The global HVAC actuator market is experiencing robust growth, driven by rising demand for energy-efficient building systems, increased automation in commercial and industrial infrastructure, and stringent government regulations on energy consumption. According to a 2023 report by Mordor Intelligence, the global HVAC market is projected to grow at a CAGR of over 7.5% from 2023 to 2028, with actuator technologies playing a critical role in enabling precise control of heating, ventilation, and air conditioning systems. Similarly, Grand View Research estimates that the global market for HVAC controls—including actuators—was valued at USD 12.4 billion in 2022 and is expected to expand at a CAGR of 7.8% through 2030. This surge is fueled by smart building adoption, IoT integration, and the shift toward sustainable building management systems. As demand for reliable, responsive, and intelligent actuators rises, a select group of manufacturers are leading innovation, scalability, and performance in the space. Below are the top 10 HVAC actuator manufacturers shaping the future of climate control technology.

Top 10 Actuator Hvac Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

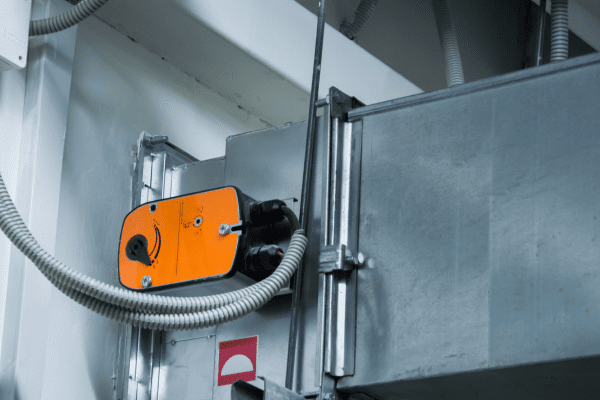

#1 Damper actuators

Domain Est. 1986

Website: siemens.com

Key Highlights: Siemens is a recognized global leader in HVAC damper actuators. Energy-efficient, robust, flexible and reliable – save time and costs….

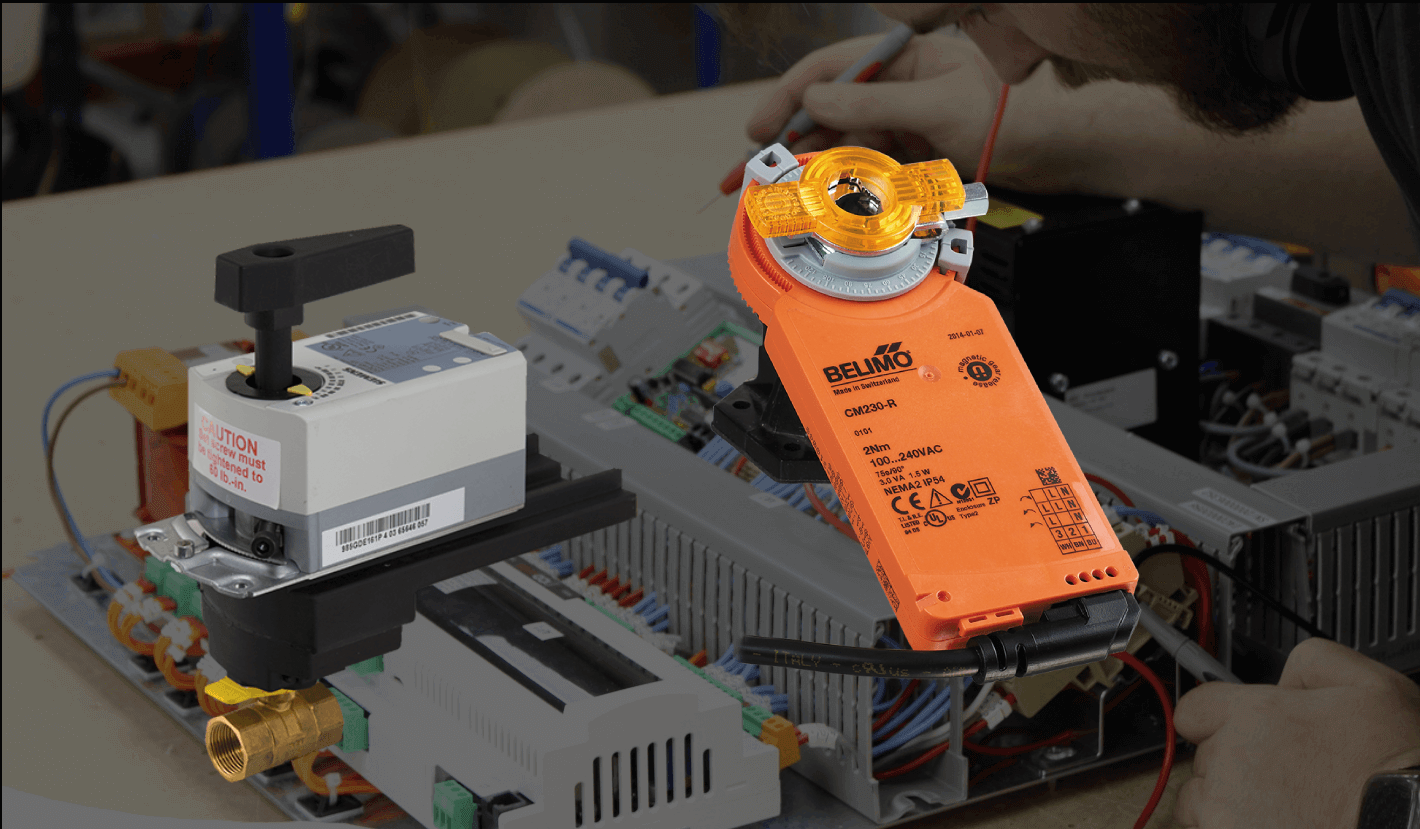

#2 Belimo

Domain Est. 1995

Website: belimo.com

Key Highlights: Our damper actuators are designed for use in HVAC applications ensuring performance, reliability and lower power consumption. Damper Actuators · Sensors/Meters….

#3 Actuators

Domain Est. 1995

Website: smcusa.com

Key Highlights: SMC offers a variety of specialty air cylinders including Sine (smooth acceleration), Load Stopping, and Clamp to name a few….

#4 Rotork

Domain Est. 1995

Website: rotork.com

Key Highlights: Precision Modulating Actuators · Valve Positioners and Controllers · Part-turn Gearboxes · HVAC Actuators · HVAC Sensors · Instrumentation Valves · Electrical ……

#5 HVAC Valves, Actuators and Accessories

Domain Est. 1995

Website: bray.com

Key Highlights: Bray manufactures a wide range of valves actuators, control products and accessories for cooling towers and chiller systems are engineered to provide zero ……

#6 HVAC Actuators

Domain Est. 1996

Website: johnsonelectric.com

Key Highlights: HVAC actuator modules are custom engineered to meet the power and integration requirements of the customer’s application….

#7 Exlar Electric Linear & Rotary Actuator Products

Domain Est. 1996

Website: actuation.curtisswright.com

Key Highlights: Exlar ® electric actuators from Curtiss-Wright deliver a broad range of capabilities, power and performance in both linear and rotary configurations. Select ……

#8 HVAC Actuator

Domain Est. 1997

Website: multiproducts.com

Key Highlights: Multi Products specializes in HVAC actuator motors, backed by 50+ years of industry expertise. Available by SPEC number or built to order in 7–10 days….

#9 iO HVAC Controls

Domain Est. 2017

Website: iohvaccontrols.com

Key Highlights: iO HVAC Controls specializes in designing and manufacturing residential and commercial HVAC controls, tailored to meet the needs of our contractors and ……

#10 Damper Actuators

Domain Est. 2020

Website: soloonactuators.com

Key Highlights: If you need to purchase damper actuators, you can directly contact the company through Soloon Controls’ official websites (solooncontrols.com or soloonactuators ……

Expert Sourcing Insights for Actuator Hvac

H2: 2026 Market Trends for HVAC Actuators

The global HVAC actuator market in 2026 is poised for significant transformation, driven by technological advancements, evolving regulatory landscapes, and shifting end-user demands. Key trends shaping the market include:

1. Dominance of Smart and Connected Actuators:

By 2026, smart actuators with integrated communication protocols (BACnet, Modbus, KNX, and wireless standards like Zigbee or LoRaWAN) will become the norm. These devices enable real-time monitoring, remote diagnostics, predictive maintenance, and seamless integration with Building Management Systems (BMS) and IoT platforms. Demand will be fueled by the global push for intelligent buildings and energy optimization.

2. Electrification and Energy Efficiency Regulations:

Stringent global energy efficiency standards (e.g., EU Ecodesign, U.S. DOE rules) will accelerate the shift from pneumatic and hydraulic actuators to electric models. Electric actuators offer superior control precision, lower lifecycle costs, and compatibility with renewable energy sources. The rise of heat pumps and electrified HVAC systems will further boost demand for efficient electric actuators.

3. Growth in Commercial and Industrial Applications:

While residential use will grow, the largest expansion is expected in commercial buildings (offices, retail, healthcare) and industrial facilities. These sectors prioritize energy savings, regulatory compliance, and system reliability. Actuators for VAV (Variable Air Volume) systems, chilled beams, and complex hydronic controls will see increased adoption.

4. Sustainability and Low-GWP Refrigerants:

As the HVAC industry transitions to low-GWP refrigerants under the Kigali Amendment, actuators must be compatible with new refrigerant types and higher operating pressures. Manufacturers are focusing on durable materials and designs that support sustainable system operation, reducing leakage and improving longevity.

5. Regional Market Diversification:

Asia-Pacific (particularly China, India, and Southeast Asia) will lead market growth due to rapid urbanization, infrastructure development, and increasing HVAC penetration. North America and Europe will maintain strong demand, driven by building retrofits, smart city initiatives, and strict environmental regulations.

6. Advancements in Actuator Technology:

Innovations such as brushless DC motors, improved torque density, silent operation, and enhanced cybersecurity features will differentiate leading products. Miniaturization and modular designs will support easier installation and maintenance.

7. Supply Chain Resilience and Localization:

Post-pandemic and geopolitical factors will push manufacturers to diversify supply chains and localize production. This trend will impact cost structures and availability, favoring companies with regional manufacturing capabilities.

In summary, the 2026 HVAC actuator market will be defined by intelligence, efficiency, connectivity, and sustainability. Companies that invest in smart technologies, comply with global regulations, and adapt to regional dynamics will be best positioned for growth.

Common Pitfalls When Sourcing HVAC Actuators (Quality and IP Rating)

Sourcing HVAC actuators involves more than just matching voltage and torque specifications. Overlooking key quality and Ingress Protection (IP) rating factors can lead to premature failures, system inefficiencies, and increased maintenance costs. Below are common pitfalls to avoid:

Inadequate IP Rating for the Environment

Choosing an actuator with an insufficient IP rating for its installation environment is a frequent error. For example, using an IP54-rated actuator in outdoor or high-humidity areas where IP65 or higher is required can result in moisture and dust ingress, leading to electrical failure or mechanical jamming. Always verify environmental conditions—indoor, outdoor, washdown areas, or dusty industrial settings—and select actuators with appropriate IP ratings to ensure long-term reliability.

Overlooking Build Quality and Materials

Many low-cost actuators use inferior materials such as plastic gears, weak motor components, or substandard seals. These compromises reduce durability, especially under continuous operation or in extreme temperatures. Prioritize actuators with metal gears, robust housing materials (e.g., UV-resistant polymers or die-cast metal), and high-quality internal components to prevent premature wear and ensure consistent performance over time.

Misunderstanding IP Rating Nuances

A common misconception is treating IP ratings as interchangeable or assuming higher numbers always mean better protection. For example, IP65 protects against dust and low-pressure water jets, while IP66 offers protection against powerful water jets—critical in car wash or outdoor installations. Confusing these levels can lead to inadequate protection. Review the specific requirements of the second digit (liquid ingress) and first digit (solid particle ingress) carefully.

Ignoring Certifications and Compliance

Actuators lacking third-party certifications (e.g., CE, UL, RoHS) may not meet safety or performance standards. Unverified products often cut corners in design and testing, increasing the risk of malfunction or non-compliance with building codes. Always source actuators from reputable manufacturers with verifiable certifications to ensure reliability and regulatory compliance.

Prioritizing Price Over Total Cost of Ownership

Opting for the cheapest actuator can lead to higher long-term costs due to frequent replacements, downtime, and labor for repairs. A higher-quality actuator with a suitable IP rating may have a higher upfront cost but offers better durability, energy efficiency, and reduced maintenance, ultimately lowering the total cost of ownership.

Mismatched Actuator Specifications

Even with proper IP and quality, selecting an actuator with incorrect torque, stroke time, or control signal (e.g., 0–10 V vs. 2–10 V) can cause operational issues. Always cross-check technical specs with the valve or damper requirements to ensure compatibility and optimal system performance.

By addressing these common pitfalls, HVAC professionals can ensure reliable, efficient, and long-lasting system operation.

Logistics & Compliance Guide for HVAC Actuators

Product Overview and Regulatory Scope

HVAC actuators are electromechanical devices used to control dampers, valves, and other components within heating, ventilation, and air conditioning systems. Ensuring proper logistics handling and compliance with regional and international standards is essential for safe distribution, installation, and operation.

Key Compliance Standards and Certifications

HVAC actuators must meet various electrical, safety, and environmental regulations depending on the market. Key standards include:

– IEC 60730-1 / IEC 60730-2-14: Safety controls for household and similar equipment, including automatic electrical controls for actuators.

– UL 60730-1 & UL 60730-2-14: North American safety standard for automatic electrical controls.

– RoHS (EU Directive 2011/65/EU): Restriction of Hazardous Substances in electrical equipment.

– REACH (EC 1907/2006): Registration, Evaluation, Authorization, and Restriction of Chemicals.

– CE Marking: Mandatory for sale in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

– UKCA Marking: Required for products placed on the market in Great Britain (England, Wales, Scotland).

– FCC Part 15 (USA): Electromagnetic compatibility (EMC) requirements for unintentional radiators.

– Energy-Related Products (ErP) Directive 2009/125/EC: May apply if the actuator contributes to system energy efficiency.

Manufacturers must provide documentation such as Declarations of Conformity (DoC), technical files, and test reports to verify compliance.

Packaging and Labeling Requirements

Proper packaging and labeling ensure product integrity and regulatory compliance during transit and storage:

– Use anti-static, moisture-resistant packaging to protect sensitive electronic components.

– Clearly label each unit with:

– Product name and model number

– Input voltage and power requirements

– Manufacturer name and contact information

– CE, UKCA, UL, or other relevant certification marks

– RoHS compliance symbol (if applicable)

– Batch/lot number and manufacturing date

– Include multilingual user manuals and safety instructions where required by local regulations.

Transportation and Handling Guidelines

HVAC actuators are sensitive to environmental and mechanical stress. Follow these logistics best practices:

– Temperature Control: Store and transport between -10°C to +50°C unless otherwise specified. Avoid condensation.

– Humidity: Maintain relative humidity below 90% (non-condensing).

– Shock and Vibration: Use cushioned packaging and avoid dropping or rough handling. Comply with ISTA 3A or equivalent shipping test standards.

– Stacking: Do not exceed maximum stacking height indicated on outer cartons.

– Hazardous Materials: Confirm that no hazardous substances are present beyond regulated thresholds (per ADR, IATA, IMDG as applicable).

Import/Export Documentation

Ensure accurate documentation for international shipments:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Test Reports and DoC for relevant standards

– RoHS and REACH compliance declarations

– ECCN (Export Control Classification Number) if applicable under dual-use regulations

Verify destination-specific import requirements (e.g., NRCan in Canada, INMETRO in Brazil).

Country-Specific Compliance Considerations

- European Union: CE marking with notified body involvement if required; register under the EU Market Surveillance Regulation.

- United States: UL listing or recognition through an NRTL (Nationally Recognized Testing Laboratory); comply with DOE efficiency rules if integrated into regulated systems.

- Canada: CSA certification (CAN/CSA-C22.2 No. 60730 series); comply withISED EMC requirements.

- China: CCC mark may be required depending on product category; check CNCA regulations.

- Australia/NZ: RCM mark for electrical safety and EMC under the ACMA framework.

Warranty, Returns, and End-of-Life Management

- Provide a minimum 1–2 year warranty with clear terms.

- Implement a returns process that includes inspection for damage and compliance verification.

- Comply with WEEE (Waste Electrical and Electronic Equipment Directive 2012/19/EU) for end-of-life product take-back and recycling in applicable regions.

- Offer disposal guidelines for customers, especially in regulated markets.

Summary

Effective logistics and compliance management for HVAC actuators involves adherence to international safety, environmental, and transportation standards. Maintaining proper documentation, secure packaging, and market-specific certifications ensures smooth global distribution and regulatory acceptance. Regular audits and supplier collaboration are recommended to stay current with evolving regulations.

Conclusion for Sourcing HVAC Actuators

In conclusion, sourcing HVAC actuators requires a strategic approach that balances performance, reliability, cost-efficiency, and compatibility with existing system requirements. After evaluating various suppliers, product types (such as modulating, on/off, spring-return, and smart actuators), and technical specifications—including torque output, voltage compatibility, response time, and communication protocols like 0–10 V, 2–3 point, or BACnet—it is evident that selecting the right actuator significantly impacts HVAC system efficiency and control accuracy.

Prioritizing quality suppliers with a proven track record, strong technical support, and compliance with industry standards (such as CE, UL, or EN) ensures long-term operational reliability and reduces maintenance costs. Additionally, considering factors such as warranty, energy efficiency, and future scalability supports sustainable building management practices.

Ultimately, a well-informed sourcing decision leads to improved system performance, enhanced occupant comfort, and lower lifecycle costs. By aligning technical needs with supplier capabilities and total cost of ownership, organizations can achieve optimal results in their HVAC control strategies.