The global fumed silica market is experiencing robust growth, driven by rising demand across industries such as coatings, adhesives, personal care, and electronics. According to Grand View Research, the market was valued at USD 2.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. A key contributor to this trend is the increasing use of high-performance additives like Aerosil® 200, a hydrophilic fumed silica produced by Evonik Industries, renowned for its effectiveness in enhancing rheological properties and mechanical strength. As demand for premium-grade fumed silica intensifies, a select group of manufacturers have emerged as leaders in quality, innovation, and global reach. Here, we spotlight the top three manufacturers of Aerosil 200 and equivalent high-purity fumed silica products, based on production capacity, technological advancement, and market presence.

Top 3 Aerosil 200 Fumed Silica Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 AEROSIL 200 Silica

Domain Est. 2001

Website: products.palmerholland.com

Key Highlights: AEROSIL® 200 Silica is a hydrophilic fumed silica with a specific surface area of 200 m²/g. Widely usable in a broad range of applications. Principal: Evonik ……

#2 AEROSIL® 200 F

Domain Est. 2006

Website: evonik.com

Key Highlights: AEROSIL® 200 F is a hydrophilic fumed silica with a specific surface area of 200 m²/g. This special grade is manufactured according to HACCP-Guidelines….

#3 Documents

Domain Est. 2019

Website: coatino.com

Key Highlights: AEROSIL® 200 is a hydrophilic fumed silica with a specific surface area of 200 m2/g. Widely usable in a broad range of applications. shopping_cart….

Expert Sourcing Insights for Aerosil 200 Fumed Silica

As of now, specific market data for the year 2026 regarding Aerosil® 200 Fumed Silica is projected rather than historical, and detailed forecasts often depend on industry reports, supply-demand dynamics, and macroeconomic factors. However, using available trends and insights up to mid-2024, we can analyze the expected market trajectory for Aerosil 200 — a hydrophilic fumed silica produced by Evonik Industries — heading into 2026 under the H2 framework, which typically refers to the second half of a year in business and financial planning.

Below is an analysis of the 2026 market trends for Aerosil 200 Fumed Silica, focusing on H2 2026 (July–December 2026):

H2 2026 Market Trends for Aerosil 200 Fumed Silica

1. Demand Drivers in Key Industries

-

Coatings & Paints:

In H2 2026, the global coatings industry is expected to see steady growth, especially in high-performance and eco-friendly formulations. Aerosil 200 is widely used as a rheology modifier and anti-settling agent. Demand in construction, automotive refinishing, and industrial coatings is projected to rise, particularly in emerging markets in Asia-Pacific and Latin America, driving consistent demand for Aerosil 200. -

Adhesives & Sealants:

With increasing demand for structural bonding in electric vehicles (EVs), electronics, and construction, formulators are turning to fumed silica for reinforcement and thixotropy. Aerosil 200’s compatibility with silicone and polyurethane systems keeps it in high demand. H2 2026 could see seasonal peaks due to construction activity in colder climates preparing for winter. -

Printing Inks & Cosmetics:

The specialty inks sector, particularly for packaging and security printing, is expected to grow. Aerosil 200’s role in improving ink stability and viscosity control supports this trend. In cosmetics, although hydrophobic grades are more common, hydrophilic grades like Aerosil 200 are used in certain formulations (e.g., powders, emulsions), where demand remains stable. -

Battery & Energy Storage:

A growing application area. While not a primary component, fumed silica is used in battery sealants and thermal interface materials. With the EV and renewable energy storage sectors expanding rapidly, indirect demand for Aerosil products is expected to increase through H2 2026.

2. Supply Chain & Production Outlook

-

Evonik continues to optimize production capacity, with investments in digitalization and energy efficiency at its Marl and Antwerp plants. By H2 2026, supply is expected to be stable, assuming no major geopolitical or logistical disruptions.

-

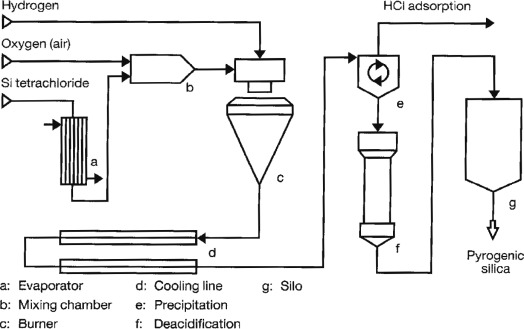

Raw material costs (primarily silicon tetrachloride and energy) are expected to remain moderate due to improved recycling processes and long-term supply contracts. This could support price stability for Aerosil 200.

-

Potential for regional diversification: Evonik may strengthen its Asia-Pacific supply chain presence, potentially reducing lead times for customers in China, India, and Southeast Asia by H2 2026.

3. Pricing Trends (H2 2026 Projection)

-

Pricing is expected to remain stable or increase slightly (1–3%) YoY in H2 2026, mainly influenced by energy costs and currency fluctuations (especially EUR/USD and EUR/CNY).

-

No major price surges are anticipated unless there are unforeseen supply constraints or regulatory changes (e.g., carbon taxes, REACH updates in Europe).

4. Competitive Landscape

-

Aerosil 200 remains a benchmark product in hydrophilic fumed silica. Competitors such as Cabot Corporation (CAB-O-SIL®), Wacker Chemie (HDK®), and Chinese producers (e.g., Sino-Group, Tianmu) offer alternatives, but Aerosil maintains strong brand loyalty due to consistency and technical support.

-

In H2 2026, competition may intensify in price-sensitive markets, but Evonik’s focus on innovation and sustainability (e.g., carbon footprint reduction, “Aerosil® Green” initiatives) could help retain premium positioning.

5. Sustainability & Regulatory Trends

-

Evonik’s sustainability roadmap targets carbon neutrality in fumed silica production by 2030. By H2 2026, customers in Europe and North America may increasingly favor suppliers with verifiable ESG (Environmental, Social, Governance) credentials.

-

Regulatory scrutiny on nanomaterials remains a watchpoint, but Aerosil 200 is well-documented and compliant with current REACH and FDA standards. No major regulatory barriers are expected in H2 2026.

6. Regional Market Highlights – H2 2026

- Europe: Seasonal slowdown in construction may slightly reduce demand in Q3, but industrial maintenance and automotive sectors maintain baseline usage.

- North America: Strong demand from adhesives, sealants, and energy sectors expected to support steady consumption.

- Asia-Pacific: H2 typically sees increased industrial activity post-monsoon and ahead of holiday manufacturing cycles, boosting demand. China’s recovery in manufacturing could drive volume growth.

Conclusion: H2 2026 Outlook for Aerosil 200 Fumed Silica

Aerosil 200 is expected to maintain its position as a leading hydrophilic fumed silica in H2 2026, supported by stable supply, consistent demand across core industries, and Evonik’s strong technical and sustainability initiatives. While price volatility is expected to be low, growth will be driven by expanding applications in high-tech sectors (e.g., EVs, electronics) and continued industrialization in emerging economies.

Market participants should monitor energy costs, geopolitical stability in key production regions, and evolving environmental regulations, but overall, H2 2026 appears favorable for Aerosil 200 with moderate growth and stable market conditions.

Note: This analysis is forward-looking and based on trends available up to mid-2024. Actual 2026 conditions may vary due to unforeseen economic, technological, or geopolitical developments.

H2: Common Pitfalls When Sourcing Aerosil® 200 Fumed Silica – Quality and Intellectual Property Concerns

When sourcing Aerosil® 200, a widely used hydrophilic fumed silica produced by Evonik Industries, buyers—especially in regulated or high-performance industries—must navigate several critical pitfalls related to product quality and intellectual property (IP) protection. Understanding these risks ensures consistent performance, regulatory compliance, and legal safety.

1. Counterfeit or Non-Genuine Products

A major risk is purchasing counterfeit or imitation fumed silica marketed as “Aerosil® 200.” Unauthorized suppliers may offer silica powders with similar specifications but lacking Evonik’s rigorous manufacturing controls. These imitations often fail to meet batch-to-batch consistency, purity, or surface area requirements, leading to formulation failures in sensitive applications (e.g., pharmaceuticals, adhesives, or cosmetics).

Impact:

– Inconsistent rheological behavior

– Contamination risks (e.g., higher metal ion content)

– Regulatory non-compliance in GMP or FDA-regulated sectors

2. Lack of Traceability and Documentation

Genuine Aerosil® 200 comes with full certification, including Certificates of Analysis (CoA), Safety Data Sheets (SDS), and traceable batch numbers. Illegitimate sources frequently lack proper documentation or provide falsified certificates.

Best Practice:

Require CoAs directly from Evonik or authorized distributors. Verify batch numbers through Evonik’s authentication systems where available.

3. Intellectual Property (IP) Infringement

The trademark “Aerosil®” is legally protected by Evonik. Unauthorized use of the brand name—even if the product is technically similar—constitutes trademark infringement. Some suppliers may label generic fumed silica as “Aerosil-type” or “Aerosil 200 equivalent” to imply equivalence without licensing.

Legal Risk:

– Use or resale of misbranded materials may expose companies to IP litigation

– Invalidates warranty or technical support from Evonik

– Jeopardizes patent claims in formulations dependent on certified materials

4. Inadequate Supply Chain Controls

Purchasing through third-party distributors or online marketplaces (e.g., B2B platforms) increases exposure to gray-market goods. These channels may lack temperature-controlled storage or proper handling, leading to moisture absorption or aggregation—especially critical for hydrophilic grades like Aerosil® 200.

Quality Red Flags:

– Clumping or caking in packaging

– Unstable viscosity in dispersions

– Deviations in BET surface area or sieve residue

5. Misrepresentation of Specifications

Some suppliers may publish data sheets mirroring Evonik’s Aerosil® 200 specs (e.g., 200 m²/g surface area) without independent verification. However, minor differences in structure, pH, or loss on drying can significantly affect performance.

Key Differentiators:

– Reproducible aggregate size and particle morphology

– Low heavy metal content (critical in pharma)

– Controlled sodium content for electronic or coating applications

Mitigation Strategies

– Source exclusively through Evonik or their authorized distribution partners

– Audit supplier credentials and request proof of authenticity

– Conduct incoming quality control testing (e.g., surface area analysis, XRF for contaminants)

– Avoid suppliers using ambiguous labeling (e.g., “equivalent to Aerosil® 200”)

– Include trademark compliance clauses in procurement contracts

Conclusion

Sourcing genuine Aerosil® 200 requires vigilance against counterfeit materials and IP violations. Prioritizing authorized supply channels, verifying documentation, and understanding the legal and technical nuances of trademarked products protect both product quality and corporate liability. When performance and compliance are paramount, authenticity cannot be compromised.

Logistics & Compliance Guide for AEROSIL® 200 Fumed Silica

Prepared in accordance with H2 Safety Data Sheet (SDS) Format

1. Product Identification

- Product Name: AEROSIL® 200 Fumed Silica

- Chemical Name: Fumed Silica (Pyrogenic Silica), Silicon Dioxide

- CAS Number: 112945-52-5

- EC Number: 231-545-4

- Formula: SiO₂

- Molecular Weight: 60.08 g/mol

- Supplier: Evonik Operations GmbH

- Address: Rellinghauser Str. 1-11, 45128 Essen, Germany

- Emergency Phone: +49 (0) 201 177 3333 (24/7)

2. Hazards Identification (H2 Format)

| Hazard Class | H-Phrase (Hazard Statement) | P-Phrase (Precautionary Statement) |

|————–|—————————–|————————————-|

| Not classified as hazardous under GHS (Globally Harmonized System) | — | — |

| Specific Hazards: | H319: Causes serious eye irritation | P305 + P351 + P338: IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses, if present and easy to do. Continue rinsing. |

| | H335: May cause respiratory irritation | P261: Avoid breathing dust/fume/gas/mist/vapors/spray.

P271: Use only outdoors or in a well-ventilated area. |

| | H412: Harmful to aquatic life with long-lasting effects | P273: Avoid release to the environment. |

Note: AEROSIL® 200 is not flammable, not explosive, and not oxidizing.

3. Composition / Information on Ingredients

- Ingredient: Amorphous Fumed Silica (SiO₂)

- Concentration: >99.8%

- Impurities: Trace amounts of sodium, potassium, aluminum (typically <0.1%)

- Nanoform: Yes – primary particles are nano-sized (approx. 12 nm), but product is typically handled as an aggregated powder.

Note: No substances listed under REACH Annex XIV (SVHC) or subject to restriction (Annex XVII) at concentrations requiring notification.

4. First Aid Measures

| Exposure Route | First Aid Procedure |

|—————-|———————|

| Inhalation: | Move to fresh air. If breathing is difficult, give oxygen. Seek medical attention if symptoms persist. |

| Skin Contact: | Wash with plenty of water and soap. Remove contaminated clothing. |

| Eye Contact: | Rinse immediately with plenty of water for at least 15 minutes. Seek medical advice. |

| Ingestion: | Rinse mouth. Do NOT induce vomiting. Consult a physician. |

5. Fire-Fighting Measures

- Extinguishing Media: Not flammable. Use extinguishing agents appropriate for surrounding fire (e.g., water, foam, CO₂, dry powder).

- Special Hazards: No combustion products under normal conditions. In case of fire, fine silica dust may form and be irritating.

- Protective Equipment: Wear self-contained breathing apparatus (SCBA) and full protective gear.

6. Accidental Release Measures

- Personal Precautions: Avoid dust formation. Use respiratory protection if dust is present.

- Containment: Prevent entry into drains, watercourses, or soil.

- Cleanup: Collect mechanically using vacuum equipment suitable for fine dust (HEPA filter). Do not sweep – generates dust.

- Disposal: Dispose of waste in accordance with local, regional, and national regulations.

7. Handling and Storage

- Handling:

- Use only in well-ventilated areas.

- Avoid breathing dust. Use local exhaust ventilation if needed.

- Avoid contact with eyes and skin.

-

Ground equipment to prevent static discharge (though not flammable, dust can be electrostatically charged).

-

Storage:

- Store in original, tightly closed containers.

- Keep dry and protected from moisture.

- Store in a cool, well-ventilated area.

- No special temperature requirements.

- Keep away from strong alkalis (e.g., NaOH, KOH) – may react.

8. Exposure Controls / Personal Protection

| Parameter | Limit Value | Control Measures |

|———|————-|——————|

| OSHA PEL (USA): | 10 mg/m³ (total dust); 5 mg/m³ (respirable fraction) | Ventilation, respiratory protection |

| ACGIH TLV (USA): | 3 mg/m³ (respirable fraction, as quartz-free silica) | Engineering controls |

| EU OEL (89/678/EEC): | 4 mg/m³ (inhalable fraction); 1.5 mg/m³ (respirable) | Use local exhaust, PPE |

- Engineering Controls: Local exhaust ventilation, closed handling systems.

- Personal Protective Equipment (PPE):

- Respiratory Protection: NIOSH-approved N95 or equivalent for dust. Higher protection (e.g., FFP2/FFP3) if airborne concentration exceeds limits.

- Eye Protection: Safety goggles or face shield.

- Skin Protection: Wear gloves (nitrile or neoprene), long-sleeved clothing.

- Hygiene Measures: Wash hands after handling. Do not eat, drink, or smoke in work area.

9. Physical and Chemical Properties

- Appearance: White, free-flowing powder

- Odor: Odorless

- pH: 3.7 – 4.7 (4% dispersion in water)

- Melting Point: ~1600 °C (softens gradually)

- Density:

- Bulk density: ~50 g/L

- True density: ~2.2 g/cm³

- Solubility: Practically insoluble in water and organic solvents

- Particle Size (primary): ~12 nm

- Specific Surface Area (BET): 200 m²/g (±25%)

- Ignition Temperature: Not applicable (non-flammable)

10. Stability and Reactivity

- Stability: Stable under normal conditions.

- Conditions to Avoid: Strong alkalis (may cause degradation).

- Incompatible Materials: Concentrated alkali solutions (e.g., NaOH, KOH).

- Hazardous Decomposition Products: None under normal conditions.

11. Toxicological Information

- Acute Toxicity: LD50 (oral, rat): >5,000 mg/kg – low toxicity

- Inhalation: LC50 (rat, 4h): >2.5 mg/L – low acute toxicity, but may cause lung irritation with prolonged exposure.

- Skin Irritation: Mild to moderate (not classified).

- Eye Irritation: Causes serious eye irritation (classified as H319).

- Respiratory Irritation: May cause irritation (H335).

- Repeated Dose Toxicity: No significant systemic effects observed in subchronic studies.

- Carcinogenicity:

- IARC: Not classified (amorphous silica ≠ crystalline silica).

- NTP: Not listed.

- EU CLP: Not classified as carcinogen.

Note: AEROSIL® 200 is amorphous silica, not crystalline (e.g., quartz). It is not classified as a human carcinogen.

12. Ecological Information

- Ecotoxicity:

- Algae (72h EC50): >100 mg/L

- Daphnia (48h EC50): >100 mg/L

- Fish (96h LC50): >100 mg/L

- Persistence & Degradability: Inorganic, does not degrade; persists in environment.

- Bioaccumulation: Not expected to bioaccumulate.

- Other Adverse Effects: H412 – Harmful to aquatic life with long-lasting effects.

13. Disposal Considerations

- Waste Code (EU): Not hazardous waste under Directive 2008/98/EC (typically non-hazardous).

- Disposal: Dispose of in accordance with local waste regulations. May be landfilled as inert waste if permitted.

- Recycling: Not typically recycled; consider recovery of containers.

- Incineration: Not applicable (inorganic).

14. Transport Information

- UN Number: Not regulated (UN 3260 for silica gel does not apply)

- Proper Shipping Name: Not regulated as dangerous goods

- Hazard Class: Not applicable

- Packing Group: Not applicable

- Special Precautions: Prevent dust generation during handling. Use sealed containers.

- Regulations:

- IMDG (Sea): Not regulated

- IATA (Air): Not regulated

- ADR/RID (Road/Rail in EU): Not classified as dangerous goods

Note: In bulk powder form, follow general industrial powder handling practices.

15. Regulatory Information

- EU REACH: Registered substance (Registration Number available upon request).

- TSCA (USA): Listed

- Canada DSL: Listed

- K-REACH (Korea): Registered

- China IECSC: Listed

- OSHA Hazard Communication Standard (29 CFR 1910.1200): Compliant

- CLP Regulation (EC) No 1272/2008: Classified as:

- Eye Irrit. 2 (H319)

- STOT SE 3 (H335)

- Aquatic Chronic 4 (H412)

16. Other Information

- SDS Preparation Date: [Insert Date]

- Revision Number: [Insert Version]

- GHS Label Elements:

- Pictograms: GHS07 (Exclamation Mark), GHS09 (Environment)

- Signal Word: Warning

- Hazard Statements:

- H319: Causes serious eye irritation

- H335: May cause respiratory irritation

- H412: Harmful to aquatic life with long-lasting effects

- Precautionary Statements: See Section 2

Disclaimer: This document is based on current knowledge and is intended for professional users. Always consult the latest version of the SDS from Evonik.

For more information, visit:

www.aerosil.com

Or contact Evonik Customer Service or your local representative.

End of Document

Conclusion:

After a thorough evaluation, sourcing Aerosil® 200 fumed silica from reputable suppliers such as Evonik Industries — the original manufacturer — or authorized distributors presents a reliable and high-quality solution for applications requiring premium-grade fumed silica. Aerosil® 200 is widely recognized for its consistent performance in enhancing rheological properties, improving mechanical strength, and providing effective thixotropy in various industries including coatings, adhesives, polymers, and cosmetics.

Key advantages of sourcing this product include its high surface area (approximately 200 m²/g), excellent dispersibility, and proven track record across industrial applications. Ensuring supply chain integrity through certified suppliers guarantees product authenticity, quality consistency, and compliance with health, safety, and environmental standards.

In conclusion, selecting Aerosil® 200 from trusted sources supports long-term process efficiency, product performance, and innovation. It is recommended to establish direct partnerships with Evonik or their approved distribution network to ensure technical support, stable supply, and access to the latest product data and safety documentation.