The global agricultural sprayer market is undergoing rapid transformation, driven by the increasing demand for precision farming, rising labor costs, and the need to enhance crop yields sustainably. According to Mordor Intelligence, the agri-spray market was valued at USD 11.5 billion in 2023 and is projected to grow at a CAGR of over 7.2% from 2024 to 2029. This growth is fueled by technological advancements such as GPS-guided systems, drone-based spraying, and IoT-enabled equipment that improve application accuracy and reduce chemical runoff. Key players in the sector are investing heavily in R&D to meet evolving agricultural demands and regulatory standards. As the industry consolidates and innovates, identifying the top agri-spray manufacturers becomes crucial for stakeholders seeking reliable, high-efficiency solutions. Based on market reach, product innovation, and performance metrics, the following eight companies have emerged as leaders shaping the future of agricultural spraying.

Top 8 Agri Spray Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Agri

Domain Est. 1996

Website: agri-fab.com

Key Highlights: Agri-Fab attachments are designed for homeowners who want beautiful lawns yet want the job of lawn care to be quick and easy….

#2 Agrifac crop sprayers

Domain Est. 2002

Website: agrifac.com

Key Highlights: Agrifac develops and produces innovative and sustainable self-propelled sprayers. Assembly takes place in the most sustainable factory in the Netherlands….

#3 Agrispray Drones

Domain Est. 2019

Website: agrispraydrones.com

Key Highlights: Spray Drones & Precision Ag Solutions. Welcome to Agri Spray Drones, North America’s most experienced distributor of agricultural spray drone technology….

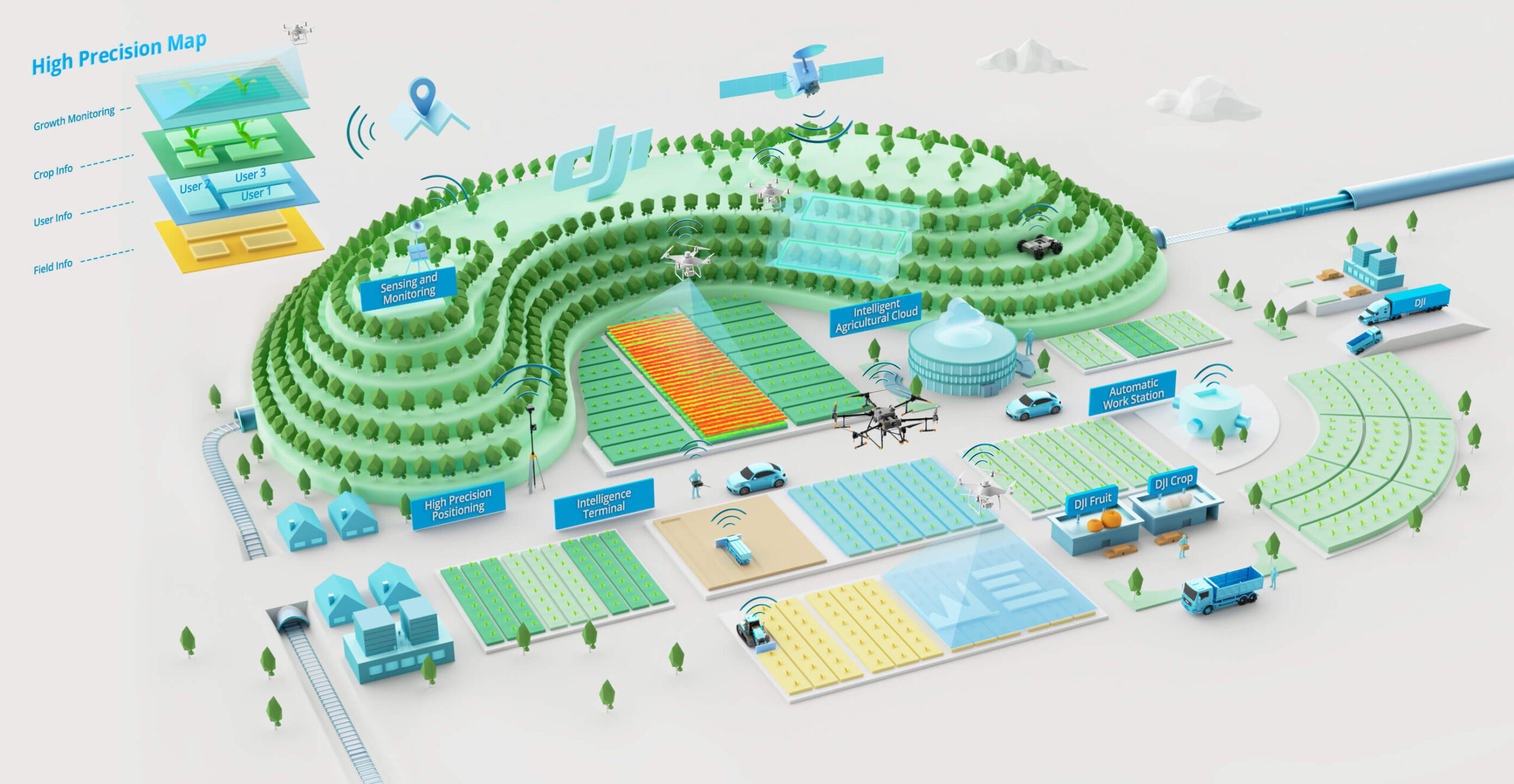

#4 DJI Agriculture

Domain Est. 1996

Website: ag.dji.com

Key Highlights: DJI Agriculture not only empowers agriculture professionals with powerful equipment but also provides intelligent solutions that save time and increase workflow ……

#5 Hopkinsville Ag Spray Location

Domain Est. 1998

Website: agspray.com

Key Highlights: Shop AG Spray Hopkinsville, KY for premium ag sprayers, quality parts, and outstanding local service that helps you get the job done right….

#6 Hylio AgDrones

Domain Est. 2014

Website: hyl.io

Key Highlights: Proudly American owned and operated, Hylio designs, manufactures, and provides drone systems for crop applications, wetland and forestry management, ……

#7 Agri Spray Drones

Domain Est. 2019

Website: wp.agrispraydrones.com

Key Highlights: Agri Spray Drones is dedicated to providing end-to-end agricultural drone solutions. Our knowledge of drones coupled with our experience in agriculture…

#8 Agriculture Sprayers & Equipment by Bestway Ag

Domain Est. 2018

Website: bestwayag.com

Key Highlights: The Bestway brand has built a reputation on quality and simplicity. Quality means solid construction, simple operations, and uncomplicated easy maintenance….

Expert Sourcing Insights for Agri Spray

H2: Market Trends Shaping the Agri-Spray Industry in 2026

The agri-spray sector is undergoing a transformative shift by 2026, driven by technological innovation, environmental regulations, and evolving agricultural practices. As global demand for food security rises alongside climate change pressures, agri-spray technologies are becoming central to sustainable and precision farming. Below are the key market trends shaping the Agri-Spray industry in 2026:

1. Precision Agriculture and Smart Spraying Technologies

By 2026, precision agriculture is the cornerstone of agri-spray adoption. Farmers are increasingly leveraging GPS-guided sprayers, variable rate technology (VRT), and AI-driven analytics to apply pesticides, herbicides, and fertilizers with pinpoint accuracy. Drones and autonomous ground vehicles equipped with multispectral sensors enable real-time crop health monitoring and targeted spraying, reducing chemical usage by up to 30–50%. This trend is especially strong in North America, Europe, and parts of Asia-Pacific, where large-scale farms dominate.

2. Regulatory Pressure and Eco-Friendly Formulations

Stricter environmental regulations across the EU (e.g., Green Deal) and North America are pushing agri-spray manufacturers toward bio-based and low-residue formulations. By 2026, demand for organic-compliant sprays and reduced-risk pesticides is rising, with biopesticides expected to grow at a CAGR of over 12%. Spray systems are also being optimized for lower drift and improved droplet control to meet compliance standards and minimize off-target effects.

3. Integration of IoT and Data Analytics

The Internet of Things (IoT) is revolutionizing agri-spray equipment. In 2026, smart sprayers are commonly connected to farm management software platforms, enabling data sharing across machinery and cloud-based analytics. Real-time data on weather, pest pressure, soil conditions, and spray coverage allows for dynamic decision-making. Companies like John Deere, AGCO, and precision tech startups are offering integrated ecosystems that enhance spray efficacy and record-keeping for traceability and regulatory compliance.

4. Growth in Drone-Based Spraying in Emerging Markets

In regions like Southeast Asia, India, and parts of Africa, drone-based agri-spraying is gaining rapid traction. Low labor costs and fragmented landholdings make traditional large-scale spraying impractical. Affordable agricultural drones from Chinese manufacturers (e.g., DJI Agras series) are being adopted widely, supported by government subsidies and training programs. By 2026, the Asia-Pacific region accounts for over 50% of global agricultural drone usage.

5. Focus on Sustainability and Carbon Footprinting

Sustainability certifications and ESG (Environmental, Social, and Governance) reporting are influencing agri-spray purchasing decisions. Equipment manufacturers are introducing energy-efficient, electric, or hybrid-powered sprayers to reduce carbon emissions. Additionally, closed-loop mixing and loading systems are being adopted to prevent chemical spills and reduce water contamination, aligning with circular economy principles.

6. Consolidation and Strategic Partnerships

The agri-spray market is witnessing increased consolidation, with agrochemical giants (e.g., Bayer, Syngenta, Corteva) partnering with tech firms and equipment manufacturers. These alliances aim to deliver integrated solutions — combining crop protection chemistry with precision delivery systems. Startups specializing in AI-driven spray optimization are being acquired or funded heavily, signaling strong investor confidence.

7. Labor Shortages Driving Automation

With ongoing labor shortages in agriculture, especially in developed economies, automation in spraying operations is accelerating. Fully autonomous sprayers capable of operating 24/7 are being piloted in countries like the U.S., Australia, and Germany. By 2026, semi-autonomous systems are becoming standard on mid-to-high-end sprayer models.

Conclusion

The 2026 agri-spray market is defined by a convergence of digital innovation, sustainability imperatives, and regulatory evolution. Success will depend on the industry’s ability to deliver efficient, precise, and environmentally responsible spraying solutions. Companies that invest in smart technologies, eco-friendly formulations, and integrated farm management platforms are best positioned to lead in this dynamic landscape.

Common Pitfalls in Sourcing Agri Spray: Quality and Intellectual Property Risks

Sourcing agricultural spray products—such as pesticides, herbicides, fungicides, or bio-stimulants—can be complex and fraught with risks, especially concerning product quality and intellectual property (IP) protection. Failing to address these pitfalls can lead to reduced crop efficacy, regulatory non-compliance, legal disputes, and reputational damage. Below are key challenges to consider:

Quality-Related Pitfalls

Inconsistent Formulation and Active Ingredient Variability

A major risk when sourcing agri sprays is receiving products with inconsistent concentrations of active ingredients. Suppliers, particularly in less-regulated markets, may vary formulations between batches or dilute active compounds to reduce costs. This inconsistency can lead to poor pest control, crop damage, or the development of resistant strains.

Lack of Standardized Testing and Certification

Many suppliers may not adhere to internationally recognized quality standards (e.g., ISO, CIPAC, or OECD guidelines). Without third-party lab testing or certification, buyers have no assurance of product purity, stability, or safety. This is especially prevalent when sourcing from manufacturers without transparent quality control processes.

Counterfeit or Substandard Products

The agrochemical market is vulnerable to counterfeit products that mimic reputable brands but lack efficacy or contain harmful contaminants. These products often enter supply chains through unauthorized distributors or online marketplaces, posing serious risks to crop health and human safety.

Improper Storage and Handling Affecting Shelf Life

Agri sprays are sensitive to temperature, light, and humidity. Sourcing from suppliers with inadequate storage infrastructure can result in degraded products upon delivery. Without proper cold chain or climate-controlled logistics, the chemical stability and potency of sprays may be compromised.

Non-Compliance with Local and International Regulations

Different countries have strict regulations on pesticide registration, labeling, and allowable residues (e.g., EPA in the U.S., EFSA in the EU). Sourcing products not approved for use in the target market can result in legal penalties, product seizure, or bans. Suppliers may claim compliance without providing verifiable documentation.

Intellectual Property-Related Pitfalls

Unauthorized Production or Generic Copies

Many agri spray formulations are protected by patents or trade secrets. Sourcing from manufacturers producing generic versions without proper licensing infringes on IP rights. This exposes the buyer to legal liability, particularly if the product is imported into jurisdictions with strong IP enforcement.

Lack of Transparency in Formulation Ownership

Suppliers may not disclose whether they own the formulation or are producing under license. This opacity makes it difficult to assess IP risks. Buyers may inadvertently distribute products that violate patents, leading to cease-and-desist orders or lawsuits from original innovators.

Reverse Engineering and Misappropriation

When working with contract manufacturers, there is a risk they may reverse engineer the formulation and sell it to competitors or under their own brand. Without strong contractual safeguards (e.g., non-disclosure agreements, IP assignment clauses), proprietary spray technologies can be compromised.

Weak Contractual Protections

Agreements with suppliers often lack robust IP clauses specifying ownership of formulations, manufacturing rights, and limitations on resale. This can lead to disputes over who controls the product design and whether the supplier can legally produce similar formulations for others.

Grey Market Distribution

Even when sourcing legitimate products, unauthorized resellers may divert goods into markets where the brand is not registered. This undermines brand control, creates legal exposure, and may void warranties or support from the original manufacturer.

Mitigation Strategies

- Conduct thorough due diligence on suppliers, including audits of manufacturing and quality control processes.

- Require batch-specific certificates of analysis (CoA) and proof of regulatory compliance.

- Use legally binding contracts that clearly define IP ownership, confidentiality, and permitted use.

- Partner with suppliers registered with recognized regulatory bodies and avoid unverified online vendors.

- Monitor supply chains for grey market activity and enforce distribution agreements.

By proactively addressing quality and IP risks, businesses can ensure the safety, efficacy, and legality of the agri sprays they source, protecting both their operations and end-users.

Logistics & Compliance Guide for Agri Spray

This guide outlines the essential logistics and compliance procedures for Agri Spray to ensure safe, efficient, and legally compliant operations in the agricultural spraying sector.

Regulatory Compliance

Adherence to national and regional regulations is mandatory for all Agri Spray activities. Key focus areas include:

- Pesticide Registration: Only use products registered with the relevant national authority (e.g., EPA in the U.S., HSE in the UK, APVMA in Australia). Verify registration status before procurement or application.

- Label Compliance: Strictly follow manufacturer instructions and label requirements for mixing, application rates, personal protective equipment (PPE), and environmental precautions.

- Sprayer Certification: Ensure all application equipment is calibrated and certified annually in accordance with industry standards and local regulations.

- Operator Licensing: All spray operators must hold valid, up-to-date certifications (e.g., NPTC PA1/PA6 in the UK, or equivalent credentials in other jurisdictions).

- Environmental Protection: Comply with buffer zone requirements near water bodies, residential areas, and sensitive habitats. Adhere to local restrictions on spray drift and runoff.

Transportation of Agricultural Chemicals

Safe and legal transport of agrochemicals is critical to prevent spills, contamination, and regulatory penalties.

- Approved Containers: Transport only in original, sealed, and labeled manufacturer containers. Never use food or beverage containers.

- Vehicle Requirements: Use vehicles equipped with spill kits, secure storage compartments, and placards if required by hazardous materials regulations (e.g., DOT in the U.S.).

- Documentation: Maintain accurate shipping manifests, safety data sheets (SDS), and transport permits where applicable. Drivers must carry required documentation at all times.

- Segregation: Store incompatible chemicals separately during transport (e.g., acids away from bases).

- Emergency Response: All drivers and field staff must be trained in spill response procedures and emergency contact protocols.

Storage Procedures

Proper storage prevents degradation of products and minimizes risk of exposure or contamination.

- Dedicated Facility: Store chemicals in a locked, well-ventilated, dry, and secure facility away from food, feed, and fuel.

- Spill Containment: Use bunded (double-walled) flooring or spill pallets to contain leaks. Secondary containment must hold at least 110% of the largest container.

- Labeling: Clearly label all stored chemicals with product name, registration number, and hazard symbols.

- Inventory Management: Maintain an updated inventory log with product names, quantities, and expiry dates. Conduct quarterly audits.

- First-In, First-Out (FIFO): Rotate stock to ensure older products are used first.

Application Protocols

Standardized field operations ensure efficacy and minimize environmental and health risks.

- Pre-Spray Planning: Conduct site assessments, review weather conditions, and confirm crop registration for selected products.

- Drift Management: Use low-drift nozzles, apply during optimal wind and temperature conditions, and respect buffer zones.

- Calibration: Calibrate sprayers before each season and after any major maintenance. Document calibration results.

- Record Keeping: Maintain detailed spray records including date, location, product used, rate, weather, target pest, and operator name. Retain for minimum 3–5 years as required by regulation.

Waste Management & Disposal

Responsible handling of waste protects the environment and ensures regulatory compliance.

- Triple Rinsing: Triple-rinse empty chemical containers and add rinse water to the spray tank. Puncture rinsed containers to prevent reuse.

- Waste Collection: Collect used containers and contaminated materials in designated labeled bins for recycling or hazardous waste disposal.

- Spill Cleanup: Use absorbent materials (e.g., vermiculite) for liquid spills. Dispose of contaminated materials as hazardous waste.

- Disposal Partners: Use only licensed waste disposal contractors. Maintain disposal receipts and manifests.

Training & Documentation

Ongoing education and meticulous record-keeping are foundational to compliance.

- Annual Training: Provide all staff with annual training on chemical safety, equipment use, emergency procedures, and regulatory updates.

- Safety Data Sheets (SDS): Maintain accessible SDS for all chemicals used on-site and in vehicles.

- Incident Reporting: Document and report all incidents (spills, exposures, near misses) promptly to management and relevant authorities if required.

- Audit Preparation: Conduct internal audits biannually to verify compliance with this guide and regulatory standards.

Environmental & Community Responsibility

Agri Spray is committed to sustainable practices and maintaining trust with local communities.

- Sensitive Area Notification: Notify nearby organic farms, schools, or apiaries before spraying within designated proximity.

- Pollinator Protection: Avoid spraying during bloom periods and adhere to pollinator protection plans.

- Water Protection: Never spray within buffer zones of rivers, lakes, or wells. Use GPS mapping to track application near sensitive areas.

- Public Communication: Provide a contact number for community inquiries and complaints related to spraying activities.

By following this guide, Agri Spray ensures operational excellence, legal compliance, environmental stewardship, and the safety of employees, clients, and the public.

Conclusion for Sourcing Agricultural Sprayers

In conclusion, sourcing agricultural sprayers requires a comprehensive approach that balances technical specifications, cost-efficiency, durability, and after-sales support. The selection process should be guided by specific farming needs, including crop type, field size, and application requirements. Evaluating suppliers based on product quality, compliance with safety and environmental standards, and availability of spare parts and servicing is crucial for long-term operational success.

Sourcing from reputable manufacturers—whether domestic or international—can lead to improved spraying efficiency, reduced chemical wastage, and enhanced crop yields. Additionally, considering innovative features such as GPS guidance, variable rate technology, and automated controls can future-proof farming operations and promote sustainable practices.

Ultimately, a well-informed sourcing strategy for agricultural sprayers not only optimizes input application but also contributes to increased productivity, environmental stewardship, and overall farm profitability. Investing time and resources in selecting the right equipment and supplier will yield significant returns across the agricultural value chain.