The global air conditioning compressor market is experiencing robust growth, driven by rising demand for energy-efficient cooling solutions across residential, commercial, and industrial sectors. According to a report by Mordor Intelligence, the AC compressor market was valued at USD 28.5 billion in 2023 and is projected to grow at a CAGR of over 6.8% from 2024 to 2029. This expansion is fueled by increasing urbanization, infrastructure development, and stringent environmental regulations promoting eco-friendly refrigerants and higher system efficiency. As a critical component of HVAC systems, the AC compressor fan plays a vital role in heat dissipation and overall system performance. With the global push toward sustainable and smart HVAC solutions, manufacturers are investing heavily in innovation and R&D. In this competitive landscape, nine key players have emerged as leaders in producing high-performance, reliable AC compressor fans—shaping the future of climate control technology.

Top 9 Ac Compressor Fan Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 ebm

Domain Est. 1998

Website: ebmpapst.com

Key Highlights: ebm‑papst Inc. is the world’s leading manufacturer of fans. As a technology company, we have continually set global industry standards since we were founded ……

#2 REVCOR Revolutionary Airflow

Domain Est. 1996

Website: revcor.com

Key Highlights: We develop revolutionary airflow solutions for a wide variety of OEM companies in diverse Industries….

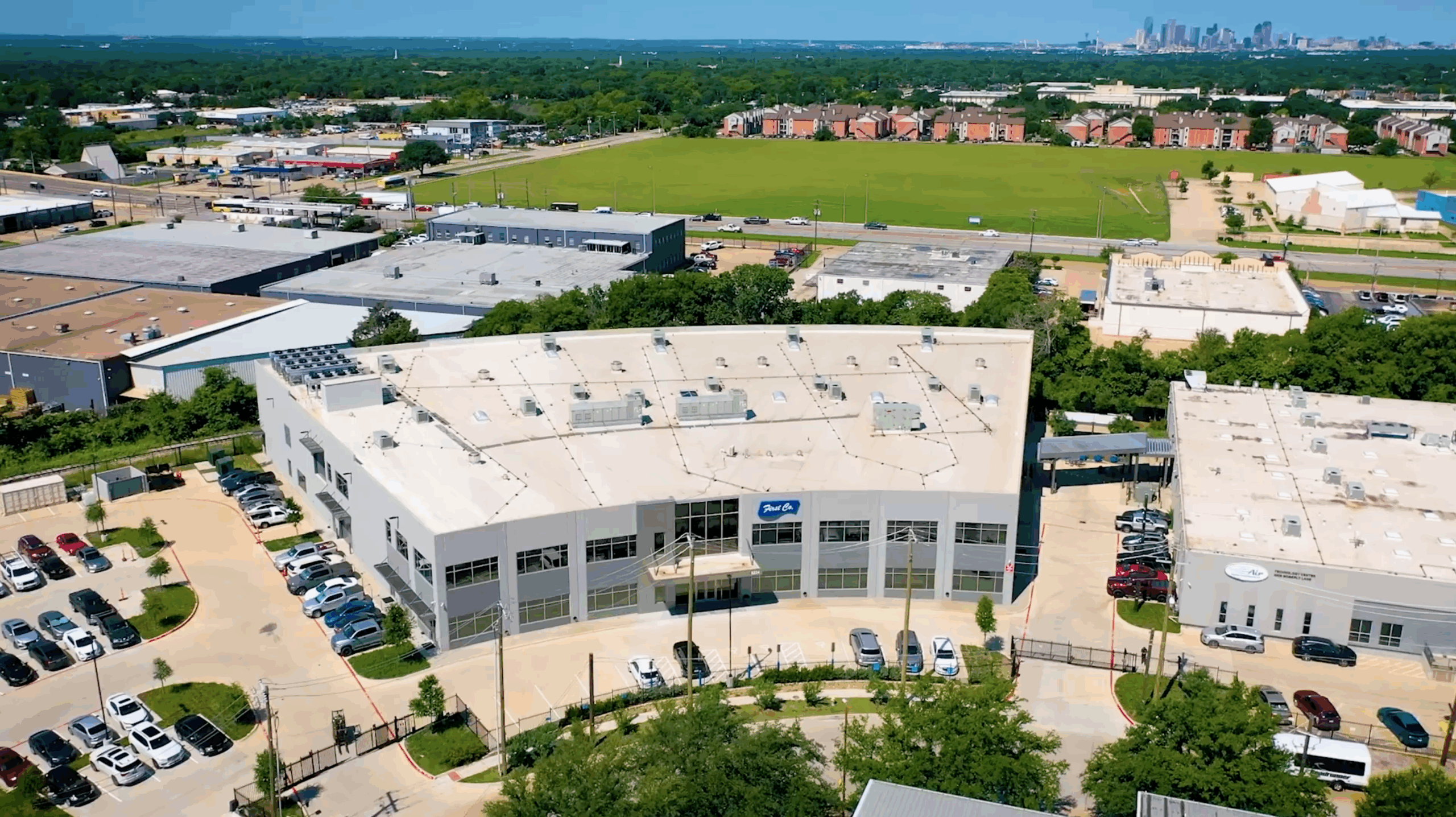

#3 First Co.

Domain Est. 1996

Website: firstco.com

Key Highlights: First Co., an HVAC manufacturer in Dallas, specializes in innovative heating and cooling systems for residential, multi-occupant, and commercial ……

#4 Four Seasons

Domain Est. 1996

Website: 4s.com

Key Highlights: We are the largest aftermarket climate control parts supplier in the industry and the largest compressor remanufacturer in the world….

#5 ZIEHL-ABEGG Fans & Ventilation Systems

Domain Est. 1997

Website: ziehl-abegg.com

Key Highlights: Welcome to ZIEHL-ABEGG US! We supply highly efficient ventilation, drive and control technology worldwide for more sustainable conservation of resources….

#6 Greenheck

Domain Est. 1995

Website: greenheck.com

Key Highlights: Greenheck is the leading supplier of air movement, air control and air conditioning equipment. Delivering reliable air comfort, safety and energy ……

#7 Thermal Management & Air

Domain Est. 2000

Website: denso.com

Key Highlights: Our compact and easy-to-mount HVAC unit, or our bus air-conditioning unit mounted on the roof provides safe and comfortable cabin space….

#8 SYM BANG AC/DC/EC Fans & Blowers

Domain Est. 2001

Website: activa.com.tw

Key Highlights: SYM BANG is a fans & blowers supplier that offers a wide range of high-quality fans and blowers for various applications….

#9 Welling Motor

Domain Est. 2008

Website: wellingmotor.com

Key Highlights: Welling has developed fixed-speed and variable-frequency products that meet the basic needs of household appliances in various regions around the world….

Expert Sourcing Insights for Ac Compressor Fan

H2: 2026 Market Trends for AC Compressor Fans

The global market for AC compressor fans is poised for significant transformation by 2026, driven by evolving technological advancements, regulatory standards, and shifting consumer demands. This analysis explores key trends expected to shape the AC compressor fan industry in the coming years.

-

Rising Demand for Energy-Efficient Systems

With global energy conservation becoming a priority, manufacturers are focusing on developing AC compressor fans that consume less power while maintaining optimal performance. In 2026, energy efficiency standards—such as updated SEER2 (Seasonal Energy Efficiency Ratio 2) regulations in North America and similar directives in Europe and Asia—are expected to push demand for high-efficiency brushless DC (BLDC) motors in compressor fan applications. These motors offer variable speed control, reducing energy consumption by up to 30–50% compared to traditional induction motors. -

Integration of Smart Technologies

The Internet of Things (IoT) is transforming HVAC systems, and compressor fans are no exception. By 2026, smart AC units equipped with connected compressor fans capable of real-time diagnostics, predictive maintenance, and remote monitoring are expected to gain market share. These smart fans will communicate with building management systems (BMS) and home automation platforms, improving system longevity and user comfort. -

Growth in Residential and Commercial Cooling Demand

Urbanization, population growth, and rising temperatures due to climate change are accelerating the need for air conditioning, particularly in emerging economies across Southeast Asia, India, the Middle East, and Africa. As a result, demand for reliable and durable AC compressor fans is expected to surge. The commercial sector, including data centers and retail spaces, will also contribute significantly due to the need for continuous cooling operations. -

Shift Toward Eco-Friendly Refrigerants and Compact Designs

As the HVAC industry transitions from high-global-warming-potential (GWP) refrigerants like R-410A to eco-friendly alternatives such as R-32 and R-290, compressor fans must adapt to new thermal loads and operating pressures. These changes influence fan design, requiring more robust materials and optimized airflow dynamics. Additionally, compact and lightweight compressor fan units are in demand to support the miniaturization of modern AC systems without sacrificing performance. -

Automation and Advanced Manufacturing

By 2026, increased adoption of automation in manufacturing will enhance precision and scalability in AC compressor fan production. Technologies such as AI-driven quality control, 3D printing for prototyping, and automated assembly lines will reduce production costs and improve consistency, allowing manufacturers to meet growing global demand efficiently. -

Supply Chain Resilience and Regionalization

The disruptions witnessed during the pandemic have prompted companies to re-evaluate supply chains. In 2026, there will be a stronger trend toward regional manufacturing hubs—especially in India, Vietnam, and Eastern Europe—to reduce dependency on single-source suppliers and mitigate logistics risks. This shift will also support faster time-to-market and customization for local climates and regulations. -

Focus on Noise Reduction and User Comfort

Consumer expectations for quieter HVAC systems are rising. As a result, manufacturers are investing in aerodynamic blade designs, vibration-damping materials, and precision-balanced motors to minimize operational noise from compressor fans. Quieter systems are particularly in demand in residential and healthcare environments.

Conclusion

By 2026, the AC compressor fan market will be shaped by innovation in energy efficiency, digital integration, sustainability, and manufacturing agility. Companies that embrace smart technologies, comply with environmental standards, and adapt to regional market needs will be best positioned for growth. As the world moves toward greener and smarter cooling solutions, the role of the compressor fan will evolve from a simple component to a critical enabler of intelligent, efficient climate control systems.

Common Pitfalls When Sourcing AC Compressor Fans (Quality and IP)

Sourcing AC compressor fans requires careful consideration of both quality and Ingress Protection (IP) ratings to ensure long-term reliability and performance. However, several common pitfalls can compromise system efficiency and durability if not properly addressed.

1. Overlooking IP Rating Requirements

One of the most frequent mistakes is selecting a fan with an inadequate IP rating for the operating environment. For example, using an IP54 fan in a high-humidity or outdoor setting may lead to moisture ingress, electrical failure, or corrosion. Always match the IP rating to the environment—IP65 or higher is often necessary for outdoor or harsh industrial applications.

2. Prioritizing Cost Over Quality

Choosing lower-cost fans without verifying build quality often leads to premature failure. Cheap fans may use inferior bearings, low-grade plastics, or substandard motors, resulting in increased maintenance, downtime, and higher total cost of ownership.

3. Inaccurate Performance Specifications

Suppliers may provide inflated performance data, such as airflow (CFM) or static pressure ratings, under ideal lab conditions. Failing to verify real-world performance or request third-party test reports can result in undersized or inefficient cooling.

4. Ignoring Noise Levels

High noise output can be a problem in residential or office environments. Some low-quality fans generate excessive noise due to imbalanced blades or poor motor design. Always check dB(A) ratings and ensure they meet application requirements.

5. Lack of Certifications and Compliance

Reputable AC compressor fans should comply with safety and electromagnetic compatibility (EMC) standards (e.g., CE, UL, RoHS). Sourcing fans without proper certifications increases the risk of product failure, safety hazards, or non-compliance with regional regulations.

6. Poor Thermal and Environmental Resilience

Fans must operate reliably across expected temperature ranges. Low-quality units may fail in extreme heat or cold. Ensure the fan is rated for the full operating temperature range and has protections like thermal overload cut-offs.

7. Inadequate Supplier Verification

Sourcing from unverified or unknown suppliers, especially online marketplaces, increases the risk of counterfeit or misrepresented products. Always audit suppliers, request samples, and validate manufacturing traceability.

8. Mismatched Mechanical and Electrical Compatibility

Even with the correct IP and quality, a fan may not fit mechanically or electrically—wrong mounting dimensions, voltage, or plug types can lead to integration issues. Double-check all form, fit, and function parameters before procurement.

Avoiding these pitfalls ensures reliable, efficient, and safe operation of AC systems over their intended lifespan.

Logistics & Compliance Guide for AC Compressor Fan

This guide outlines the key logistics considerations and compliance requirements for the transportation, handling, and sale of AC Compressor Fans, applicable to manufacturers, distributors, importers, and retailers.

Product Classification and Identification

- HS Code (Harmonized System Code): Typically classified under HS 8414.30 (Electric fans of a kind used for air conditioning systems). Confirm local customs classification as variations may exist by country.

- UN Number (if applicable): Not usually assigned unless the fan includes integral hazardous components (e.g., lithium batteries). Verify if packaging contains regulated materials.

- Product Specifications: Maintain accurate records of voltage, wattage, dimensions, weight, motor type, and material composition for compliance and safety assessments.

Packaging and Labeling Requirements

- Protective Packaging: Use sturdy, shock-resistant packaging to prevent damage during transit. Include cushioning materials to protect blades and motor housing.

- Labeling: Clearly display:

- Product name and model number

- Manufacturer/importer name and address

- Voltage and power rating (e.g., 120V~, 60Hz, 50W)

- Safety certifications (e.g., UL, CE, ETL marks)

- Direction of rotation (if applicable)

- Warning labels (e.g., “Caution: Moving Parts”)

- Barcoding: Include UPC or EAN codes for inventory and retail tracking.

Regulatory Compliance

- Electrical Safety Standards:

- North America: Must comply with UL 507 (Standard for Electric Fans) and be certified by a Nationally Recognized Testing Laboratory (NRTL) such as UL, CSA, or ETL.

- European Union: Must meet Low Voltage Directive (2014/35/EU) and carry the CE mark. Compliance with EN 60335-1 and EN 60335-2-80 is required.

- Other Regions: Adhere to local standards (e.g., CCC in China, PSE in Japan, BIS in India).

- Energy Efficiency Regulations:

- Comply with regional energy performance standards (e.g., DOE regulations in the U.S., Ecodesign Directive in EU). Verify minimum efficiency requirements for motor types.

- RoHS and REACH Compliance (EU):

- Restriction of Hazardous Substances (RoHS) limits the use of lead, mercury, cadmium, and other substances.

- REACH requires disclosure of Substances of Very High Concern (SVHC) in articles.

- WEEE Compliance (EU):

- AC compressor fans fall under WEEE Category 5 (Monitoring and control instruments) or 6 (Electric and electronic tools). Producers must register and finance take-back programs.

Import and Export Documentation

- Commercial Invoice: Include detailed product description, value, quantity, HS code, and Incoterms (e.g., FOB, CIF).

- Packing List: Specify number of packages, gross/net weight, dimensions, and marks/numbers.

- Certificate of Origin: Required by some countries for tariff determination.

- Test Reports and Certificates: Provide copies of safety certification (e.g., UL, CE) and compliance declarations (DoC).

- Customs Declarations: Ensure accurate classification and valuation to avoid delays or penalties.

Transportation and Handling

- Mode of Transport: Suitable for air, sea, or ground freight. Avoid exposure to moisture and extreme temperatures.

- Stacking and Storage: Store in dry, well-ventilated areas. Limit stacking height to prevent crushing.

- Hazardous Materials: Confirm the fan does not contain regulated substances (e.g., refrigerants, ozone-depleting substances) unless explicitly designed to do so.

- Fragile Handling: Label packages as “Fragile” and “This Side Up” to minimize risk of damage.

Environmental and Sustainability Considerations

- Recyclability: Design for disassembly and use recyclable materials where possible.

- Carbon Footprint: Optimize logistics routes and consolidate shipments to reduce emissions.

- Packaging Materials: Use recyclable or biodegradable packaging; minimize plastic use.

Returns and End-of-Life Management

- Warranty Handling: Establish clear return logistics for defective units, including inspection and repair/replacement processes.

- End-of-Life Disposal: Provide guidance for proper disposal in accordance with local e-waste regulations. Support take-back programs where legally required.

Compliance Monitoring and Recordkeeping

- Maintain records of certifications, test reports, shipping documents, and compliance audits for a minimum of 5 years (or as required by jurisdiction).

- Conduct periodic reviews of regulatory changes in target markets to ensure ongoing compliance.

By adhering to this guide, stakeholders can ensure safe, efficient, and legally compliant handling and distribution of AC Compressor Fans across global markets.

Conclusion for Sourcing Air Conditioner Compressor Fan

Sourcing an air conditioner compressor fan requires a careful evaluation of technical specifications, quality standards, supplier reliability, and cost-effectiveness. It is essential to ensure compatibility with the existing HVAC system by verifying parameters such as fan size, motor voltage, RPM, airflow capacity (CFM), and mounting configuration. Prioritizing components from reputable manufacturers that adhere to industry standards enhances durability, performance, and energy efficiency.

Additionally, establishing relationships with trusted suppliers—whether OEMs, aftermarket manufacturers, or certified distributors—helps maintain a consistent supply chain and reduces downtime for repairs or installations. Evaluating total cost of ownership, including energy consumption and maintenance needs, rather than focusing solely on initial price, leads to better long-term outcomes.

In conclusion, a strategic sourcing approach that balances quality, compatibility, and supplier credibility ensures reliable operation of the AC system, improved system lifespan, and optimal cooling performance. Regular market assessment and staying informed about technological advancements will further support effective procurement decisions in the evolving HVAC industry.