The global military uniform market is experiencing steady growth, driven by rising defense expenditures, modernization of armed forces, and increased emphasis on functional, high-performance tactical apparel. According to Grand View Research, the global military clothing market was valued at USD 4.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.1% from 2023 to 2030. This growth is further fueled by technological advancements in fabric engineering, including moisture-wicking, flame-resistant, and camouflage-enhanced materials tailored for diverse operational environments. Within this expanding landscape, ACU (Army Combat Uniform)-style apparel remains a cornerstone of modern military dress, used not only by U.S. Armed Forces but also adopted or adapted by defense and security units worldwide. As demand intensifies, a select group of manufacturers have emerged as leaders in producing high-quality, specification-compliant ACU uniforms, combining durability, comfort, and adherence to military standards. The following overview identifies the top seven ACU uniform manufacturers shaping the industry through innovation, scale, and proven delivery performance.

Top 7 Acu Uniform Army Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

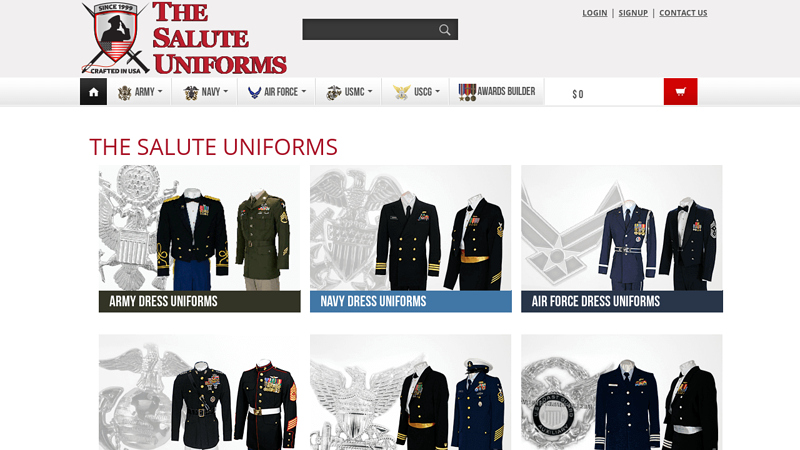

#1 The Salute Uniforms

Domain Est. 2005

Website: uniforms-4u.com

Key Highlights: We have more than a decade of expertise in manufacturing US Military apparel & Insignia, wear our uniforms and Salute with Pride! Place you order today!…

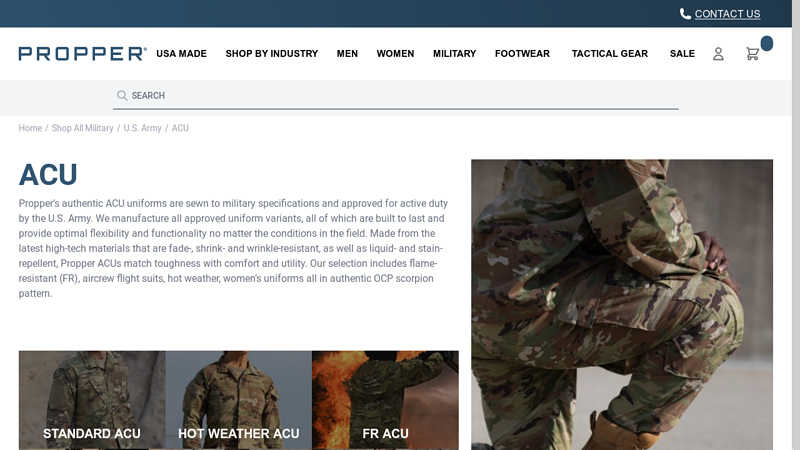

#2 Propper ACU Uniform

Domain Est. 1999

Website: propper.com

Key Highlights: Free delivery over $99Authentic ACU Uniform by Propper. Army Combat Uniform Jackets & Pants approved for active duty. Free shipping on Army ACU Uniform orders over $60….

#3 Scorpion OCP Uniforms

Domain Est. 2001

Website: kellac.com

Key Highlights: 5-day deliveryKel-Lac’s military OCP uniforms feature regulation OCP camouflage in 50/50 NYCO Ripstop, FR, or protective combat uniform fabrics for all your OCP needs….

#4 Army ACU Uniforms

Domain Est. 2003

#5 U.S. Army OCP (ACU) Combat Uniforms

Domain Est. 2009

Website: uspatriottactical.com

Key Highlights: 2–4 day deliveryShop US Patriot Tactical for the best selection of U.S. Army OCP (ACU) Uniforms at unbeatable prices. USP is the #1 source for military & tactical ……

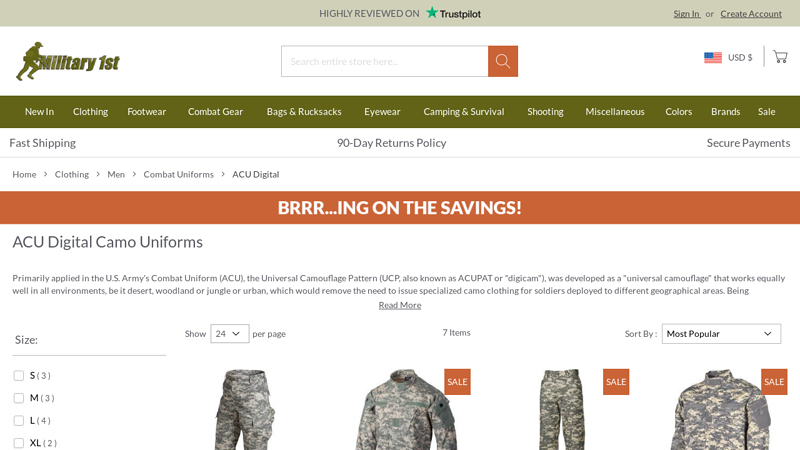

#6 ACU Digital Camo Uniforms US

Domain Est. 2011

Website: military1st.com

Key Highlights: 7–12 day delivery 90-day returnsA wide selection of combat shirts and tactical cargo pants in classic ACU Digital camo is available now at Military 1st online superstore….

#7 ACU pattern officially retired; new uniform improvements on the way

Website: army.mil

Key Highlights: Soldiers of the US Army will no longer wear the Universal Camouflage Pattern, otherwise known as the Army Combat Uniform (ACU) pattern or Digital Camouflage as ……

Expert Sourcing Insights for Acu Uniform Army

H2: 2026 Market Trends for Army Uniforms (Acu Uniform)

The market for Army Combat Uniforms (ACU) in 2026 is expected to be shaped by several key trends driven by advancements in technology, evolving military requirements, sustainability demands, and geopolitical dynamics. Although “Acu Uniform Army” may refer to the U.S. Army’s Advanced Combat Uniform (ACU) system, the broader market includes suppliers, global defense procurement, and next-generation uniform development. Below is an analysis of projected 2026 market trends:

-

Transition to Next-Generation Uniforms

By 2026, the U.S. Army and allied forces are anticipated to continue phasing out the traditional ACU in favor of the Operational Camouflage Pattern (OCP), also known as “Scorpion W2.” The OCP offers improved concealment across varied terrains and has become the standard. However, research and development will focus on next-generation uniforms incorporating multi-spectral camouflage (visible, infrared, and thermal signature reduction), which will become increasingly vital in modern surveillance-dominated battlefields. -

Integration of Smart Textiles and Wearable Technology

The 2026 market will see increased integration of smart fabrics into combat uniforms. These include moisture-wicking, temperature-regulating materials, and embedded sensors for biometric monitoring (e.g., heart rate, hydration levels, fatigue). Companies investing in conductive fibers and lightweight power systems will gain market share, as militaries seek to enhance soldier performance and real-time health tracking. -

Emphasis on Sustainability and Ethical Sourcing

Environmental concerns are influencing defense procurement. By 2026, there will be growing pressure on uniform suppliers to use sustainable materials (e.g., recycled fibers, bio-based textiles) and reduce carbon footprints in manufacturing. The Department of Defense (DoD) may introduce green procurement guidelines, favoring contractors with eco-certifications and transparent supply chains. -

Modular and Multi-Environment Design

Future uniforms will emphasize modularity—allowing soldiers to adapt gear for different climates (arctic, desert, jungle) through interchangeable layers. This trend reduces logistical burdens and increases operational flexibility. Uniforms will feature improved ergonomics, enhanced durability, and compatibility with body armor and load-bearing equipment. -

Rise of Domestic and Resilient Supply Chains

Geopolitical instability and lessons from recent global disruptions (e.g., pandemics, trade tensions) will drive a shift toward onshoring or nearshoring uniform production. In 2026, the U.S. and NATO allies are expected to prioritize domestic manufacturing to ensure supply chain resilience and reduce dependency on foreign textile producers. -

Increased Private Sector Innovation and Public-Private Partnerships

Defense contractors and tech startups will play a larger role in developing advanced uniforms. Collaborations between the military and private companies—such as those seen with the Army Futures Command—will accelerate innovation in material science, camouflage effectiveness, and protective features (e.g., flame resistance, chemical/biological protection). -

Global Market Expansion

While the U.S. remains a major market, international demand for modern combat uniforms will grow, especially in Asia-Pacific, Eastern Europe, and the Middle East due to regional tensions and military modernization programs. Export opportunities for U.S. and European uniform manufacturers are expected to expand.

Conclusion

By 2026, the ACU uniform market will have evolved beyond traditional fabric-based garments into high-performance, tech-integrated combat systems. The focus will shift from standardization to adaptability, sustainability, and soldier-centric design. Stakeholders in the defense apparel sector must invest in R&D, comply with evolving regulations, and align with strategic military modernization goals to remain competitive.

Common Pitfalls When Sourcing ACU Uniforms for the Army (Quality and Intellectual Property)

Sourcing Army Combat Uniforms (ACUs) involves strict requirements to ensure operational effectiveness, soldier safety, and legal compliance. Failing to address key pitfalls related to quality and intellectual property (IP) can result in contract termination, financial losses, and reputational damage. Below are the most common challenges to avoid.

Quality Inconsistencies and Non-Compliance

One of the primary risks in sourcing ACUs is receiving uniforms that fail to meet military specifications. Common quality pitfalls include:

- Fabric Non-Conformance: Using incorrect ripstop fabric blends (e.g., failing to meet the 50/50 nylon-cotton or specified FR-treated cotton-nylon blends) affects durability and flame resistance.

- Color and Digital Pattern Deviations: Slight mismatches in the Operational Camouflage Pattern (OCP) or Universal Camouflage Pattern (UCP) colors can lead to rejection, as exact Pantone or military-issued color standards must be followed.

- Stitching and Seam Weakness: Inadequate stitching density (stitches per inch) or improper seam construction reduces uniform longevity under field conditions.

- Component Failures: Substandard zippers, buttons, or hook-and-loop closures that do not meet military durability tests (e.g., MIL-DTL-44418) can compromise functionality.

- Lack of Testing and Certification: Suppliers may skip required testing for flame resistance, shrinkage, colorfastness, and abrasion resistance, leading to failed inspections.

To mitigate these risks, always require third-party lab reports and conduct pre-production sampling in alignment with military specifications.

Intellectual Property (IP) and Trademark Infringement

Unauthorized production or distribution of ACUs presents serious IP risks:

- Unauthorized Use of Military Patterns: The OCP and former UCP patterns are protected under U.S. Army licensing. Producing or selling these patterns without authorization—especially for commercial resale—can lead to legal action for trademark or copyright infringement.

- Misuse of Government Specifications: While military specs (e.g., MIL-DTL-XXXXX) are public, replicating uniforms for non-governmental use using these specs may still violate IP if branded or marketed as genuine military gear.

- Counterfeit Goods and Gray Market Sales: Sourcing from unauthorized manufacturers increases the risk of receiving counterfeit or diverted military-issue uniforms, which may not only be illegal but also substandard.

Ensure your supplier holds proper licensing or government contracts to produce military-pattern uniforms. Avoid suppliers offering “military-spec” gear for civilian markets unless they clearly state compliance with IP laws.

Conclusion

Sourcing ACU uniforms demands rigorous attention to both material quality and legal compliance. Partnering with vetted, contract-compliant suppliers and verifying all specifications and IP rights upfront will help avoid costly delays, rejections, or legal exposure. Always prioritize official supply channels or authorized vendors to maintain integrity and performance standards.

Logistics & Compliance Guide for Acu Uniform Army

This guide outlines the key logistics procedures and compliance requirements for the procurement, distribution, handling, and maintenance of Army Combat Uniforms (ACUs) within the Acu Uniform Army supply chain. Adherence ensures operational readiness, regulatory compliance, and mission success.

Procurement Standards and Vendor Compliance

All ACU procurement must conform to current U.S. Department of Defense (DoD) specifications, including MIL-DTL-44455 (or its latest revision). Vendors must be certified through the Defense Supply Center Philadelphia (DSCP) or equivalent authorized channels. Each shipment must include a Certificate of Conformance (CoC), batch testing documentation, and itemized packing lists. Non-compliant goods will be rejected, and repeat violations may result in contract termination.

Inventory Management and Warehousing

Maintain a centralized digital inventory system compliant with DoD 4500.9-R (Defense Supply Chain Material Management Regulation). All ACUs must be stored in climate-controlled facilities meeting safety and security standards. Uniforms should be segregated by size, pattern (e.g., OCP, MultiCam), and issue status. Conduct quarterly physical audits and reconcile with system records to ensure 98% inventory accuracy. Use barcoding or RFID for real-time tracking.

Distribution and Transportation Protocols

Shipments must follow established military distribution channels or approved commercial carriers with DoD transport credentials. All transport vehicles must be GPS-tracked and secured against tampering. Delivery manifests must be submitted 72 hours in advance to receiving units. Ensure temperature-sensitive materials (e.g., flame-resistant variants) are transported within specified ranges. Emergency resupply logistics must be pre-planned and validated biannually.

Uniform Issuance and Personnel Compliance

ACUs are issued through authorized personnel supply points (PSPs) upon verification of service member eligibility and rank-appropriate sizing. Issue logs must be maintained in the Defense Logistics Information System (DLIS) and include serial numbers or lot tracking for accountability. Personnel must adhere to Army Regulation (AR) 670-1 for proper wear, care, and modification restrictions. Unauthorized alterations or commercial resale are strictly prohibited.

Maintenance, Repair, and Turn-In Procedures

Establish unit-level inspection schedules for uniform condition and compliance with wear standards. Damaged or unserviceable ACUs must be reported and processed through the Repairable Items Management System (RIMS) when applicable. Used uniforms must be turned in upon separation, transfer, or upgrade. Destroyed or excess stock must be disposed of via Defense Reutilization and Marketing Office (DRMO) protocols to prevent leakage into civilian markets.

Regulatory and Audit Compliance

All logistics operations are subject to regular audits by Defense Contract Management Agency (DCMA) and internal compliance officers. Maintain records for a minimum of six years, including procurement contracts, inspection reports, and distribution logs. Ensure full compliance with International Traffic in Arms Regulations (ITAR) when handling uniforms with integrated tactical gear. Report any compliance breaches immediately through the Defense Hotline or chain of command.

Training and Accountability

Personnel involved in ACU logistics must complete annual training on supply chain ethics, handling procedures, and regulatory updates. Designate a Logistics Compliance Officer (LC0) at each major distribution node to oversee adherence and conduct spot checks. Accountability rests with the chain of command; failure to comply may result in administrative or disciplinary action under UCMJ guidelines.

In conclusion, sourcing Army Combat Uniforms (ACU) for military or tactical use requires careful consideration of several key factors, including compliance with military specifications (MIL-SPEC), material quality, durability, proper sizing, and adherence to authorization and procurement regulations. Whether sourcing through government contracts, authorized vendors, or commercial suppliers, it is essential to ensure authenticity, uniformity, and suitability for operational requirements. Additionally, staying informed about updates in uniform standards and engaging with reputable suppliers helps maintain uniform integrity and mission readiness. Proper due diligence in the sourcing process ensures that personnel are equipped with reliable, high-performance ACU gear that meets the demanding standards of military service.