The global demand for noise control solutions in HVAC systems has driven significant growth in the acoustic lining for ductwork market. According to Grand View Research, the global HVAC noise control market was valued at USD 2.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030, fueled by increasing construction activities and stringent noise regulation standards in commercial and industrial buildings. Similarly, Mordor Intelligence projects steady market expansion, attributing growth to rising urbanization and the growing emphasis on indoor environmental quality. As energy-efficient and quieter HVAC systems become a priority, acoustic lining plays a critical role in reducing sound transmission and improving occupant comfort. With innovation in materials—such as fiberglass, mineral wool, and eco-friendly composites—manufacturers are enhancing performance while meeting fire safety and sustainability standards. In this evolving landscape, identifying leading acoustic lining manufacturers is essential for engineers, contractors, and specifiers aiming to balance acoustic performance, durability, and regulatory compliance.

Top 9 Acoustic Lining For Ductwork Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Sound Seal

Domain Est. 1996 | Founded: 1978

Website: soundseal.com

Key Highlights: Sound Seal is a leading manufacturer of industrial & architectural acoustic sound control products. Controlling noise in every environment since 1978….

#2 OEM Acoustic Insulation Solutions

Domain Est. 1998

Website: insulfab.net

Key Highlights: Insul-Fab offers a one-stop shop for industrial noise control products. To learn more about our OEM acoustic insulation solutions, contact us today!…

#3 Kinetics Noise Control

Domain Est. 1996

Website: kineticsnoise.com

Key Highlights: Kinetics NOISEBLOCK PW275 is a lightweight noise barrier wall, panel system engineered for acoustic and structural performance. Manufactured with durable, ……

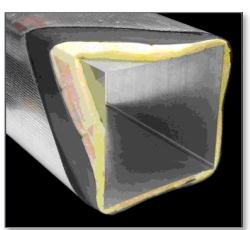

#4 QuietR Spiral Duct Liner

Domain Est. 1996

Website: owenscorning.com

Key Highlights: Owens Corning QuietR Spiral Duct Liner fits your specific duct size, compression at grooves and joints is kept to a minimum, providing consistent thermal ……

#5 K

Domain Est. 1996

Website: kflex.com

Key Highlights: K-FLEX DUCT LINER is an NBR/PVC-based closed cell, flexible elastomeric foam thermal and acoustic insulation. It is environmentally friendly….

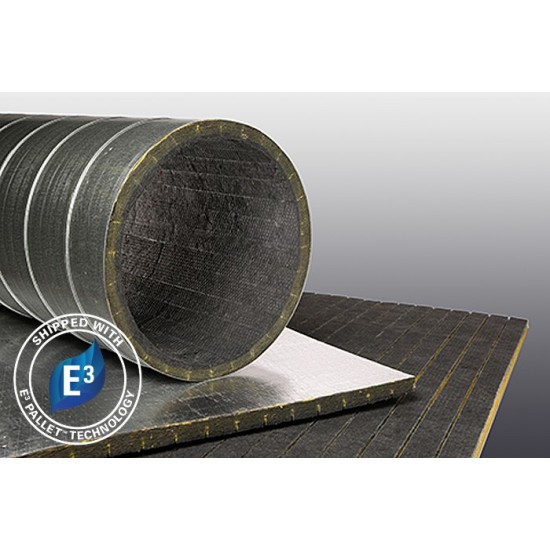

#6 Linacoustic RC

Domain Est. 1997

Website: jm.com

Key Highlights: Johns Manville Linacoustic RC duct liner provides superior thermal and acoustical performance and improved handling during fabrication when lining metal ducts….

#7 Acoustic Duct Liners for HVAC System Insulation

Domain Est. 1998

Website: acousticalsurfaces.com

Key Highlights: Quiet Liner™ HVAC acoustic insulation reduces heat loss and gain while providing excellent noise absorption. Purchase this acoustic duct liner here….

#8 Akousti-Liner™

Domain Est. 2008

Website: imanson.com

Key Highlights: This flexible duct liner provides both thermal and acoustical insulation, and is made from inorganic glass fibers bonded by a thermosetting binder….

#9 Duct Liner Insulation

Domain Est. 2019

Website: knaufnorthamerica.com

Key Highlights: Looking for duct liner insulation solutions? Try Knauf Insulation duct liner. It delivers both thermal efficiency and sound control at an efficient cost….

Expert Sourcing Insights for Acoustic Lining For Ductwork

H2: 2026 Market Trends for Acoustic Lining for Ductwork

The global market for acoustic lining for ductwork is poised for significant evolution by 2026, driven by growing emphasis on noise control, energy efficiency, and sustainable building practices. Several key trends are expected to shape the industry landscape during this period:

-

Increased Demand in Commercial and Residential Construction

With urbanization accelerating and building codes becoming stricter—especially in regions like North America and Europe—the demand for effective noise mitigation solutions is rising. Acoustic lining in HVAC ductwork is increasingly integrated into commercial buildings, hospitals, educational institutions, and high-end residential complexes to meet stringent acoustic comfort standards. This trend is expected to continue growing through 2026. -

Stringent Regulatory Standards and Green Building Certifications

Regulations such as ISO 16272-1 (acoustic performance of duct liners) and green building certifications like LEED, BREEAM, and WELL are pushing architects and contractors to adopt high-performance acoustic materials. By 2026, compliance with these standards will be a key purchasing driver, favoring advanced acoustic linings that offer both sound absorption and thermal insulation. -

Shift Toward Sustainable and Non-Fibrous Materials

Environmental and health concerns over traditional fiberglass-based acoustic linings are driving innovation. Manufacturers are increasingly exploring bio-based, recyclable, and non-fibrous alternatives such as recycled polyester, wood fiber, and mineral wool with low emissions. By 2026, eco-friendly acoustic linings are expected to capture a larger market share, particularly in environmentally conscious regions like Western Europe. -

Growth in Retrofit and Renovation Projects

Aging infrastructure in developed economies is fueling demand for retrofit HVAC systems. Acoustic lining upgrades are a cost-effective way to improve indoor environmental quality without full system replacement. The retrofit segment is expected to grow steadily through 2026, especially in public and institutional buildings. -

Technological Advancements and Smart HVAC Integration

Innovations such as nano-coated linings, multi-layer composites, and acoustically optimized geometries are enhancing performance while reducing thickness and weight. Additionally, integration with smart HVAC systems that monitor noise levels in real time may create new opportunities for adaptive acoustic solutions by 2026. -

Regional Market Expansion in Asia-Pacific and Middle East

Rapid urbanization, industrialization, and infrastructure development in countries like China, India, and the UAE are boosting HVAC demand. As building standards evolve in these regions, acoustic lining for ductwork will see increased adoption. The Asia-Pacific region is projected to be one of the fastest-growing markets by 2026. -

Supply Chain Resilience and Localization

Post-pandemic supply chain disruptions have prompted manufacturers to localize production. By 2026, regional manufacturing hubs are expected to emerge, reducing dependency on global logistics and improving response time to market demands—particularly for custom acoustic solutions.

In conclusion, the acoustic lining for ductwork market in 2026 will be shaped by regulatory pressures, sustainability imperatives, technological innovation, and expanding construction activity—especially in emerging economies. Companies that prioritize eco-friendly materials, performance efficiency, and compliance with global standards will be best positioned to lead the market.

Common Pitfalls When Sourcing Acoustic Lining for Ductwork (Quality & Intellectual Property)

Sourcing acoustic lining for ductwork involves more than just comparing price and thickness—overlooking key quality and intellectual property (IP) aspects can lead to performance failures, compliance issues, and legal risks. Here are common pitfalls to avoid:

Inadequate Material Quality and Performance Verification

Many suppliers provide generic or exaggerated performance claims without certified test data. Buyers often assume all fiberglass or composite linings offer similar sound attenuation, but actual performance varies significantly based on density, fiber composition, facing materials, and installation methods. Relying solely on manufacturer brochures without third-party acoustic testing reports (e.g., ASTM C423, ISO 354) can result in underperforming systems, leading to noise control failures in sensitive environments like hospitals or offices.

Poor Fire and Safety Compliance

Acoustic linings must meet strict fire safety standards (e.g., ASTM E84, UL 181, EN 13501-1). A common pitfall is sourcing materials that claim compliance but lack valid certification for the target region or application. Using non-compliant lining can compromise building safety, fail inspections, and void insurance. Always verify test reports match the exact product being supplied and confirm compliance with local building codes and HVAC regulations.

Substandard Erosion and Abrasion Resistance

In high-velocity duct systems, low-quality linings can degrade over time, shedding fibers into the airstream. This not only reduces acoustic performance but also poses indoor air quality (IAQ) and health risks. Buyers may overlook erosion resistance specifications (e.g., ASTM C1071), leading to premature failure. Ensure the lining includes a durable, UL-listed facing (e.g., foil-scrim-kraft or perforated metal) appropriate for the airflow conditions.

Misrepresentation of Intellectual Property and Brand Authenticity

Counterfeit or imitation products are prevalent in the HVAC insulation market. Some suppliers falsely claim their lining is “equivalent to” or “compatible with” branded products (e.g., Owens Corning QuietZone, Knauf Ecose), infringing on trademarks or patented technologies. Using such products may void equipment warranties and expose the specifier or contractor to IP litigation. Always source from authorized distributors and request proof of authenticity and licensing.

Lack of Traceability and Documentation

Reputable acoustic lining products come with batch-specific documentation, including material safety data sheets (MSDS), test reports, and compliance certificates. A frequent oversight is accepting products without full traceability, making it difficult to address quality issues or prove compliance during audits. Ensure suppliers provide complete documentation tied to the delivered goods.

Overlooking Environmental and Sustainability Claims

Many modern projects require sustainable materials (e.g., low-VOC, recyclable, formaldehyde-free). Some suppliers make unsubstantiated green claims (“eco-friendly” or “green certified”) without third-party validation (e.g., Declare Label, Cradle to Cradle). This can mislead project teams aiming for LEED or BREEAM certification. Verify environmental claims with legitimate certifications and avoid vague marketing language.

Failure to Match System Design Requirements

Acoustic lining performance depends on correct application—thickness, placement (partial vs. full lining), and duct geometry. Sourcing based on cost alone without consulting an acoustical engineer can lead to mismatched solutions. For example, using thin lining in a low-frequency noise environment will be ineffective. Always align product specifications with the acoustic design intent and project noise criteria (NC or RC values).

Logistics & Compliance Guide for Acoustic Lining for Ductwork

This guide provides essential information on the logistics handling and regulatory compliance considerations for acoustic lining used in HVAC ductwork systems. Proper management ensures safety, performance, and adherence to industry standards.

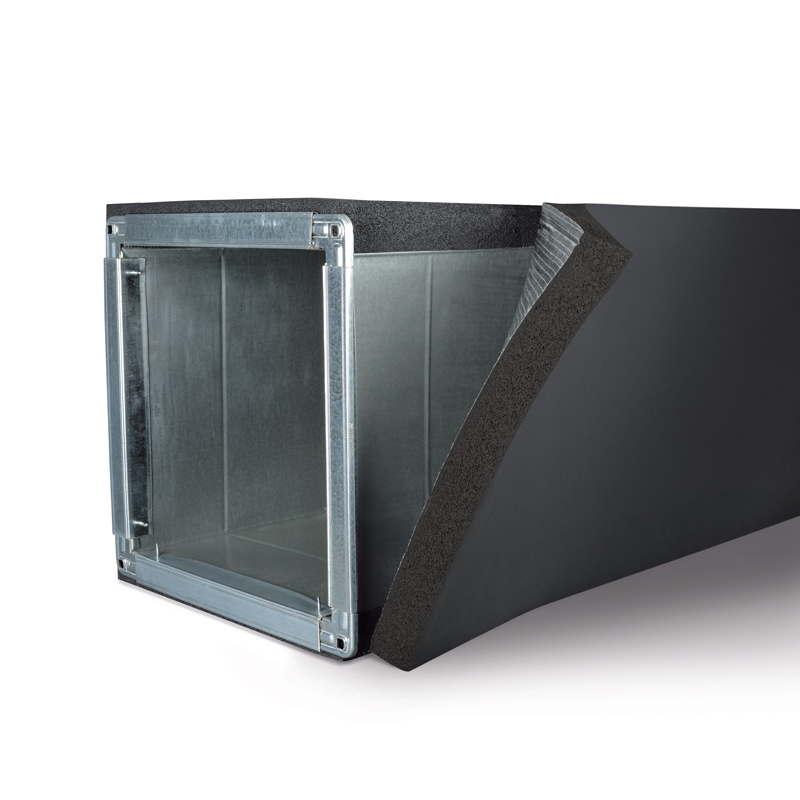

Product Overview and Handling

Acoustic lining for ductwork typically consists of fibrous materials (such as mineral wool or fiberglass) bonded to a perforated facing (e.g., foil, scrim, or fabric) designed to reduce noise transmission in ventilation systems. Due to its composition, careful handling and storage are required to maintain performance and worker safety.

- Packaging: Acoustic lining is commonly supplied in rolls, panels, or pre-formed duct liners, packaged in polyethylene wrap or cardboard cartons to protect against moisture and physical damage.

- Handling Precautions: Use gloves and long sleeves to minimize skin irritation from fiberglass or mineral wool fibers. Avoid excessive bending or crushing to prevent delamination or performance degradation.

- Storage Conditions: Store in a dry, indoor environment with controlled temperature and humidity. Keep off the ground on pallets and away from direct sunlight to prevent moisture absorption and material degradation.

Transportation Requirements

Proper transportation ensures that acoustic lining arrives at the jobsite undamaged and ready for installation.

- Loading & Securing: Roll or panelized lining must be secured vertically or flat on transport vehicles to prevent unrolling or edge damage. Use edge protectors and avoid stacking excessive weight on top.

- Moisture Protection: Cover loads with waterproof tarps during transit, especially in wet or humid conditions. Condensation inside containers or trailers can compromise fire and acoustic performance.

- Temperature Considerations: Avoid prolonged exposure to extreme temperatures during transport, which may affect adhesive bonds or facing materials.

Regulatory Compliance

Compliance with local, national, and international standards is critical for fire safety, indoor air quality, and environmental performance.

Fire Safety Standards

- UL 181 Class 0 / Class 1: In North America, duct liner must meet UL 181 standards for flame spread and smoke development. Class 0 indicates a flame spread index ≤25 and smoke-developed index ≤50; Class 1 allows up to 25/50.

- BS 476 Part 6 & 7 (UK): Certifies fire propagation and surface spread of flame. Compliance is required for public and commercial buildings.

- EN 13501-1 (Europe): Classifies reaction to fire; acoustic linings typically need at least Class B-s1,d0 for non-combustibility and low smoke production.

Indoor Air Quality (IAQ) and Emissions

- GREENGUARD / UL 2818: Ensures low chemical emissions for indoor environments. Products labeled GREENGUARD Gold comply with stringent VOC limits suitable for schools and healthcare facilities.

- REACH & RoHS (EU): Confirm absence of restricted hazardous substances (e.g., certain flame retardants or heavy metals).

- CRI Indoor Air Quality Testing (U.S.): May be required for carpet and insulation products in LEED-certified buildings.

Environmental and Sustainability Standards

- Environmental Product Declarations (EPD): Provide transparent lifecycle impact data (e.g., carbon footprint, resource use).

- Recycled Content: Many acoustic liners contain post-industrial recycled glass or slag. Verify percentages for sustainability reporting.

- End-of-Life Disposal: Fiberglass and mineral wool are non-hazardous but not biodegradable. Follow local waste regulations—landfilling is common, though some regions support recycling programs for mineral wool.

Installation and Job-Site Compliance

- OSHA / COSHH Compliance: Workers must use appropriate PPE (N95 masks, goggles, gloves) when cutting or handling uncured or exposed lining to prevent inhalation of fibers.

- Sealing and Adhesion: Use UL-listed adhesives or mechanical fasteners per manufacturer guidelines. Improper installation can lead to liner detachment, noise issues, or fire hazards.

- Inspection and Certification: Final ductwork installations may require third-party inspection to verify compliance with SMACNA (Sheet Metal and Air Conditioning Contractors’ National Association) standards.

Documentation and Traceability

Maintain the following documentation for compliance audits and project certification:

- Material Safety Data Sheets (MSDS/SDS)

- Product test reports (fire, emissions, acoustic performance)

- Certifications (UL, FM, CE, BBA, etc.)

- Batch/lot numbers for traceability

- Installation manuals and warranty information

Conclusion

Effective logistics and compliance management of acoustic duct lining ensures product integrity, regulatory adherence, and long-term system performance. Always consult manufacturer specifications and local building codes before procurement and installation.

In conclusion, sourcing acoustic lining for ductwork requires a careful balance between acoustic performance, thermal insulation, fire safety, durability, and compliance with industry standards. Selecting the right material—such as fiberglass, mineral wool, or composite linings—depends on the specific requirements of the HVAC system and the environment in which it operates. Factors including sound attenuation needs, airflow resistance, hygiene, and ease of installation must be thoroughly evaluated. Engaging with reputable suppliers who provide certified, tested products ensures long-term efficiency and regulatory compliance. Ultimately, a well-informed sourcing decision contributes significantly to occupant comfort, noise control, and the overall performance of the building’s mechanical systems.