The global AC power cord market is experiencing steady growth, driven by rising demand across consumer electronics, industrial equipment, and healthcare sectors. According to Grand View Research, the global power cord market size was valued at USD 13.4 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This expansion is supported by increasing electrification, the proliferation of portable devices, and the need for reliable power connectivity solutions worldwide. With two-prong AC power cords remaining a staple in regions with grounded plug standards, such as North America and Japan, demand for high-quality, compliant cords continues to rise. As manufacturers focus on durability, safety certifications, and efficiency, the competitive landscape is evolving to meet regulatory and performance expectations. In this context, identifying the leading two-prong AC power cord manufacturers becomes essential for OEMs, electronics distributors, and procurement professionals seeking reliable supply chain partners.

Top 10 Ac Power Cord Two Prong Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Quail Electronics Inc. ®

Domain Est. 1996

Website: quail.com

Key Highlights: Our selection of NEMA cables include the common 2-prong and 3-prong plug types for traditional household appliances as well as an extensive inventory of ……

#2 Power Cord Manufacturers

Domain Est. 2001

Website: cordsets.org

Key Highlights: For a broad selection of power cord products, detailed industry resources, and direct supplier connections, check out our Power Cords website….

#3 Power Cord Manufacturers

Domain Est. 2019

Website: powercordmanufacturers.com

Key Highlights: An AC power cord is a detachable way of providing an alternating current of electric energy from a mains power supply to an electrical appliance or equipment….

#4 China Two Prong Power Cord Suppliers, Manufacturers

Domain Est. 2021

Website: hongzhoucable.com

Key Highlights: We’re professional two prong power cord manufacturers and suppliers in China, specialized in providing high quality products….

#5 Power Cords, Plugs, Connectors, Receptacles

Website: volex.com

Key Highlights: Volex is a leading manufacturer and supplier of power cords, plugs, connectors and receptacles. Volex power cord products are sold to manufacturers for a ……

#6 Power Cords and Adapters

Domain Est. 1996

Website: tripplite.eaton.com

Key Highlights: We offer AC power cords, extension cords, splitters and adapters for computers, servers and PDUs. Our cords have innovative features like coiled cords and ……

#7 Power Cord & Electrical Cords

Domain Est. 1999

#8 The Technical Side of Power Cords

Domain Est. 1999

Website: cablewholesale.com

Key Highlights: Discover the differences between various types of power cords and extension wires. You’ll be surprised to find that they aren’t all the same….

#9 Products – AC Connectors

Domain Est. 2014

#10 Best Two Prong Ac Power Cord Manufacturer and Factory, Company

Domain Est. 2023

Website: orient-elec.com

Key Highlights: Two Prong Ac Power Cord Manufacturers, Factory, Suppliers From China, To benefit from our strong OEM/ODM capabilities and considerate services, ……

Expert Sourcing Insights for Ac Power Cord Two Prong

H2: Projected 2026 Market Trends for AC Power Cord Two Prong

In 2026, the market for two-prong AC power cords is expected to undergo notable shifts driven by technological advancements, regulatory changes, and evolving consumer preferences. While these cords—commonly used in double-insulated devices without grounding requirements—remain in demand, their role is being redefined in the context of global electrification and safety standards.

1. Declining Demand in Developed Markets

In North America and Western Europe, the demand for two-prong AC power cords is projected to plateau or slightly decline. Increasing safety regulations and the widespread adoption of grounded (three-prong) outlets in new constructions are reducing reliance on non-grounded connections. Additionally, consumer electronics manufacturers are increasingly integrating power supplies with higher safety certifications that favor grounded systems, further limiting the use of two-prong cords in high-power or sensitive devices.

2. Sustained Demand in Emerging Economies

Conversely, in regions such as Southeast Asia, Africa, and parts of Latin America, two-prong power cords will continue to see steady demand. These markets often feature older electrical infrastructures with limited grounding capabilities. Cost-sensitive consumers and manufacturers favor two-prong cords due to their lower production cost and compatibility with legacy systems. The proliferation of affordable consumer electronics—such as phone chargers, lamps, and small kitchen appliances—will sustain the need for these cords.

3. Shift Toward Universal and Hybrid Solutions

A key trend in 2026 is the rise of hybrid and universal power cords that support multiple plug types, including two-prong configurations. As global supply chains require compatibility across regions, manufacturers are designing cords with interchangeable tips or dual-standard compliance (e.g., Type A and Type C). This adaptability allows two-prong cords to remain relevant in export-oriented markets without sacrificing versatility.

4. Environmental and Material Innovations

Environmental regulations, especially in the EU under RoHS and REACH, are pushing manufacturers to use halogen-free, recyclable materials in power cord production. By 2026, a growing share of two-prong cords will be made from bioplastics or recycled PVC, aligning with corporate sustainability goals. Energy efficiency standards may also influence cord design, though the impact is more indirect compared to active components.

5. Niche Applications and Longevity in Low-Power Devices

Two-prong cords will maintain a stronghold in low-voltage, double-insulated appliances such as phone chargers, LED lighting, and small personal electronics. Their simplicity, lower cost, and sufficient safety for these use cases ensure continued relevance. The Internet of Things (IoT) expansion may also support demand, as many smart home sensors and devices operate safely on non-grounded power.

6. Impact of Plug Standard Harmonization

Efforts toward plug standardization—such as the EU’s push for a common charging solution (e.g., USB-C)—may reduce dependency on proprietary AC cords. However, for mains-powered appliances without USB charging, two-prong AC cords will remain essential. The transition is gradual, and 2026 will still see a mixed ecosystem of legacy and new standards.

Conclusion

The 2026 market for two-prong AC power cords reflects a dichotomy: diminishing relevance in safety-conscious, developed markets versus enduring utility in cost-driven, developing regions. While innovation and regulation are reshaping the landscape, the two-prong cord is not disappearing—it is adapting. Manufacturers who focus on compliance, sustainability, and regional customization will best navigate this evolving terrain.

Common Pitfalls When Sourcing AC Power Cord Two Prong (Quality, IP)

Sourcing two-prong AC power cords may seem straightforward, but overlooking key quality and Ingress Protection (IP) considerations can lead to safety hazards, compliance failures, and product reliability issues. Below are common pitfalls to avoid:

1. Ignoring Safety Certifications and Compliance

One of the most critical mistakes is sourcing cords without proper safety certifications such as UL, CSA, CE, or ETL. Non-certified cords may not meet regional electrical safety standards, increasing the risk of electrical shock, fire, or equipment damage. Always verify that the power cord complies with local regulations and industry standards for your target market.

2. Underestimating Build Quality and Materials

Low-cost cords often use substandard materials such as thin insulation, inferior PVC jackets, or undersized conductors. These compromises can lead to premature wear, cracking, overheating, or short circuits. Ensure cords are constructed with durable materials rated for the intended voltage, temperature, and flexing requirements.

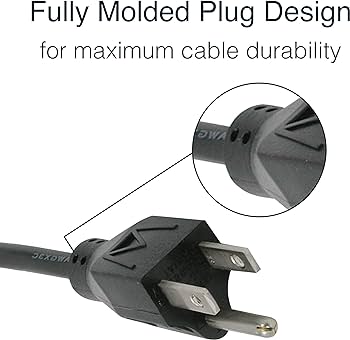

3. Overlooking Strain Relief and Connector Durability

Poor strain relief at the plug and connector junctions increases the likelihood of internal wire breakage from repeated bending or pulling. Inadequate strain relief compromises safety and reduces product lifespan. Choose cords with robust overmolding and integrated strain relief designed to withstand mechanical stress.

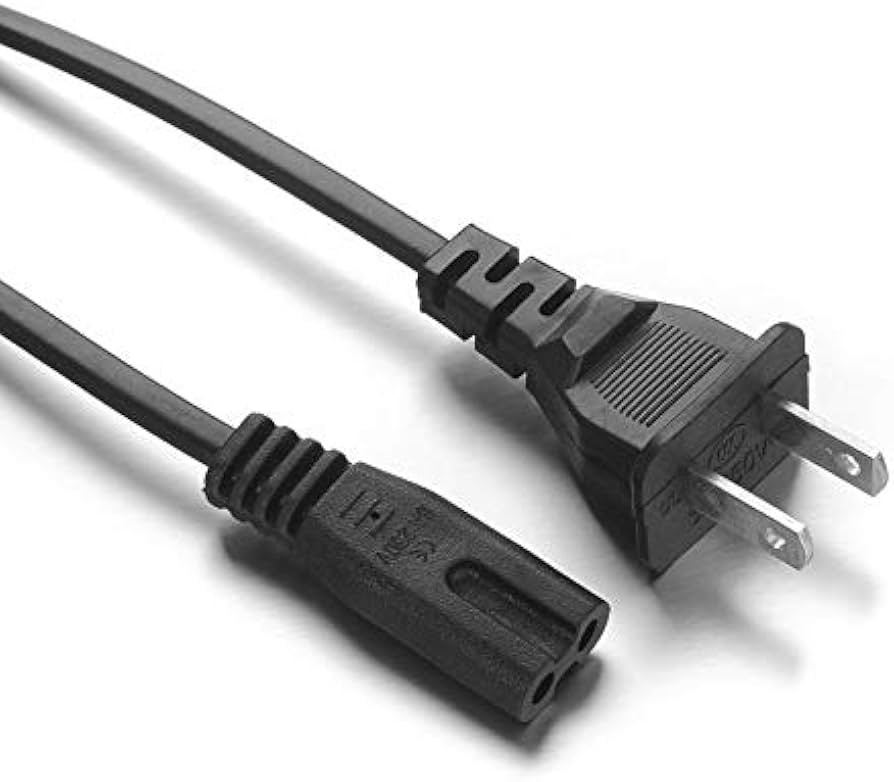

4. Assuming All Two-Prong Cords Are Interchangeable

Two-prong cords vary significantly in current rating, voltage rating, wire gauge (AWG), and jacket type (e.g., SJT, SJOOW). Using a cord with insufficient current capacity or unsuitable jacket material for the environment (e.g., outdoor, industrial) can result in overheating or insulation failure. Match cord specifications precisely to your application requirements.

5. Neglecting Ingress Protection (IP) Ratings for Connectors

While power cords themselves typically don’t carry an IP rating, the connector housing or mating interface might. If the cord is used in damp, dusty, or outdoor environments, failing to consider IP-rated connectors (e.g., IP67) can expose internal components to moisture and contaminants, leading to corrosion or electrical faults. Ensure compatible IP-rated connectors when environmental protection is needed.

6. Sourcing from Unreliable or Non-Transparent Suppliers

Purchasing from suppliers without verifiable quality control processes increases the risk of counterfeit or non-compliant products. Always request test reports, material certifications, and conduct supplier audits when possible. Transparent documentation is key to ensuring long-term reliability.

7. Failing to Consider Environmental and Usage Conditions

Using a standard indoor-rated cord in harsh environments—such as industrial settings, outdoor installations, or high-moisture areas—can lead to rapid degradation. Select cords with appropriate temperature ratings, UV resistance, oil resistance, and flexibility for the intended operating conditions.

8. Not Verifying Cord Length and Gauge Impact on Performance

Excessively long cords or those with undersized conductors can cause significant voltage drop, especially under load, leading to inefficient operation or device malfunction. Always calculate voltage drop based on length, gauge, and expected current draw to ensure proper performance.

Avoiding these pitfalls ensures the safe, reliable, and compliant integration of two-prong AC power cords in your products or systems. Prioritize certified, well-constructed cords matched to both electrical and environmental demands.

Logistics & Compliance Guide for AC Power Cord Two Prong

This guide outlines key logistics and compliance considerations for the import, distribution, and sale of two-prong AC power cords in global markets. Adherence to these guidelines ensures product safety, legal conformity, and smooth supply chain operations.

Regulatory Compliance

Two-prong AC power cords must meet electrical safety and electromagnetic compatibility (EMC) standards in each target market. Key regulations include:

- United States (FCC, UL, NEC):

- FCC Part 15 governs electromagnetic interference.

- UL 817 certification ensures safety for power supply cords.

- Compliance with National Electrical Code (NEC) is required for installation safety.

-

Devices may require listing by Nationally Recognized Testing Laboratories (NRTL).

-

European Union (CE Marking, RoHS, REACH, Low Voltage Directive):

- CE marking indicates conformity with health, safety, and environmental protection standards.

- RoHS restricts hazardous substances (e.g., lead, cadmium).

- REACH regulates chemical substances.

-

Compliance with EN 50525 or HD 21.3 S4 for cord specifications.

-

Canada (ISED, CSA):

- ISED certification (formerly IC) for EMC.

-

CSA C22.2 No. 21 for cord safety.

-

Other Regions:

- UK: UKCA marking (post-Brexit), adhering to BS standards.

- Australia/NZ: RCM mark per AS/NZS 3112 and AS/NZS 3191.

- China: CCC certification may be required depending on end-use application.

Always verify local requirements, as some countries mandate third-party testing or certification.

Product Labeling and Documentation

Ensure accurate labeling and documentation for compliance and traceability:

- Clearly mark voltage, current rating, wire gauge (e.g., 16 AWG), and temperature rating on the cord jacket.

- Include manufacturer name, model number, and compliance marks (e.g., UL, CE, CSA).

- Provide user instructions highlighting proper usage, safety warnings, and compatible devices.

- Maintain technical documentation, test reports, and certificates of conformity (CoC) for audits.

Packaging and Shipping

Proper packaging ensures product integrity and regulatory compliance during transit:

- Use anti-static and moisture-resistant packaging if required.

- Clearly label outer packaging with product details, compliance marks, and handling instructions.

- Include safety data sheets (SDS) if applicable (e.g., for PVC materials under REACH).

- Follow carrier-specific guidelines for hazardous materials (note: standard cords are typically non-hazardous).

Import and Customs Clearance

Facilitate smooth customs entry by preparing accurate documentation:

- Provide commercial invoice with HS code (e.g., 8544.42 for insulated wire, or 8544.60 for other electrical conductors).

- Include packing list, bill of lading/airway bill, and relevant certificates (CE, FCC, RoHS, etc.).

- Verify tariff classifications and duty rates with local customs authorities.

- For the U.S., ensure compliance with 19 CFR Part 12.90 (country of origin marking).

Environmental and Disposal Compliance

Adhere to environmental directives regarding material use and end-of-life handling:

- Comply with WEEE (Waste Electrical and Electronic Equipment) in the EU, requiring proper disposal and recycling.

- Ensure materials are recyclable and labeled accordingly.

- Avoid restricted substances per RoHS, Prop 65 (California), and other regional laws.

Quality Assurance and Testing

Implement a quality control process to ensure ongoing compliance:

- Conduct periodic safety and performance testing (dielectric strength, pull tests, flex endurance).

- Audit suppliers for consistent material and manufacturing standards.

- Retain samples and test records for traceability.

Market-Specific Considerations

- Two-prong cords lack grounding and are suitable only for double-insulated (Class II) devices.

- Verify compatibility with regional plug types (e.g., NEMA 1-15P in North America, Europlug in EU).

- Some countries restrict or ban ungrounded cords for certain appliances (e.g., high-power or medical devices).

By following this guide, businesses can ensure safe, legal, and efficient handling of two-prong AC power cords across global supply chains. Always consult local regulatory bodies for the latest requirements.

In conclusion, sourcing a two-prong AC power cord requires careful consideration of compatibility, safety standards, and application requirements. These cords are typically used with devices that are double-insulated and do not require a grounding connection, making them suitable for low-risk electronics such as lamps, chargers, and certain household appliances. When selecting a two-prong power cord, ensure it meets relevant regional electrical standards (such as UL in the U.S. or CE in Europe), matches the plug configuration of your country, and is rated for the appropriate voltage and current. Additionally, prioritize cords made from high-quality, durable materials to ensure long-term reliability and safety. By verifying device specifications and adhering to safety guidelines, sourcing the correct two-prong AC power cord can be a straightforward and secure process.