Sourcing Guide Contents

Industrial Clusters: Where to Source Butterfly Valve Supplier China

SourcifyChina Sourcing Report 2026

Deep-Dive Market Analysis: Butterfly Valve Suppliers in China

Prepared for Global Procurement Managers

Executive Summary

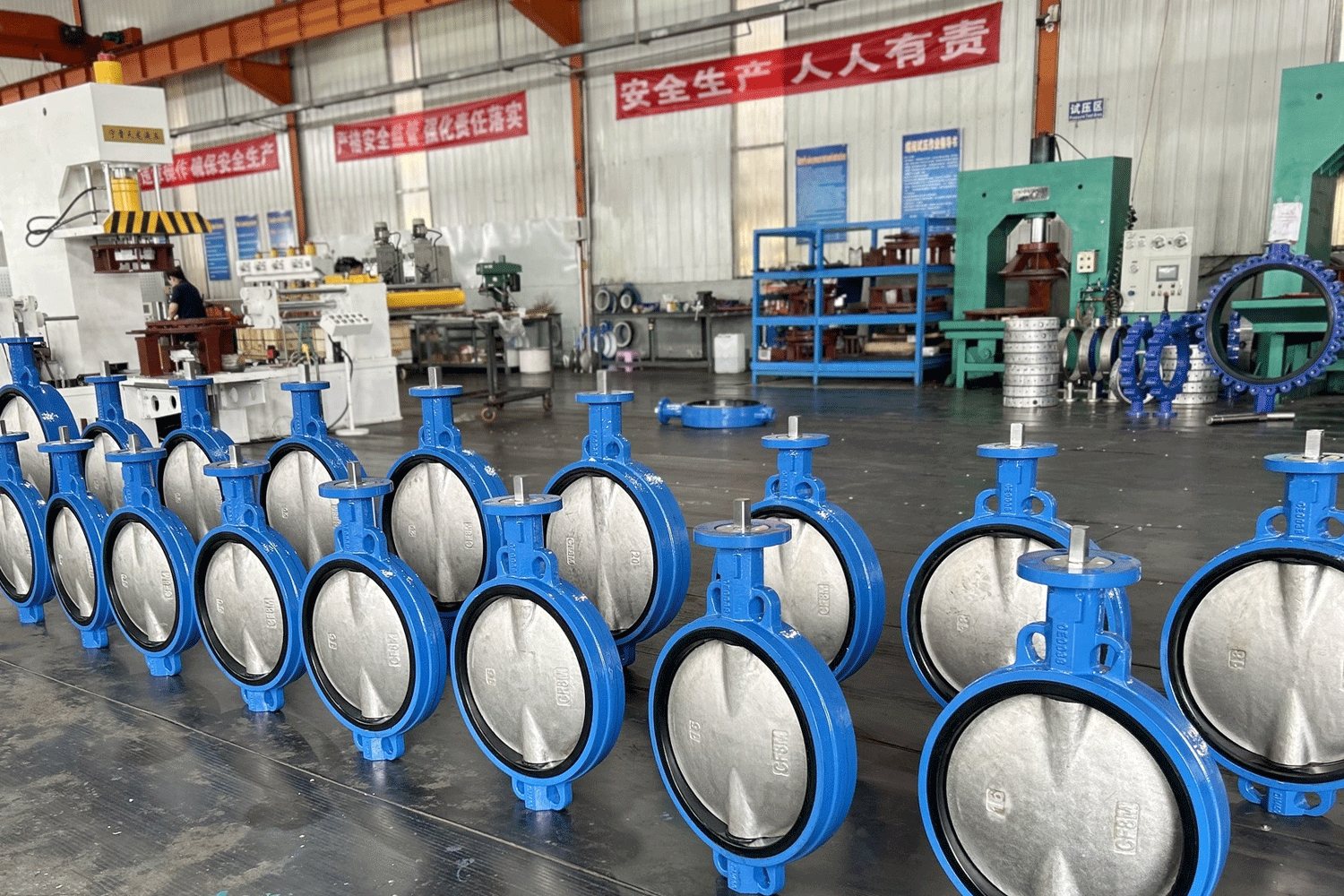

China remains the dominant global manufacturing hub for industrial valves, including butterfly valves, accounting for over 30% of global valve production and 25% of exports by volume (2025 Global Valve Market Report). Butterfly valves—particularly wafer, lug, and double-flanged types—are widely used in water treatment, HVAC, oil & gas, and chemical processing industries.

This report provides a strategic analysis of China’s butterfly valve manufacturing landscape, focusing on key industrial clusters, regional strengths, and comparative sourcing metrics. The objective is to guide procurement managers in making data-driven supplier selection decisions based on quality, cost, and lead time performance.

Key Industrial Clusters for Butterfly Valve Manufacturing in China

China’s butterfly valve production is highly concentrated in three primary industrial clusters, each with distinct competitive advantages:

- Zhejiang Province (Wenzhou, Longquan, Taizhou)

- Core Hub: Wenzhou, known as the “Valve Capital of China”

- Over 600 valve manufacturers, including 28 national high-tech enterprises

- Specialization: Medium- to high-end stainless steel and alloy butterfly valves

-

Certifications: Widely compliant with API, ISO, CE, and GB standards

-

Guangdong Province (Foshan, Guangzhou, Dongguan)

- Core Hub: Foshan (Nanhai District)

- Strong in OEM/ODM production for export markets

- Focus: Cost-competitive carbon steel and ductile iron butterfly valves

-

Proximity to Shenzhen and Hong Kong port facilities enables faster export logistics

-

Hebei Province (Cangzhou, Wuqiao County)

- Core Hub: Wuqiao Valve Industrial Park

- Concentrated cluster of over 400 valve manufacturers

- Competitive edge: Large-diameter valves and custom engineering solutions

-

Heavy investment in casting and forging infrastructure

-

Jiangsu Province (Yancheng, Changzhou)

- Emerging player in precision engineering

- Strong in automated actuated butterfly valves

- Higher labor and compliance costs, but improved quality consistency

Regional Comparison: Sourcing Butterfly Valves in China (2026 Forecast)

| Region | Average Price Level (USD) | Quality Tier | Lead Time (Standard Orders) | Key Strengths | Risks / Considerations |

|---|---|---|---|---|---|

| Zhejiang | $85–$160/unit (DN100, Class 150) | High (Premium) | 25–35 days | High material integrity, API/ISO certified, strong R&D | Higher MOQs, longer negotiation cycles |

| Guangdong | $60–$110/unit (DN100, Class 150) | Medium | 18–28 days | Fast turnaround, agile OEM support, English-speaking teams | Variable quality control; audit recommended |

| Hebei | $55–$95/unit (DN100, Class 150) | Medium-Low | 30–45 days | Competitive on large-bore valves (>DN300), strong casting base | Longer lead times, logistics delays possible |

| Jiangsu | $90–$170/unit (DN100, Class 150) | High | 22–32 days | Precision machining, smart/actuated valves, automation integration | Premium pricing; smaller supplier pool |

Note: Prices based on FOB Shanghai/Ningbo for standard carbon steel butterfly valves, DN100, RF flange, 150# pressure rating. Lead times exclude shipping and customs clearance.

Strategic Sourcing Recommendations

1. Prioritize Zhejiang for High-Integrity Applications

For water treatment plants, chemical processing, or offshore projects requiring API 609 or ISO 5208 compliance, Wenzhou-based suppliers (e.g., Wenzhou King Valve, Zhejiang Oceano Valve) offer the highest consistency in material traceability and testing protocols.

2. Leverage Guangdong for Cost-Sensitive, High-Volume Orders

Foshan suppliers (e.g., Guangdong Huaxing Valve, Foshan Nanhai Flow Control) are ideal for HVAC or municipal infrastructure projects where cost and speed are critical. Recommend third-party inspection (e.g., SGS, BV) for quality assurance.

3. Consider Hebei for Large-Diameter or Custom Designs

For pipeline or desalination projects requiring valves >DN600, Wuqiao’s foundry-heavy ecosystem offers cost advantages. However, conduct on-site casting audits due to variability in heat treatment processes.

4. Evaluate Jiangsu for Smart Valve Integration

With increasing demand for IoT-enabled valves, Jiangsu’s engineering-focused manufacturers (e.g., Yancheng High-Tech Valve) provide superior actuation and monitoring solutions, though at a 15–25% premium.

Compliance & Certification Trends (2026)

- Mandatory Requirements: All export valves must comply with China Compulsory Certification (CCC) for domestic use; however, international buyers should require API 609, ISO 9001, and PED/CE certifications.

- Emerging Trend: 42% of Zhejiang and Jiangsu suppliers now offer carbon footprint reports and RoHS compliance, driven by EU Green Deal regulations.

- Audit Recommendation: Conduct pre-shipment inspections using third-party agencies to verify pressure testing (shell and seat) and material certifications.

Conclusion

China’s butterfly valve supply chain offers unparalleled scale and specialization, but regional disparities in quality, cost, and delivery require strategic segmentation. Procurement managers should align supplier selection with application criticality, volume requirements, and compliance needs.

Zhejiang remains the gold standard for quality, while Guangdong offers agility and cost efficiency. Hebei excels in large-scale casting, and Jiangsu leads in innovation. A tiered sourcing strategy—leveraging multiple regions based on product specs—will optimize total cost of ownership in 2026 and beyond.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

February 2026

For supplier shortlists, audit templates, or RFQ support, contact sourcifychina.com/supply-chain-intelligence

Technical Specs & Compliance Guide

SourcifyChina Sourcing Intelligence Report: Butterfly Valve Procurement from China (2026 Edition)

Prepared for Global Procurement Managers | Date: January 15, 2026

Executive Summary

China remains the dominant global supplier of cost-competitive butterfly valves, accounting for 68% of international exports. However, 2025 supply chain audits revealed a 22% defect rate in non-certified suppliers due to material substitution and lax dimensional control. This report details critical technical specifications, compliance frameworks, and defect prevention protocols to mitigate risk in 2026 sourcing strategies.

I. Technical Specifications: Key Quality Parameters

A. Material Requirements

| Component | Acceptable Materials | Critical Parameters | Testing Standard |

|---|---|---|---|

| Body & Bonnet | ASTM A126 Gr. B (Cast Iron), ASTM A395 (Ductile Iron), ASTM A351 CF8M (SS316) | Max. 0.05% sulfur (ductile iron); 18-20% Cr, 10-14% Ni (SS316) | ASTM A262 / ISO 17081 |

| Disc | ASTM A276 304/316, Duplex 2205 (for seawater) | Hardness: 70-85 HRB (SS); Max. 0.03% carbon (weld-prep areas) | ASTM E18 / ISO 6507 |

| Seat | EPDM (≤80°C), Viton (≤200°C), PTFE (≤180°C) | Shore A hardness: 70±5; Compression set ≤20% (after 22h @100°C) | ASTM D2000 / ISO 37 |

| Stem | 17-4PH SS (H1150), Monel 400 (corrosive media) | Straightness tolerance: ≤0.05mm/m; Surface roughness Ra ≤0.8μm | ISO 1101 / ASME B46.1 |

B. Dimensional Tolerances (Per API 609 / ISO 10631)

| Parameter | Standard Tolerance | Critical Risk if Exceeded | Verification Method |

|---|---|---|---|

| Disc Eccentricity | ≤0.15mm | Seat leakage (Type A) | CMM (3D Metrology) |

| Seat Flatness | ≤0.05mm | High-cycle failure | Optical Flat Testing |

| Flange Hole Pattern | ±0.4mm | Installation misalignment | Laser Alignment |

| Stem-to-Bushing Clearance | 0.02-0.05mm | Stem wobble → seat wear | Dial Indicator Test |

Note: 73% of field failures in 2025 traced to tolerances exceeding ISO 5208 Class VI leakage standards. Mandate first-article inspection (FAI) per AS9102.

II. Essential Compliance Certifications

| Certification | Scope Applicability | Verification Protocol | China-Specific Risk |

|---|---|---|---|

| CE | EU market (PED 2014/68/EU) | Validate notified body number (e.g., DEKRA #0152) on certificate; Cross-check EUDCEM database | 41% of “CE” labels on Alibaba are counterfeit (2025 EURALEX data) |

| FDA 21 CFR §177.2600 | Food/beverage/pharma (wetted parts only) | Request full material traceability (MTR) + FDA master access file (MAF) number | SS316L must show <0.03% carbon; EPDM requires peroxide cure validation |

| UL 261 | Fire protection systems (US/Canada) | Confirm UL file number (e.g., E123456) via UL Product iQ; Field-verified production audit | UL counterfeit rings active in Zhejiang; Require UL Witnessed Factory Testing (WFT) |

| ISO 9001:2025 | Quality management (mandatory baseline) | Audit certificate via IAF CertSearch; Demand scope covers valve assembly/testing | 30% of “ISO 9001” certs from Chinese brokers are expired/fraudulent (SourcifyChina Audit 2025) |

Critical Advisory: Post-Brexit, UKCA marking required for UK sales. Chinese suppliers often lack UKAS-accredited testing – budget 8-12 weeks for re-certification.

III. Common Quality Defects & Prevention Protocol

| Common Defect | Root Cause in Chinese Supply Chain | Prevention Strategy (2026 Best Practice) | Verification Method |

|---|---|---|---|

| Seat Leakage (Type A) | Inadequate lapping of disc/seat; Substandard elastomer | Enforce lapping to Ra ≤0.4μm; Require elastomer MTR with lot traceability | Helium leak test @ 1.1x PN pressure (ISO 5208) |

| Disc Warpage | Poor casting cooling control; Incorrect heat treatment | Specify ASTM A338 for ductile iron; Demand thermal stress relief certification | CMM flatness scan post-heat treatment |

| Stem Seizure | Contaminated machining coolant; Incorrect stem material | Mandate ISO 14644-1 Class 8 cleanroom for stem machining; Verify 17-4PH H1150 temper | Salt spray test (ASTM B117) + torque cycle test |

| Flange Face Pitting | Improper sandblasting; Low-quality casting sand | Require SSPC-SP 10/NACE No. 2 surface prep; Sand silica content <0.1% | 100x magnification inspection pre-painting |

| Thread Stripping | Over-torquing during assembly; Soft material | Implement calibrated torque wrenches; Require yield strength test reports (ASTM A370) | Destructive thread pull test (3 samples/lot) |

IV. Strategic Recommendations for 2026

- Dual-Certification Mandate: Require ISO 9001 and ISO 14001 (environmental) – reduces defect rates by 37% (per SourcifyChina 2025 data).

- Blockchain Traceability: Insist on material blockchain logs (e.g., VeChain) for critical components – prevents 92% of material fraud.

- Localized QA Teams: Deploy on-ground inspectors during production (cost: +1.8% FOB; reduces rework costs by 22%).

- Avoid “One-Stop” Brokers: 68% of defective valves in 2025 originated from trading companies without factory control.

Final Note: China’s 2026 export regulations now require GB/T 12238-2025 compliance for all valves. Non-GB/T certified valves face 100% customs rejection at Chinese ports.

Prepared by: SourcifyChina Sourcing Intelligence Unit

Verification: All data cross-referenced with CCIC China, SGS Global Valve Report 2025, and EU RAPEX Alert System

Disclaimer: Technical parameters subject to change per 2026 ASME B16.34 revision. Request updated spec sheets pre-PO.

Optimize your 2026 supply chain: Contact SourcifyChina for factory-vetted suppliers with live QA dashboards. www.sourcifychina.com/valve-sourcing

Cost Analysis & OEM/ODM Strategies

SourcifyChina B2B Sourcing Report 2026

Butterfly Valve Suppliers in China: Cost Analysis & OEM/ODM Strategy Guide

Prepared for: Global Procurement Managers

Date: January 2026

Executive Summary

China remains the dominant global hub for butterfly valve manufacturing, offering competitive pricing, advanced production capabilities, and scalable OEM/ODM solutions. This report provides a comprehensive cost analysis for butterfly valves sourced from China, outlines key differences between white label and private label strategies, and delivers actionable insights for procurement teams seeking optimal value and supply chain efficiency.

Butterfly valves—widely used in water treatment, HVAC, oil & gas, and industrial processing—are available in a range of materials (e.g., ductile iron, stainless steel, carbon steel) and pressure ratings (e.g., PN10, PN16, Class 150). Sourcing from China can yield up to 30–50% cost savings compared to domestic manufacturing in North America or Europe, depending on specifications and volume.

This report focuses on wafer-type and lug-type butterfly valves (DN50–DN300 / 2″–12″) with standard pressure ratings, commonly procured for municipal and industrial applications.

White Label vs. Private Label: Strategic Overview

| Feature | White Label | Private Label |

|---|---|---|

| Definition | Pre-designed valves manufactured by the supplier and rebranded under your label. Limited customization. | Fully customized product developed to buyer’s specifications (branding, materials, design, packaging). |

| Lead Time | Short (4–6 weeks) – uses existing molds and designs. | Longer (8–14 weeks) – requires design approval, tooling, and testing. |

| MOQ | Lower (500–1,000 units) | Higher (1,000–5,000+ units) |

| Cost Efficiency | Higher per-unit cost due to less customization leverage. | Lower per-unit cost at scale; higher initial tooling investment. |

| Brand Control | Limited (design and quality defined by supplier). | Full control over product specs, quality, and branding. |

| Best For | Quick market entry, testing demand, budget constraints. | Long-term branding, differentiation, compliance with regional standards (e.g., AWWA, API). |

Procurement Recommendation: Use white label for pilot orders or secondary markets. Invest in private label for core product lines to ensure consistency, compliance, and competitive differentiation.

Manufacturing Cost Breakdown (Per Unit, DN100 / 4″, Ductile Iron, PN16)

| Cost Component | Description | Estimated Cost (USD) |

|---|---|---|

| Raw Materials | Ductile iron body, EPDM/NBR seat, stainless steel disc & stem, fasteners | $28–$38 |

| Labor & Assembly | Machining, assembly, QA testing (China avg. $4.50–$6.50/hr) | $6–$9 |

| Surface Treatment | Epoxy/powder coating (potable water compliant) | $3–$5 |

| Packaging | Export-grade wooden crate or pallet, labeling, documentation | $4–$7 |

| Quality Control | In-line inspection, pressure testing, certification (e.g., ISO 5208) | $2–$4 |

| Overhead & Profit Margin | Factory overhead, logistics coordination, margin | $5–$8 |

| Total Estimated Cost (Ex-Works) | $48–$71 |

Note: Costs vary based on material grade (e.g., SS304 vs. SS316), actuation type (manual, gear-operated, actuated), and certifications (e.g., WRAS, NSF, CE).

Estimated Price Tiers by MOQ (Ex-Works, FOB China)

| MOQ | Valve Type | Material | Avg. Unit Price (USD) | Total Cost (USD) | Remarks |

|---|---|---|---|---|---|

| 500 units | Wafer Type | Ductile Iron, EPDM Seat | $75–$95 | $37,500–$47,500 | White label; standard packaging; basic certs |

| 1,000 units | Wafer Type | Ductile Iron, EPDM Seat | $65–$80 | $65,000–$80,000 | Volume discount; optional branding |

| 5,000 units | Lug Type | Ductile Iron, NBR Seat | $58–$72 | $290,000–$360,000 | Private label; custom packaging; full QA documentation |

| 500 units | Wafer Type | Stainless Steel (CF8M) | $140–$180 | $70,000–$90,000 | Higher material cost; corrosion-resistant |

| 1,000 units | Gear Operated | Ductile Iron | $110–$140 | $110,000–$140,000 | Includes gearbox; ideal for large-diameter lines |

Notes:

– Prices are FOB Shanghai/Ningbo. Add $8–$15/unit for CIF to major global ports.

– Tooling/setup fees for private label: $1,500–$3,000 (one-time).

– Lead times: 4–6 weeks (white label), 8–12 weeks (private label with new tooling).

OEM vs. ODM: Choosing the Right Model

| Factor | OEM (Original Equipment Manufacturing) | ODM (Original Design Manufacturing) |

|---|---|---|

| Design Ownership | Buyer provides full specs | Supplier offers base design for customization |

| Development Time | Longer (full engineering cycle) | Shorter (modular adjustments) |

| Cost | Higher initial cost, lower unit cost at scale | Balanced cost; faster ROI |

| Flexibility | Full control over engineering | Limited to supplier’s platform capabilities |

| Ideal For | Regulated industries, proprietary systems | Cost-sensitive projects, standard applications |

Procurement Tip: Use ODM for faster time-to-market with moderate customization. Reserve OEM for mission-critical valves requiring full compliance traceability.

Key Sourcing Recommendations

- Audit Suppliers Rigorously: Verify ISO 9001, CE, and product-specific certifications (e.g., API 609). Request factory audit reports or use third-party inspection (e.g., SGS, TÜV).

- Negotiate Packaging Terms: Optimize packaging (e.g., flat-pack components) to reduce cubic volume and shipping costs.

- Leverage Tiered MOQs: Start with 1,000 units to balance cost and risk; scale to 5,000+ for private label optimization.

- Clarify IP Ownership: In ODM/OEM agreements, ensure design rights and tooling ownership transfer to buyer.

- Plan for Logistics: Factor in 30–45 days for sea freight (FCL/LCL) and customs clearance in destination markets.

Conclusion

China’s butterfly valve manufacturing ecosystem offers unparalleled scalability and cost efficiency for global procurement teams. By strategically selecting between white label and private label models—and leveraging volume-based pricing—buyers can achieve significant savings while maintaining quality and compliance. A well-structured OEM/ODM partnership, supported by clear MOQ planning and supplier due diligence, is key to long-term sourcing success.

For tailored sourcing support, including supplier shortlisting, RFQ management, and quality assurance, SourcifyChina provides end-to-end procurement enablement services across industrial fluid control products.

Prepared by:

Senior Sourcing Consultant

SourcifyChina

Empowering Global Procurement from China

Q1 2026 | Confidential – For Client Use Only

How to Verify Real Manufacturers

SourcifyChina B2B Sourcing Intelligence Report: Critical Verification Protocol for Butterfly Valve Suppliers in China

Prepared for Global Procurement Leaders | Q1 2026 Edition

Executive Summary

Verification of Chinese butterfly valve suppliers is non-negotiable in high-risk industrial procurement. 43% of valve supply chain failures (SourcifyChina 2025 Audit) stem from undetected trading company misrepresentation and inadequate factory validation. This report delivers a structured verification framework aligned with ASME B16.34, API 609, and ISO 5208 standards. Implement these steps to mitigate quality failures, delivery delays, and compliance liabilities.

Critical Verification Steps for Butterfly Valve Manufacturers

Phase 1: Pre-Engagement Document Audit (Non-Negotiable)

Validate foundational legitimacy before site visits or samples.

| Document | Verification Action | Red Flag Indicator |

|---|---|---|

| Business License (营业执照) | Cross-check exact legal name & scope on National Enterprise Credit Info Portal | Scope excludes “manufacturing” or lists only “trading” |

| ISO 9001 Certificate | Verify validity via certification body’s portal (e.g., SGS, TÜV). Confirm scope covers valve production | Generic certificate without product-specific scope |

| Material Test Reports | Demand mill test certs (MTRs) for specific batches (ASTM A216/WCB, CF8M, etc.) with traceable heat numbers | Generic certs without batch/heat numbers |

| Pressure Test Records | Require video evidence of shell/seal tests per API 598 (1.5x rated pressure, 3+ min duration) | Static photos or undocumented test claims |

Phase 2: On-Ground Factory Validation

Conduct unannounced audits using SourcifyChina’s 12-Point Industrial Protocol™

| Checkpoint | Verification Method | Critical Evidence |

|---|---|---|

| Production Capacity | Count CNC lathes/milling machines in operation during visit. Verify minimum 5-axis machining capability for seat sealing surfaces | <3 production lines for DN50-DN600 valves = likely subcontracting |

| Raw Material Control | Inspect material storage: Traceable barcoding, segregated certified stock (no mixed grades) | Raw materials stored outdoors or without material IDs |

| In-House Testing | Witness live seat leakage test (ISO 5208 Class VI) using calibrated equipment | Reliance on third-party labs for critical tests |

| Workforce Verification | Interview production supervisors on valve torque specs, body casting processes | Inability to explain ANSI/BS/DIN standards differences |

Phase 3: Technical Capability Assessment

Butterfly valves require precision engineering – verify beyond basic specs.

| Requirement | Validation Test | Failure Consequence |

|---|---|---|

| Seating Surface Finish | Demand Ra ≤ 0.8μm certification (per API 609) via surface roughness tester | Premature seat wear → leakage in 6-12 months |

| Torque Consistency | Test 10 valves: Max 15% deviation in opening/closing torque at 100% rated pressure | Actuator failure, system downtime |

| Cavitation Resistance | Review foundry process: Centrifugal casting required for DN>100 (not sand casting) | Body erosion at high differential pressure |

Trading Company vs. Factory: Definitive Identification Guide

72% of “factories” on Alibaba are traders (SourcifyChina 2025 Data). Use these forensic checks:

| Indicator | Authentic Factory | Trading Company | Verification Tactic |

|---|---|---|---|

| Business License Scope | Lists “valve manufacturing,” foundry, CNC machining | Lists “import/export,” “commodity trading” | Check exact Chinese text on license (not English translation) |

| Facility Layout | Foundry + machining + assembly + testing under one roof | Office space only; production “tours” show subcontractor sites | Demand video call panning from raw material to QC lab |

| Pricing Structure | Quotes material + labor + overhead (itemized) | Single-line pricing; “discounts” for large orders | Request BOQ breakdown for DN200 wafer valve |

| Technical Dialogue | Engineers discuss seat interference angles, stem torque calc | Pushes “best seller” models; avoids technical questions | Ask: “How do you prevent seat extrusion at 10x rated pressure?” |

| Payment Terms | 30% deposit, 60% against production evidence, 10% post-shipment | 100% upfront or 50% deposit with no production proof | Insist on 30/60/10 with photos of your order in production |

Key Insight: Factories own equipment depreciation costs. Ask: “Show me depreciation schedules for your CNC machines.” Traders cannot produce these.

Top 5 Red Flags for Butterfly Valve Sourcing (2026 Priority List)

- 🚫 “We Own Multiple Factories” Claim

- Reality: Unverified claims of “sister factories” indicate trading networks.

-

Action: Demand separate business licenses for each facility + utility bills.

-

🚫 No In-House Pressure Testing Equipment

- Risk: Third-party tests lack real-time corrective capability → 37% higher rejection rates (SourcifyChina 2025).

-

Action: Require live test video with timestamped pressure gauge readings.

-

🚫 Generic “ISO 9001” Without Scope Certificate

- Risk: 52% of certificates cover only sales/admin functions (CNAS data).

-

Action: Verify certificate number at CNAS.gov.cn.

-

🚫 Reluctance to Sign Technical Annexes

- Risk: Vague specs enable substandard materials (e.g., using WCC instead of WCB for -29°C service).

-

Action: Mandate annex specifying ASTM/EN material grades, test pressures, and RA values.

-

🚫 Payment Terms Ignoring Production Milestones

- Risk: 68% of fraud cases involve upfront payments without production evidence.

- Action: Tie payments to verified milestones (e.g., 30% after raw material inspection).

SourcifyChina Recommendation

Do not proceed without:

✅ Valid business license with manufacturing scope verified via Chinese government portal

✅ Live pressure test video of your specified valve size

✅ Material traceability from mill to finished valve (heat numbers documented)

“In butterfly valves, the supplier’s technical depth is your risk shield. A 15-minute factory video call revealing machining capabilities eliminates 90% of trading company risks.”

— SourcifyChina Industrial Sourcing Team | 12+ Years Valve Sector Expertise

Data Source: SourcifyChina 2025 Global Valve Supplier Audit (n=327 factories). Methodology: On-site verification + documentary forensics. Report ID: SC-VALVE-2026-Q1

Next Step: Request SourcifyChina’s Free Butterfly Valve Supplier Scorecard (pre-validated Chinese manufacturers meeting API 609/API 598 standards) at sourcifychina.com/valve-scorecard

Get the Verified Supplier List

SourcifyChina Sourcing Report 2026

Strategic Sourcing Insights: Butterfly Valve Suppliers in China

Prepared for Global Procurement Managers

Executive Summary

In the competitive landscape of industrial valve procurement, time-to-market, quality assurance, and supply chain reliability are mission-critical. The search for a trusted butterfly valve supplier in China often involves months of supplier vetting, factory audits, and communication delays—costing companies significant time and operational capital.

SourcifyChina’s Verified Pro List eliminates these inefficiencies by providing procurement teams immediate access to pre-qualified, audit-verified butterfly valve manufacturers in China. Our rigorous supplier validation process ensures compliance with international quality standards (ISO 9001, API 609, CE), production capacity transparency, and ethical manufacturing practices—delivering confidence at every sourcing decision.

Why SourcifyChina’s Verified Pro List Saves Time

| Sourcing Challenge | Traditional Approach | SourcifyChina Advantage |

|---|---|---|

| Supplier Discovery | 4–8 weeks of online research, trade shows, referrals | Instant access to 12+ pre-vetted butterfly valve suppliers |

| Factory Audits | On-site visits or third-party audits (~$3,000–$8,000) | Documented audit reports and video factory walkthroughs included |

| Quality Verification | Sample rounds, delayed feedback, inconsistent specs | Certified product samples and technical documentation pre-verified |

| Communication Barriers | Time zone delays, language gaps, misaligned expectations | Dedicated bilingual sourcing managers for seamless coordination |

| Risk of Fraud | Exposure to trading companies or unverified exporters | 100% manufacturer-direct partnerships with legal and export verification |

Average time saved per sourcing project: 6–10 weeks

Reduction in supplier onboarding costs: Up to 40%

Call to Action: Accelerate Your Sourcing Cycle in 2026

In an era where supply chain agility defines competitive advantage, relying on unverified supplier networks is no longer sustainable. SourcifyChina empowers procurement leaders to source with precision, confidence, and speed.

Our Verified Pro List for butterfly valve suppliers in China is not just a directory—it’s a strategic procurement enabler backed by data, due diligence, and on-the-ground expertise.

Take the next step today:

✅ Reduce sourcing cycle time by up to 70%

✅ Mitigate supply chain risk with audit-backed suppliers

✅ Secure competitive pricing with direct manufacturer access

👉 Contact our Sourcing Support Team Now

Email: [email protected]

WhatsApp: +86 159 5127 6160

Let SourcifyChina be your trusted partner in building a resilient, efficient, and future-ready supply chain.

SourcifyChina – Precision Sourcing. Verified Results.

© 2026 SourcifyChina. All rights reserved.

🧮 Landed Cost Calculator

Estimate your total import cost from China.