The global actuator rod market is experiencing steady growth, driven by rising demand across industrial automation, oil & gas, and manufacturing sectors. According to a report by Mordor Intelligence, the global industrial actuators market—of which actuator rods are a critical component—was valued at USD 6.5 billion in 2023 and is projected to grow at a CAGR of over 4.8% from 2024 to 2029. Similarly, Grand View Research estimates that the broader actuators market will expand at a CAGR of approximately 5.2% during the same period, fueled by advancements in smart manufacturing and increasing adoption of electromechanical systems. With these trends amplifying the need for durable, precision-engineered components, the role of reliable actuator rod manufacturers has become more pivotal than ever. This report highlights the top 8 manufacturers shaping the industry through innovation, quality, and global reach.

Top 8 Actuator Rod Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 OEM Rod Style Actuator Factory and Manufacturers, Suppliers

Domain Est. 2022

Website: kggfa.com

Key Highlights: Rod Style Actuator – Manufacturers, Suppliers, Factory from China. Sticking for the principle of “Super Quality, Satisfactory service” ,We have been striving ……

#2 Tolomatic

Domain Est. 1996

Website: tolomatic.com

Key Highlights: Tolomatic is a US manufacturer of linear motion solutions made to last. Design engineers rely on us for mission-critical automation….

#3 Electric Linear Actuators & Cylinders

Domain Est. 1998

Website: intelligentactuator.com

Key Highlights: Electric Actuator, Cylinder, Linear Actuators and Robot Manufacturer site for North America including United States, USA, Canada, Mexico. Slider, Rod, SCARA ……

#4 Actuator

Domain Est. 1995

Website: thk.com

Key Highlights: THK develops and manufactures mechanical components including the Linear Motion system, LM Guides, Ball Splines, Ball Screws, and electric actuators for our ……

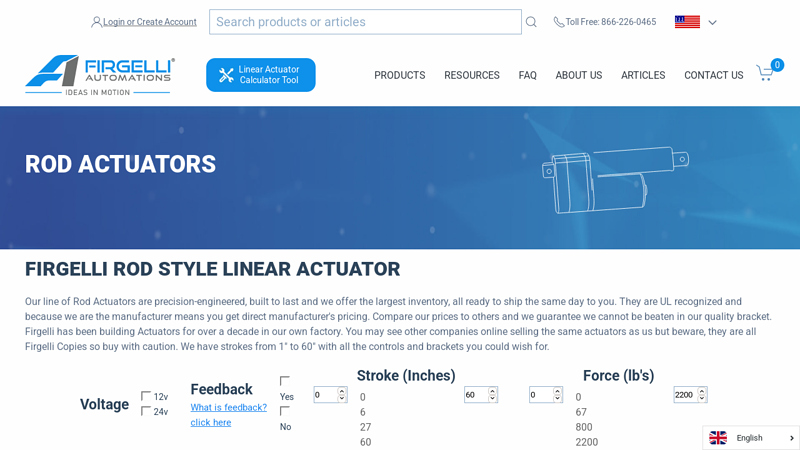

#5 Rod Actuators

Domain Est. 2004

Website: firgelliauto.com

Key Highlights: 2–5 day deliveryOur line of Rod Actuators are precision-engineered, built to last and we offer the largest inventory, all ready to ship the same day to you….

#6 Rod Style Actuators

Domain Est. 2016

Website: actuonix.com

Key Highlights: Rod actuators utilize an electric motor to push a cylindrical shaft. For the best range of rod-style actuators, trust Actuonix. Our rod actuators include ……

#7 ACTUATOR ROD ASSY

Domain Est. 2021 | Founded: 1959

Website: garlockequipment.com

Key Highlights: In stock 30-day returnsACTUATOR ROD ASSY … Since 1959, Garlock has been filling the needs of commercial roofing contractors with quality equipment that gets the job done. Garlock…

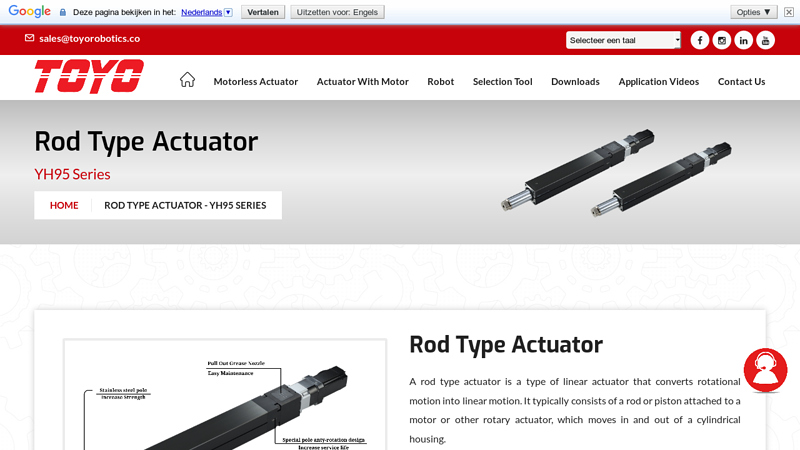

#8 Rod Type Linear Actuator

Domain Est. 2024

Website: toyorobotics.co

Key Highlights: Rod type actuators convert rotations to linear motion. Features 50-800mm strokes, 1500rpm speed, and 100W-750W motor capacity….

Expert Sourcing Insights for Actuator Rod

H2: 2026 Market Trends for Actuator Rods

The global actuator rod market is poised for significant transformation by 2026, driven by technological advancements, rising automation across industries, and increasing demand for precision motion control systems. This analysis outlines key trends expected to shape the actuator rod sector in the coming years.

1. Surge in Industrial Automation and Industry 4.0 Adoption

The continued rollout of Industry 4.0 initiatives is accelerating demand for high-performance actuator rods in manufacturing, logistics, and process industries. Smart factories are integrating IoT-enabled actuators with feedback systems, requiring durable, responsive, and corrosion-resistant rod materials such as stainless steel and engineered composites. This trend is expected to boost the demand for precision-ground and polished actuator rods capable of reliable performance in automated environments.

2. Growth in Electric Actuators Over Hydraulic and Pneumatic Systems

Environmental regulations and energy efficiency targets are driving a shift from hydraulic and pneumatic actuators to electric variants. Electric linear actuators, which rely heavily on high-tolerance actuator rods, offer better control, lower maintenance, and reduced environmental impact. By 2026, electric actuator rods are projected to capture a larger market share, particularly in automotive, aerospace, and renewable energy sectors.

3. Expansion in Renewable Energy and EV Applications

The renewable energy sector—especially solar tracking systems and wind turbine pitch control—and the rapid growth of electric vehicles (EVs) are creating new demand for actuator rods. In EVs, actuator rods are used in adjustable suspensions, battery cooling systems, and charging mechanisms. These applications require lightweight, high-strength rods with long operational life, spurring innovation in material science and surface treatments.

4. Regional Market Shifts and Manufacturing Localization

Asia-Pacific, led by China, India, and Japan, is expected to dominate actuator rod production and consumption by 2026 due to expanding manufacturing bases and government support for automation. However, reshoring trends in North America and Europe—driven by supply chain resilience concerns—are also fostering localized production of high-precision actuator rods, particularly for aerospace and medical device industries.

5. Advancements in Materials and Surface Engineering

To meet demands for longer lifespan and operation in extreme conditions, manufacturers are adopting advanced materials such as titanium alloys, ceramic-coated rods, and composite polymers. Surface treatments like nitriding, chrome plating, and PTFE coating are becoming standard to enhance wear resistance and reduce friction. These innovations are critical for applications in harsh environments such as offshore oil & gas and subsea robotics.

6. Integration with Smart Sensors and Predictive Maintenance

Future actuator rods are increasingly being designed with embedded sensors to monitor stress, temperature, and wear. This integration supports predictive maintenance strategies, reducing downtime and extending equipment life. By 2026, smart actuator rods with integrated feedback capabilities are expected to become standard in high-value industrial applications.

Conclusion

By 2026, the actuator rod market will be characterized by a shift toward smarter, more efficient, and environmentally friendly solutions. Growth will be fueled by automation, electrification, and digitalization across key end-use industries. Manufacturers who invest in advanced materials, precision engineering, and IoT integration will be best positioned to capitalize on these evolving market dynamics.

Common Pitfalls Sourcing Actuator Rods (Quality, IP)

Sourcing actuator rods—especially for critical applications involving precision motion control, automation, or harsh environments—can present several challenges. Two of the most common areas of concern are quality inconsistencies and incorrect Ingress Protection (IP) ratings. Overlooking these factors can lead to premature failure, safety hazards, and increased maintenance costs.

Quality-Related Pitfalls

-

Inconsistent Material Composition

Many low-cost suppliers may not adhere to specified material standards (e.g., stainless steel grades like 304 vs. 316). Using substandard materials can result in corrosion, reduced strength, or poor performance under load or temperature variations. -

Poor Surface Finish and Tolerances

Actuator rods require precise machining for smooth operation and sealing compatibility. Inadequate surface finishes (e.g., roughness beyond specified Ra values) can accelerate wear on seals and lead to leakage or binding. -

Lack of Traceability and Certifications

Reputable suppliers provide material test reports (MTRs) and certifications (e.g., ISO 9001). Sourcing from vendors without documentation increases the risk of counterfeit or non-compliant parts. -

Inadequate Heat Treatment

Improper or skipped heat treatment processes (like hardening or tempering) can compromise rod strength and fatigue resistance, especially in dynamic applications.

IP (Ingress Protection) Rating Pitfalls

-

Misrepresented or Unverified IP Ratings

Some suppliers may claim high IP ratings (e.g., IP67, IP69K) without third-party testing or certification. This can lead to unexpected failures when exposed to dust, moisture, or high-pressure washdowns. -

Incorrect Sealing Design

The actuator rod’s integration with seals (e.g., wipers, O-rings) must match the intended IP rating. Poorly designed or incompatible sealing systems can compromise protection even if the rod itself is robust. -

Neglecting Environmental Conditions

Failing to match the IP rating to the actual operating environment—such as outdoor exposure, chemical washdowns, or dusty industrial settings—can result in contamination, corrosion, or mechanical failure. -

Overlooking Dynamic IP Performance

IP ratings are often tested in static conditions. However, actuator rods move during operation, which can compromise seals over time. Suppliers may not account for dynamic sealing performance in their ratings.

Mitigation Strategies

- Source from Reputable Suppliers with proven quality management systems and product testing.

- Request Documentation including material certifications, IP test reports, and dimensional inspection data.

- Conduct Sample Testing under real-world conditions before full-scale procurement.

- Clarify IP Requirements with engineers, considering both static and dynamic operation.

- Engage in Supplier Audits for high-volume or mission-critical applications.

Avoiding these pitfalls ensures reliable actuator performance, longer service life, and reduced downtime.

Logistics & Compliance Guide for Actuator Rod

Product Overview

The Actuator Rod is a precision mechanical component designed for use in linear motion systems, commonly integrated into industrial automation, robotics, and control systems. Due to its material composition, dimensional tolerances, and potential end-use applications, specific logistics and compliance considerations must be observed throughout its supply chain journey.

Packaging & Handling

- Protective Packaging: Actuator rods must be individually wrapped in anti-corrosion paper or VCI (Vapor Corrosion Inhibitor) film and placed in rigid cardboard or wooden crates to prevent scratches, bending, or contamination during transit.

- Moisture Control: Include desiccant packs in sealed packaging when shipping to high-humidity regions or over long durations.

- Labeling: Clearly label each package with part number, batch/lot number, net weight, country of origin, and handling symbols (e.g., “Fragile,” “Do Not Stack”).

- Handling Instructions: Prohibit dragging or dropping of packages; use mechanical aids (forklifts, pallet jacks) for heavy shipments.

Storage Conditions

- Environment: Store in a dry, climate-controlled area with temperatures between 10°C and 30°C and relative humidity below 60%.

- Orientation: Store horizontally on flat, clean shelving to avoid deformation.

- Shelf Life: Inspect for corrosion or damage if stored longer than 12 months. Reapply protective coating if necessary before use.

Transportation Requirements

- Domestic Shipments: Use enclosed, non-hazardous freight carriers. Secure loads on pallets with stretch wrap and corner boards.

- International Shipments:

- Comply with ISPM 15 regulations for wooden packaging (heat-treated and stamped).

- Provide commercial invoice, packing list, and bill of lading.

- Declare accurate HTS (Harmonized Tariff Schedule) code—typically 8483.10 or 8481.80 depending on design and function.

- Air Freight: Avoid if possible due to cost; ensure compliance with IATA packaging standards if used.

Regulatory Compliance

- Material Compliance: Confirm rod material (e.g., stainless steel, alloy steel) meets RoHS and REACH standards. Provide Declaration of Conformity when requested.

- Export Controls: Verify if the actuator rod falls under dual-use regulations (e.g., ECCN 2B201 under EAR) based on precision, application, and destination country.

- Country-Specific Regulations:

- EU: CE marking may be required if sold as part of a safety-related system; ensure compliance with Machinery Directive 2006/42/EC when integrated.

- USA: No FDA or DOT requirements apply unless used in regulated sectors (e.g., medical, aerospace).

- China: Comply with CCC certification if incorporated into controlled equipment.

Documentation

- Mandatory Documents:

- Certificate of Origin

- Material Test Report (MTR) or Mill Certificate

- Commercial Invoice and Packing List

- Optional but Recommended:

- RoHS/REACH Compliance Certificate

- Conflict Minerals Reporting Template (CMRT) if applicable

Import & Customs Clearance

- Provide accurate product description emphasizing mechanical function (e.g., “Stainless Steel Linear Actuator Rod for Industrial Automation Equipment”).

- Specify end-use to avoid misclassification as a controlled component.

- Partner with a licensed customs broker in destination country to ensure smooth clearance.

Quality & Traceability

- Maintain batch-level traceability from raw material to final shipment.

- Implement a recall procedure in case of non-conformance.

- Retain documentation for a minimum of 5 years.

Environmental & Safety Considerations

- No hazardous materials under normal conditions; dispose of packaging per local waste regulations.

- Safety Data Sheet (SDS) not typically required unless surface coatings contain regulated substances.

Contact & Support

For compliance inquiries, logistics coordination, or documentation requests, contact:

Supply Chain Compliance Team

Email: [email protected]

Phone: +1 (555) 123-4567

Conclusion for Sourcing Actuator Rod:

After a thorough evaluation of technical specifications, quality standards, supplier capabilities, and cost considerations, the most suitable sourcing strategy for the actuator rod has been identified. Selecting a reliable supplier with proven experience in precision engineering, material durability, and consistent manufacturing processes ensures the actuator rod will meet required performance and safety standards. Factors such as material grade (e.g., stainless steel or alloy steel), corrosion resistance, tensile strength, dimensional accuracy, and compliance with industry certifications (e.g., ISO, ASTM) were critical in the decision-making process.

Additionally, a balanced approach between cost-efficiency and long-term reliability has been achieved by choosing a supplier that offers competitive pricing without compromising on quality. Establishing a long-term partnership with the selected vendor will also support supply chain stability, on-time delivery, and opportunities for continuous improvement.

In conclusion, the chosen sourcing solution for the actuator rod supports operational efficiency, product integrity, and overall project success, aligning with both technical requirements and strategic business objectives.