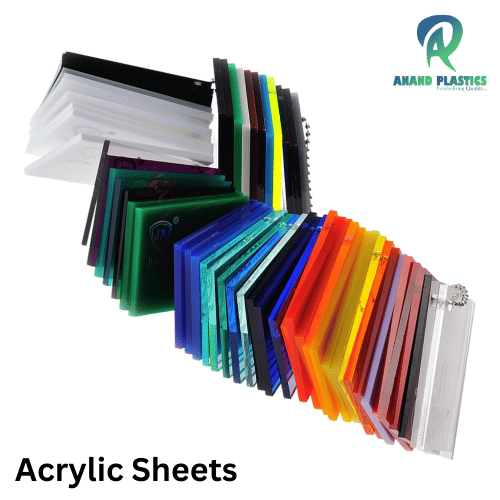

The global acrylic sheets market is experiencing robust growth, driven by increasing demand across construction, automotive, signage, and consumer goods industries. According to Grand View Research, the global acrylic market size was valued at USD 11.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.8% from 2023 to 2030. This sustained growth is fueled by acrylic’s durability, optical clarity, and weather resistance, making it a preferred alternative to glass in a wide range of applications. Additionally, rising infrastructure development in emerging economies and the shift toward lightweight, energy-efficient materials are amplifying demand. As procurement professionals and manufacturers seek reliable, high-volume supply chains, identifying reputable wholesale acrylic sheet manufacturers has become critical. The following list highlights nine leading manufacturers known for scale, product quality, and global distribution—key partners positioned to meet the expanding market demand.

Top 9 Acrylic Sheets Wholesale Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Regal Plastic

Domain Est. 1996

Website: regalplastic.com

Key Highlights: Regal Plastic stocks high-quality materials, including acrylic, polycarbonate, HDPE, PVC, and a variety of specialty plastics, ideal for industrial, commercial ……

#2 Plexiglass Sheet

Domain Est. 1997

Website: professionalplastics.com

Key Highlights: 3-day returnsWe will cut-to-size & ship sheets of plexiglass directly to your door. Buy plexiglass online or shop for various grades of plexiglass from our website….

#3 Wholesale Acrylic Sheets

Domain Est. 1997

Website: regal-plastics.com

Key Highlights: Wholesale Acrylic and Plexiglass Sheets. Our acrylic sheets include everything from assorted colored acrylic sheets to bullet-resistant acrylic sheets….

#4 Plastic, Acrylic & Polycarbonate Sheet Supplier

Domain Est. 1997 | Founded: 1973

Website: acplasticsinc.com

Key Highlights: A&C Plastics has been a leading acrylic and polycarbonate sheet supplier since 1973. We have plastic, plastic sheets, acrylic sheets, PVC, ABS and more ……

#5 Acme Plastics

Domain Est. 1997

Website: acmeplastics.com

Key Highlights: Free delivery 15-day returnsAcme Plastics offers a wide variety of durable and long-lasting plastic sheet, rod, and tube options. Our team of experts are here to help meet your pro…

#6 Calsak Plastics

Domain Est. 2000

Website: calsakplastics.com

Key Highlights: Backed by over five decades of expertise, our plastic sheet division delivers a robust inventory of materials including acrylic sheets, polycarbonate, HDPE, PVC ……

#7 Min Plastics

Domain Est. 2000

Website: minplastics.com

Key Highlights: Official distributor of PLEXIGLAS®, Polycarbonate, Expanded/Foamed PVC, HDPE, Starboard, and Laser-Engraveable sheets. Supporting projects from cut-to-size ……

#8 Delvie’s Plastics

Domain Est. 2002

Website: delviesplastics.com

Key Highlights: 4-day delivery 30-day returnsLocated in Salt Lake City, UT – we have built our reputation on offering quality acrylic sheets and acrylic supplies with outstanding customer service….

#9 Red Solid Cast Acrylic

Domain Est. 2005

Website: jpplus.com

Key Highlights: In stock Rating 5.0 (1) Single-ply cast acrylic sheets come with a glass like glossy finish. Cast acrylic is perfect for jewelry, home decor, layered signage, inlayed signage and…

Expert Sourcing Insights for Acrylic Sheets Wholesale

H2: 2026 Market Trends for Acrylic Sheets Wholesale

The wholesale market for acrylic sheets is poised for significant transformation by 2026, driven by technological advancements, evolving consumer demands, sustainability initiatives, and regional economic shifts. As a versatile thermoplastic known for its clarity, durability, and lightweight properties, acrylic (polymethyl methacrylate or PMMA) continues to gain traction across diverse industries such as construction, signage, automotive, healthcare, and consumer goods. Here are the key trends expected to shape the wholesale acrylic sheets market in 2026:

-

Growing Demand in Construction and Architecture

By 2026, the construction sector is projected to remain a dominant consumer of wholesale acrylic sheets. Architects and builders are increasingly favoring acrylic over glass due to its impact resistance, ease of fabrication, and thermal insulation properties. Applications in skylights, partitions, façades, and interior design elements are expanding, particularly in green building projects that prioritize energy efficiency and natural lighting. -

Rise of Sustainable and Recycled Acrylic

Sustainability is becoming a pivotal factor in material selection. In response, manufacturers are investing in recycled and bio-based acrylic variants. The 2026 market will likely see a broader availability of post-consumer recycled acrylic sheets, driven by corporate ESG (Environmental, Social, and Governance) goals and tightening environmental regulations. Wholesalers offering eco-friendly or certified sustainable acrylic products are expected to gain a competitive edge. -

Expansion in Signage and Retail Display Applications

The retail and advertising sectors continue to rely heavily on acrylic for custom signage, display stands, and point-of-purchase fixtures. With the ongoing rebound of physical retail post-pandemic and the need for visually appealing, durable materials, demand for colored, textured, and digitally printed acrylic sheets is expected to grow. Wholesalers catering to niche customization needs will benefit from this trend. -

Technological Advancements in Manufacturing

Improvements in extrusion and cell-cast production technologies are enabling higher precision, enhanced optical clarity, and better UV resistance in acrylic sheets. Antimicrobial and anti-fog acrylic variants—initially developed during the pandemic—are gaining long-term relevance in healthcare and public infrastructure. By 2026, these high-performance acrylics are likely to constitute a larger share of wholesale volumes. -

Asia-Pacific as a Key Growth Region

The Asia-Pacific region is anticipated to lead global demand growth for wholesale acrylic sheets, fueled by rapid urbanization, infrastructure development, and rising consumer spending in countries like China, India, and Vietnam. Local production capacity expansions and government investments in smart cities will further stimulate regional demand, making it a strategic market for global wholesalers. -

Supply Chain Diversification and Resilience

Following supply chain disruptions in preceding years, companies are focusing on nearshoring and regional sourcing strategies. By 2026, wholesale distributors are expected to strengthen partnerships with regional manufacturers to ensure consistent supply, reduce lead times, and mitigate geopolitical and logistical risks. -

Digitalization of Wholesale Platforms

E-commerce and digital B2B marketplaces are transforming the way acrylic sheets are bought and sold. Wholesalers adopting digital platforms offering real-time inventory, 3D visualization tools, and automated quoting systems will enhance customer experience and streamline operations. Integration with procurement software used by contractors and designers will become increasingly important. -

Price Volatility and Raw Material Challenges

Acrylic production depends on propylene and other petrochemical derivatives, making it susceptible to oil price fluctuations. While recycling and alternative feedstocks may dampen volatility over time, wholesalers must remain agile in pricing and inventory management to maintain margins amid uncertain input costs.

In conclusion, the 2026 wholesale acrylic sheets market will be characterized by innovation, sustainability, and regional diversification. Wholesalers who adapt to eco-conscious consumer preferences, embrace digital transformation, and expand into high-growth sectors and geographies will be best positioned for long-term success.

Common Pitfalls Sourcing Acrylic Sheets Wholesale (Quality, IP)

Sourcing acrylic sheets in bulk can offer significant cost savings, but it comes with risks—especially concerning product quality and intellectual property (IP) protection. Being aware of these pitfalls helps ensure a reliable supply chain and protects your brand.

Inconsistent Material Quality

One of the most frequent issues when buying acrylic sheets wholesale is variability in quality. Not all manufacturers adhere to the same production standards, leading to inconsistencies in thickness, clarity, color accuracy, and surface finish. Lower-tier suppliers might use recycled content or substandard resins, resulting in sheets that are brittle, prone to warping, or exhibit visible imperfections. Always request material test reports (MTRs) and physical samples before placing large orders.

Misrepresentation of Acrylic Type

Suppliers may falsely advertise the type of acrylic—such as casting versus extrusion. Cast acrylic offers superior optical clarity and durability but is more expensive. Extruded acrylic is cheaper but less resistant to stress and temperature changes. Some wholesalers blend or mislabel lower-grade materials as high-performance cast sheets, leading to product failure in demanding applications.

Lack of Traceability and Certification

Reputable acrylic products should come with traceability documentation, including certifications like ISO 9001 or compliance with industry standards (e.g., ASTM D4802). Without proper documentation, it’s difficult to verify quality claims or address issues post-purchase. Wholesale suppliers, especially from unverified sources, may lack these certifications, increasing the risk of receiving non-compliant materials.

Intellectual Property Infringement Risks

When sourcing branded or specialty acrylics (e.g., Plexiglas®, Acrylite®), there’s a risk of inadvertently purchasing counterfeit or unauthorized products. Unauthorized replication of proprietary formulations or trademarks constitutes IP infringement. Using such materials can expose your business to legal liability, especially if the counterfeit product underperforms or causes damage.

Unlicensed Use of Branding and Trademarks

Some wholesalers may use trademarked brand names in their listings without authorization. Purchasing from these suppliers—even unknowingly—can implicate your business in trademark violations. Always verify that the supplier is an authorized distributor of branded acrylic products.

Insufficient Legal Protections in Contracts

Many wholesale agreements, especially with overseas suppliers, lack clear clauses on quality assurance, IP indemnification, and dispute resolution. Without strong contractual terms, you may have limited recourse if substandard or counterfeit materials are delivered. Ensure contracts specify material specifications, compliance requirements, and consequences for IP violations.

Supply Chain Opacity

Opaque supply chains make it difficult to verify where and how the acrylic is produced. This lack of visibility increases the risk of receiving off-spec or counterfeit materials. Partner with suppliers who offer transparency in sourcing and manufacturing processes to mitigate this risk.

By conducting due diligence, requesting documentation, and working with reputable suppliers, businesses can avoid these common pitfalls and ensure they receive high-quality, legally compliant acrylic sheets.

Logistics & Compliance Guide for Acrylic Sheets Wholesale

Overview of Acrylic Sheets in Wholesale Trade

Acrylic sheets, also known as polymethyl methacrylate (PMMA), are widely used across industries such as construction, signage, retail displays, and manufacturing due to their durability, clarity, and lightweight properties. In wholesale operations, efficient logistics and adherence to compliance standards are critical to ensure product integrity, timely delivery, and legal conformity across domestic and international markets.

Packaging and Handling Standards

Proper packaging is essential to prevent scratches, cracking, or warping during transit. Acrylic sheets should be wrapped in protective film or paper and securely palletized with edge protectors. Corrugated cardboard or foam spacers must be used between layers to minimize friction. Pallets should be stretch-wrapped and labeled with handling instructions such as “Fragile,” “This Side Up,” and weight specifications. Avoid stacking excessive weight to prevent deformation.

Transportation and Shipping Considerations

Acrylic sheets are typically shipped via flatbed trucks, enclosed trailers, or container freight depending on volume and destination. Temperature control is crucial—acrylic can expand or contract under extreme heat or cold. Avoid direct sunlight exposure during transport. For international shipments, use ISO-compliant containers with moisture barriers to prevent condensation. Coordinate with carriers experienced in handling large, flat, and delicate materials to reduce damage risks.

Inventory Management and Storage

Store acrylic sheets vertically in racks with protective padding, or horizontally on flat, clean surfaces with adequate support to prevent sagging. Maintain a climate-controlled environment (ideally 15–25°C with low humidity) and protect from direct UV exposure, which can degrade some acrylic types. Implement a first-in, first-out (FIFO) inventory system to minimize aging and yellowing over time.

Regulatory Compliance and Safety Data

Ensure all acrylic sheet products comply with relevant regional and international standards such as ASTM D4802 (Standard Specification for Acrylic Sheet) and ISO 7823. Provide Safety Data Sheets (SDS) in accordance with OSHA’s Hazard Communication Standard (HCS) and REACH/GHS regulations in the EU. Acrylic is generally non-toxic but may release hazardous fumes when cut or heated; proper labeling and handling instructions must accompany wholesale shipments.

Import/Export Regulations

For cross-border trade, verify customs classifications under the Harmonized System (HS Code: typically 3920.51 or 3926.30 for acrylic sheets). Compliance with destination country regulations—such as EU CE marking, UKCA marking, or FDA approval for food-contact applications—is mandatory. Include accurate commercial invoices, packing lists, and certificates of origin. Be aware of anti-dumping duties or trade restrictions that may apply in certain regions.

Environmental and Sustainability Requirements

Many markets require documentation on recyclability and environmental impact. Acrylic is recyclable (Resin Identification Code 7), and some wholesale buyers demand proof of sustainable manufacturing practices. Consider offering recycled-content acrylic options and maintain records of waste management and emissions compliance where applicable.

Quality Assurance and Documentation

Implement a quality control process to inspect incoming and outgoing sheets for defects, thickness consistency, and optical clarity. Maintain traceability through batch numbers and production dates. Provide mill test reports or certificates of conformance with each wholesale shipment to validate compliance with agreed specifications.

Risk Management and Insurance

Ensure comprehensive cargo insurance covers breakage, theft, and environmental damage during transit. Clearly define liability terms in contracts with suppliers and customers. Conduct regular audits of logistics partners to verify adherence to handling and compliance protocols.

Conclusion

Successful wholesale distribution of acrylic sheets hinges on meticulous logistics planning and strict compliance with safety, environmental, and trade regulations. By standardizing packaging, optimizing storage, and staying current with regulatory requirements, wholesalers can ensure product quality, customer satisfaction, and operational efficiency in a competitive global market.

In conclusion, sourcing acrylic sheets wholesale offers numerous advantages for businesses and large-scale projects, including significant cost savings, consistent material quality, and reliable supply chains. By partnering with reputable suppliers, buyers can access a wide range of acrylic types, thicknesses, colors, and finishes tailored to specific applications—whether for signage, displays, construction, or industrial use. It is essential to evaluate suppliers based on product quality, minimum order requirements, delivery timelines, and customer service to ensure a successful long-term partnership. With the growing demand for durable, lightweight, and versatile materials, wholesale sourcing of acrylic sheets proves to be a strategic move for enhancing efficiency and competitiveness in various industries.