The global aluminum composite material (ACM) sheet market has experienced steady expansion, driven by rising demand in architectural cladding, signage, and interior design applications. According to a report by Mordor Intelligence, the ACM sheet market was valued at approximately USD 13.7 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of over 6.5% from 2024 to 2029. This growth is fueled by rapid urbanization, increased infrastructure investments, and the construction sector’s shift toward lightweight, durable, and aesthetically versatile materials. Regions such as Asia-Pacific—led by China, India, and Southeast Asia—are emerging as both production hubs and key consumption markets, while stringent building regulations in North America and Europe are further boosting demand for fire-resistant and high-performance ACM solutions. As competition intensifies and innovation accelerates, identifying the leading manufacturers becomes critical for architects, contractors, and procurement professionals navigating this dynamic landscape. Below is a data-informed overview of the top 10 ACM sheet manufacturers shaping the industry’s future.

Top 10 Acm Sheet Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Rainware, Soffit, Fascia, Trim Coil, Edge Metals, Roofing and Siding …

Domain Est. 2009

Website: acm-metals.com

Key Highlights: ACM manufacturer of rainware gutter systems, trim coil, soffit, fascia, drip edge, edge metals, roofing and siding accessories for residential homes and ……

#2 Aluminum Metal Composite Materials

Domain Est. 2014

Website: alpolic-americas.com

Key Highlights: One of the world’s leading manufacturers of aluminum and metal composite materials manufactured from up to 50% recycled materials….

#3 Alumanate

Domain Est. 2017

Website: alumanate.com

Key Highlights: Only manufacturer of sign-grade ACM in the U.S.A.. Stocking facilities in Los Angeles, Chicago and Houston. Quick turnaround on production orders….

#4 Global Aluminum Metal Composite Materials – ACM/MCM

Domain Est. 1996

Website: alpolic.com

Key Highlights: ALPOLIC™ is the world’s leading metal composite material brand. MORE INFO. 12.June.2023ALPOLIC 50th Anniversary special website has been launched….

#5 Aluminum Composite Material (ACM)

Domain Est. 1997

Website: acplasticsinc.com

Key Highlights: $30 deliveryA&C Plastics offers a variety of Aluminum Composite Material (ACM) solutions for any industry. Order sheeting online or contact our sales experts today!…

#6 Maxmetal® ACM Panels

Domain Est. 2003

Website: maxmetal.com

Key Highlights: A heavy duty aluminum composite panel ready for digital printing or a lightweight, low-cost panel for a temporary sign, Maxmetal® has you covered….

#7 Aluminum Composite Panels for Modern Architecture

Domain Est. 2004

Website: alucobondusa.com

Key Highlights: ALUCOBOND manufactures innovative fire retardant aluminum composite panels for modern building design. Browse our products for your next project….

#8 Aluminium composite panels and assembly systems STACBOND

Domain Est. 2008

Website: stacbond.com

Key Highlights: We are specialists in the manufacture of aluminium composite panel and development of assembly systems. In addition, we offer coil painting services….

#9 ACM Products

Domain Est. 2010

Website: 3acompositesusa.com

Key Highlights: Alucobond and Dibond advanced metal panels can achieve virtually any design concept. These aluminum composite materials are extremely easy to fabricate….

#10 Aluminum Composite Cladding Toronto & GTA

Domain Est. 2014

Website: alumaxpanel.com

Key Highlights: Rating 4.8 (16) We develop custom Alumax Aluminum Composite Panels to match your exact brand or requested color. With a speed unequaled in the industry and guaranteed for an ……

Expert Sourcing Insights for Acm Sheet

H2: 2026 Market Trends for ACM (Aluminum Composite Material) Sheets

The global ACM (Aluminum Composite Material) sheet market is poised for significant evolution by 2026, driven by advancements in building technologies, sustainability mandates, and shifting architectural preferences. As urbanization accelerates and green construction standards become more stringent, the demand for lightweight, durable, and aesthetically versatile building materials like ACM sheets continues to grow. Below is an in-depth analysis of key market trends expected to shape the ACM sheet industry in 2026.

1. Rising Demand in Architectural and Facade Applications

ACM sheets are increasingly favored in commercial and high-rise building façades due to their excellent strength-to-weight ratio, design flexibility, and ease of installation. By 2026, the expansion of smart cities and mixed-use developments—particularly in Asia-Pacific, the Middle East, and parts of Africa—is expected to drive robust demand. Innovations in digital printing and custom color finishes will further enhance the aesthetic appeal of ACM panels, making them a top choice for modern architectural projects.

2. Sustainability and Eco-Friendly Product Development

Environmental regulations and green building certifications (e.g., LEED, BREEAM) are pushing manufacturers to adopt sustainable practices. In 2026, expect a surge in the production of recyclable ACM sheets with low-VOC (volatile organic compound) coatings and bio-based core materials. Leading producers are investing in closed-loop recycling systems to minimize waste and carbon footprint, aligning with global net-zero goals.

3. Fire Safety Regulations and Non-Combustible Core Innovations

Following high-profile fire incidents involving combustible cladding, regulatory scrutiny has intensified, especially in North America and Europe. By 2026, the market will see a stronger shift toward fire-retardant and non-combustible ACM variants, such as those with mineral-filled or fire-safe cores (e.g., A2-rated panels). Compliance with updated fire safety codes will be a key differentiator in competitive markets.

4. Growth in Retrofitting and Renovation Projects

With increasing focus on energy efficiency and building modernization, ACM sheets are being widely adopted in retrofitting older structures. Their lightweight nature reduces structural load, making them ideal for façade upgrades without extensive reinforcement. The renovation sector is expected to contribute significantly to market growth, especially in Europe and North America.

5. Technological Integration and Smart Facades

The integration of ACM panels with smart technologies—such as photovoltaic cells, sensors, and dynamic insulation systems—is emerging as a niche but fast-growing segment. By 2026, smart ACM façades capable of energy harvesting, temperature regulation, or self-cleaning properties could gain traction in high-end commercial and institutional buildings.

6. Regional Market Dynamics

– Asia-Pacific will remain the largest market for ACM sheets, led by rapid urbanization in China, India, and Southeast Asia.

– Middle East & Africa will see growth due to large-scale infrastructure projects and government-led urban development initiatives.

– North America and Europe will experience steady demand, driven by renovation activities and strict building performance standards.

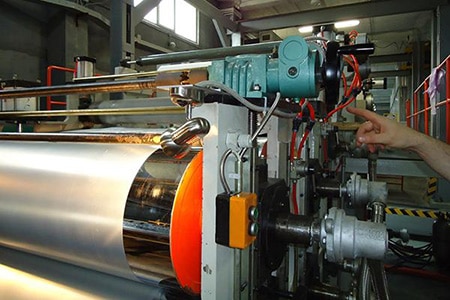

7. Supply Chain Resilience and Raw Material Volatility

Fluctuations in aluminum prices and logistical challenges may continue to impact production costs. By 2026, manufacturers are expected to focus on supply chain localization, strategic partnerships, and alternative material sourcing to ensure stability and cost-efficiency.

Conclusion

By 2026, the ACM sheet market will be shaped by a convergence of technological innovation, regulatory compliance, and sustainability imperatives. Companies that prioritize fire-safe formulations, eco-conscious manufacturing, and value-added functionalities will be best positioned to capitalize on emerging opportunities. As the construction industry evolves toward smarter, greener buildings, ACM sheets will remain a critical component in the future of modern architecture.

Common Pitfalls When Sourcing ACM Sheets: Quality and Intellectual Property Issues

Logistics & Compliance Guide for ACM Sheet

Overview of ACM Sheets

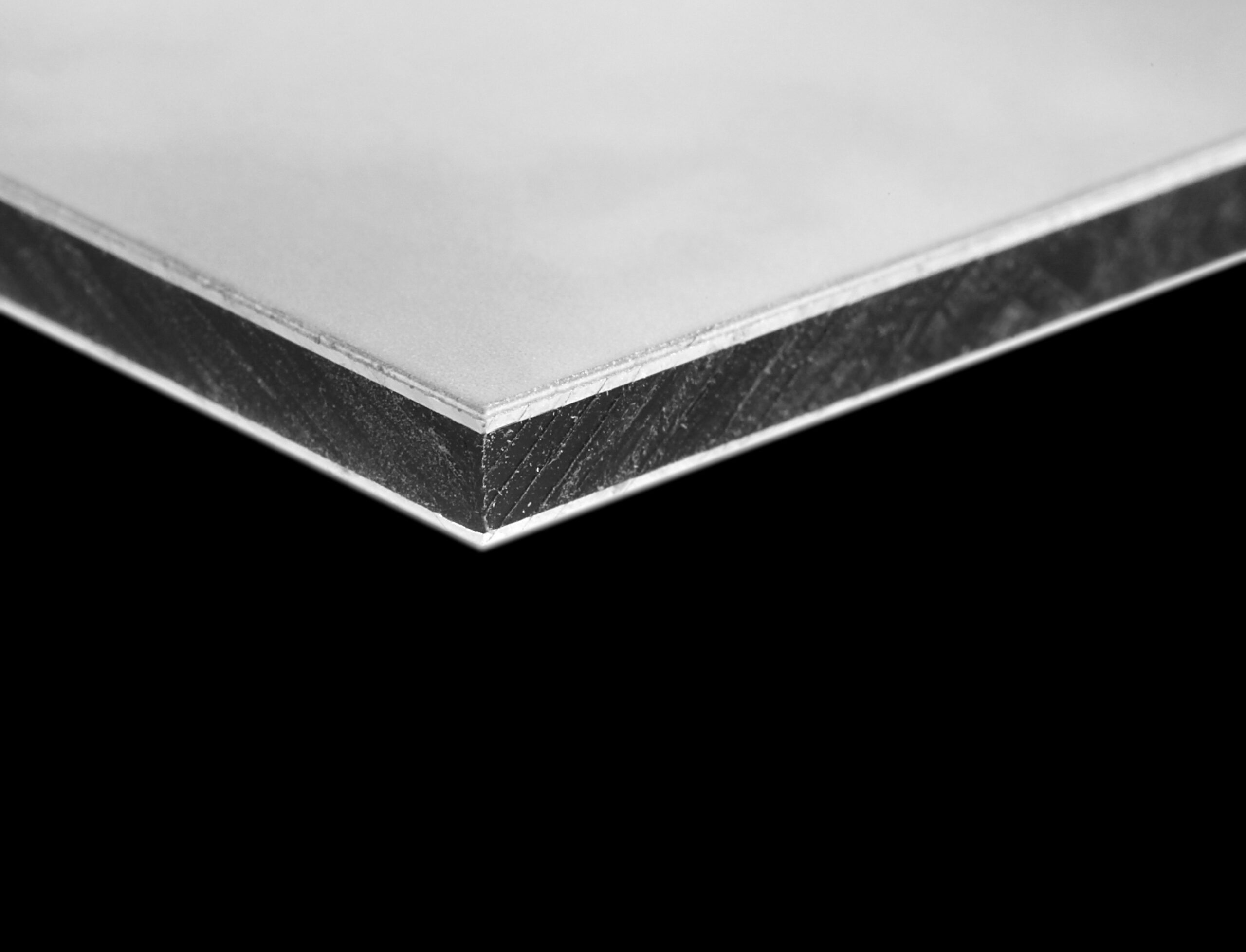

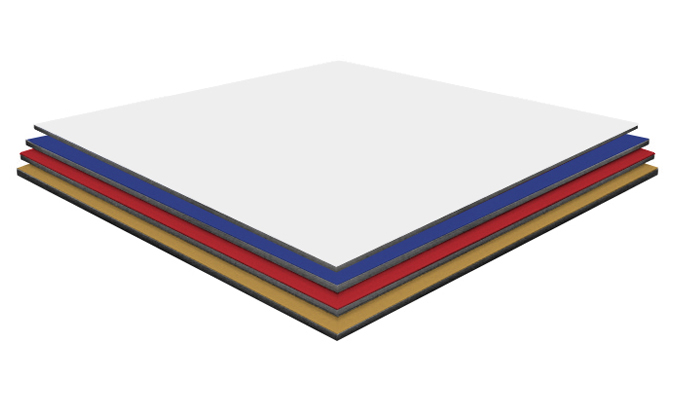

Aluminum Composite Material (ACM) sheets are lightweight, durable panels consisting of two thin aluminum skins bonded to a polyethylene or fire-retardant core. Widely used in architectural cladding, signage, and interior design, ACM sheets require careful handling and compliance due to fire safety and regulatory concerns, especially following incidents like the Grenfell Tower fire.

Regulatory Compliance Requirements

ACM sheets must comply with regional and international building and fire safety standards. Key regulations include:

– UK Building Regulations (Approved Document B): Prohibits the use of ACM panels with polyethylene cores on high-rise residential buildings over 18 meters. Only ACM with fire-retardant (Class A2 or Class B) cores may be permitted under strict conditions.

– International Building Code (IBC) – USA: Requires exterior cladding materials to meet ASTM E84 or NFPA 285 testing standards. Most polyethylene-core ACM panels fail NFPA 285, limiting their use in high-rise construction.

– EU Construction Products Regulation (CPR): Mandates CE marking and classification under EN 13501-1 for fire performance. ACM panels must achieve at least Class B-s1,d0 for use in many applications.

– Australia (NCC): Bans combustible cladding, including most ACM types, on buildings over 3 storeys unless an alternative compliance pathway is approved.

Fire Safety Classification

Understanding fire performance ratings is critical:

– Class A2: Non-combustible materials with limited contribution to fire. Acceptable in many high-risk applications.

– Class B: Limited combustibility; requires additional fire-stopping and cavity barriers.

– Class E/F: Highly combustible; banned in many countries for external cladding.

Always verify the core type (e.g., PE, FR, A2) and obtain test reports from the manufacturer.

Transportation & Handling Logistics

ACM sheets are typically shipped flat on pallets with protective film. Key logistics considerations:

– Packaging: Sheets must be securely strapped and protected from moisture, scratches, and deformation.

– Loading/Unloading: Use forklifts or crane lifts with spreader beams to avoid bending. Never drag or drop panels.

– Stacking: Store horizontally on flat, level surfaces with adequate support. Avoid excessive height to prevent bottom sheet damage.

– Weather Protection: Keep under cover; avoid prolonged exposure to rain or direct sunlight, which may degrade adhesives or coatings.

Storage Guidelines

- Indoor Storage: Preferred in dry, well-ventilated warehouses. Maintain temperature between 10°C and 30°C.

- Outdoor Storage: Only if unavoidable; elevate pallets off the ground and fully cover with UV-resistant tarpaulins. Limit exposure time.

- Duration: Avoid long-term storage. Inspect periodically for warping, coating damage, or moisture ingress.

Installation & Site Compliance

- Qualified Installers: Use trained professionals familiar with ACM-specific systems and fire-sealing techniques.

- Cavity Barriers: Install fire-stopping at every floor level and around openings when using combustible-core ACM.

- Separation from Ignition Sources: Maintain safe distances from exhausts, lighting, or electrical fixtures.

- Documentation: Retain material test reports, CE marks, and installation certifications for audit purposes.

Disposal & Recycling

- Recycling: Aluminum layers are recyclable; however, separation from the core is complex. Use certified e-waste or metal recyclers.

- Disposal: If contaminated or non-recyclable, dispose of as construction waste in compliance with local environmental regulations. Do not incinerate.

Documentation & Certification

Ensure availability of:

– Manufacturer’s Declaration of Performance (DoP)

– Fire test reports (e.g., NFPA 285, BS 8414)

– CE marking or equivalent certification

– Material Safety Data Sheet (MSDS)

– Installation manual and system warranty

Conclusion

ACM sheets offer aesthetic and functional benefits but require strict adherence to fire safety and building codes. Proper logistics, compliance verification, and documentation are essential to ensure safety, avoid legal liability, and maintain project integrity. Always consult local authorities and fire safety experts before specifying or installing ACM cladding.

Conclusion for Sourcing ACM Sheets:

Sourcing ACM (Aluminum Composite Material) sheets requires a careful evaluation of quality, supplier reliability, cost, and compliance with industry standards. It is essential to select suppliers who offer products that meet international specifications such as ASTM or EN standards, ensuring durability, fire resistance (especially with fire-rated cores), and weather performance for both architectural and industrial applications. Conducting thorough due diligence—comprising material testing, sample evaluation, and verification of certifications—helps mitigate risks related to safety and longevity. Additionally, considering logistical factors, lead times, and after-sales support contributes to a successful procurement process. Ultimately, establishing long-term partnerships with reputable ACM suppliers enables consistent quality, cost efficiency, and project reliability in construction, façade design, and other applications.