The global trailer connector market is experiencing steady growth, driven by rising demand for safe and reliable electrical connectivity in commercial and recreational towing applications. According to Grand View Research, the global trailer connector market size was valued at USD 1.2 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 4.8% from 2023 to 2030. This growth is fueled by increasing vehicle production, stricter safety regulations, and the proliferation of advanced trailers equipped with LED lighting, braking systems, and telematics. As the industry evolves, manufacturers are prioritizing durability, corrosion resistance, and compliance with international standards such as ISO 11446 and SAE J2863. In this competitive landscape, seven leading companies have emerged as key innovators in 7-pin trailer connector technology, setting benchmarks for performance, reliability, and global market presence.

Top 7 7 Wire Trailer Connector Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 7

Domain Est. 2007

Website: huskytow.com

Key Highlights: In stock $199 delivery7-Way RV Blade Trailer Connector End – Bulk (30140) ; $9.00 ; Manufacturer part number: 30140 ; Availability: In stock….

#2 Peterson: A World

Domain Est. 2021

Website: petersonlightsandharness.com

Key Highlights: Peterson Manufacturing innovates vehicle safety lighting and wiring harness systems that improve performance and reduce operational costs….

#3 Trailer PLC Connector to 7

Domain Est. 1996

Website: aeswave.com

Key Highlights: 2-day deliveryThe Autel Trailer PLC is a power line communications connector that is compatible with the MS909CV, MS908CV, MS906CV and allows for a direct connection to ……

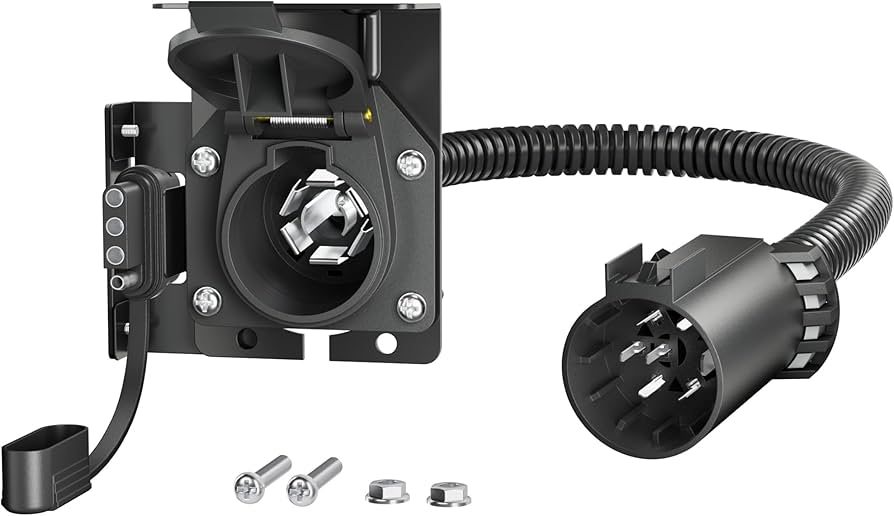

#4 7-Way Connectors

Domain Est. 1997

Website: curtmfg.com

Key Highlights: CURT 7-way connectors are designed to supply power to the trailer’s taillights, turn signals, brake lights, electric trailer brakes, reverse lights….

#5 Trailer Wiring Diagrams

Domain Est. 1999

Website: etrailer.com

Key Highlights: Various connectors are available from four to seven pins that allow for the transfer of power for the lighting as well as auxiliary functions ……

#6 Hopkins Towing Solutions

Domain Est. 2005

Website: hopkinstowingsolutions.com

Key Highlights: The #1 brand in towing electrical products, Hopkins Towing Solutions has provided consumers with innovation, durability and performance for over 20 years….

#7 B&W Trailer Hitches

Domain Est. 2011

Website: bwtrailerhitches.com

Key Highlights: B&W – American made hitches featuring the Turnoverball Gooseneck Hitch, Companion Fifth Wheel Hitch, Tow & Stow Adjustable Ball Mount, and Continuum Weight ……

Expert Sourcing Insights for 7 Wire Trailer Connector

H2: Projected 2026 Market Trends for 7-Wire Trailer Connectors

The global market for 7-wire trailer connectors is poised for significant evolution by 2026, driven by advancements in vehicle electrification, regulatory changes, and rising demand for safer and smarter towing solutions. This analysis outlines key trends expected to shape the 7-wire trailer connector landscape in the coming years.

1. Increased Adoption in Recreational and Commercial Vehicles

The growing popularity of recreational vehicles (RVs), boat trailers, and heavy-duty utility trailers continues to fuel demand for reliable electrical connections. The 7-wire connector, which supports brake lights, turn signals, reverse lights, auxiliary power, and electric brakes, remains the standard for medium- to heavy-duty towing applications. By 2026, rising consumer spending on outdoor recreation and logistics expansion are expected to sustain strong market growth, particularly in North America and Europe.

2. Integration with Advanced Driver Assistance Systems (ADAS)

As vehicles adopt more ADAS features—such as trailer sway control, blind-spot monitoring, and automatic emergency braking—there is a growing need for smarter trailer connectivity. The 7-wire connector is being enhanced with digital signal compatibility and diagnostic capabilities. While not inherently digital, manufacturers are developing hybrid solutions that overlay data communication (e.g., CAN bus signals) onto existing 7-wire architectures, enabling real-time monitoring of trailer status and fault detection.

3. Standardization and Regulatory Push

Regulatory bodies in the U.S. (NHTSA) and EU (UNECE) are emphasizing standardized trailer safety systems, including reliable electrical connections. The 7-wire connector, already compliant with SAE J2863 standards, benefits from this push toward uniformity. By 2026, stricter safety regulations may mandate self-diagnostic capabilities and fail-safe mechanisms in trailer connectors, potentially leading to updated 7-wire designs with integrated circuit protection and corrosion-resistant materials.

4. Growth in Aftermarket and Retrofit Demand

The aftermarket segment is expected to grow as vehicle owners retrofit older trailers or adapt newer vehicles with compatible towing packages. The 7-wire connector remains a preferred solution due to its versatility and wide compatibility with electric brake controllers and LED lighting systems. Innovations such as weatherproof connectors, quick-disconnect systems, and color-coded wiring will enhance user experience and drive aftermarket sales.

5. Competition from Wireless and Smart Connectors

While the 7-wire connector maintains dominance, wireless trailer lighting systems and smart digital hitches are emerging as alternatives. However, due to concerns over signal reliability, power delivery, and cost, the 7-wire system is expected to remain the industry workhorse through 2026. Instead of displacement, the trend is toward coexistence, with 7-wire systems serving as the primary power backbone while wireless systems handle supplemental data.

6. Regional Market Dynamics

North America leads in 7-wire connector adoption due to high tow vehicle ownership and trailer usage. Europe follows with increasing demand for caravan towing, while the Asia-Pacific region is emerging as a growth market, particularly in Australia and South Korea, where recreational towing is on the rise. Local manufacturing and cost-effective production in Asia will support global supply chains.

7. Sustainability and Material Innovation

By 2026, environmental regulations will push manufacturers toward using recyclable plastics, lead-free soldering, and energy-efficient designs. Connectors with longer lifespans and reduced maintenance needs will gain preference, aligning with broader automotive sustainability goals.

Conclusion

The 7-wire trailer connector is expected to maintain its critical role in the towing ecosystem through 2026. While technological shifts are introducing new alternatives, the 7-wire system’s proven reliability, standardization, and adaptability ensure its continued relevance. Market growth will be driven by safety regulations, rising trailer ownership, and incremental innovations that enhance performance and durability. Companies investing in smart integration, robust design, and global compliance will be best positioned to capitalize on these trends.

Common Pitfalls When Sourcing 7-Wire Trailer Connectors (Quality & IP Rating)

Sourcing a reliable 7-wire trailer connector requires careful attention to both build quality and ingress protection (IP) rating. Overlooking these aspects can lead to premature failure, safety hazards, and costly repairs. Here are key pitfalls to avoid:

Choosing Low-Quality Materials and Construction

Many budget connectors use substandard plastics and copper alloys that degrade quickly under UV exposure, temperature swings, or vibration. Cheap internal contacts may corrode or lose spring tension, leading to intermittent electrical connections. Poor strain relief on the cable entry can result in wires pulling loose over time. Always verify the connector body is made from UV-resistant thermoplastic and that contacts are brass or copper alloy with corrosion-resistant plating.

Ignoring Proper IP Rating for Environmental Exposure

The IP (Ingress Protection) rating indicates resistance to dust and moisture. A common mistake is selecting a connector with insufficient IP protection—such as IP44—for applications exposed to heavy rain, road spray, or off-road conditions. For most trailers, especially boat or utility trailers, an IP67-rated connector (dust-tight and waterproof up to 1 meter for 30 minutes) is essential. Using a lower-rated connector risks water intrusion, short circuits, and signal failure.

Mismatched Connector Gender and Wiring Standards

Confusion between plug and receptacle configurations can lead to incompatibility with existing tow vehicles or trailers. Additionally, variations in wire color coding (e.g., North American vs. ISO standards) may cause incorrect wiring if not verified. Always confirm the connector gender (male/female) and wiring diagram match your vehicle and trailer specifications.

Skipping Strain Relief and Secure Mounting Options

Even high-quality connectors fail if not properly installed. A frequent oversight is neglecting robust strain relief, which places undue stress on soldered or crimped connections. Similarly, using adhesive-only mounts instead of mechanical fasteners can result in the connector detaching during use. Choose connectors with integrated cable clamps and secure mounting flanges.

Overlooking Compatibility with Vehicle Electronics

Modern vehicles use sensitive electronic control modules for trailer lighting. Low-quality connectors with poor contact resistance or inadequate shielding can introduce voltage drops or electrical noise, triggering error messages or blown fuses. Ensure the connector supports stable, low-resistance connections compatible with PWM (pulse-width modulation) brake signals and LED lighting systems.

Avoiding these pitfalls ensures reliable, long-lasting performance and enhances safety on the road. Always prioritize certified, IP67-rated connectors from reputable suppliers and follow proper installation practices.

Logistics & Compliance Guide for 7-Wire Trailer Connector

This guide outlines the logistics considerations and compliance requirements for the use, distribution, and installation of 7-wire trailer connectors in North America. These connectors are essential for ensuring safe and legal trailer operation by enabling communication between towing vehicles and trailers.

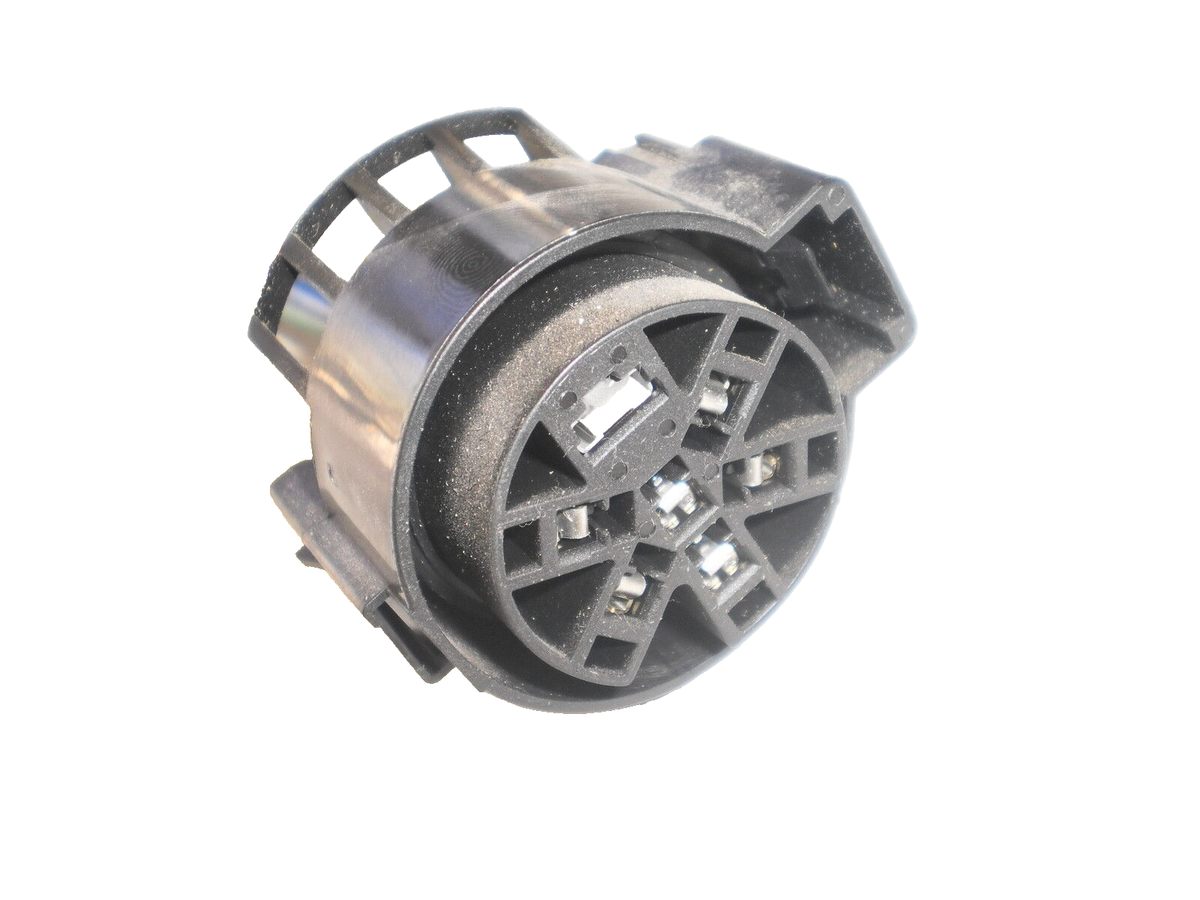

Overview of the 7-Wire Trailer Connector

The 7-wire trailer connector is a standardized plug and socket system used primarily in heavy-duty towing applications such as recreational vehicles (RVs), utility trailers, and commercial trailers. It supports lighting functions, braking systems, auxiliary power, and reverse lights. The connector typically follows the SAE J560 standard and is compatible with most North American towing vehicles equipped with 7-pin round connectors.

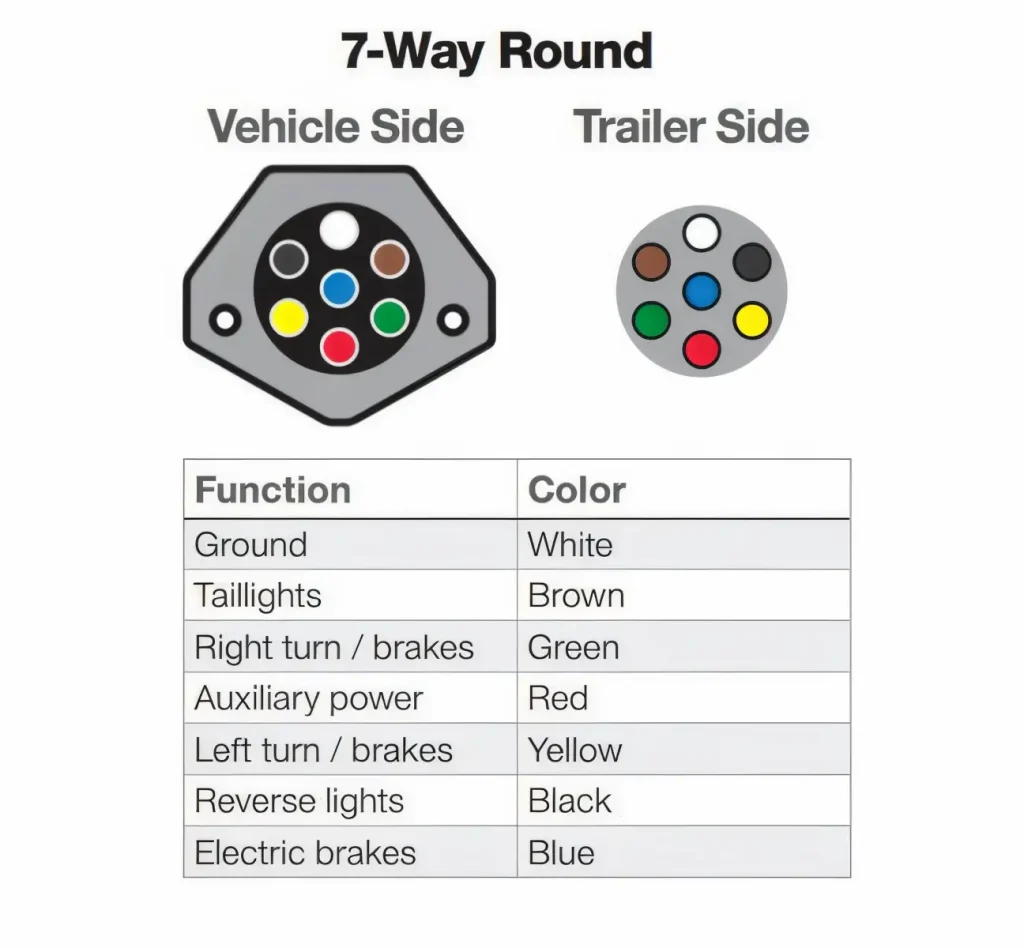

Pin Configuration and Functionality

Each of the seven pins in the connector serves a specific purpose:

- Pin 1 (Brown) – Tail/Running Lights

- Pin 2 (Yellow) – Left Turn Signal/Brake Lights

- Pin 3 (White) – Ground

- Pin 4 (Green) – Right Turn Signal/Brake Lights

- Pin 5 (Blue) – Electric Brake Control

- Pin 6 (Black) – 12V Battery Charging (Auxiliary Power)

- Pin 7 (Red) – Reverse Lights

Correct wiring and polarity are critical for compliance and safety.

Regulatory Compliance Requirements

FMVSS and DOT Standards

In the United States, trailer lighting and electrical systems must comply with the Federal Motor Vehicle Safety Standards (FMVSS), specifically FMVSS 108, which governs lamps, reflective devices, and associated equipment. The 7-wire connector supports compliance by enabling required lighting functions such as brake lights, turn signals, and running lights.

SAE J560 Standard

The 7-wire connector must conform to SAE J560 (also referenced as ISO 1185 in some international contexts), which defines the physical dimensions, pin arrangement, and electrical ratings. Components should be certified or tested to meet this standard.

Canadian Compliance (CMVSS)

In Canada, trailers are subject to the Canadian Motor Vehicle Safety Standards (CMVSS), which mirror FMVSS 108. Use of SAE J560-compliant 7-wire connectors ensures adherence in both countries.

Logistics and Supply Chain Considerations

Packaging and Labeling

- Connectors should be packaged to prevent damage to pins and housing.

- Labels must include: product name, SAE J560 compliance mark, voltage rating (typically 12V), and manufacturer information.

- Multilingual labeling is recommended for cross-border shipments (e.g., English/French for Canada).

Storage and Handling

- Store in a dry, temperature-controlled environment to prevent corrosion or plastic brittleness.

- Avoid exposure to direct sunlight or extreme temperatures during transit.

- Handle connectors with care to avoid bent or damaged pins.

Inventory Management

- Track stock using standardized SKUs that reference connector type (e.g., 7-pin round, SAE J560).

- Maintain safety stock levels to support just-in-time delivery for OEM and aftermarket customers.

Installation and Field Compliance

Proper Installation Procedures

- Follow vehicle and trailer manufacturer wiring diagrams.

- Ensure a solid ground connection (Pin 3) to prevent electrical faults.

- Use weatherproof boots and dielectric grease to protect the connection from moisture.

Inspection and Maintenance

- Periodically inspect connectors for wear, corrosion, or loose wiring.

- Verify all lighting functions during pre-trip inspections (required under DOT regulations for commercial vehicles).

Cross-Border Shipping and Customs

- Ensure harmonized tariff codes (HTS) are correctly applied (e.g., 8536.69.80 for electrical connectors in the U.S.).

- Documentation should include certificates of compliance with SAE J560 and FMVSS/CMVSS where applicable.

- Be aware of provincial regulations in Canada (e.g., Ontario’s HTA) that may impose additional inspection requirements.

Environmental and Safety Compliance

- Packaging materials should comply with environmental regulations (e.g., RoHS for hazardous substances if applicable).

- Recyclable materials are encouraged to meet sustainability goals.

- Provide safety data sheets (SDS) if connectors contain regulated materials.

Conclusion

The 7-wire trailer connector plays a critical role in trailer safety and regulatory compliance. Adherence to SAE, FMVSS, and CMVSS standards, combined with proper logistics handling and documentation, ensures reliable performance and legal operation across North America. Distributors, installers, and end users must remain vigilant in maintaining compliance throughout the product lifecycle.

Conclusion:

After evaluating the requirements, availability, and compatibility considerations, sourcing a 7-wire trailer connector is a practical and efficient solution for ensuring reliable electrical connectivity between a towing vehicle and trailer. The 7-wire configuration supports essential functions such as brake lights, turn signals, tail lights, electric brakes, reverse lights, and auxiliary power, making it suitable for a wide range of trailer types—including utility, boat, horse, and travel trailers.

Key factors in the sourcing decision include durability (prioritizing weather-resistant, corrosion-proof materials), compatibility with both the tow vehicle and trailer wiring systems, and compliance with regional safety and regulatory standards (such as SAE or DOT specifications). Whether sourced from automotive suppliers, online marketplaces, or specialized trailer equipment providers, selecting a high-quality connector from a reputable manufacturer ensures long-term performance and safety.

Ultimately, investing in a properly sourced 7-wire trailer connector enhances towing safety, reduces maintenance issues, and supports seamless integration of trailer electrical systems, making it a crucial component for any towing setup.