market to grow at a CAGR of over 7.4% during the forecast period of 2024–2029, citing increased adoption of smart thermostats and variable refrigerant flow (VRF) systems as key drivers. As air conditioners become more sophisticated, integrating IoT connectivity and advanced diagnostics, the role of the circuit board has become mission-critical. This growing complexity is reshaping the supply chain, positioning specialized electronics manufacturers at the forefront of AC innovation. In this evolving landscape, the top 10 air conditioner circuit board manufacturers are distinguishing themselves through technical expertise, scale, and strategic partnerships with leading HVAC OEMs worldwide.

Top 10 Air Conditioner Circuit Board Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Innovair Corporation (United States)

Domain Est. 1999

Website: innovair.com

Key Highlights: • PCB design with refrigerant cooling technology … We are committed to being one of the world’s most efficient manufacturers in air conditioning equipment….

#2 HONGFA

Domain Est. 1997

Website: hongfa.com

Key Highlights: HONGFA is the world’s largest relay manufacturer, holding the leading market share in power relays, automotive relays, HVDC relays, latching relays, ……

#3 Micro-Air – Come Chill with Us

Domain Est. 2016

Website: micro-air.com

Key Highlights: The leading manufacturer of Electronic Soft Starters. Marine Air Conditioning Control Boards and Communication Displays….

#4 AdvancedPCB

Domain Est. 2018

Website: advancedpcb.com

Key Highlights: Prototype to Production PCBs from AdvancedPCB. Choose us as your trusted PCB board manufacturer and circuit board manufacturer.Missing: air conditioner…

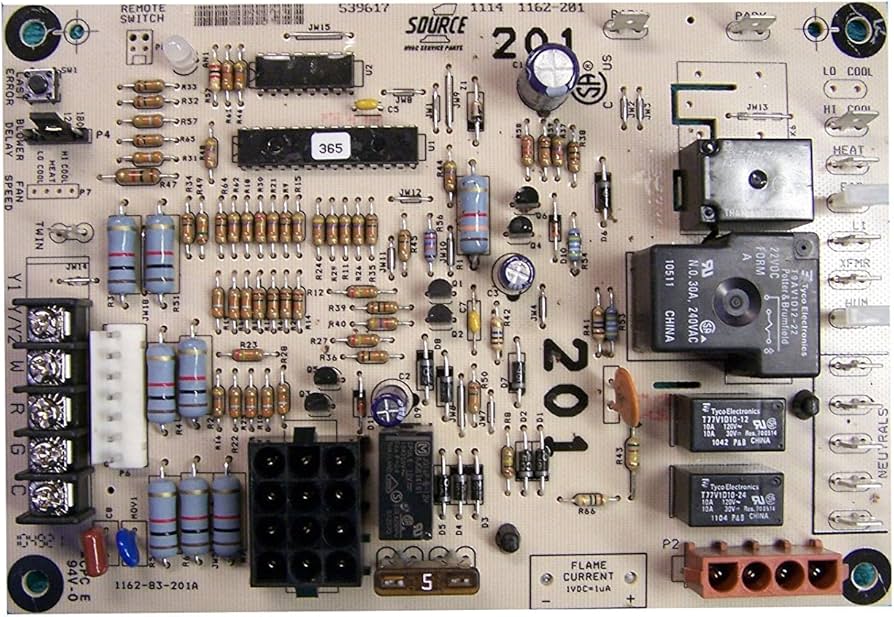

#5 Control Boards PCBs

Domain Est. 1995

Website: carrier.com

Key Highlights: Various Control Boards / PCB for different Tonnage of AC’s available in Stock for Carrier , Toshiba and Totaline AC’s….

#6 YORK

Domain Est. 1995

Website: york.com

Key Highlights: From cooling systems and heating systems to HVAC components that control humidity, YORK provides indoor air quality solutions for the way you live today….

#7 ICM Controls

Domain Est. 1996

#8 Bard Manufacturing

Domain Est. 1996

Website: bardhvac.com

Key Highlights: Bard offers high-quality commercial heating and cooling equipment to support a functional, comfortable environment….

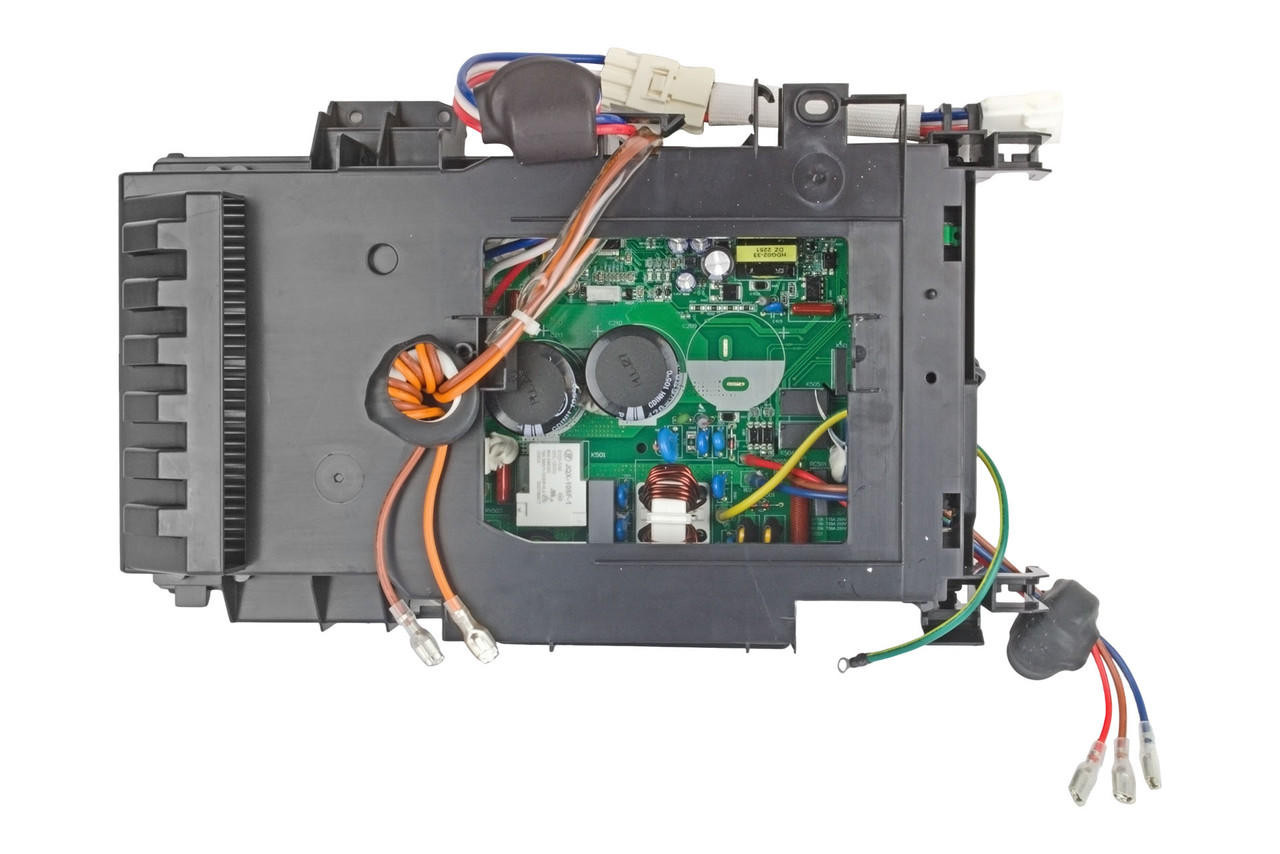

#9 HVAC/R Control Board & Electronics Contract Manufacturing

Domain Est. 2003

Website: etimfg.com

Key Highlights: ETI delivers HVAC contract manufacturing services for control boards and heating equipment PCBA built for performance, reliability, and scale….

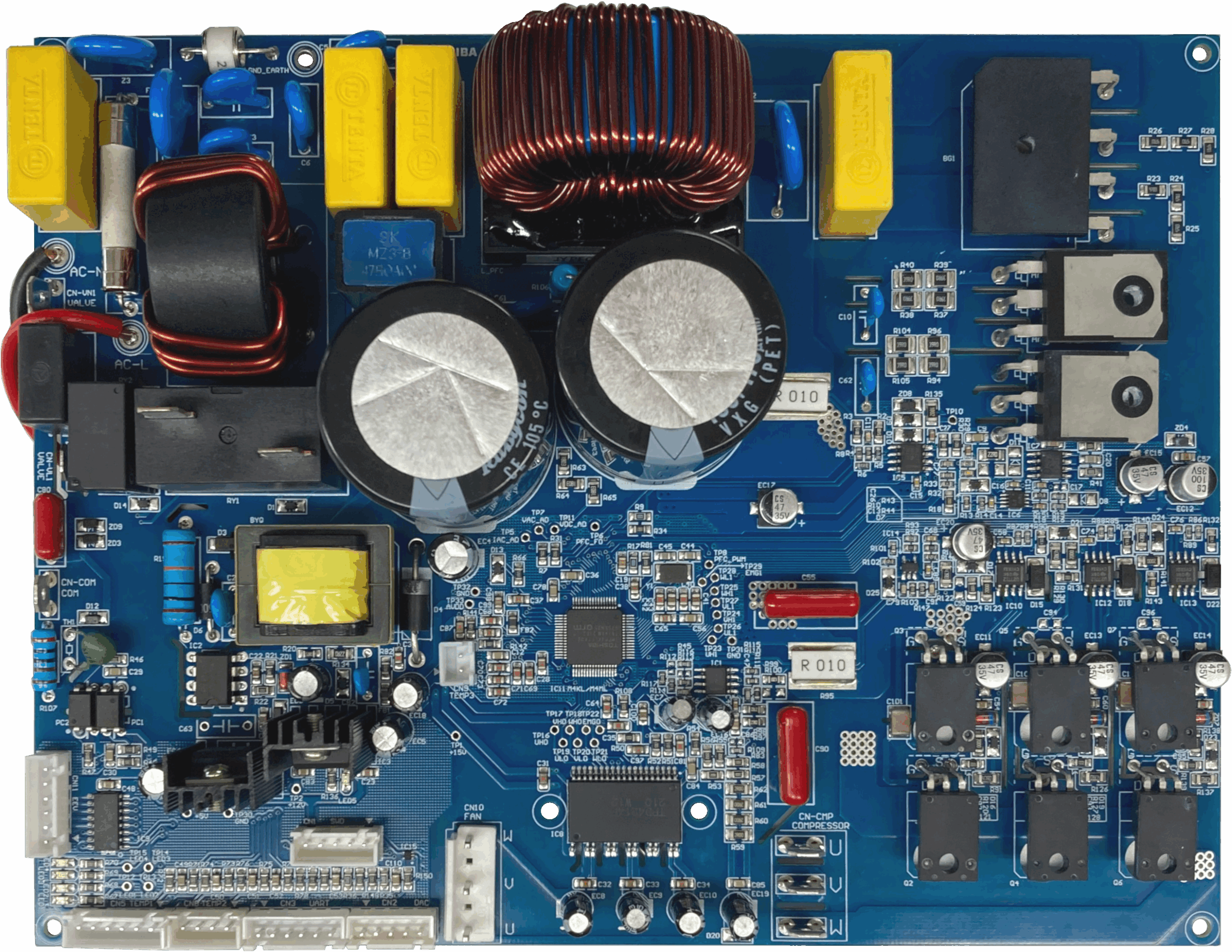

#10 Air Conditioner Outdoor Unit Control Circuit

Domain Est. 2014

Website: toshiba.semicon-storage.com

Key Highlights: This Reference Design provides design guide, data and other contents of the Air Conditioner Outdoor Unit that control two motors (fan motor, compressor) and a ……

Expert Sourcing Insights for Air Conditioner Circuit Board

H2: 2026 Market Trends for Air Conditioner Circuit Boards

The global market for air conditioner (AC) circuit boards is poised for significant transformation by 2026, driven by technological innovation, regulatory shifts, and evolving consumer demands. As the backbone of modern HVAC systems, circuit boards are becoming increasingly intelligent, energy-efficient, and integrated. Key trends shaping the 2026 landscape include:

-

Rise of Smart and IoT-Enabled AC Systems

The integration of Internet of Things (IoT) technology into residential and commercial air conditioning units is accelerating. By 2026, a growing share of AC circuit boards will support Wi-Fi connectivity, remote monitoring, and AI-driven climate control. This shift demands more advanced microcontrollers, enhanced communication protocols (e.g., Zigbee, Bluetooth Low Energy), and improved cybersecurity features in circuit design. -

Energy Efficiency and Regulatory Compliance

With global energy standards tightening—such as updates to SEER2 (Seasonal Energy Efficiency Ratio) in North America and Ecodesign regulations in the EU—manufacturers are prioritizing circuit boards that enable precise compressor control, variable-speed operation, and real-time energy optimization. In 2026, AC circuit boards will increasingly incorporate power management ICs and sensor fusion technology to meet stringent efficiency benchmarks. -

Growth in Inverter AC Adoption

Inverter technology, which relies heavily on sophisticated circuit boards for DC-AC conversion and motor control, continues to gain market share. Especially in Asia-Pacific and emerging markets, rising disposable incomes and energy cost concerns are fueling demand for inverter air conditioners. This trend will drive higher demand for PCBs with advanced power electronics, including IGBTs (Insulated Gate Bipolar Transistors) and intelligent gate drivers. -

Miniaturization and High-Density Interconnect (HDI) PCBs

To accommodate compact and aesthetically pleasing AC units, manufacturers are adopting smaller, more powerful circuit boards. By 2026, HDI and multilayer PCBs with improved thermal management will be standard, enabling greater functionality in reduced footprints. This also supports integration with sensors, touch controls, and voice assistant compatibility. -

Sustainability and Circular Economy Pressures

Environmental regulations are pushing for reduced use of hazardous materials (e.g., lead-free soldering) and greater recyclability. AC circuit board producers are expected to adopt eco-design principles, modular architectures, and improved traceability (e.g., through embedded QR codes or RFID tags) to support repairability and end-of-life recycling. -

Supply Chain Resilience and Regional Manufacturing Shifts

Geopolitical tensions and post-pandemic supply chain disruptions have prompted OEMs to diversify manufacturing locations. By 2026, we anticipate increased regional production of AC circuit boards in Southeast Asia, India, and Mexico, reducing dependency on single-source suppliers and lowering logistics costs. -

Increased Investment in R&D for AI and Predictive Maintenance

Leading HVAC companies are embedding machine learning algorithms into circuit board firmware to enable predictive diagnostics, such as detecting refrigerant leaks or compressor wear. These advancements will require more powerful onboard processors and over-the-air (OTA) update capabilities in AC control boards.

In summary, the 2026 air conditioner circuit board market will be defined by intelligence, efficiency, and connectivity. Manufacturers that invest in smart integration, energy optimization, and sustainable design will be best positioned to capture growth in a competitive and rapidly evolving industry.

Common Pitfalls Sourcing Air Conditioner Circuit Boards (Quality, IP)

Sourcing air conditioner (AC) circuit boards presents several critical challenges, particularly concerning quality and intellectual property (IP). Overlooking these pitfalls can lead to product failures, legal disputes, and damage to brand reputation. Below are key issues to watch for:

Poor Component Quality and Manufacturing Standards

Many suppliers, especially in low-cost regions, use substandard components such as capacitors, relays, or microcontrollers that degrade quickly under heat and humidity. Boards may also suffer from poor soldering, inadequate PCB layering, or lack of conformal coating, which compromises performance and lifespan. Always verify component sourcing and request certifications (e.g., ISO 9001, RoHS) to ensure manufacturing consistency.

Inaccurate or Incomplete IP Documentation

Circuit board designs often contain proprietary firmware, circuit layouts, or software algorithms. Sourcing from unauthorized manufacturers can result in IP infringement, especially if designs are reverse-engineered or copied without licensing. Ensure suppliers provide clear IP ownership documentation and sign Non-Disclosure Agreements (NDAs) to protect your designs and avoid legal exposure.

Lack of Environmental and IP Protection

Many AC circuit boards are exposed to moisture, dust, and temperature extremes. Sourcing boards without proper Ingress Protection (IP) ratings (e.g., IP54 or higher) increases failure risks. Boards lacking conformal coating or sealed connectors may corrode or short-circuit. Always specify required IP ratings and verify testing reports for humidity, vibration, and thermal cycling.

Incompatibility with OEM Specifications

Aftermarket or generic boards may claim compatibility but fail to match original equipment manufacturer (OEM) timing, voltage tolerances, or communication protocols. This leads to erratic operation, compressor damage, or system shutdowns. Request full technical specifications and conduct bench testing before full-scale procurement.

Firmware and Software Locks or Hidden Backdoors

Some sourced boards come with locked firmware, preventing updates or customization. Others may contain unauthorized code or backdoors, creating security vulnerabilities. Audit firmware sources and require access to flash or update capabilities under your control.

Supply Chain Transparency and Traceability Issues

Unverified suppliers may source counterfeit ICs or recycled components. Without a transparent supply chain, tracing component origins becomes impossible, increasing the risk of latent defects. Insist on full Bill of Materials (BOM) disclosure and use third-party inspection services when necessary.

Avoiding these pitfalls requires due diligence, clear contractual terms, and technical validation. Partnering with reputable, vetted suppliers and conducting regular quality audits are essential for ensuring reliable and legally compliant AC circuit board sourcing.

Logistics & Compliance Guide for Air Conditioner Circuit Board

This guide outlines key logistics and compliance considerations for the safe, efficient, and legal transportation and handling of air conditioner circuit boards (ACCBs). Adherence to these guidelines ensures product integrity, regulatory compliance, and supply chain reliability.

Regulatory Classification and Documentation

Proper classification under international and national regulations is foundational. ACCBs are typically classified as electrical components, often falling under HS Code 8537.10 or 8537.20 (printed circuit assemblies for appliances). Accurate classification determines applicable duties, taxes, and regulatory requirements.

Ensure all shipments are accompanied by accurate commercial invoices, packing lists, and bills of lading/air waybills. Include detailed descriptions (e.g., “Printed Circuit Board Assembly for Split-Type Air Conditioner, Model XYZ”), Harmonized System (HS) codes, country of origin, and declared value. Maintain records for at least five years for audit and customs verification.

Packaging and Handling Standards

Protect ACCBs from electrostatic discharge (ESD), moisture, physical shock, and contamination. Use ESD-safe packaging such as static-shielding bags, conductive foam, or pink poly bags, clearly labeled with ESD warning symbols.

Outer packaging must be robust, using double-wall corrugated boxes with internal cushioning (e.g., molded pulp, foam inserts) to prevent movement. Seal boxes securely and label with “Fragile,” “This Side Up,” and “Do Not Stack” if applicable. Avoid overpacking to prevent crushing.

Transportation Requirements

Coordinate transportation via air, sea, or land based on urgency, cost, and volume. For air freight, comply with IATA Dangerous Goods Regulations (DGR); while most ACCBs are not hazardous, some may contain small batteries or capacitors requiring specific handling.

For ocean freight, ensure containers are weatherproof and protected from condensation. Use desiccants in packaging and consider container desiccants for long voyages. Clearly label pallets or containers with shipping marks, barcodes, and handling instructions.

Import/Export Controls and Permits

Verify if ACCBs are subject to export controls, particularly under the Wassenaar Arrangement or national regulations (e.g., US EAR, EU Dual-Use Regulation), due to potential dual-use technology. Obtain necessary export licenses if required.

Check destination country import restrictions, including product standards, registration requirements (e.g., India’s BIS, China’s CCC), and potential bans on electronic waste (e-waste). Some countries require pre-shipment inspections or certificates of conformity.

Environmental and Safety Compliance

Ensure ACCBs comply with RoHS (Restriction of Hazardous Substances) and REACH regulations, restricting substances like lead, mercury, and certain phthalates. Provide compliance documentation (e.g., RoHS Declaration of Conformity) upon request.

Adhere to WEEE (Waste Electrical and Electronic Equipment) directives in applicable markets, which may require registration, reporting, and participation in take-back programs. Design packaging to minimize environmental impact and use recyclable materials where possible.

Customs Clearance and Duties

Facilitate smooth customs clearance by providing complete and accurate documentation. Utilize Authorized Economic Operator (AEO) status if available to benefit from simplified procedures and reduced inspections.

Determine duty rates based on the correct HS code and country of origin. Leverage free trade agreements (FTAs) where applicable by providing valid certificates of origin. Account for import VAT, customs processing fees, and potential anti-dumping duties.

Quality Assurance and Traceability

Implement lot tracking and serialization to enable traceability throughout the supply chain. Maintain quality control records for each batch, including test results and conformity certifications.

Conduct regular audits of logistics partners to ensure compliance with packaging, labeling, and handling standards. Address non-conformances promptly to prevent damage or delays.

Risk Management and Contingency Planning

Identify risks such as supply chain disruptions, customs delays, natural disasters, or regulatory changes. Develop mitigation strategies, including alternate shipping routes, buffer inventory, and insurance coverage for cargo (e.g., all-risk marine cargo insurance).

Maintain up-to-date contact lists for customs brokers, freight forwarders, and regulatory authorities in key markets to resolve issues swiftly.

Conclusion for Sourcing Air Conditioner Circuit Boards

In conclusion, sourcing air conditioner circuit boards requires a strategic approach that balances cost, quality, reliability, and technical compatibility. As a critical component responsible for controlling and regulating the operation of the air conditioning system, the circuit board must meet stringent performance and safety standards. Careful evaluation of suppliers—considering factors such as certifications (e.g., ISO, RoHS), manufacturing capabilities, technical support, and after-sales service—is essential to ensure long-term product reliability and customer satisfaction.

Sourcing from reputable manufacturers, whether domestic or international, can offer cost advantages, but it must be accompanied by rigorous quality control processes, including sample testing, factory audits, and ongoing compliance checks. Additionally, staying informed about technological advancements and regulatory requirements helps future-proof procurement decisions.

Ultimately, building strong partnerships with trusted suppliers, maintaining clear communication, and implementing a robust supply chain management strategy will enable consistent access to high-quality air conditioner circuit boards, supporting efficient production and enhancing end-product performance in a competitive market.