The global market for acrylic cutting machinery has seen robust growth, driven by rising demand in industries such as signage, architecture, automotive, and consumer goods. According to Grand View Research, the global laser cutting machines market—widely used for acrylic processing—was valued at USD 3.7 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This growth is fueled by increasing adoption of precision fabrication technologies and the rising preference for automation in manufacturing processes. Mordor Intelligence also highlights that the Asia-Pacific region is emerging as a key market due to rapid industrialization and expanding small to medium enterprises (SMEs) utilizing CNC and laser cutting solutions. As demand for high-accuracy acrylic cutting machines rises, manufacturers are innovating with advanced software integration, improved beam delivery systems, and energy-efficient designs. Below are the top 9 acrylic cutter machine manufacturers leading this evolution with reliable, scalable, and technologically advanced solutions.

Top 9 Acrylic Cutter Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

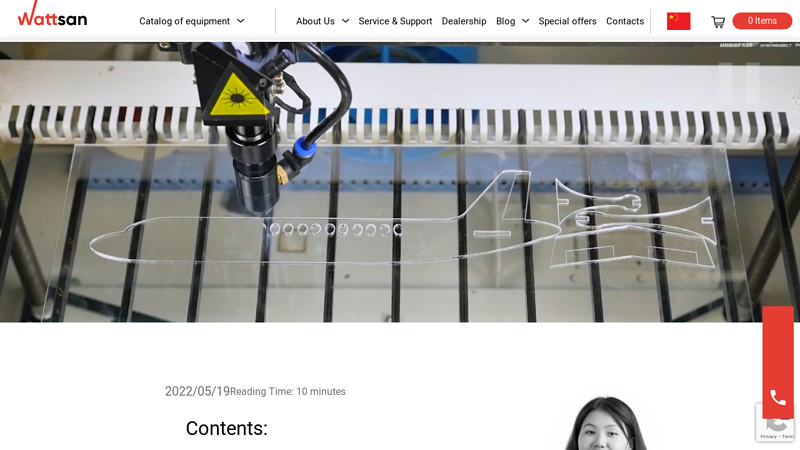

#1 Acrylic & Plexiglass Laser Cutting Engraving Machines

Domain Est. 2016

Website: wattsan.com

Key Highlights: Buy acrylic & plexiglass cutting and engraving machine directly from the manufacturer. Acrylic laser machine at low price with delivery in…

#2 Acrylic Laser Cutting and Engraving Machines

Domain Est. 1997

Website: epiloglaser.com

Key Highlights: Explore the advantages of Laser Machines for cutting and engraving acrylic to achieve high-quality results for your various projects….

#3 Acrylic cutting and engraving laser systems

Domain Est. 1998

Website: kernlasers.com

Key Highlights: Acrylic cutting and engraving laser equipment allows for a flame polish cut edge and high speed laser processing. Kern is made in the USA….

#4 Acrylic laser cutter machine

Domain Est. 2002

Website: troteclaser.com

Key Highlights: Trotec laser machines as versatile tool for acrylic processing. You can quickly and easily produce neon signs, regular signs, POS displays and more from ……

#5 PMMA, Plexiglas® and Acrylic engraving, etching and cutting

Domain Est. 2007

Website: gravotech.us

Key Highlights: PMMA, Plexiglas® and Acrylic engraving, etching and cutting. Discover our rotary and laser Acrylic engraving and cutting machines!…

#6 Laser Cutter for wood, acrylic and metal

Domain Est. 2011

Website: justlaser.com

Key Highlights: The Industry leading Laser Cutter for laser cutting and engraving large surfaces of wood, stone, metal, acrylic, plastic, and many more….

#7 Laser Cutting Machine

Domain Est. 2015

Website: varisigns.com

Key Highlights: Varisigns CNC laser cutting machine, acrylic laser cutters for sale are best for metal and nonmetal cutting in high speed and accuracy. Get a free quote!…

#8 Acrylic

Domain Est. 2018

Website: thunderlaserusa.com

Key Highlights: Acrylic has become a favored material among laser engraving cutting machine experts, from signage to point-of-sale displays, illuminated advertisements,…

#9 Laser Cutter for Acrylic

Domain Est. 2024

Expert Sourcing Insights for Acrylic Cutter Machine

2026 Market Trends for Acrylic Cutter Machines

The acrylic cutter machine market is poised for significant transformation by 2026, driven by technological advancements, shifting industry demands, and evolving user expectations. Key trends shaping the landscape include:

Increased Adoption of Automation and Smart Features

By 2026, automation will be a cornerstone of acrylic cutter machines. Integration with AI-driven software for automated material detection, real-time cutting optimization, and predictive maintenance will streamline operations. Machines with IoT connectivity will enable remote monitoring, performance analytics, and over-the-air updates, enhancing productivity for manufacturers and hobbyists alike.

Rise of Compact, Desktop Models for Small Businesses and Makers

The growing maker movement and demand for on-demand customization will fuel the popularity of affordable, precision desktop acrylic cutters. These compact machines, often laser-based, will offer professional-grade cutting capabilities for signage, prototyping, and art, making advanced fabrication accessible to small businesses, educational institutions, and DIY enthusiasts.

Sustainability and Energy Efficiency as Key Differentiators

Environmental concerns will drive innovation in energy-efficient motors, low-emission cutting technologies, and recyclable machine components. Manufacturers will emphasize eco-friendly designs and compliance with green manufacturing standards, appealing to environmentally conscious buyers and corporate sustainability goals.

Expansion in Industrial Applications

Beyond traditional uses in signage and displays, acrylic cutter machines will see increased deployment in automotive interiors, medical device manufacturing, and architectural models. High-precision CNC and laser systems will meet the demand for complex, repeatable cuts in specialized acrylic composites and multi-layer materials.

Integration with Digital Workflows and Cloud-Based Design Platforms

Seamless integration with CAD/CAM software and cloud-based design ecosystems will become standard. This allows users to directly import designs, simulate cuts, and manage production queues across multiple machines, reducing errors and accelerating turnaround times—especially vital for mass customization trends.

Growing Demand in Emerging Markets

Developing regions in Asia-Pacific, Latin America, and Africa will experience rising demand due to expanding manufacturing sectors, urbanization, and investment in infrastructure. Localized support, affordable models, and multilingual software will be critical for market penetration.

In summary, the 2026 acrylic cutter machine market will be defined by smarter, more connected, and sustainable solutions catering to both industrial scalability and personal fabrication needs. Companies that prioritize innovation, user accessibility, and environmental responsibility will lead the competitive landscape.

Common Pitfalls When Sourcing an Acrylic Cutter Machine (Quality, IP)

Sourcing an acrylic cutter machine—especially one involving laser or CNC technology—can be complex. Buyers often face challenges related to machine quality and intellectual property (IP) risks. Being aware of these pitfalls helps ensure a reliable, legal, and long-term viable investment.

Poor Build Quality and Component Selection

Many suppliers, particularly low-cost manufacturers, use substandard materials and components to cut costs. This includes weak frame construction, low-grade stepper motors, or inferior optics in laser cutters. Machines built with poor quality control often suffer from misalignment, inconsistent cutting, and shorter lifespans, leading to increased downtime and maintenance costs.

Inaccurate or Overstated Machine Specifications

Suppliers may exaggerate cutting speed, precision, or power output. For example, a machine advertised as capable of cutting 20mm acrylic might only manage 10mm effectively. These discrepancies become evident only after purchase, resulting in unmet production needs and potential project delays.

Lack of Compliance with Safety and Regulatory Standards

Acrylic cutting machines—especially laser cutters—must comply with electrical, laser safety (e.g., FDA/CDRH in the U.S., CE in Europe), and emissions standards. Some imported machines lack proper certifications or use counterfeit compliance labels, posing safety hazards and risking customs seizure or legal penalties.

Inadequate After-Sales Support and Spare Parts Availability

Many overseas suppliers offer limited technical support, slow response times, and no local service centers. When machines break down, the lack of available spare parts or firmware updates can halt production for weeks, especially if the supplier disappears or refuses support after the sale.

Intellectual Property (IP) Infringement Risks

Purchasing machines that replicate patented designs or incorporate unauthorized software (e.g., pirated control systems like Ruida or LightBurn) exposes buyers to legal liability. Even unintentional use of IP-infringing equipment can result in lawsuits, fines, or forced equipment seizure, particularly in markets with strict IP enforcement.

Hidden Costs and Lack of Transparency

Initial quotes may exclude essential accessories (air assist, exhaust systems, rotary attachments), software licenses, shipping fees, or import duties. Buyers often face unexpected costs upon delivery, inflating the total investment well beyond the advertised price.

Counterfeit or Rebranded Machines

Some suppliers rebrand low-quality machines as premium brands or use fake branding to mislead buyers. These machines may lack proper documentation, firmware support, or compatibility with industry-standard software, reducing reliability and resale value.

Insufficient Testing and Validation Before Shipment

Machines shipped without comprehensive testing may arrive with calibration issues, faulty wiring, or missing components. Without pre-shipment inspection or video validation, buyers bear the risk of receiving non-functional or unsafe equipment.

Dependence on Proprietary Software with No IP Clearance

Some machines come with closed-source control software that may violate third-party IP rights. If the software is later deemed illegal, users may lose access to critical updates or face enforcement actions, jeopardizing ongoing operations.

Failure to Verify Supplier Authenticity

Scammers or intermediaries may pose as original equipment manufacturers (OEMs) with fake websites and customer testimonials. Conducting due diligence—such as verifying business licenses, visiting factories, or obtaining third-party audits—is essential to avoid fraud and ensure sourcing legitimacy.

Logistics & Compliance Guide for Acrylic Cutter Machine

Product Classification and HS Code

Identify the correct Harmonized System (HS) code for the acrylic cutter machine to ensure accurate customs declaration. Typical classifications may fall under HS 8465.95 (Machines for working wood, cork, bone, hard rubber, hard plastics, or similar hard materials) or a more specific subcategory based on the machine’s function (e.g., laser cutting, CNC routing). Confirm with local customs authorities or a customs broker to avoid misclassification and potential delays.

Export Documentation Requirements

Prepare essential export documents, including:

– Commercial Invoice (detailing product description, value, quantity, and Incoterms)

– Packing List (itemizing contents, dimensions, and weight per package)

– Bill of Lading or Air Waybill (based on transport mode)

– Certificate of Origin (if required by the destination country)

– Technical Specifications Sheet (to support customs valuation and compliance checks)

Safety and Electrical Compliance

Ensure the machine complies with electrical safety standards of the destination country, such as:

– CE Marking (for EU markets under Machinery Directive 2006/42/EC and Low Voltage Directive 2014/35/EU)

– UL/CSA Certification (for North American markets)

– EAC Certification (for Eurasian Economic Union countries)

Include user manuals in the local language and provide safety warnings, emergency stop instructions, and proper grounding details.

Laser Safety Regulations (If Applicable)

For laser-based acrylic cutters:

– Comply with IEC 60825-1 for laser product safety classification.

– Provide FDA compliance documentation (CDRH report) for exports to the United States.

– Include protective enclosures, interlocks, and appropriate laser warning labels.

– Supply required protective eyewear and training materials.

Packaging and Shipping Standards

Use robust, export-grade packaging to protect the machine during transit:

– Wooden crates or reinforced cardboard with internal bracing

– Anti-static and moisture protection for electronic components

– Clearly labeled orientation and handling symbols (e.g., “This Side Up,” “Fragile”)

– Secured loose parts and accessories with inventory checklist

Import Duties and Taxes

Research import duties, VAT, and any additional taxes in the destination country. Some regions may impose additional environmental or recycling fees on electronic equipment. Utilize free trade agreements where applicable to reduce tariffs.

Restricted Materials and Environmental Compliance

Verify that the machine does not contain restricted substances under regulations such as:

– RoHS (Restriction of Hazardous Substances) for EU and other compliant regions

– REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals)

Ensure compliance with WEEE (Waste Electrical and Electronic Equipment) directives if applicable.

Transportation Mode and Carrier Selection

Choose the appropriate transportation method based on urgency, cost, and machine size:

– Air freight: Faster but more expensive; suitable for smaller units

– Sea freight: Cost-effective for large or heavy machines; requires proper containerization

Select carriers experienced in handling industrial machinery and sensitive electronics.

Customs Clearance and Local Representation

Appoint a reliable customs broker or freight forwarder in the destination country to manage import clearance. Provide all necessary documentation in advance to avoid port delays. Confirm any import licenses or permits required for industrial equipment.

Installation, Training, and After-Sales Support

Include in your logistics planning:

– On-site installation and calibration services (if offered)

– Remote or on-site operator training

– Warranty documentation and service contact details

– Availability of spare parts and technical support in the destination region

Adhering to this guide ensures smooth international logistics and regulatory compliance for the acrylic cutter machine, minimizing risks and enhancing customer satisfaction.

Conclusion for Sourcing an Acrylic Cutter Machine:

After thorough evaluation of available options, sourcing an acrylic cutter machine is a strategic investment that significantly enhances precision, efficiency, and productivity in cutting acrylic and similar materials. Whether opting for a laser cutter, CNC router, or specialized acrylic cutting machine, the decision should be based on application requirements, material thickness, production volume, and budget constraints.

Laser cutters offer excellent precision and clean edges, ideal for intricate designs, while CNC routers are better suited for thicker acrylic sheets and heavy-duty applications. Additionally, key considerations such as machine durability, ease of operation, safety features, after-sales support, and software compatibility must not be overlooked.

Sourcing from reputable suppliers—either domestic or international—ensures reliability, warranty coverage, and technical assistance. Investing in the right acrylic cutting machine not only improves product quality but also reduces material waste and long-term operational costs. Ultimately, the selected machine should align with current needs while allowing room for future scalability, ensuring a strong return on investment and sustained operational growth.