The global acrylic embedment market has experienced steady growth, driven by rising demand across industries such as consumer electronics, automotive, architecture, and custom design. According to Grand View Research, the global acrylic market was valued at USD 18.6 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030, fueled by innovation in material applications and increasing adoption in decorative and functional components. This surge in demand has led to the emergence of specialized manufacturers offering high-precision acrylic embedment solutions—from encasing electronics and mementos to creating seamless architectural elements. As the market becomes more competitive, manufacturers are differentiating through advanced fabrication techniques, scalability, and material integrity. Based on industry capability, production volume, technological expertise, and client reach, we’ve identified the top 9 acrylic embedment manufacturers shaping the future of this niche yet expanding segment.

Top 9 Acrylic Embedment Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Lucite Standard Shapes 1 Financial & Lucite Corporate Gifts

Domain Est. 1999

Website: lucitetombstones.com

Key Highlights: Create a unique Lucite investment award or gift. Deal Items in brass, marble, silver, gold, crystal and acrylic. Bulls and bears!…

#2 Custom Acrylic Embedment Awards

Domain Est. 2000

Website: crownawards.com

Key Highlights: Creating your own CUSTOM ACRYLIC EMBEDMENT AWARD is fast and easy. Our designers will create FREE Artwork with your order….

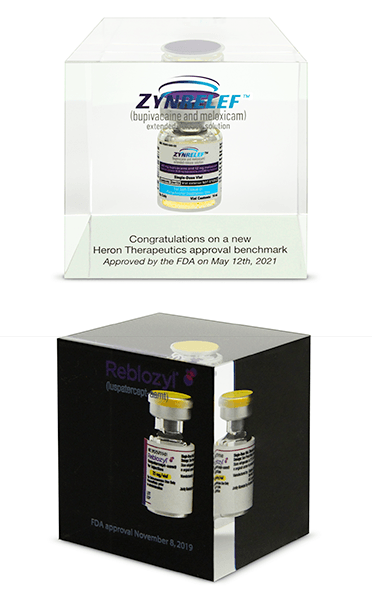

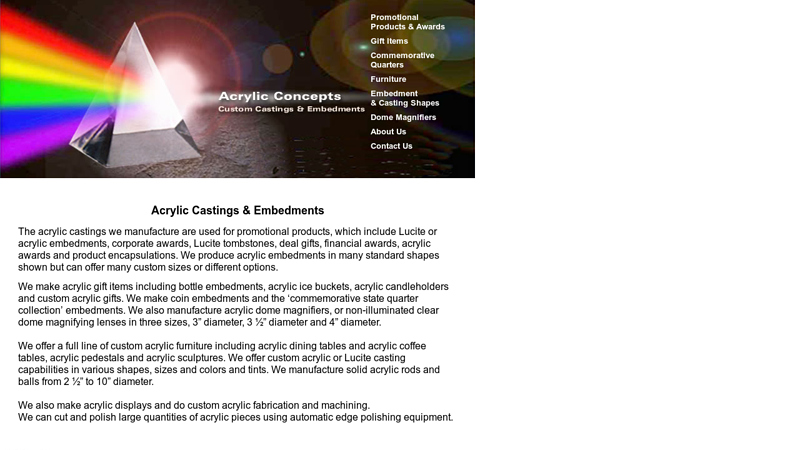

#3 Acrylic Castings Embedments Lucite Acrylic Encapsulations

Domain Est. 2001

Website: embedment.com

Key Highlights: We manufacture solid acrylic rods and balls from 2 ½” to 10” diameter. We also make acrylic displays and do custom acrylic fabrication and machining. We can cut ……

#4 Lucite® Embedments

Domain Est. 2020

Website: usacrylicawards.com

Key Highlights: Free delivery over $200 · 15-day returnsCustom-crafted acrylic embedded displays that encase and preserve objects or printed materials in clear, durable Lucite® for a sleek, profe…

#5 Embedments

Domain Est. 1999

Website: clearimageinc.com

Key Highlights: Clear Image, Inc. is a manufacturer of Acrylic Awards & Lucite Embedments. Our products are hand crafted in the U.S.A. by skilled artisans who each have an ……

#6 Century Manufacturing

Domain Est. 1997

Website: centurymfg.com

Key Highlights: With Century Manufacturing, you can create quality, custom awards and promotional products expertly made by our team from acrylic, wood, and Lucite. With ……

#7 Acrylic Embedments Awards

Domain Est. 2000

Website: fineawards.com

Key Highlights: Commemorate a deal, achievement, or your brand by embedding your items into acrylic. We can custom design any shape for your item to float inside the award….

#8 Company Profile

Domain Est. 2000

Website: crystal-likeplastics.com

Key Highlights: Company Profile. As the oldest embedment company in the United States, we offer over 71 years of expertise applied to all its castings….

#9 Acrylic Warehouse

Domain Est. 2002

Website: acrylicwarehouse.com

Key Highlights: Acrylic Warehouse has been designing and manufacturing affordable, high-quality Acrylic Awards for organizations across the country for over 20 years….

Expert Sourcing Insights for Acrylic Embedment

2026 Market Trends for Acrylic Embedment

The acrylic embedment market is poised for dynamic growth and transformation by 2026, driven by increasing demand in decorative, industrial, and personalized product sectors. Acrylic embedment—the process of sealing objects within clear acrylic resin for preservation, display, or functional purposes—is gaining traction across multiple industries due to its aesthetic appeal, durability, and versatility. This analysis explores key market trends expected to shape the acrylic embedment landscape in 2026.

Rising Demand in Custom and Personalized Products

One of the most influential trends propelling the acrylic embedment market is the surge in demand for personalized and custom-made products. Consumers are increasingly seeking unique, emotionally resonant items such as keepsakes, memorial jewelry, and custom awards. Acrylic embedment allows the encapsulation of personal items—like wedding flowers, pet paw prints, or military insignia—into durable, visually appealing forms. By 2026, e-commerce platforms and on-demand manufacturing are expected to further amplify this trend, enabling mass customization at competitive prices.

Expansion in Art and Interior Design Applications

The art and interior design industries are embracing acrylic embedment for its modern, sleek aesthetic. Designers are integrating embedded objects into furniture, wall art, lighting fixtures, and architectural elements. The transparency and high-gloss finish of acrylic make it ideal for contemporary minimalist and luxury interiors. By 2026, collaborations between artists, designers, and material engineers are likely to yield innovative applications, such as embedments with LED integration or interactive elements, pushing the boundaries of functional art.

Technological Advancements in Resin and Curing Processes

Advancements in acrylic resin formulations and curing technologies are enhancing the quality and efficiency of embedment processes. Low-viscosity, bubble-free resins with improved UV resistance and reduced yellowing are becoming standard. Automated and vacuum-assisted casting systems are minimizing defects and increasing production speed. These innovations are making acrylic embedment more accessible to small businesses and artisans while maintaining professional-grade results—fueling market growth across hobbyist and commercial segments.

Sustainability and Eco-Friendly Materials

Environmental concerns are shaping material choices across industries, and acrylic embedment is no exception. By 2026, there will be a growing shift toward bio-based resins, recyclable acrylics, and low-VOC (volatile organic compound) formulations. Consumers and businesses alike are demanding sustainable alternatives without compromising on clarity or strength. Companies that adopt eco-conscious practices in sourcing, production, and packaging are expected to gain a competitive edge in the marketplace.

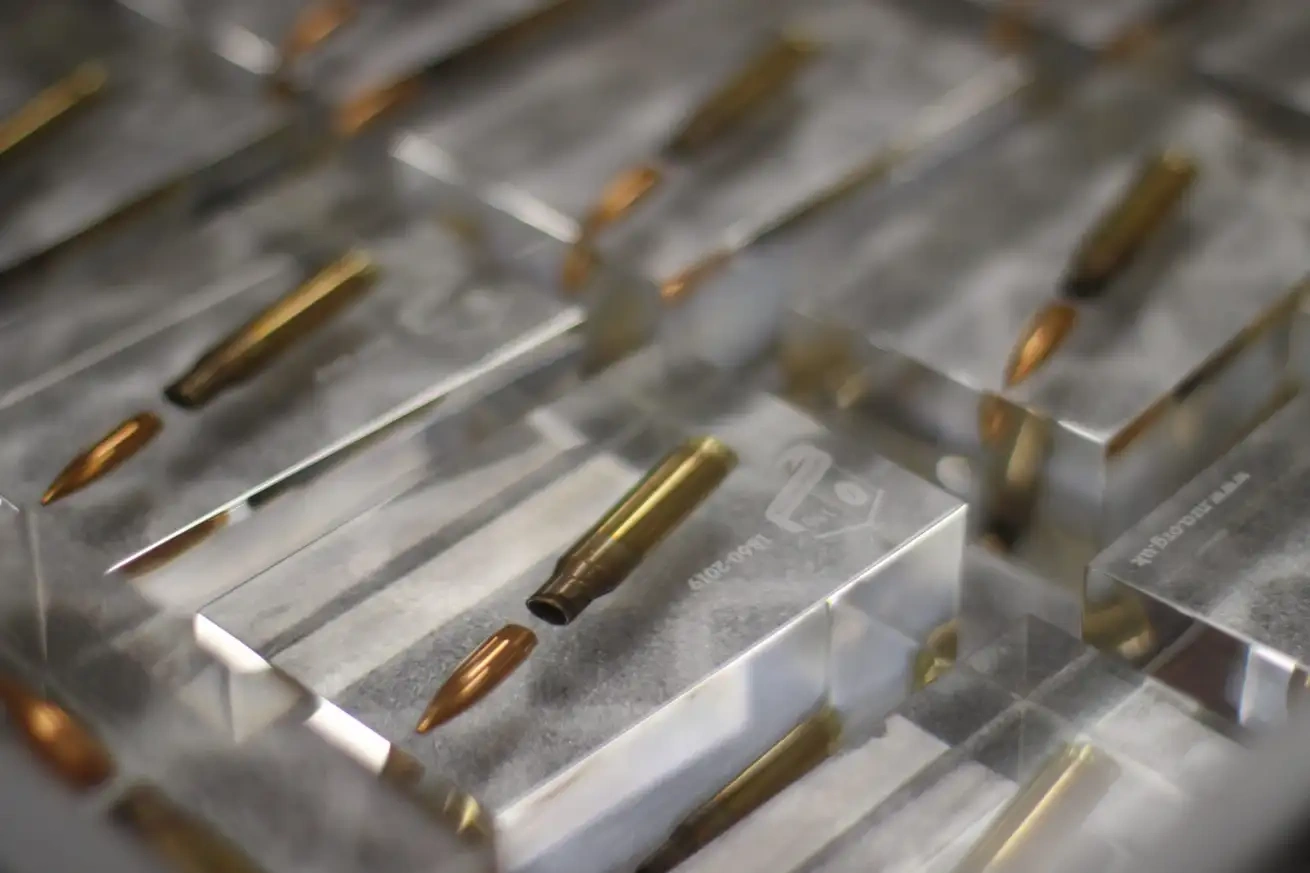

Growth in Industrial and Functional Applications

Beyond decorative uses, acrylic embedment is expanding into industrial and technical fields. It is being used to seal and protect sensitive components in electronics, sensors, and medical devices. The insulating and protective properties of acrylic make it ideal for encapsulating fragile parts in harsh environments. As industries prioritize miniaturization and durability, demand for precision embedment solutions is expected to rise significantly by 2026, particularly in automotive, aerospace, and IoT (Internet of Things) sectors.

Geographic Market Expansion

While North America and Europe currently dominate the acrylic embedment market, Asia-Pacific is projected to be the fastest-growing region by 2026. Increasing urbanization, rising disposable incomes, and a booming creative economy in countries like China, India, and South Korea are driving demand. Additionally, government support for small businesses and maker communities is fostering innovation and local production, contributing to regional market expansion.

Conclusion

By 2026, the acrylic embedment market will be shaped by a confluence of technological innovation, consumer personalization trends, sustainability demands, and expanding industrial applications. As the technique evolves from niche craft to mainstream application, businesses that invest in quality materials, scalable production, and eco-friendly practices will be best positioned to capture emerging opportunities in this vibrant and growing market.

Common Pitfalls When Sourcing Acrylic Embedment: Quality and Intellectual Property Concerns

Sourcing acrylic embedment products—often used in custom awards, decorative items, or industrial applications—can present several challenges, particularly in ensuring consistent quality and avoiding intellectual property (IP) issues. Below are key pitfalls to watch for:

1. Inconsistent Material Quality

One of the most common issues is variability in acrylic clarity, thickness, and durability. Low-grade acrylic may yellow over time, contain bubbles or imperfections, or lack the optical clarity expected in premium embedments. Sourcing from suppliers without rigorous quality control can result in batch inconsistencies that undermine product integrity.

2. Poor Embedment Precision and Alignment

Acrylic embedments require precise placement of objects (e.g., logos, electronics, or memorabilia) within the resin. Inexperienced manufacturers may misalign embedded items or introduce air pockets, leading to aesthetic flaws or structural weaknesses. This often stems from manual casting processes lacking automation or quality checks.

3. Use of Non-Optical-Grade Acrylic

Not all acrylic is created equal. Some suppliers use standard extruded acrylic, which can have internal stresses and lower transparency compared to optical-grade cast acrylic. This affects both visual appeal and long-term performance, especially under UV exposure or extreme temperatures.

4. Inadequate Curing and Processing Standards

Improper curing of the resin or acrylic can lead to cracking, cloudiness, or delamination. Suppliers may cut corners by rushing production cycles or using substandard equipment, compromising the final product’s durability and appearance.

5. Intellectual Property Infringement Risks

When embedding logos, artwork, or branded elements, sourcing partners may unknowingly—or deliberately—use IP-protected designs without proper licensing. This exposes the buyer to legal liability, especially if the embedments are used in commercial products or resale items.

6. Lack of Design Ownership and Documentation

Some suppliers retain rights to molds, digital files, or custom designs created during production. Without clear contractual agreements, buyers may lose control over their designs, limiting future manufacturing options or exposing them to IP disputes.

7. Insufficient Compliance and Certification

Depending on the application (e.g., medical, aerospace, or consumer goods), acrylic embedments may need to meet safety, environmental, or industry-specific standards (e.g., RoHS, REACH, or FDA compliance). Sourcing from non-compliant suppliers can result in failed audits or product recalls.

8. Hidden Costs and Scalability Issues

Initial quotes may appear competitive, but hidden costs related to tooling, setup, or low-volume inefficiencies can inflate expenses. Additionally, suppliers may lack the capacity to scale production, leading to delays or inconsistent quality during ramp-up.

To avoid these pitfalls, thoroughly vet suppliers, request physical samples, audit production processes, and ensure clear IP agreements are in place before finalizing any sourcing arrangement.

Logistics & Compliance Guide for Acrylic Embedment

This guide outlines the essential logistics and compliance considerations for manufacturing, handling, transporting, and selling acrylic embedment products. These items—typically decorative or commemorative pieces where objects (e.g., flowers, electronics, memorabilia) are encased in clear acrylic—must adhere to safety, environmental, and shipping regulations.

Product Classification and Regulatory Requirements

Acrylic embedment products may fall under various regulatory frameworks depending on their composition, intended use, and embedded materials. Key considerations include:

- Material Safety Data Sheets (MSDS/SDS): Maintain up-to-date SDS for all resins, hardeners, and acrylic components used in production, especially if handling uncured materials.

- Consumer Product Safety Improvement Act (CPSIA): If the product is intended for children (e.g., toys), compliance with lead content, phthalates, and testing requirements is mandatory.

- Proposition 65 (California): If selling in California, evaluate whether embedded materials or acrylic components contain chemicals listed under Prop 65 (e.g., certain plasticizers or hardeners) and provide required warnings.

- REACH and RoHS (EU): For international sales, ensure compliance with EU regulations restricting hazardous substances (e.g., heavy metals, flame retardants) and requiring chemical registration.

Environmental and Handling Compliance

Production of acrylic embedments involves chemicals and processes that require proper handling and disposal:

- Volatile Organic Compounds (VOCs): Many acrylic resins emit VOCs during curing. Ensure proper ventilation, use of respirators, and compliance with local air quality regulations (e.g., EPA, state-level air boards).

- Waste Disposal: Uncured resin, cleaning solvents, and contaminated materials are often classified as hazardous waste. Follow EPA or local waste management guidelines for disposal.

- Spill Containment: Implement spill kits and secondary containment for liquid resin storage to prevent environmental contamination.

Packaging and Shipping Logistics

Proper packaging ensures product integrity and regulatory compliance during transit:

- Fragility Protection: Acrylic is prone to scratching and cracking. Use bubble wrap, foam inserts, or custom molded packaging to prevent damage.

- Labeling Requirements:

- Clearly label packages containing uncured resin (if shipped separately) as hazardous materials under DOT/IATA regulations.

- Finished embedments are generally non-hazardous but must include safety warnings if applicable (e.g., choking hazards for small embedded items).

- International Shipping: For cross-border distribution, ensure harmonized system (HS) code accuracy (typically under 3926.30 – other articles of plastics) and prepare commercial invoices, certificates of origin, and import compliance documentation.

Import/Export Compliance

When moving acrylic embedments across borders:

- Customs Declarations: Accurately declare product value, origin, and material composition to avoid delays or penalties.

- Tariff Classifications: Confirm correct HS code classification to determine import duties. Misclassification can lead to fines or seizure.

- Restricted Materials: Verify that embedded items (e.g., organic matter, electronic components) do not violate import restrictions in destination countries (e.g., agricultural bans, e-waste regulations).

Workplace Safety and Training

Ensure compliance with OSHA (or equivalent) standards:

- Personal Protective Equipment (PPE): Require gloves, goggles, and respirators when handling resins and during cutting/polishing.

- Training Programs: Train staff on chemical handling, emergency procedures, and equipment safety (e.g., saws, polishers).

- Fire Safety: Store flammable liquids in approved cabinets and maintain fire suppression systems in production areas.

Sustainability and Disposal Information

Provide end-of-life guidance:

- Recyclability: Acrylic (PMMA) is recyclable but not universally accepted. Include disposal instructions on packaging or website.

- Eco-Labeling: If using recycled or bio-based resins, consider certifications like Cradle to Cradle or Declare labels to support marketing claims.

By adhering to these logistics and compliance protocols, manufacturers and distributors of acrylic embedment products can ensure legal operation, consumer safety, and environmental responsibility.

Conclusion for Sourcing Acrylic Embedment:

Sourcing acrylic embedments requires a careful balance of material quality, manufacturing precision, customization capabilities, and cost-efficiency. As demonstrated, selecting the right supplier involves evaluating their expertise in working with optical-grade acrylic, their capacity for custom molding or laser engraving, and their ability to maintain clarity and durability in the final product. Additionally, factors such as lead times, scalability, and compliance with environmental or safety standards play a crucial role in long-term sourcing decisions.

Ultimately, establishing a relationship with a reputable supplier who offers consistent quality, transparent communication, and technical support ensures reliable production of high-impact acrylic embedments. Whether for promotional items, industrial components, or artistic applications, strategic sourcing enhances product value and supports brand integrity. Continued evaluation and potential diversification of suppliers can further mitigate risks and support innovation in future projects.