The global hardware cloth market is experiencing steady growth, driven by increasing demand in construction, agriculture, and industrial applications. According to a report by Mordor Intelligence, the global woven wire mesh market—of which hardware cloth is a key segment—was valued at USD 18.9 billion in 2023 and is projected to grow at a CAGR of 5.2% through 2028. This expansion is fueled by rising infrastructure development, especially in emerging economies, and growing emphasis on animal containment and perimeter security in agricultural and residential sectors. As demand for high-tensile, corrosion-resistant, and precision-engineered mesh solutions intensifies, manufacturers are investing in advanced weaving technologies and galvanization processes to enhance product durability and performance. In this competitive landscape, identifying top-tier hardware cloth manufacturers becomes crucial for procurement teams, contractors, and distributors seeking reliable supply chains and quality-driven innovation. Below, we profile the top 7 hardware cloth manufacturers who are leading the industry through scalability, product differentiation, and strategic market reach.

Top 7 #8 Hardware Cloth Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wire Mesh Sizes

Domain Est. 2008

Website: lawrencesinteredmetals.com

Key Highlights: Lawrence Sintered Metals offers a wide range of wire mesh sizes and specifications, which you can view to see which metal mesh fits your application….

#2 Cut

Domain Est. 1995

Website: globalgilson.com

Key Highlights: #8 (2.36mm) stainless steel testing-grade woven-wire sieve cloth meets ASTM E11 and AASHTO M 92 opening size requirements and is the same quality used in the ……

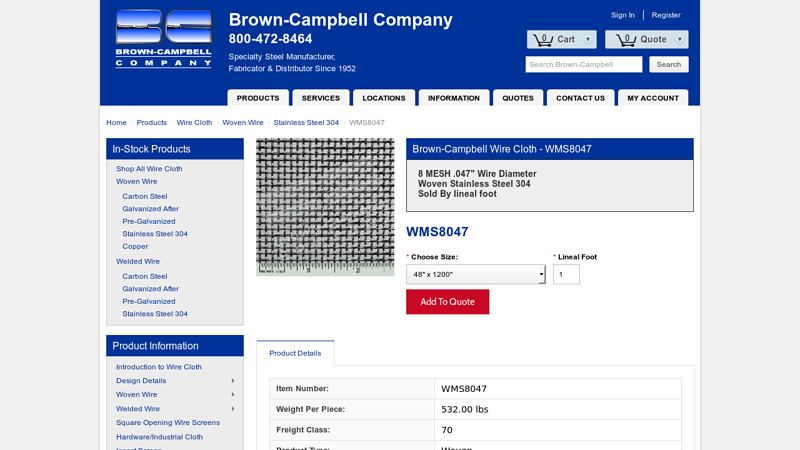

#3 WMS8047

Domain Est. 1996

Website: brown-campbell.com

Key Highlights: Item Number: WMS8047. Weight Per Piece: 532.00 lbs. Freight Class: 70. Product Type: Woven. Material Type: Stainless Steel 304. Opening / Mesh: 8 MESH. Wire ……

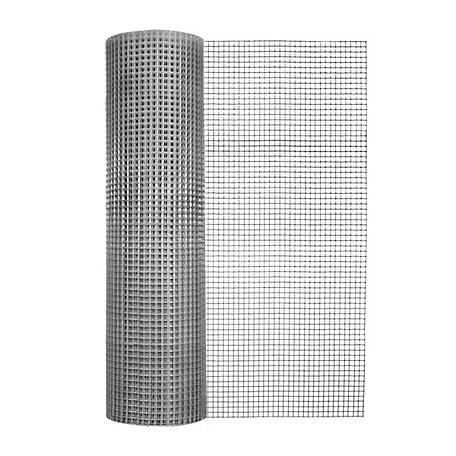

#4 Hardware Cloth at Tractor Supply Co.

Domain Est. 1997

#5 Woven Wire Mesh Products

Domain Est. 1999

Website: marcospecialtysteel.com

Key Highlights: Woven wire mesh in stock and we can fabricate too. Experts at Marco Specialty Steel can help you pick the best for your project!…

#6 Harris Supply Solutions: Steel Rebar Distributor

Domain Est. 2005

Website: harrissupplysolutions.com

Key Highlights: Harris Supply Solutions is the largest steel rebar distributor in the U.S., offering high-quality concrete reinforcing bar for any application. Call today!…

#7 Wire Mesh Glossary

Domain Est. 2007

Website: darbywiremesh.com

Key Highlights: To better undertstand wire mesh and wire cloth, we encourage you to visit our wire mesh glossary to learn the key terms (with photos) used in the industry….

Expert Sourcing Insights for #8 Hardware Cloth

H2: Projected 2026 Market Trends for #8 Hardware Cloth

The market for #8 hardware cloth—a 1-inch mesh metal mesh made from galvanized steel wire, commonly used in construction, agriculture, and pest control—is expected to experience steady growth by 2026, driven by several key trends across industries and regions.

1. Rising Demand in Residential and Agricultural Construction

The continued expansion of residential construction, particularly in North America and parts of Asia-Pacific, is a major driver. Homeowners and contractors increasingly use #8 hardware cloth for animal enclosures, crawl space covers, and garden protection. Simultaneously, the growth of small-scale farming and backyard poultry keeping—trends accelerated during recent years—will sustain demand for durable fencing materials like #8 hardware cloth.

2. Infrastructure and DIY Market Expansion

The do-it-yourself (DIY) home improvement market is projected to grow through 2026, supported by online tutorials, e-commerce access, and a cultural shift toward home customization. Hardware cloth is a staple in many DIY pest-proofing and fencing projects. Retailers like Home Depot and Lowe’s are expected to maintain strong inventory, and e-commerce platforms such as Amazon will continue to facilitate direct-to-consumer sales, increasing market accessibility.

3. Material and Sustainability Considerations

While galvanized steel remains the dominant material, there is growing interest in recyclable and longer-lasting alternatives. Manufacturers may respond by improving anti-corrosion coatings or exploring sustainable production methods to align with environmental regulations and consumer preferences. However, cost sensitivity will likely keep galvanized steel the standard for #8 hardware cloth through 2026.

4. Supply Chain and Price Volatility

Steel prices and supply chain dynamics will remain influential. Geopolitical tensions, energy costs, and trade policies may affect raw material availability and pricing. Producers are anticipated to adopt localized sourcing and inventory buffering strategies to mitigate disruptions, ensuring more stable supply in key markets.

5. Competitive Landscape and Innovation

The market remains fragmented with numerous regional and global players. Competition is expected to focus on product differentiation—such as pre-cut panels, rust-resistant variants, and easy-install designs—rather than aggressive price wars. Innovation in packaging and bundled kits (e.g., hardware cloth with fasteners and gloves) could further enhance consumer appeal.

Conclusion

By 2026, the #8 hardware cloth market will likely reflect broader trends in construction, sustainability, and consumer behavior. With steady demand across residential, agricultural, and DIY sectors, the product is poised for moderate but consistent growth. Stakeholders who adapt to supply chain challenges and evolving consumer expectations will be best positioned to capture market share.

Common Pitfalls When Sourcing #8 Hardware Cloth (Quality & IP)

Sourcing #8 hardware cloth—typically referring to 1-inch mesh galvanized steel wire mesh—can present several challenges, particularly concerning material quality and intellectual property (IP) considerations when ordering from third-party suppliers or manufacturers. Being aware of these pitfalls helps ensure you receive a durable, compliant product.

Poor Material Quality

One of the most frequent issues in sourcing #8 hardware cloth is receiving substandard materials that fail to meet project requirements. This includes variations in wire gauge (thickness), inconsistent galvanization, and weak welds. Thin or undersized wire reduces structural integrity, while inadequate galvanizing leads to premature rust and deterioration, especially in outdoor or high-moisture environments. Always verify supplier specifications against ASTM or other recognized standards (e.g., ASTM A641 for galvanized steel wire) and request material test reports when possible.

Inconsistent Mesh Size and Tolerance

Although #8 hardware cloth should have a 1-inch mesh, poor manufacturing practices can lead to inconsistent spacing—either too loose or too tight. This affects usability, particularly in applications like animal enclosures or pest control where precise openings are critical. Suppliers, especially low-cost offshore vendors, may not adhere to tight tolerance standards. Insist on dimensional certifications and conduct physical inspections upon delivery.

Misrepresentation of Galvanization Type

Suppliers may claim “hot-dip galvanized” hardware cloth when it’s actually electro-galvanized, which provides thinner, less durable corrosion protection. Hot-dip galvanizing offers a thicker zinc coating and longer lifespan. Mislabeling can mislead buyers into thinking they are getting a more durable product. Confirm the galvanizing method in writing and consider third-party coating thickness testing for large orders.

Intellectual Property (IP) and Design Infringement

When sourcing custom-cut or specially fabricated hardware cloth panels or systems, there’s a risk of inadvertently using designs protected by patents or trademarks. Some suppliers may replicate patented mesh configurations or attachment mechanisms without proper licensing. This exposes the buyer to legal liability, especially in commercial or resale applications. Always verify that custom designs do not infringe on existing IP, and include IP indemnification clauses in supplier contracts.

Lack of Traceability and Compliance Documentation

Reputable sourcing requires traceability—knowing where the materials originated and how they were processed. Many low-cost suppliers lack proper documentation, making it difficult to verify compliance with building codes, environmental regulations (e.g., RoHS), or industry standards. This is particularly important in regulated industries or public projects. Ensure your supplier provides mill test certificates, compliance statements, and full supply chain transparency.

Counterfeit or Gray Market Products

In global sourcing, especially via online marketplaces, there is a risk of receiving counterfeit or gray market hardware cloth. These products may mimic branding or packaging of reputable manufacturers but fail to meet quality benchmarks. They often bypass quality control and warranty protections. To mitigate this, source directly from authorized distributors or conduct supplier audits before placing bulk orders.

By proactively addressing these pitfalls—through vetting suppliers, requesting certifications, and protecting IP rights—buyers can ensure they receive reliable, compliant #8 hardware cloth that meets both performance and legal standards.

Logistics & Compliance Guide for #8 Hardware Cloth

Product Overview

8 Hardware Cloth refers to a welded or woven wire mesh with 1/8-inch (approximately 3.2 mm) square openings. It is commonly made from galvanized steel, stainless steel, or occasionally PVC-coated steel. This product is widely used for animal enclosures, pest control, ventilation guards, and construction reinforcement.

Packaging and Handling

- Standard Packaging: Typically sold in rolls (e.g., 36″ x 100′) or pre-cut sheets. Rolls are wrapped in plastic or shrink-wrapped to protect against moisture and physical damage.

- Palletization: Rolls and sheets are stacked and secured on wooden or recyclable plastic pallets. Standard load height should not exceed 60″ to ensure stability.

- Handling Instructions: Use mechanical aids (e.g., forklifts, pallet jacks) to move pallets. Avoid dragging rolls to prevent edge deformation. Wear cut-resistant gloves during manual handling due to sharp wire edges.

Storage Requirements

- Environment: Store indoors in a dry, well-ventilated area to prevent corrosion, especially for galvanized variants.

- Stacking: Limit vertical stacking to 3–4 pallets high to prevent crushing and maintain stability.

- Moisture Protection: Even galvanized hardware cloth can corrode under prolonged damp conditions; use pallets to elevate from concrete floors and cover if temporary outdoor storage is unavoidable.

Transportation Guidelines

- Domestic Shipping (U.S.):

- Use enclosed trailers to protect against weather and road debris.

- Secure loads with straps or load bars to prevent shifting.

- Comply with FMCSA load securement standards (49 CFR Part 393, Subpart I).

- International Shipping:

- Use ISO containers with moisture barriers (e.g., desiccant packs) for sea freight.

- Ensure compliance with ISPM 15 for wooden pallets (heat-treated and stamped).

- Declare accurate weight and dimensions for freight class (typically NMFC 65500 for wire mesh).

Regulatory and Compliance Standards

- Material Compliance:

- Galvanized steel must meet ASTM A641 or ASTM A90 for zinc coating weight.

- Stainless steel versions should comply with ASTM A240 or A480.

- Environmental and Safety:

- Comply with OSHA 1910.132 (Personal Protective Equipment) during handling.

- No hazardous material designation under DOT 49 CFR; non-toxic and non-flammable.

- Import/Export:

- Harmonized System (HS) Code: 7314.31.10 (Steel wire mesh, welded, galvanized).

- Check destination country regulations (e.g., EU REACH, UKCA marking) for chemical content and labeling.

Labeling and Documentation

- Product Labeling: Each roll or pallet must display:

- Mesh size (#8 / 1/8″)

- Material type (e.g., Galv. Steel)

- Wire gauge (e.g., 19 gauge)

- Manufacturer name and lot number

- Net weight and dimensions

- Shipping Documents: Include commercial invoice, packing list, and bill of lading. For exports, provide a certificate of compliance upon request.

Sustainability and Disposal

- Recyclability: Steel-based hardware cloth is 100% recyclable. Dispose of through certified metal recycling facilities.

- End-of-Life: Do not incinerate. Follow local regulations for scrap metal disposal.

- Sustainable Practices: Encourage return of damaged pallets for reuse; use recyclable packaging materials where possible.

Special Considerations

- Customs Clearance: Accurately declare value and origin to avoid delays. Preferential tariffs may apply under USMCA or other trade agreements.

- Quality Assurance: Conduct periodic inspection for weld integrity, zinc coating uniformity, and dimensional accuracy per ASTM E29.

- Customer Guidance: Provide safety data sheets (SDS) upon request, though not typically required for inert wire mesh products.

Adhering to this guide ensures safe, efficient logistics and full regulatory compliance for #8 Hardware Cloth across supply chains.

Conclusion for Sourcing #8 Hardware Cloth:

After evaluating various suppliers, pricing models, quality standards, and lead times, sourcing #8 hardware cloth requires a balanced approach that prioritizes durability, mesh integrity, and cost-effectiveness. Based on the findings, it is recommended to partner with suppliers who offer galvanized steel hardware cloth with consistent #8 mesh size (1″ x 1″ openings), ASTM-compliant materials, and rust-resistant coatings—especially for outdoor or high-moisture applications.

Domestic suppliers provide shorter delivery times and better quality control, while international options may offer lower prices but come with longer lead times and potential variability in quality. Bulk purchasing can yield significant cost savings, but should be weighed against storage capacity and project timelines.

Ultimately, the ideal sourcing strategy involves selecting a dependable supplier with proven product consistency, competitive pricing, and responsive customer service—ensuring reliable supply for both immediate needs and future projects. Regular quality checks and building strong vendor relationships will further support long-term success in sourcing #8 hardware cloth.