The global aerated concrete block market is experiencing robust growth, driven by rising demand for energy-efficient and sustainable construction materials. According to a 2023 report by Mordor Intelligence, the market was valued at USD 5.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.4% from 2023 to 2028. This expansion is fueled by increasing urbanization, stringent building regulations promoting thermal insulation, and the construction industry’s shift toward lightweight, fire-resistant, and eco-friendly materials. Aerated autoclaved concrete (AAC) blocks, known for their superior insulation properties, ease of handling, and reduced structural load, are becoming a preferred alternative to traditional bricks. As demand surges across residential, commercial, and industrial sectors—particularly in emerging economies—the competitive landscape has intensified, giving rise to innovative manufacturing players across Asia, Europe, and North America. In this evolving market, identifying the leading aerated concrete block manufacturers provides critical insight for contractors, developers, and procurement professionals seeking high-performance, cost-effective building solutions.

Top 10 Aerated Concrete Block Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 – Aircrete Europe

Domain Est. 2003

Website: aircrete.com

Key Highlights: Aircrete Europe is the leader in AAC panel production technology with it`s unique flat-cake cutting line for accurate dimensions and SUPER SMOOTH surfaces….

#2 AERCON AAC

Domain Est. 2005

Website: aerconaac.com

Key Highlights: AERCON AAC is the Leading Manufacturer of American-made Autoclaved Aerated Concrete (AAC) Products. AERCON AAC provides comprehensive technical support and ……

#3 AAC Blocks Manufacturers

Domain Est. 2008

Website: magicrete.in

Key Highlights: Rating 4.8 (35) Magicrete AAC blocks represent a new era in construction materials, offering unmatched strength, lightweight design, and eco-friendliness….

#4 Megaacrete

Domain Est. 2023

Website: megaacrete.com

Key Highlights: Megaacrete Systems provides cutting-edge construction technology through ultra-lightweight concrete solutions designed to enhance the performance and resilience ……

#5 Bauroc group

Founded: 2001

Website: bauroc.eu

Key Highlights: Bauroc is the largest producer of aircrete i.e. autoclaved aerated concrete (AAC) products in Northern Europe. The family-owned group, established in 2001 ……

#6 Aerblock

Domain Est. 2000

Website: aerblock.com

Key Highlights: We strive to play a crucial role in furthering the advancement of aerated, lightweight cementitious technologies here in the US and around the world….

#7 AAC Block

Domain Est. 2000

Website: brocoindustries.com

Key Highlights: LeichtBric Premium AAC (Aerated Autoclaved Concrete) is a high-grade masonry material that is both light weight and solid, and that can be used internally and ……

#8 AAC Blocks

Domain Est. 2004

Website: shreecement.com

Key Highlights: Autoclaved Aerated Concrete (AAC) block is an environment friendly precast building material that provides high thermal insulation and durability….

#9 Light Weight Cement Blocks,Autoclaved Aerated Concrete Blocks by …

Domain Est. 2012

Website: aerconindia.com

Key Highlights: The AAC Blocks made by us at Aercon India are manufactured by combining Fly ash, Cement, Lime, Gypsum, Aluminium Powder & Water….

#10 Bigbloc Construction

Domain Est. 2024

Website: bigbloc.in

Key Highlights: We are engaged in the manufacturing and supplying of AAC (Autoclaved Aerated Concrete) Blocks, construction chemicals, and building materials….

Expert Sourcing Insights for Aerated Concrete Block

H2: 2026 Market Trends for Aerated Concrete Blocks

The global aerated concrete block (AAC) market is poised for significant transformation and growth by 2026, driven by a confluence of technological innovation, environmental regulations, and shifting construction dynamics. Key trends shaping the market include rising demand for sustainable building materials, advancements in manufacturing efficiency, expanding urbanization in emerging economies, and supportive government policies promoting energy-efficient construction.

Sustainability and Green Building Initiatives:

One of the dominant drivers of the AAC market through 2026 is the increasing emphasis on green building practices. Aerated concrete blocks are inherently energy-efficient, offering superior thermal insulation and reducing the need for heating and cooling in buildings. As global carbon reduction targets tighten—especially under frameworks like the Paris Agreement—governments and private developers are prioritizing low-carbon construction materials. Certifications such as LEED, BREEAM, and GreenPro are encouraging the adoption of AAC, which contributes to higher scores due to its recyclability, low embodied energy, and improved indoor air quality.

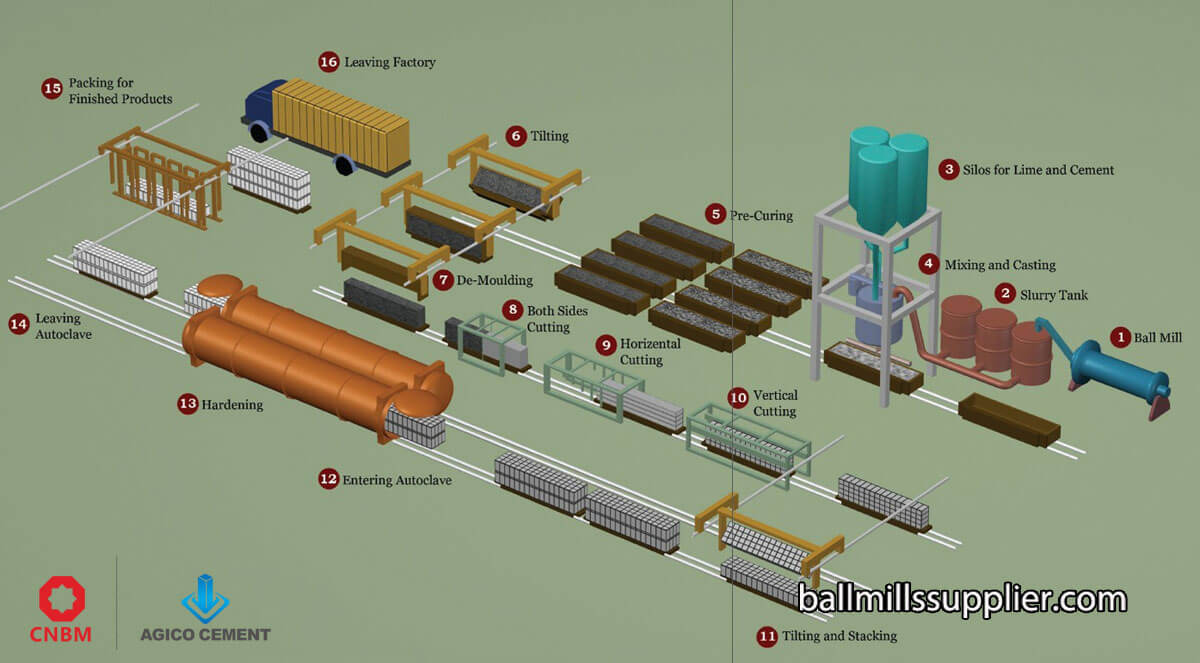

Technological Advancements and Production Optimization:

By 2026, manufacturers are expected to adopt smart manufacturing technologies, including automation, IoT-enabled monitoring, and AI-driven quality control systems, to enhance production precision and reduce waste. Innovations in raw material sourcing—such as increased use of fly ash and other industrial by-products—are improving the environmental profile of AAC while reducing production costs. Additionally, research into lightweight, high-strength AAC formulations is expanding its applications beyond non-load-bearing walls to structural elements, opening new market segments.

Growth in Emerging Markets:

Asia-Pacific, particularly India, China, and Southeast Asian countries, will remain the epicenter of AAC market expansion through 2026. Rapid urbanization, housing shortages, and government-backed infrastructure projects are fueling demand. In India, for instance, initiatives like “Housing for All” and “Smart Cities Mission” are accelerating the use of prefabricated and sustainable materials like AAC. Similarly, in the Middle East and Africa, construction booms in countries such as Saudi Arabia and Nigeria are creating new opportunities for AAC adoption due to its cost-effectiveness and quick installation.

Regulatory Support and Building Code Revisions:

Several countries are revising building codes to mandate higher energy efficiency standards, indirectly promoting AAC usage. In Europe, the Energy Performance of Buildings Directive (EPBD) and similar regulations in North America are pushing builders toward thermally efficient materials. By 2026, it is anticipated that more regions will integrate AAC-friendly standards into national construction codes, further validating its role in modern construction.

Challenges and Competitive Landscape:

Despite strong growth momentum, the AAC market faces challenges including high initial capital investment for manufacturing plants, competition from traditional bricks and alternative lightweight blocks (e.g., foam concrete), and inconsistent raw material quality. However, leading players such as H+H International, Bansal Group, and Shree Pushkar Chemicals & Fertilizers are investing in R&D and regional expansion to consolidate market share. Strategic partnerships with construction firms and developers are also becoming common, ensuring integrated supply chains and faster project delivery.

In conclusion, the 2026 aerated concrete block market will be characterized by robust growth, technological innovation, and strong alignment with global sustainability goals. As urban development continues and environmental regulations tighten, AAC is expected to transition from a niche alternative to a mainstream construction material across residential, commercial, and industrial sectors.

Common Pitfalls Sourcing Aerated Concrete Blocks (Quality and IP)

Sourcing high-quality aerated concrete blocks (AAC blocks) requires careful attention to both material specifications and intellectual property considerations. Overlooking key factors can lead to structural issues, project delays, and legal complications. Below are common pitfalls to avoid:

Inadequate Quality Control and Specification Oversight

One of the most frequent issues when sourcing AAC blocks is failing to enforce strict quality standards. Buyers may accept blocks based on price alone, neglecting critical performance metrics such as density, compressive strength, dimensional accuracy, and moisture content. Poor quality control can result in blocks that crumble during handling, have inconsistent sizes affecting masonry work, or exhibit reduced thermal and acoustic insulation properties. Always require certified test reports from manufacturers and conduct third-party inspections when necessary.

Lack of Compliance with Regional Building Codes

AAC blocks must meet local and national construction standards (e.g., ASTM C129 in the U.S., EN 771-4 in Europe, or IS 2185 in India). Sourcing blocks that do not comply with these standards can lead to failed inspections, rework, or even structural failure. Buyers often assume that all AAC blocks are equivalent, but regional variations in raw materials and manufacturing processes affect performance. Always verify that supplied blocks are certified for use in the project’s jurisdiction.

Ignoring Intellectual Property and Licensing Issues

AAC technology is often protected by patents and proprietary manufacturing processes. Reputable manufacturers may license their technology from companies like Ytong, Hebel, or Siporex. Sourcing from unauthorized producers who replicate patented methods or branding can expose buyers and contractors to intellectual property infringement claims. This is particularly risky when importing blocks or working with lesser-known suppliers claiming to offer “equivalent” products. Always confirm that suppliers are licensed or using non-infringing methods.

Overlooking Consistent Supply and Logistics Planning

AAC blocks are fragile and require careful handling and transportation. A common pitfall is selecting a supplier without evaluating their logistical capabilities, leading to damaged blocks upon delivery or inconsistent supply schedules that stall construction. Additionally, reliance on a single regional supplier with limited production capacity can result in delays. Evaluate suppliers based on their track record in timely delivery and proper packaging.

Failing to Verify Raw Material Sourcing and Sustainability Claims

Some suppliers market AAC blocks as eco-friendly due to their energy-efficient production and insulation properties. However, without due diligence, buyers may unknowingly source materials made with substandard or environmentally harmful practices—such as unregulated fly ash or non-renewable energy use in manufacturing. Verify environmental certifications (e.g., EPD, LEED compliance) and ensure transparency in the supply chain.

Avoiding these pitfalls ensures that AAC blocks contribute effectively to efficient, durable, and compliant construction projects while protecting stakeholders from legal and financial risks.

Logistics & Compliance Guide for Aerated Concrete Block (AAC Block)

Aerated Concrete Blocks (AAC Blocks) are lightweight, precast building materials known for their thermal insulation, fire resistance, and ease of handling. Efficient logistics and strict compliance with regulations are essential to ensure product integrity, safety, and project timelines. This guide outlines key considerations for the transportation, storage, handling, and regulatory compliance of AAC blocks.

Transportation

- Packaging & Palletization: AAC blocks should be factory-packed on sturdy wooden or plastic pallets, secured with steel or plastic strapping and wrapped in waterproof shrink film to prevent moisture absorption and mechanical damage during transit.

- Loading & Securing: Use forklifts or cranes with soft slings to load blocks onto flatbed or enclosed trucks. Ensure even weight distribution and secure loads with straps or nets to prevent shifting.

- Vehicle Type: Prefer covered trucks or trailers to protect blocks from rain, snow, and direct sunlight. Open trucks require additional waterproof tarpaulins.

- Route Planning: Optimize delivery routes to minimize travel time and avoid rough terrain, which can cause vibration damage. Coordinate deliveries with site readiness to reduce on-site storage duration.

Handling & On-Site Storage

- Unloading: Use forklifts or crane lifts with spreader beams to avoid edge damage. Never drop or drag pallets. Unload directly to stable, level storage areas.

- Storage Conditions: Store AAC blocks on level, dry, and well-drained surfaces. Use wooden bearers to elevate pallets off the ground (minimum 10 cm). Keep under cover or covered with waterproof tarpaulins to prevent water absorption.

- Stacking: Do not stack more than two pallets high unless designed for multi-tier storage. Follow manufacturer’s stacking guidelines to avoid crushing lower layers.

- Access & Safety: Maintain clear access paths around stored blocks. Ensure storage areas are away from excavation zones or heavy equipment traffic.

Quality Control & Inspection

- Pre-Delivery Check: Verify block dimensions, density, compressive strength, and moisture content meet project specifications (e.g., ASTM C129, EN 771-4, or IS 2185).

- On-Site Inspection: Check for chipping, cracking, or moisture damage upon delivery. Reject damaged or wet pallets.

- Documentation: Maintain delivery notes, batch numbers, test certificates, and compliance documents for traceability.

Regulatory & Environmental Compliance

- Standards & Certifications: Ensure AAC blocks comply with local and international standards:

- USA: ASTM C129 (Standard Specification for Loadbearing Concrete Masonry Units)

- EU: EN 771-4 (Specification for Masonry Units – Part 4: Autoclaved Aerated Concrete Masonry Units)

- India: IS 2185 (Part 3) – Specifications for Concrete Masonry Units

- Fire Safety: Confirm blocks meet required fire-resistance ratings (typically 2–4 hours depending on thickness).

- Thermal & Acoustic Performance: Verify declared U-values and sound insulation properties align with building code requirements.

- Environmental Regulations: Ensure raw materials and production processes comply with environmental standards (e.g., low embodied carbon, recyclability). AAC blocks are generally non-toxic and inert, but disposal should follow local waste management rules.

Safety & Worker Training

- PPE Requirements: Workers must wear gloves, safety footwear, and eye protection when handling AAC blocks.

- Training: Provide training on safe lifting techniques, proper use of handling equipment, and awareness of edge fragility.

- MSDS (Safety Data Sheet): Maintain and provide access to MSDS for AAC materials, especially regarding dust during cutting (use dust masks and wet-cutting methods).

Documentation & Traceability

- Maintain complete records including:

- Batch numbers and manufacturing dates

- Certificates of conformity and test reports

- Delivery dockets and inspection reports

- Compliance statements for fire, thermal, and structural performance

Conclusion

Proper logistics and compliance practices are critical to maximizing the performance and longevity of Aerated Concrete Blocks. By adhering to standardized handling, storage, and regulatory requirements, construction teams can ensure material quality, worker safety, and project compliance with building codes and sustainability goals. Always consult manufacturer guidelines and local regulations for project-specific requirements.

Conclusion for Sourcing Aerated Concrete Blocks

Sourcing aerated concrete blocks (AAC blocks) offers a sustainable, cost-effective, and efficient solution for modern construction projects. These lightweight, energy-efficient blocks provide excellent thermal insulation, fire resistance, and sound attenuation, making them ideal for residential, commercial, and industrial buildings. Their precise dimensional accuracy reduces material waste and speeds up construction timelines, ultimately lowering labor and overall project costs.

When sourcing AAC blocks, it is essential to select reliable suppliers who adhere to international quality standards (such as ASTM or EN) and ensure consistent product performance. Factors such as transportation logistics, lead times, and local availability should also be evaluated to maintain project schedules. Additionally, considering environmental benefits—such as reduced carbon footprint and improved energy efficiency—aligns with sustainable building practices and green certification goals like LEED or BREEAM.

In conclusion, sourcing aerated concrete blocks represents a strategic decision that enhances construction efficiency, promotes sustainability, and delivers long-term economic and structural benefits. With careful supplier selection and planning, AAC blocks can significantly contribute to high-performance, resilient, and eco-friendly buildings.