The global threaded fasteners market, which includes specialized products such as Acme threaded components, is experiencing steady growth driven by rising demand in industrial machinery, automation, and precision engineering sectors. According to a 2023 report by Mordor Intelligence, the global threaded fasteners market is projected to grow at a CAGR of approximately 5.8% from 2023 to 2028. Acme threads, known for their trapezoidal profile and superior load-carrying capacity, are increasingly favored in power transmission applications such as lead screws, linear actuators, and valve systems. With industries like aerospace, automotive, and manufacturing investing in high-efficiency mechanical components, the demand for precision-engineered Acme threaded parts continues to rise. This growth is further supported by advancements in CNC machining and tighter industry tolerances, reinforcing the importance of reliable, high-quality manufacturers. Based on production capabilities, global reach, engineering expertise, and adherence to ISO and ASME standards, the following eight companies have emerged as leading Acme threaded manufacturers shaping the future of motion control and mechanical systems.

Top 8 Acme Threaded Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Acme Industrial Co.

Website: acmeindustrial.com

Key Highlights: Acme Industrial Company is a leading manufacturer of precision machined components for industrial, commercial, aerospace and military markets….

#2 Dependable Acme Threaded Products

Domain Est. 2000

Website: dependableacme.com

Key Highlights: We are the manufacturers of ACME threaded screws, ACME rods and nuts. We have been manufacturing these items for over 65 years….

#3 Acme Thread

Domain Est. 1989

Website: forums.autodesk.com

Key Highlights: Acme Thread. Would be nice to have Acme threading into the hole feature menu….

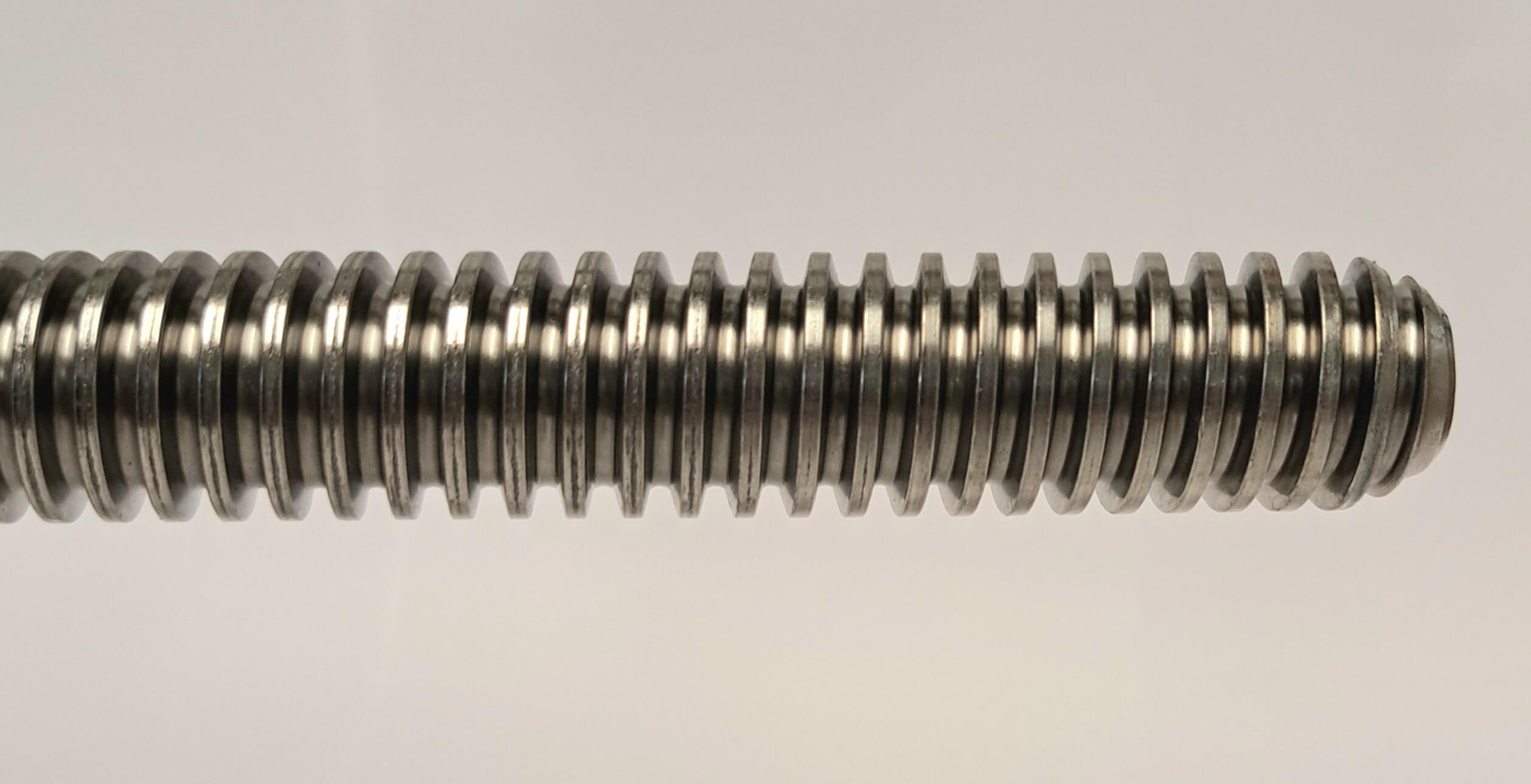

#4 ACME Threaded Rod

Domain Est. 1996

Website: nutty.com

Key Highlights: Free delivery over $100 30-day returnsAcme threaded rods excel in applications requiring controlled linear motion and force transmission. They’re commonly used in machinery like la…

#5 Acme Threaded Bars

Domain Est. 1997

Website: keystonethreaded.com

Key Highlights: Our Acme Threaded Bars are roll threaded, producing uniform, smooth, precise threads of superior physical quality, and manufactured to your specifications….

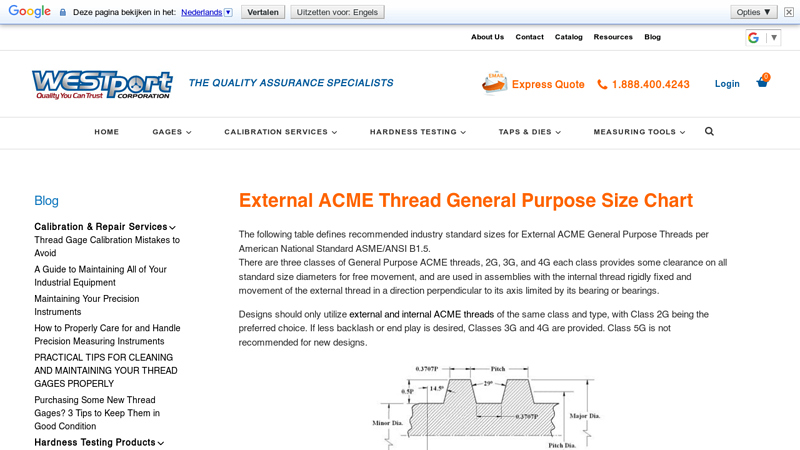

#6 External ACME Thread General Purpose Size Chart

Domain Est. 1997

Website: westportcorp.com

Key Highlights: There are three classes of General Purpose ACME threads, 2G, 3G, and 4G each class provides some clearance on all standard size diameters for free movement, ……

#7 ACME Thread Callout

Domain Est. 1998

Website: cr4.globalspec.com

Key Highlights: I need help with an ACME thread callout on a drawing. We are purchasing two locknuts for a bearing application and the vendor lists the ……

#8 Threaded Rod

Domain Est. 2005

Website: acmemfgco.com

Key Highlights: All America Threaded Products offers a huge selection of custom steel threaded products, threaded rod, studs, anchor bolts, u bolts, and fasteners….

Expert Sourcing Insights for Acme Threaded

H2: 2026 Market Trends Forecast for Acme Threaded

As we approach 2026, the industrial manufacturing sector is undergoing transformative shifts driven by technological innovation, sustainability mandates, and evolving supply chain dynamics. For Acme Threaded—a key player in threaded fasteners and precision components—the following market trends are expected to shape strategy, competitiveness, and growth opportunities:

-

Increased Demand in Renewable Energy and EV Infrastructure

The global push toward decarbonization is accelerating investment in wind, solar, and electric vehicle (EV) manufacturing. Acme Threaded is well-positioned to benefit from rising demand for high-strength, corrosion-resistant threaded components used in wind turbine assemblies, EV battery housings, and charging station infrastructure. By 2026, renewable energy projects are projected to account for over 35% of new fastener demand in North America and Europe, presenting a major growth vector. -

Adoption of Smart Manufacturing and Industry 4.0

Acme Threaded is expected to integrate more advanced automation, IoT-enabled monitoring, and predictive maintenance systems into its production lines. By leveraging real-time data analytics and digital twins, the company can improve precision, reduce waste, and enhance customization capabilities—critical factors as customers demand shorter lead times and higher traceability in mission-critical applications. -

Reshoring and Supply Chain Localization

Geopolitical instability and trade disruptions continue to drive a strategic shift toward nearshoring and domestic production, particularly in the U.S. and EU. By 2026, over 60% of industrial buyers are expected to prioritize suppliers with localized manufacturing and inventory. Acme Threaded can capitalize on this trend by expanding regional production facilities, reducing logistics risks, and offering faster turnaround. -

Sustainability and Regulatory Compliance

Environmental regulations such as the EU Green Deal and U.S. Buy Clean Initiative are imposing stricter standards on carbon emissions and material sourcing. Acme Threaded will need to invest in low-carbon production methods, recycled material usage, and lifecycle assessments to meet compliance and customer ESG expectations. By 2026, sustainable sourcing could become a key differentiator in winning government and OEM contracts. -

Customization and High-Performance Materials

Demand for specialized threaded solutions—such as those made from titanium, high-grade stainless steel, or composite alloys—is growing in aerospace, defense, and medical sectors. Acme Threaded’s ability to offer engineered-to-order components with tight tolerances and certifications (e.g., AS9100, ISO 13485) will be critical in capturing premium-margin markets. -

Consolidation and Competitive Pressure

The fastener industry is experiencing consolidation, with larger players acquiring niche manufacturers to broaden capabilities. Acme Threaded may face intensified competition from both global conglomerates and agile regional suppliers. Strategic partnerships, digital marketing, and customer-centric innovation will be essential to maintain market share.

In summary, the 2026 landscape for Acme Threaded is defined by technological integration, sustainability imperatives, and shifting customer expectations. To thrive, the company should focus on innovation in materials and processes, strengthen regional supply chains, and align with high-growth sectors such as clean energy and advanced transportation.

Common Pitfalls Sourcing Acme Threaded Components (Quality and Intellectual Property)

Sourcing Acme threaded components—such as lead screws, nuts, and rod ends—can present several challenges, particularly concerning product quality and intellectual property (IP) protection. Being aware of these pitfalls helps ensure reliable performance and legal compliance in your applications.

Poor Quality Control and Dimensional Inaccuracy

One of the most frequent issues when sourcing Acme threaded parts, especially from low-cost or non-specialist suppliers, is inconsistent quality. Poor machining practices can lead to:

- Incorrect thread pitch or minor/major diameters, resulting in binding or excessive backlash

- Lack of thread form accuracy, reducing load capacity and increasing wear

- Inadequate surface finish, accelerating friction and galling

- Improper heat treatment, leading to premature failure under load

These inconsistencies compromise the performance and lifespan of linear motion systems, and may lead to costly downtime or redesign.

Misrepresentation of Material and Specifications

Suppliers may falsely claim materials (e.g., saying “alloy steel” when it’s mild steel) or omit critical details like thread class (e.g., 2G vs. 3G fit) and lead accuracy. This misrepresentation can result in components that fail under expected loads or don’t meet regulatory or industry standards (e.g., ASTM, ASME, or ISO).

Always verify material certifications and request test reports or samples before bulk purchasing.

Infringement of Intellectual Property (IP)

Acme thread forms themselves are generally considered public domain, but specific designs, proprietary coatings, or patented assembly methods (e.g., anti-backlash nut mechanisms) may be protected by IP rights. Sourcing from unauthorized manufacturers can lead to:

- Patent infringement if the component incorporates a patented design (e.g., a self-lubricating nut system)

- Trademark violations when counterfeit parts carry branded logos (e.g., “Acme” used deceptively)

- Legal liability for both the supplier and end user in regulated industries

Always vet suppliers for IP compliance and avoid “copycat” components that mimic proprietary solutions.

Lack of Traceability and Documentation

Many budget suppliers provide no lot traceability, material certifications, or quality inspection reports. This becomes a critical issue in regulated industries (aerospace, medical, defense), where compliance audits and component traceability are mandatory.

Ensure your supplier provides full documentation, including certifications (e.g., RoHS, REACH, ISO 9001), and maintains a documented quality management system.

Counterfeit or Gray Market Components

Third-party sellers may offer “original equipment” Acme components at suspiciously low prices, but these could be counterfeit, used, or diverted from legitimate supply chains. These parts often lack performance guarantees and expose buyers to reliability and legal risks.

Purchase from authorized distributors or directly from OEMs when possible.

Inadequate Technical Support and Application Guidance

Low-cost suppliers may lack engineering support, making it difficult to confirm compatibility, load ratings, or lubrication requirements. This can lead to improper selection and premature failure in service.

Choose suppliers who offer technical datasheets, application engineering, and support for integration.

By recognizing these pitfalls—poor quality control, misrepresentation, IP risks, lack of documentation, counterfeits, and insufficient support—buyers can make informed decisions and mitigate risk when sourcing Acme threaded components.

Logistics & Compliance Guide for Acme Threaded

This guide outlines the essential logistics and compliance protocols for Acme Threaded to ensure efficient operations, regulatory adherence, and customer satisfaction.

Order Processing and Fulfillment

All customer orders must be entered into the centralized ERP system within one business hour of receipt. Each order undergoes an automated compliance check for export controls, restricted parties, and material certifications. Orders involving international shipping require validation by the Compliance Officer before fulfillment. Pick, pack, and ship procedures follow documented workflows to ensure accuracy. Shipping documentation, including packing lists and commercial invoices, must be generated and verified prior to dispatch.

Inventory Management

Maintain real-time inventory tracking using barcode scanning across all warehouse locations. Conduct monthly cycle counts and annual physical inventories to reconcile stock levels. Store materials according to specifications—segregated by material grade, thread type, and certification status. Hazardous materials, if applicable, must be stored in designated areas with proper labeling and safety data sheets (SDS) on file.

Transportation and Shipping

Shipments are dispatched via pre-approved carriers with proven reliability and compliance with transportation regulations (e.g., FMCSA, IATA, IMDG). Domestic shipments within the U.S. must include tracking and delivery confirmation. International shipments require accurate HS codes, proper export declarations (e.g., AES filing), and adherence to Incoterms agreed upon with the customer. Temperature-sensitive or high-value shipments must be monitored with real-time tracking and insurance coverage.

Export Compliance

Acme Threaded strictly complies with U.S. export regulations, including the Export Administration Regulations (EAR) administered by the Bureau of Industry and Security (BIS). All exports undergo a classification review to determine ECCN (Export Control Classification Number) and licensing requirements. Screen all customers, vendors, and end-users against the OFAC SDN list, BIS Denied Persons List, and other restricted party lists prior to shipment. Maintain records of all export transactions for a minimum of five years.

Regulatory Documentation

Ensure all threaded products are accompanied by required certifications, including Material Test Reports (MTRs), Certificates of Conformance (CoC), and, where applicable, NIST-traceable calibration documents. Retain documentation electronically with controlled access and backup protocols. Product labeling must comply with ANSI/ASME standards for thread identification and include part number, material type, grade, and lot number.

Quality and Safety Compliance

Adhere to ISO 9001 quality management standards across all logistics operations. Implement corrective and preventive actions (CAPA) for any non-conformances identified during audits or customer feedback. All warehouse personnel must complete annual safety training, including handling procedures, forklift operation, and emergency response. Maintain OSHA-compliant records of incidents and safety inspections.

Audit and Continuous Improvement

Conduct quarterly internal audits of logistics and compliance procedures. Address findings through documented action plans with assigned responsibilities and timelines. Participate in external audits by customers, regulatory bodies, or certification agencies. Use key performance indicators (KPIs)—such as on-time delivery rate, order accuracy, and compliance violation count—to drive continuous improvement initiatives.

Contact and Escalation

For compliance or logistics concerns, contact the Logistics Manager or Compliance Officer immediately. Escalate unresolved issues to the Operations Director within 24 hours. Emergency after-hours contacts are posted in all warehouse and shipping areas.

Conclusion for Sourcing ACME Threaded Components

Sourcing ACME threaded components requires a careful evaluation of application requirements, material specifications, thread standards, and supplier reliability. ACME threads are preferred in power transmission applications—such as lead screws, linear actuators, and valve systems—due to their high load-bearing capacity, durability, and ease of manufacturing compared to standard threaded fasteners. When sourcing these components, it is essential to confirm thread dimensions (including diameter, pitch, and class of fit), material compatibility (commonly steel, stainless steel, or brass), and compliance with industry standards such as ASME B1.5.

Additionally, selecting a reputable supplier that offers precision manufacturing, quality certifications, and consistent lead times ensures reliable performance and reduces downtime in critical systems. Customization options, technical support, and cost-effectiveness should also be factored into the sourcing decision. By taking a strategic and informed approach, organizations can secure ACME threaded products that meet performance demands while optimizing cost and supply chain efficiency.

In summary, successful sourcing of ACME threaded components hinges on balancing technical accuracy, quality assurance, and supplier partnership to support long-term operational success.