The global air compressor market is experiencing robust growth, driven by increasing demand across industrial, construction, and automotive sectors. According to Grand View Research, the global air compressor market was valued at USD 29.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.7% from 2023 to 2030. This growth is fueled by rising infrastructure development and the need for energy-efficient compressed air systems in surface preparation applications such as sandblasting. As industries prioritize durability, performance, and operational efficiency, demand for specialized air compressors compatible with sand blasters has surged. This has prompted leading manufacturers to innovate with higher CFM outputs, improved thermal management, and enhanced portability. Based on market trends and technical performance metrics, the following analysis highlights the top 10 air compressor manufacturers meeting the rigorous demands of sandblasting applications.

Top 10 Air Compressor For Sand Blaster Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Sandblast Solutions Inc.

Domain Est. 2014

Website: sandblastinc.com

Key Highlights: Sandblast Solutions provides surface preparation equipment, rentals, blasting gear, coatings, abrasives and more. Trusted nationwide for industrial job site ……

#2 Industrial Compressors for Sandblasting Applications

Domain Est. 1997

Website: milessupply.com

Key Highlights: We have a range of compressors to suit your sandblasting needs. Featured brands include Kaeser, ConX, VanAir, and Atlas Copco….

#3 Applied PI

Domain Est. 2007

Website: appliedpi.com

Key Highlights: Discover Our Reliable and Durable Sand Blasting Equipment, Proudly Made in Ireland. Explore Our Range of Products and Why You Should Choose Applied PI….

#4 Central Pneumatic® Air Compressor, Sand Blaster, Spray Gun …

Domain Est. 2024

Website: thecentralpneumatic.com

Key Highlights: Central Pneumatic is the leading manufacturer of high-quality air tools that get the job done. With a wide range of products including air compressors, sand ……

#5 Media and Sandblasting Compressed Air Systems

Domain Est. 1996

Website: us.kaeser.com

Key Highlights: Kaeser manufactures high pressure air compressors designed for sand and media blasting applications in both stationary and mobile options….

#6 Air Compressors for Sandblasting

Domain Est. 1997

Website: quincycompressor.com

Key Highlights: Sandblasters are most efficient when they produce 90-100 psi, and it’s best to choose a compressor capable of achieving that consistently….

#7 Commercial Mobile Sandblaster

Domain Est. 2011

Website: dustlessblasting.com

Key Highlights: The S Series trailer gives you the freedom to choose between two powerful options: a 185 CFM compressor or a 300 CFM upgrade—each built to meet different job ……

#8 Typhoon Blaster

Domain Est. 2014

Website: typhoonblaster.com

Key Highlights: Free delivery 3-day returnsNo air compressor is needed with the Typhoon Blaster. It is a patented system that uses water pressure and sand to clean surfaces. Ideal for cleaning pai…

#9 Eclipse Surface Technologies I Abrasive Blasting Equipment

Domain Est. 2017

Website: eclipseblast.com

Key Highlights: ClearBlast CB185x. Complete tow-behind system with a 185 CFM compressor, CB150 and docking station to keep your machine in place….

#10 Sandblasting Air Compressors

Domain Est. 2020

Website: kotechgroup.net

Key Highlights: Compressors for sandblasting are designed with high-power motors and efficient cylinders to maintain continuous operation….

Expert Sourcing Insights for Air Compressor For Sand Blaster

H2: Projected Market Trends for Air Compressors for Sand Blasters in 2026

The global market for air compressors specifically designed for sand blasters is expected to witness steady growth by 2026, driven by rising industrialization, infrastructure development, and increasing demand for surface preparation technologies across key sectors. Several macroeconomic and technological factors are shaping this trajectory.

-

Growing Demand in Industrial and Construction Sectors

The construction, automotive, shipbuilding, and manufacturing industries are increasingly adopting sand blasting for rust removal, paint stripping, and surface cleaning. As global infrastructure projects expand—especially in emerging economies like India, Southeast Asia, and parts of Africa—the need for reliable, high-pressure air compressors compatible with sand blasters is expected to rise significantly by 2026. -

Shift Toward Energy-Efficient and Portable Models

Environmental regulations and operational cost concerns are pushing manufacturers to develop energy-efficient air compressors. By 2026, there will be a noticeable shift toward oil-free, variable speed drive (VSD), and portable compressors that deliver consistent CFM (cubic feet per minute) and PSI (pounds per square inch) for sand blasting applications. Lightweight, mobile units are especially gaining traction among contractors and small-to-medium enterprises (SMEs). -

Adoption of Smart and IoT-Enabled Compressors

The integration of IoT (Internet of Things) and smart monitoring systems in industrial air compressors is a growing trend. By 2026, leading manufacturers are expected to offer smart air compressors equipped with sensors to monitor pressure, temperature, and maintenance needs in real time. These features enhance performance reliability and reduce downtime in sand blasting operations. -

Stringent Environmental and Safety Regulations

Environmental standards are becoming stricter, particularly concerning oil-lubricated compressors and emissions. Regulations such as ISO 8573 (air quality standards) and OSHA safety guidelines are influencing the design and operation of compressors used in abrasive blasting. This is accelerating the adoption of oil-free and low-noise compressors, especially in indoor or confined workspace environments. -

Regional Market Dynamics

North America and Europe will remain key markets due to high industrial activity and regulatory compliance requirements. However, the Asia-Pacific region is projected to register the highest CAGR (Compound Annual Growth Rate) by 2026, fueled by rapid urbanization, industrial modernization, and government investments in manufacturing and transportation infrastructure. -

Expansion of Rental and Shared Equipment Models

With the high upfront cost of industrial-grade air compressors, the equipment rental market is expanding. By 2026, an increasing number of construction firms and contractors are expected to opt for leased or shared air compressor units tailored for sand blasting, promoting cost efficiency and flexibility. -

Material Innovation and Performance Optimization

Advances in compressor materials—such as corrosion-resistant alloys and composite components—are enhancing durability and lifespan. These innovations will be critical for compressors used in abrasive environments like sand blasting, where moisture, dust, and particulate exposure are common.

In conclusion, the 2026 market landscape for air compressors for sand blasters will be defined by technological innovation, regulatory compliance, energy efficiency, and regional industrial growth. Manufacturers who align with these trends—focusing on portability, smart features, and sustainability—are likely to capture significant market share in the coming years.

Common Pitfalls When Sourcing an Air Compressor for a Sand Blaster (Quality and IP Considerations)

Logistics & Compliance Guide for Air Compressor For Sand Blaster

Product Classification & HS Code

Air compressors designed specifically for sandblasting applications are typically classified under the Harmonized System (HS) for international trade. The most common HS code is 8414.80, which covers “Air or vacuum pumps, air or other gas compressors and fans: Other.” However, exact classification may vary by country and specific technical specifications (e.g., motor power, pressure rating, portability). It is recommended to consult with a customs broker or use a binding tariff classification (BTC) ruling to confirm the correct code for your destination country.

Regulatory Compliance

Air compressors used with sand blasters must comply with safety, environmental, and quality regulations in both the country of origin and the destination market. Key compliance requirements include:

-

CE Marking (EU): Required for sale in the European Economic Area (EEA). The compressor must meet directives such as the Pressure Equipment Directive (PED) 2014/68/EU, Electromagnetic Compatibility (EMC) Directive 2014/30/EU, and Machinery Directive 2006/42/EC, depending on the design and components.

-

OSHA & ANSI (USA): In the United States, compressors must comply with OSHA 29 CFR 1910.169 (for compressed air equipment) and relevant ANSI standards, such as ANSI/NACE SP0188 for abrasive blasting safety. Pressure vessels may also require ASME certification.

-

Pressure Vessel Regulations: Compressors with storage tanks are considered pressure vessels and must meet jurisdictional requirements. In Canada, this includes compliance with the CSA B51 Boiler, Pressure Vessel, and Pressure Piping Code. In many countries, third-party certification (e.g., TÜV, UL, or CSA) is required.

-

RoHS & REACH (EU): Ensure electrical components comply with RoHS (Restriction of Hazardous Substances) and that materials meet REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) standards.

Packaging & Shipping Requirements

Proper packaging is essential to prevent damage during transit and ensure safe handling:

-

Crate or Palletized Shipping: Secure the compressor on a wooden or recyclable pallet using stretch wrap and corner protectors. For high-value or sensitive units, use a wooden crate with internal bracing.

-

Weather Protection: Use moisture-resistant wrapping or desiccant packs to prevent rust, especially for sea freight. Include waterproof covers if shipped in open containers.

-

Labeling: Clearly label packages with:

- Product name and model number

- Gross and net weight

- “Fragile,” “This Side Up,” and “Do Not Stack” indicators

- HS code and country of origin

-

Compliance marks (e.g., CE, UL)

-

Hazardous Materials: If the compressor contains oil or batteries, declare accordingly. Oil-lubricated compressors may be subject to IATA/IMDG regulations if shipped internationally.

Import Documentation

Ensure all necessary documents are prepared to avoid customs delays:

- Commercial Invoice (with detailed description, unit value, and total value)

- Packing List (itemizing contents per package)

- Bill of Lading (for sea) or Air Waybill (for air freight)

- Certificate of Origin

- Test Reports or Certificates of Conformity (e.g., CE, UL, CSA)

- Import License (if required by destination country)

Transportation Modes

- Air Freight: Best for urgent or high-value shipments. Weight and size restrictions apply; ideal for smaller, portable compressors.

- Sea Freight (FCL/LCL): Cost-effective for large volumes or heavy industrial units. Allow 2–6 weeks transit time depending on route.

- Ground Transport (Domestic/Regional): Suitable for regional distribution. Ensure compliance with local vehicle weight and load securement laws.

Storage & Handling

Upon arrival, handle and store units properly:

- Store indoors in a dry, temperature-controlled environment.

- Avoid exposure to moisture, dust, or corrosive agents.

- Follow manufacturer’s instructions for pre-use inspection and maintenance.

Environmental & Safety Considerations

- Noise Levels: Compressors must comply with local noise emission standards (e.g., EU Directive 2000/14/EC).

- Oil Disposal: For oil-lubricated models, follow local regulations for used oil handling and recycling.

- End-of-Life: Design for recyclability and comply with WEEE (Waste Electrical and Electronic Equipment) directives where applicable.

Summary

Successfully shipping air compressors for sand blasters requires attention to classification, compliance, packaging, and documentation. Partner with certified suppliers, verify local regulations, and use experienced freight forwarders to ensure smooth international logistics operations.

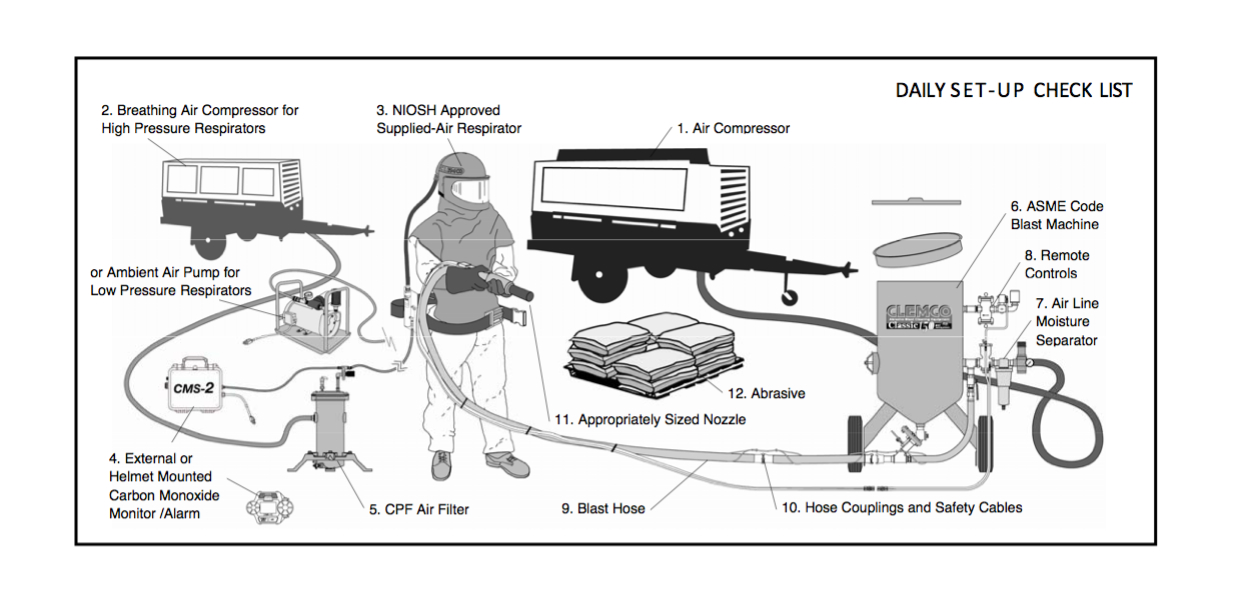

Conclusion: Sourcing an Air Compressor for a Sand Blaster

Selecting the right air compressor for a sand blasting operation is crucial to ensure efficient, consistent, and safe performance. After evaluating various factors such as CFM (cubic feet per minute) and PSI (pounds per square inch) requirements, duty cycle, compressor type (rotary screw vs. reciprocating), portability, and power source, it is clear that matching the compressor’s output to the sand blaster’s specifications is essential. An undersized compressor will lead to poor blasting performance and frequent downtime, while an oversized unit may result in unnecessary energy costs and maintenance.

For most sandblasting applications—especially in industrial or commercial settings—a high-capacity rotary screw compressor with sufficient CFM and consistent airflow delivers the best long-term value. However, for smaller, intermittent jobs, a durable reciprocating compressor may be more cost-effective. Additional considerations such as noise levels, maintenance requirements, and compatibility with existing equipment should also influence the final decision.

Ultimately, sourcing the appropriate air compressor involves balancing performance needs with operational efficiency and budget constraints. Consulting manufacturer specifications, seeking expert recommendations, and possibly renting equipment for testing can further ensure the chosen compressor meets the demands of the sandblasting process. A well-chosen air compressor not only improves productivity but also extends the lifespan of the blasting equipment, contributing to overall project success.