The global demand for effective piping insulation solutions continues to surge, driven by increasing energy efficiency regulations, industrial modernization, and infrastructure development. According to a 2023 report by Mordor Intelligence, the global insulation materials market was valued at USD 54.8 billion and is projected to grow at a compound annual growth rate (CAGR) of 5.8% through 2028. Rigid and flexible cellular glass, elastomeric, and closed-cell foam—commonly used in A/C pipe insulation—are seeing heightened adoption across HVAC, oil & gas, and commercial construction sectors. As sustainability standards tighten and building performance requirements evolve, selecting high-performance insulation from reliable manufacturers is more critical than ever. In this context, identifying the top 10 A/C pipe insulation manufacturers provides valuable insights for engineers, contractors, and procurement professionals focused on thermal efficiency, durability, and regulatory compliance.

Top 10 A C Pipe Insulation Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Pipe Insulation Products

Domain Est. 1996

Website: owenscorning.com

Key Highlights: Select Owens Corning’s pipe insulation products for outstanding above & underground insulation & thermal protection in commercial & industrial settings….

#2

Domain Est. 1996

Website: kflex.com

Key Highlights: K-FLEX products are safe to handle, easy to install, available in different sizes and based on innovative and sustainable technologies….

#3 Thermaflex: Technical Insulation and Pre

Domain Est. 1996

Website: thermaflex.com

Key Highlights: Advanced technical insulation and pre-insulated piping systems, reduce energy loss, protect systems and improve long-term reliability….

#4 Pipe Insulation

Domain Est. 1997

Website: jm.com

Key Highlights: Our pipe insulation portfolio includes fiberglass and foam insulations and can cover a broad spectrum of temperatures, ranging from -237°F to 800°F….

#5 FlexClad®

Domain Est. 1999

Website: flexclad.com

Key Highlights: FlexClad is the flexible, weatherproof, economical, and easy-to-install jacketing system for pipe and duct applications….

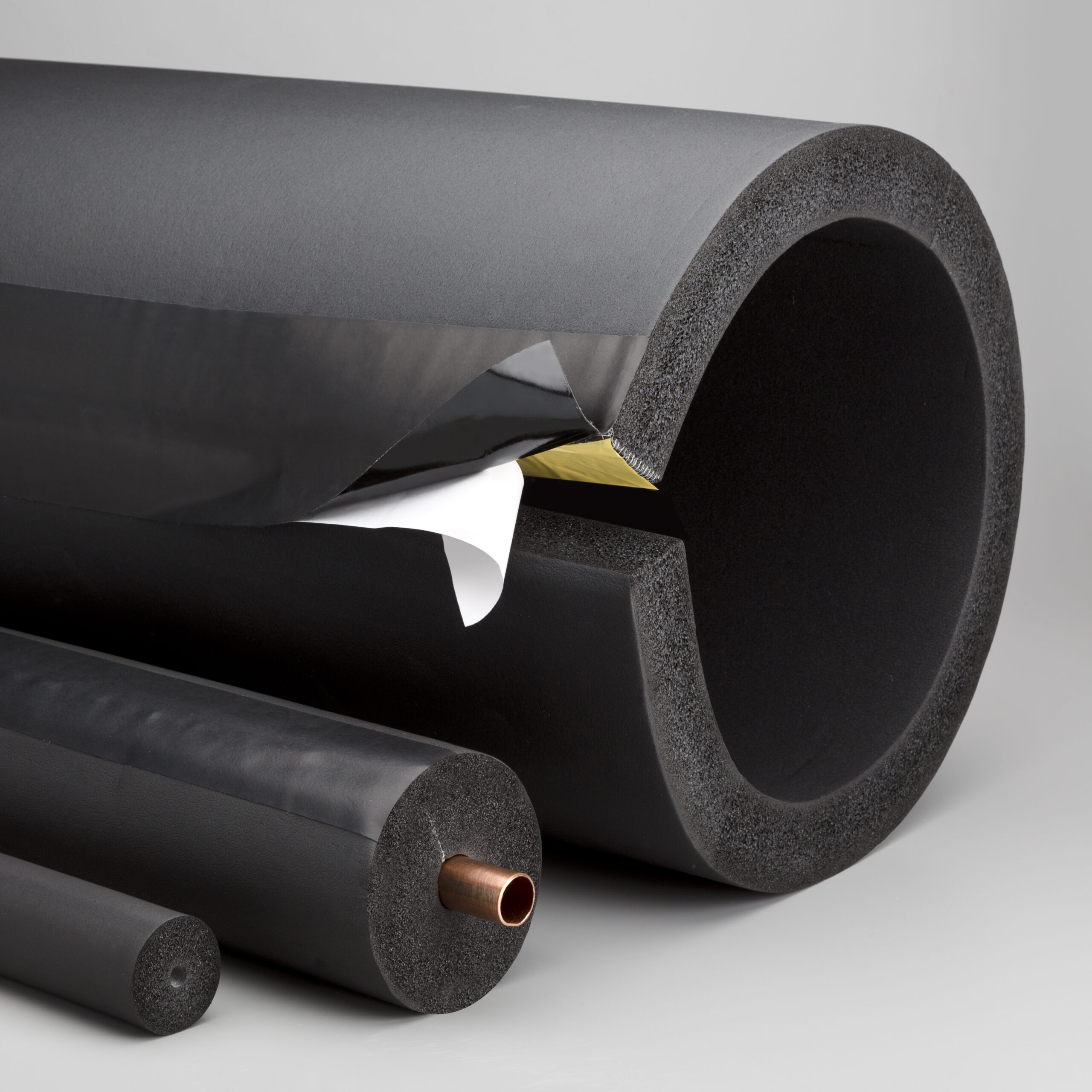

#6 Aeroflex USA

Domain Est. 2000

Website: aeroflexusa.com

Key Highlights: Closed-Cell Elastomeric Foam Insulation uniquely formulated for success in mechanical, refrigeration, HVAC, and plumbing systems….

#7 General Insulation Company

Domain Est. 2001

Website: generalinsulation.com

Key Highlights: A wholesale distributor, providing a full line of sustainable products and solutions for thermal efficiency, condensation/moisture control, and life safety….

#8 Airex Manufacturing Inc

Domain Est. 2009

Website: airexmfg.com

Key Highlights: The #1 PRO HVAC industry choice for wall refrigerant piping penetration outlet seals and outdoor refrigerant piping insulation protection….

#9 PDM®

Domain Est. 2009

Website: pdmus.com

Key Highlights: PDM draws on nearly 50 years of experience in the HVAC industry from our origins in Europe. PDM was the First one in 2008 to introduce the polyethylene tough ……

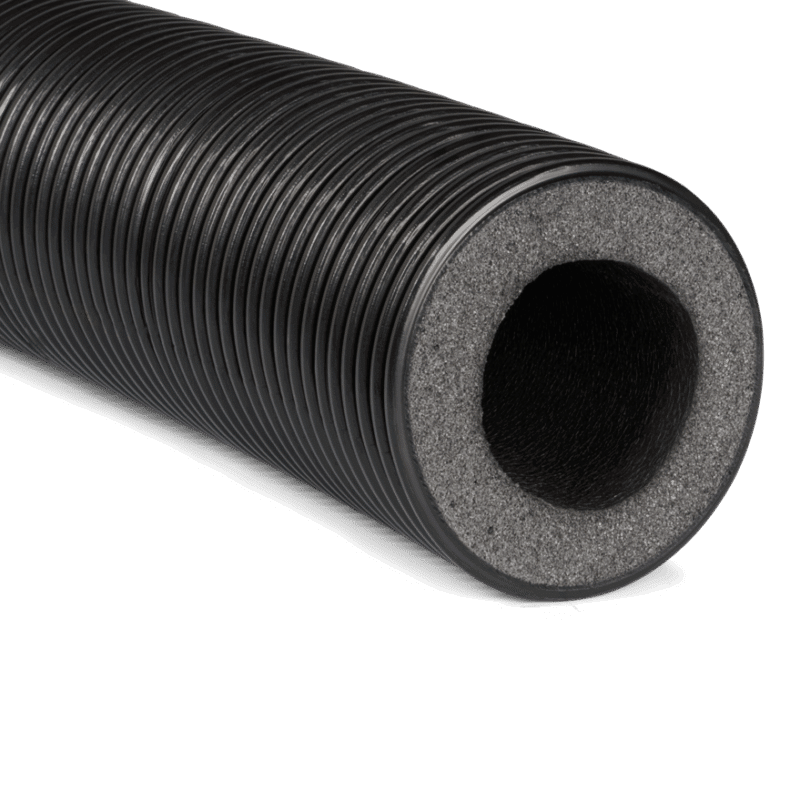

#10 XLPE PRO

Domain Est. 2013

Website: astralpipes.com

Key Highlights: Astral XLPE Pro insulation tubes are specifically designed for plastic and metal piping systems used in building construction and various industries….

Expert Sourcing Insights for A C Pipe Insulation

H2: Market Trends for A/C Pipe Insulation in 2026

As we approach 2026, the global market for air conditioning (A/C) pipe insulation is undergoing significant transformation, driven by technological advancements, regulatory changes, and growing environmental concerns. The following key trends are shaping the A/C pipe insulation industry:

1. Increased Demand for Energy Efficiency

With rising energy costs and stricter building efficiency standards, demand for high-performance insulation materials continues to grow. A/C pipe insulation plays a critical role in minimizing thermal losses in HVAC systems. In 2026, building codes in regions like North America, the EU, and parts of Asia are mandating higher R-values and tighter energy performance benchmarks, pushing contractors and manufacturers toward advanced insulation solutions such as elastomeric foam, polyethylene, and closed-cell rubber.

2. Shift Toward Sustainable and Eco-Friendly Materials

Environmental sustainability is a major driver in 2026. Consumers and regulators are prioritizing low-global warming potential (GWP) and recyclable insulation materials. Manufacturers are responding by developing bio-based, low-VOC (volatile organic compound), and recyclable insulation products. Certifications like LEED, BREEAM, and Energy Star are influencing procurement decisions, especially in commercial and green building projects.

3. Growth in Emerging Markets

Urbanization and rising living standards in Asia-Pacific, Latin America, and the Middle East are fueling HVAC adoption, particularly in residential and commercial construction. Countries such as India, Indonesia, and Saudi Arabia are investing heavily in infrastructure and cooling systems due to extreme heat, driving demand for A/C pipe insulation. This regional expansion is expected to account for a significant share of market growth by 2026.

4. Integration with Smart Building Technologies

The rise of smart buildings and IoT-enabled HVAC systems has created a need for insulation materials compatible with sensors and monitoring systems. In 2026, some insulation products feature embedded temperature sensors or moisture detection capabilities to prevent condensation and system inefficiency. This trend is particularly strong in data centers, hospitals, and high-end commercial buildings.

5. Supply Chain Resilience and Localization

Following disruptions from global events in prior years, manufacturers are re-evaluating supply chains. In 2026, there’s a growing trend toward localized production and inventory management to reduce lead times and mitigate risks. This also supports faster response to regional regulations and customer demands.

6. Innovation in Material Performance

Advancements in nanotechnology and composite materials are enhancing the thermal, acoustic, and fire-resistant properties of A/C pipe insulation. Products with improved durability, easier installation (e.g., pre-slit or self-sealing designs), and resistance to mold and UV exposure are gaining traction in both retrofit and new construction markets.

Conclusion

By 2026, the A/C pipe insulation market is characterized by a strong emphasis on sustainability, performance, and smart integration. Stakeholders—including manufacturers, installers, and policymakers—must adapt to evolving standards and consumer expectations to remain competitive. The market is projected to grow steadily, supported by urbanization, climate challenges, and the global push for energy-efficient infrastructure.

Common Pitfalls When Sourcing AC Pipe Insulation (Quality, IP)

Sourcing Air Conditioning (AC) pipe insulation involves more than just selecting a material—overlooking critical factors can lead to poor thermal performance, condensation, energy loss, and even system failure. Below are common pitfalls related to quality and Insulation Performance (IP), with practical guidance to avoid them.

1. Prioritizing Low Cost Over Long-Term Quality

One of the most frequent mistakes is choosing the cheapest insulation option without evaluating long-term durability and performance. Low-cost materials often degrade faster, compress under load, or absorb moisture, compromising insulation effectiveness.

Impact: Reduced energy efficiency, increased HVAC runtime, and higher maintenance costs.

Avoidance Tip: Evaluate total cost of ownership (TCO), including lifespan, maintenance, and energy savings. Invest in high-quality, closed-cell elastomeric or polyethylene foam known for durability and moisture resistance.

2. Ignoring Thermal Conductivity (k-value) Specifications

Not all insulation materials offer the same thermal resistance. Selecting insulation with a high k-value (poor insulator) significantly reduces system efficiency, especially in hot and humid climates.

Impact: Inadequate temperature maintenance, condensation on pipes, and mold growth.

Avoidance Tip: Choose materials with low k-values (e.g., <0.034 W/m·K at 0°C mean temperature). Verify test certifications (ASTM C518 or ISO 8497) and ensure values are reported at actual operating temperatures.

3. Overlooking Moisture Resistance and Vapor Transmission

In humid environments, poor moisture resistance leads to water absorption in insulation, drastically reducing thermal performance and promoting corrosion under insulation (CUI).

Impact: Mold growth, pipe corrosion, insulation degradation, and health hazards.

Avoidance Tip: Opt for closed-cell materials with low water vapor transmission rates (WVTR). Check ASTM E96 or ISO 12572 test data and ensure the insulation includes a built-in vapor barrier or requires compatible jacketing.

4. Mismatching Insulation Thickness to Application

Using insufficient thickness compromises energy efficiency and increases the risk of surface condensation. Conversely, over-insulating can be unnecessarily costly and impractical in tight spaces.

Impact: Condensation, energy waste, or installation difficulties.

Avoidance Tip: Calculate required thickness based on ambient conditions, fluid temperature, and local climate using standards like ASHRAE 90.1 or ISO 12241. Always consult engineering guidelines for your specific climate zone.

5. Assuming All “IP-Rated” Insulation Meets Performance Claims

Some suppliers use misleading claims about “high-performance” or “IP-compliant” insulation without third-party validation. Without proper testing, real-world performance may fall short.

Impact: False expectations, system inefficiencies, and warranty disputes.

Avoidance Tip: Request independent test reports and product certifications (e.g., UL, FM, or ISO). Verify that insulation has been tested for compression resistance, aging, and sustained performance under real conditions.

6. Neglecting Fire Safety and Local Code Compliance

Failing to consider fire rating requirements (e.g., flame spread, smoke development) can result in non-compliance with building codes and safety hazards.

Impact: Fire risk, failed inspections, and liability issues.

Avoidance Tip: Ensure insulation meets local fire codes (e.g., ASTM E84, UL 723) and has appropriate fire safety ratings (e.g., Class A flame spread, low smoke index). Always check municipal or national building regulations.

7. Poor Attention to Installation Quality and Fit

Even high-quality insulation underperforms if improperly installed—gaps, compression, or poor sealing at joints reduce effectiveness and allow thermal bridging.

Impact: Hotspots, condensation, and reduced system efficiency.

Avoidance Tip: Source insulation with factory-applied adhesive or pre-slit designs for easier, tighter fits. Train installers or use certified contractors who follow manufacturer guidelines and use compatible sealants and tapes.

8. Overlooking Environmental and Sustainability Factors

Some insulation materials contain harmful blowing agents (e.g., high-GWP HFCs) or are non-recyclable, leading to environmental concerns and potential regulatory issues.

Impact: Higher carbon footprint and non-compliance with green building standards (e.g., LEED, BREEAM).

Avoidance Tip: Choose insulation with low global warming potential (GWP), recycled content, and environmental product declarations (EPDs). Consider materials with third-party sustainability certifications.

By recognizing and avoiding these common pitfalls—especially those tied to quality degradation and inaccurate insulation performance assumptions—buyers can ensure reliable, efficient, and compliant AC pipe insulation systems over their entire lifecycle.

Logistics & Compliance Guide for AC Pipe Insulation

This guide outlines the key logistics and compliance considerations for handling, transporting, storing, and using AC (typically referring to ArmaFlex® or similar elastomeric closed-cell foam) pipe insulation. Proper adherence ensures product performance, safety, and regulatory compliance.

Product Identification and Specifications

AC pipe insulation is a flexible, closed-cell elastomeric foam primarily made from synthetic rubber (often Nitrile Butadiene Rubber – NBR). It is widely used for insulating HVAC, refrigeration, and plumbing systems to control condensation, reduce energy loss, and maintain temperature. Key characteristics include low thermal conductivity, moisture resistance, and ease of installation.

Regulatory and Safety Compliance

Ensure all AC pipe insulation products meet relevant industry standards and certifications. Common compliance requirements include:

- ASTM Standards: Verify compliance with ASTM C534 (Standard Specification for Preformed Flexible Elastomeric Cellular Thermal Insulation) and ASTM C1136 (Standard Specification for Flexible Water Vapor Retarders).

- Fire Safety: Confirm products meet fire performance standards such as ASTM E84 (Surface Burning Characteristics), with typical ratings of Class A/Class 1 for flame spread and smoke development. UL 181 and UL 723 compliance may also apply.

- Environmental and Health Regulations: Ensure materials are compliant with VOC (Volatile Organic Compound) regulations (e.g., CDPH Standard Method v1.2). Check for compliance with REACH and RoHS where applicable.

- Local Building Codes: Confirm compatibility with local mechanical, plumbing, and energy codes (e.g., IMC, UPC, IECC).

Packaging and Handling

Proper packaging and handling preserve the integrity of AC pipe insulation:

- Packaging: Typically supplied in pre-slit tubular sections, rolls, or sheets. Products are often shrink-wrapped or boxed to protect against moisture, dust, and mechanical damage.

- Handling: Use gloves to prevent skin contact with dust or residues. Avoid dragging or dropping packages. Cut with sharp knives or insulation slitters to prevent fraying or compression damage.

- Labeling: Ensure all packaging includes product type, dimensions, manufacturer details, safety warnings, and compliance markings.

Transportation Requirements

Transport AC pipe insulation under controlled conditions to maintain quality:

- Moisture Protection: Keep materials dry during transit. Use covered vehicles and waterproof tarps if needed. Avoid exposure to rain or high humidity.

- Temperature Control: While elastomeric insulation tolerates a range of temperatures, prolonged exposure to extreme heat (>140°F/60°C) or freezing conditions may degrade performance. Store and transport within 40°F–100°F (4°C–38°C) when possible.

- Stacking and Securing: Stack packages evenly and securely to prevent crushing. Do not exceed recommended load heights. Use pallets for stability and forklift access.

Storage Conditions

Proper storage prevents material degradation and ensures performance:

- Environment: Store indoors in a clean, dry, well-ventilated area away from direct sunlight and heat sources.

- Shelving: Use racks or pallets to elevate materials off the floor. Avoid direct contact with concrete to reduce moisture absorption.

- Stacking Limits: Follow manufacturer guidelines for maximum stack height to prevent compression damage.

- Shelf Life: Most AC insulation has a shelf life of 5–10 years when stored properly. Rotate stock using FIFO (First In, First Out) principles.

Installation Best Practices

Compliance extends to proper installation:

- Surface Preparation: Clean and dry pipes before insulation. Use appropriate adhesives as specified by the manufacturer.

- Seams and Joints: Seal all longitudinal and circumferential joints with compatible mastic or tape to ensure vapor integrity.

- Vapor Retarder: Maintain the integrity of the insulation’s built-in vapor retarder. Repair any punctures immediately.

- Support and Fastening: Use mechanical supports at regular intervals per manufacturer recommendations to prevent sagging.

Documentation and Traceability

Maintain complete documentation for compliance audits:

- Certificates of Compliance (CoC): Obtain and retain CoCs for each product batch.

- Material Safety Data Sheets (MSDS/SDS): Keep updated safety data sheets accessible to personnel.

- Inspection Records: Document storage conditions, handling procedures, and installation quality checks.

Disposal and Environmental Responsibility

Dispose of waste material responsibly:

- Recycling: Check with the manufacturer or local facilities for recycling options for elastomeric insulation scraps.

- Landfill Disposal: If recycling is not available, dispose of in accordance with local solid waste regulations.

- Hazardous Waste: AC insulation is generally non-hazardous, but confirm with SDS before disposal.

Training and Personnel Safety

Ensure all personnel involved in handling or installing AC pipe insulation are properly trained:

- Conduct safety training covering handling, cutting, adhesive use, and PPE requirements.

- Provide appropriate personal protective equipment (PPE), including gloves, safety glasses, and dust masks when cutting.

- Educate teams on fire safety, ventilation needs, and emergency procedures.

Adhering to this logistics and compliance guide ensures the safe, effective, and code-compliant use of AC pipe insulation throughout its lifecycle.

Conclusion:

Sourcing C-shaped (or split) pipe insulation is a practical and efficient solution for thermal and acoustic insulation of piping systems in various industrial, commercial, and residential applications. The pre-slit design allows for easy installation and retrofitting without the need to dismantle existing pipes, significantly reducing labor time and costs. When sourcing C pipe insulation, it is essential to consider factors such as insulation material (e.g., elastomeric, fiberglass, mineral wool, or foam), temperature rating, environmental conditions, fire safety requirements, and energy efficiency goals.

Selecting a reliable supplier who offers certified, high-quality products that comply with relevant industry standards ensures long-term performance and durability. Additionally, proper sizing and compatibility with the piping system are crucial to minimize thermal bridging and achieve optimal energy savings. In conclusion, thoughtful sourcing of C pipe insulation—balancing quality, cost, and application-specific needs—leads to improved system efficiency, reduced energy loss, and enhanced protection against condensation and noise, contributing to sustainable and cost-effective operations.