The global adapter market is experiencing robust growth, driven by increasing demand for consumer electronics, rising urbanization, and the proliferation of portable devices across residential and commercial sectors. According to Grand View Research, the global power adapter market was valued at USD 24.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This expansion is further supported by the growing adoption of switching power supplies and energy-efficient adapters, particularly in regions with expanding electrical infrastructure and increasing electrification rates. As demand for reliable 220V adapters rises—especially in Europe, Asia-Pacific, and the Middle East—manufacturers are scaling innovation in efficiency, durability, and smart power management. In this competitive landscape, a select group of companies have emerged as leaders, setting industry benchmarks in quality, compliance, and global supply chain performance.

Top 10 Adapter 220V Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 FSP TECHNOLOGY INC. |AC/DC Power Supply Manufacturer

Domain Est. 1998

Website: fsp-group.com

Key Highlights: FSP Group is a global leader in power supply manufacturing and solution supplier. By combining innovative technologies with professional R&D capabilities, ……

#2 MEAN WELL Switching Power Supply Manufacturer

Domain Est. 1997

Website: meanwell.com

Key Highlights: MEAN WELL is one of the world’s few standard power supply mainly professional manufacturers, covering 0.5 to 25600W products are widely used in industrial ……

#3 Cincon

Domain Est. 1998

Website: cincon.com

Key Highlights: Cincon Electronics is a leading manufacturer of DC/DC converters and AC/DC power supplies offering the high-quality and reliable power module solutions….

#4 Euro Plugs

Domain Est. 2003

Website: europlugs.com

Key Highlights: $14 delivery 30-day returnsEuroPlugs is manufacturer and distributor of highest quality Plug Adapters, 220-volt power bars, 220v power strips, European adapter….

#5 Power Cords and Adapters

Domain Est. 1996

Website: tripplite.eaton.com

Key Highlights: We offer AC power cords, extension cords, splitters and adapters for computers, servers and PDUs. Our cords have innovative features like coiled cords and ……

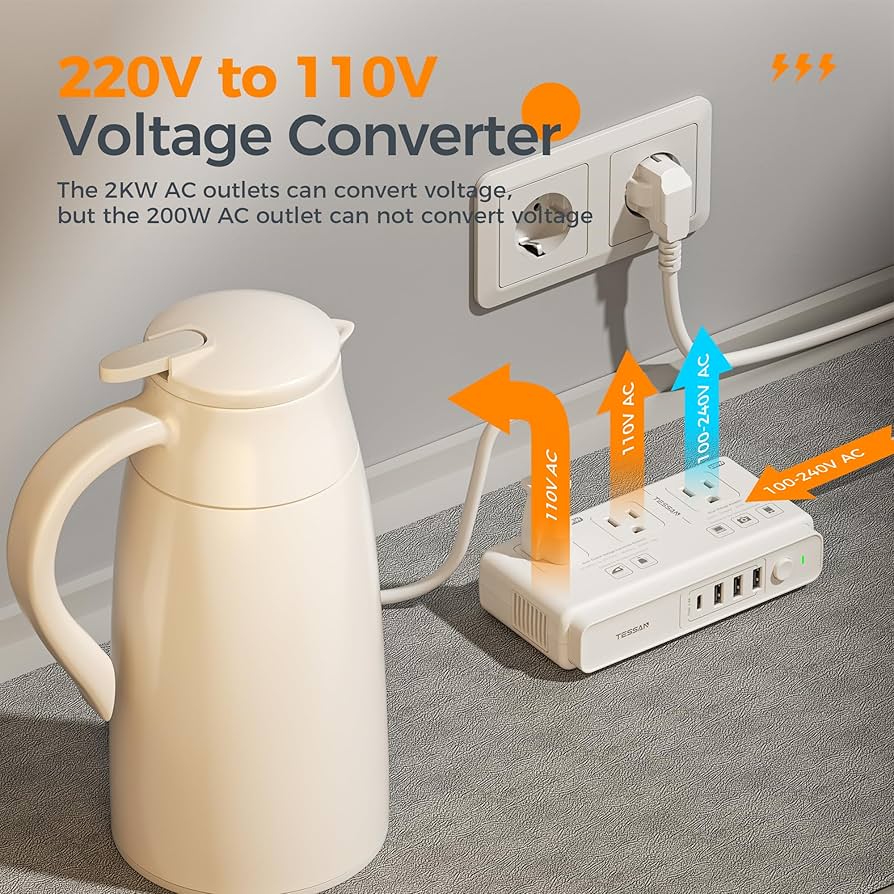

#6 Voltage Converters

Domain Est. 1999

Website: voltageconverters.com

Key Highlights: Free delivery over $25 30-day returns2000 WATTS HEAVY-DUTY VOLTAGE CONVERTER – Works as a step-up and/or as a step down transformer that converts 110-120 Volts to 220-240 Volts and…

#7 Quick 220 Electrical Systems

Domain Est. 2000

Website: quick220.com

Key Highlights: Power your 208-240V computer servers, appliances, air conditioners, power tools, European appliances power tools with ordinary 110-120V outlets….

#8 Ceptics Travel Plug Adapters Connecting the World

Domain Est. 2011

Website: ceptics.com

Key Highlights: Based in the USA, Ceptics travel adapters are the #1 choice for travelers to and from US to the world….

#9 220V

Domain Est. 2019

#10 Universal Power Converter 100

Domain Est. 2017

Expert Sourcing Insights for Adapter 220V

H2: Projected 2026 Market Trends for 220V Adapters

The global market for 220V adapters is poised for significant transformation by 2026, driven by technological innovation, evolving consumer needs, and regulatory developments. As international travel rebounds and the demand for universal power solutions grows, 220V adapters—devices enabling electrical compatibility across regions with differing voltage standards—are expected to witness robust expansion. Key trends shaping this market include:

-

Increased Demand for Universal Travel Adapters: With rising global mobility and the proliferation of digital nomadism, consumers are increasingly seeking compact, multi-port 220V-compatible travel adapters. These devices often integrate USB-C PD (Power Delivery), supporting fast charging for laptops, smartphones, and tablets. The market is responding with smart, all-in-one solutions that support 100–240V inputs, ensuring compatibility with both 110V and 220V regions.

-

Integration of Smart Technology: By 2026, smart features such as surge protection, energy monitoring, and Bluetooth connectivity are expected to become standard in premium 220V adapters. Some models may include app-based controls to monitor power usage or remotely disable connected devices, appealing to environmentally conscious and tech-savvy consumers.

-

Regulatory and Safety Standards: Governments and international bodies are tightening electrical safety regulations, particularly in Europe and Asia, where 220–240V is standard. Compliance with certifications such as CE, UKCA, and CCC will be critical for market entry. Enhanced safety features—like auto-shutoff and overheat protection—will become differentiators among leading brands.

-

Growth in E-Commerce and Direct-to-Consumer Models: Online platforms will continue to dominate 220V adapter sales, allowing niche brands to reach global audiences. Subscription models for adapter replacements or bundled tech kits may emerge, especially targeting frequent travelers and expatriates.

-

Sustainability and Eco-Design: Environmental concerns are driving demand for recyclable materials, reduced packaging, and energy-efficient designs. By 2026, leading manufacturers are expected to adopt circular economy principles, offering take-back programs and longer product lifecycles.

-

Regional Market Expansion: While Europe and Asia remain core markets due to standard 220–240V infrastructure, demand in Africa and parts of South America is growing as electrification efforts expand. Adapters tailored to local plug types (e.g., Type C, G, D, M) with durable builds for rugged environments will gain traction.

-

Competition from Built-in Voltage Converters: A potential challenge comes from electronic devices with built-in auto-switching power supplies (e.g., most modern laptops and phone chargers), which reduce the need for standalone voltage adapters. However, plug shape incompatibility ensures continued demand for physical adapters, especially multi-socket variants.

In conclusion, the 2026 market for 220V adapters will be characterized by innovation, safety, and convenience. Manufacturers that prioritize universal compatibility, smart features, and sustainability are likely to capture significant market share in an increasingly interconnected world.

Common Pitfalls When Sourcing 220V Adapters (Quality & IP Rating)

When sourcing 220V adapters—especially for industrial, outdoor, or safety-critical applications—overlooking quality and Ingress Protection (IP) rating can lead to performance issues, safety hazards, and increased lifecycle costs. Below are common pitfalls to avoid.

Poor Quality Components and Construction

Many low-cost 220V adapters on the market use substandard materials and lack proper manufacturing oversight. Key indicators of poor quality include:

- Use of Non-Compliant Capacitors and Transformers: Cheap adapters often use electrolytic capacitors with low temperature ratings (<85°C), leading to premature failure under load or in warm environments.

- Inadequate PCB Design: Thin copper traces and poor heat dissipation increase the risk of overheating and short circuits.

- Lack of Safety Certifications: Absence of recognized certifications (e.g., CE, UL, CCC, RoHS) is a red flag. Some suppliers fake certifications or use uncertified batches.

- Inconsistent Output Voltage and Ripple: Poor voltage regulation can damage sensitive electronics. Look for adapters with <1% voltage deviation and low ripple noise.

Mitigation: Source from reputable manufacturers, request test reports, and conduct sample batch testing for efficiency, temperature rise, and output stability.

Misunderstanding or Misrepresenting IP Ratings

The IP (Ingress Protection) rating defines protection against solids and liquids. Common mistakes include:

- Overstating IP Ratings: Some suppliers claim high IP ratings (e.g., IP67) without third-party validation. True IP67 requires certification through standardized testing (dust chamber, water immersion).

- Ignoring Environmental Conditions: Even with a high IP rating, factors like UV exposure, chemical contact, or thermal cycling can degrade seals and housings over time.

- Confusing IP with Waterproofing: IP65 offers protection against water jets but is not suitable for submersion. Assuming IP65 equals “waterproof” leads to failures in wet environments.

- Poor Sealing at Cable Entry Points: The weakest point is often where the cable enters the adapter. Inadequate strain relief or sealing compromises the entire IP rating.

Mitigation: Request certified test reports (e.g., IEC 60529), inspect gasket materials (silicone vs. rubber), and verify design features like double O-rings and sealed connectors.

Cost-Driven Compromises

Prioritizing low cost over reliability leads to:

- Short Lifespan: Cheap adapters may fail within months, increasing downtime and replacement costs.

- Safety Risks: Poor isolation, inadequate creepage distances, and lack of overcurrent/overvoltage protection increase fire and electrocution risks.

- Hidden TCO (Total Cost of Ownership): Frequent replacements, maintenance, and system failures outweigh initial savings.

Mitigation: Conduct a total cost analysis and consider lifecycle performance. Invest in adapters with proven reliability and comprehensive warranties.

Inadequate Thermal Management

220V adapters generate heat, especially in enclosed or high-ambient environments. Pitfalls include:

- Lack of Heat Dissipation Features: No heatsinks or ventilation despite high power output.

- Poor Derating Specifications: Some adapters don’t specify output reduction at elevated temperatures, leading to overheating.

Mitigation: Verify thermal performance data and ensure adequate airflow or heatsinking in the application design.

By addressing these pitfalls—focusing on verified quality, accurate IP ratings, and long-term reliability—organizations can ensure safe, durable, and cost-effective operation of 220V adapter-powered systems.

Logistics & Compliance Guide for 220V Adapter

This guide outlines key logistics and compliance considerations for the import, export, distribution, and use of 220V adapters in international markets. Adhering to these guidelines ensures product safety, regulatory compliance, and efficient supply chain operations.

Regulatory Compliance

Ensure all 220V adapters meet the regulatory standards of the target market. Non-compliant products may be rejected at customs or recalled.

- Electrical Safety Standards

Adapters must comply with regional electrical safety certifications: - Europe: CE marking per Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive. Compliance with EN 60950-1 or EN 62368-1 (for IT equipment).

- United Kingdom: UKCA marking (post-Brexit). UKCA requirements mirror CE but apply to Great Britain.

- United States: While designed for 220V systems (common in homes abroad), adapters used in the U.S. must comply with UL 1363 (for relocatable power taps) or UL 817 (for cord sets and power supply cords) if marketed there.

- Australia & New Zealand: Must meet AS/NZS 3112 and carry the Regulatory Compliance Mark (RCM).

-

Canada: Requires CSA C22.2 No. 21 or equivalent, with cCSAus certification.

-

Plug and Socket Compatibility

Adapters must conform to the physical plug standards of the destination country (e.g., Type C, E, F in Europe; Type G in the UK; Type I in Australia). Verify compatibility with local socket designs and voltage tolerances (typically 220–240V AC, 50Hz). -

RoHS and REACH (EU)

Comply with the Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulations. Ensure no prohibited substances (e.g., lead, cadmium, phthalates) are used above permissible limits. -

Energy Efficiency

Some regions (e.g., EU, California) require compliance with energy efficiency standards for external power supplies (e.g., EU CoC Tier 2, U.S. DOE Level VI). Verify no-load power consumption and energy efficiency ratings.

Packaging and Labeling Requirements

Proper packaging and labeling are essential for compliance and consumer safety.

-

Multilingual Labeling

Include safety warnings, input/output voltage (e.g., Input: 220–240V AC, 50Hz), and manufacturer information in the official language(s) of the destination country. -

Warning Labels

Clearly state: - “For use with 220–240V systems only”

- “Not a voltage converter – does not change voltage”

-

“Use only with devices rated for 220–240V”

-

Markings on Product

Permanently affixed markings must include: - Manufacturer or importer name

- Model number

- Electrical ratings (voltage, current, frequency)

- Certification marks (e.g., CE, UKCA, RCM)

Logistics and Shipping

Efficient logistics planning reduces delays and ensures on-time delivery.

- HS Code Classification

Use correct Harmonized System (HS) code for customs clearance: - Typical code: 8536.69 (Electrical apparatus for switching or protecting electrical circuits) or 8504.40 (Other AC adapters/power supplies), depending on design.

-

Confirm exact code with local customs authority, as misclassification may lead to fines or delays.

-

Voltage and Frequency Verification

Confirm that end users understand the adapter is for physical plug compatibility only and does not convert voltage. Include instructions to verify device compatibility with 220V power sources. -

Temperature and Humidity Control

Store and transport in dry, temperature-controlled environments to prevent damage to insulation and electronic components. -

Battery Restrictions (if applicable)

If the adapter includes a built-in battery (e.g., for surge protection), comply with IATA/IMDG regulations for lithium batteries during air or sea freight.

Import and Customs Documentation

Prepare complete documentation to avoid customs delays.

- Required Documents:

- Commercial Invoice

- Packing List

- Certificate of Conformity (CoC) for target market

- Test Reports from accredited labs (e.g., TÜV, SGS, Intertek)

- Bill of Lading or Air Waybill

-

Import License (if required by destination country)

-

Importer of Record (IoR)

Designate a legal entity responsible for customs compliance in the destination country. The IoR ensures duties and taxes are paid and regulations are followed.

Product Liability and Insurance

Mitigate risks associated with product use.

-

Product Liability Insurance

Maintain insurance coverage that includes electrical products, especially for markets with strict liability laws (e.g., EU, U.S.). -

Recall Preparedness

Establish a recall procedure in case of non-compliance or safety issues. Retain production and test records for at least 10 years.

Environmental and End-of-Life Compliance

Adapters must follow environmental regulations for disposal and recycling.

-

WEEE (EU)

Comply with Waste Electrical and Electronic Equipment (WEEE) Directive. Register with national WEEE authorities and provide take-back options. -

Labeling for Recycling

Include the crossed-out wheeled bin symbol on packaging and product to indicate proper disposal.

Conclusion

Successfully distributing 220V adapters globally requires strict adherence to electrical safety, labeling, and customs regulations. Partner with certified testing laboratories and logistics providers experienced in electrical goods to ensure compliance and smooth operations across markets.

Conclusion on Sourcing a 220V Adapter:

Sourcing a 220V adapter requires careful consideration of voltage compatibility, plug type, power rating, and safety standards to ensure safe and efficient operation of electrical devices. It is essential to match the adapter specifications with the requirements of the device and the electrical system of the destination country. Choosing certified, high-quality adapters from reputable suppliers helps prevent damage to equipment and reduces the risk of electrical hazards. Additionally, for frequent travelers or businesses operating internationally, investing in universal or multi-voltage adapters can offer greater flexibility and long-term cost efficiency. Always verify local regulations and consult device manuals before purchasing to ensure compatibility and compliance.