The global PVC-Al alloy ferrule market, particularly for 6-inch variants used in high-pressure fluid transfer systems, is experiencing steady growth driven by rising demand in construction, oil & gas, and industrial manufacturing sectors. According to a 2023 report by Mordor Intelligence, the global PVC piping systems market is projected to grow at a CAGR of 5.8% from 2023 to 2028, with Asia-Pacific leading in both production and consumption. This expansion is fueled by infrastructure investments and the increasing adoption of corrosion-resistant, lightweight piping solutions. As demand for reliable, high-performance ferrules intensifies, manufacturers are scaling innovation in material composition and production precision. Based on production capacity, export volume, product compliance (ISO 3419, DIN 8078), and market presence, we analyze the top five manufacturers leading the 6-inch PVC-Alve ferrule segment in 2024.

Top 5 6Inch Pvc Alve Ferrule Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Hart Industries, Inc.

Domain Est. 1995

Website: hose.com

Key Highlights: Hart Industries, Inc. is a Hose Supplier founded in Middletown, Ohio in 1967. We also sell products such as hose fittings, hose connectors, and valves….

#2 Shop our Ferrules and Sleeves for Industrial Hose Collection

Domain Est. 2012

#3 6in I

Domain Est. 1995

#4 Spears Manufacturing, PVC & CPVC Plastic Pipe Fittings & Valves

Domain Est. 1996

Website: spearsmfg.com

Key Highlights: ISO9001 Certified – PVC & CPVC Sch 40 and 80 fittings molded from 1/8 – 14 inch.Missing: 6inch alve ferrule…

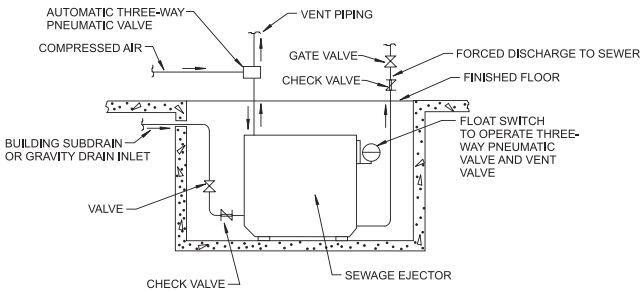

#5 CHAPTER 7 SANITARY DRAINAGE

Domain Est. 2002

Website: codes.iccsafe.org

Key Highlights: Chapter 7 regulates the methods and piping systems that remove water that has served a purpose such as flushing water closets, bathing, culinary activities and ……

Expert Sourcing Insights for 6Inch Pvc Alve Ferrule

H2: Analysis of 2026 Market Trends for 6-Inch PVC Alve Ferrule

The global market for 6-inch PVC Alve Ferrules is expected to undergo significant transformation by 2026, shaped by evolving construction demands, material innovation, regional infrastructure development, and sustainability imperatives. As a critical component in piping systems—particularly in water supply, irrigation, and drainage networks—the 6-inch PVC Alve Ferrule plays a vital role in ensuring leak-free, durable connections between PVC pipes and fittings. The following trends are projected to influence its market trajectory through 2026:

1. Rising Demand in Infrastructure and Urbanization

Accelerated urbanization, especially in emerging economies across Asia-Pacific, Africa, and Latin America, is driving growth in water infrastructure projects. Governments are investing heavily in municipal water networks, sewage systems, and rural electrification, directly boosting demand for standard-sized PVC fittings such as the 6-inch Alve Ferrule. The push for smart cities is further amplifying the need for reliable, corrosion-resistant piping components.

2. Shift Toward Durable and Sustainable Materials

Environmental regulations and green building certifications are favoring sustainable construction materials. PVC remains a preferred choice due to its longevity, low carbon footprint, and recyclability. Innovations in modified PVC compounds—such as CPVC and UV-stabilized variants—are enhancing the performance of Alve Ferrules in harsh environments, supporting market growth. Additionally, manufacturers are focusing on reducing volatile organic compound (VOC) emissions during production, aligning with global ESG standards.

3. Regional Market Dynamics

Asia-Pacific is anticipated to dominate the 6-inch PVC Alve Ferrule market by 2026, led by China, India, and Indonesia. These countries are expanding their water management systems to support growing populations and agricultural needs. In contrast, North America and Europe are experiencing moderate growth, driven primarily by infrastructure rehabilitation projects and replacement of aging pipelines. The Middle East is also emerging as a high-potential market due to large-scale desalination and irrigation initiatives.

4. Technological Advancements in Manufacturing

Automation and precision molding technologies are improving the consistency and quality of PVC ferrules. Injection molding with tighter tolerances ensures better sealing and reduced failure rates. Digital supply chain integration allows manufacturers to respond more efficiently to demand fluctuations, reducing lead times and inventory costs—key factors in maintaining competitiveness.

5. Competitive Landscape and Pricing Pressures

The market remains moderately fragmented, with both multinational corporations and regional players competing on price, quality, and distribution networks. Raw material price volatility—especially fluctuations in vinyl chloride monomer (VCM)—poses a challenge, prompting companies to adopt long-term supply agreements and explore cost-optimized designs. Private-label branding and e-commerce platforms are also reshaping distribution, particularly in B2B procurement.

6. Regulatory and Safety Standards

Compliance with international standards such as ISO 1452, ASTM D2466, and WRAS (UK) is becoming increasingly critical. These standards ensure the ferrule’s performance under pressure, chemical resistance, and suitability for potable water. As regulatory scrutiny intensifies, manufacturers are investing in certification processes to gain market access, especially in regulated markets like North America and Western Europe.

Conclusion

By 2026, the 6-inch PVC Alve Ferrule market is poised for steady growth, fueled by infrastructure expansion, material innovation, and regulatory alignment. Stakeholders who prioritize product quality, sustainability, and regional adaptability are likely to capture greater market share. Continued investment in R&D and digital supply chains will be essential to navigate evolving customer needs and remain competitive in a dynamic global landscape.

Common Pitfalls When Sourcing 6-Inch PVC Alve Ferrule (Quality and IP)

Sourcing a 6-inch PVC alve ferrule—commonly used in pipeline and industrial applications—requires careful attention to both quality standards and intellectual property (IP) considerations. Failure to address these aspects can lead to operational failures, legal issues, or financial losses. Below are key pitfalls to avoid.

Quality-Related Pitfalls

1. Substandard Material Composition

One of the most frequent issues is receiving ferrules made from low-grade PVC or non-compliant polymer blends. Inferior materials may not withstand pressure, temperature fluctuations, or chemical exposure, leading to premature failure. Always verify that the PVC meets relevant standards such as ASTM D1785 or ISO 1452.

2. Inconsistent Dimensional Accuracy

A 6-inch ferrule must adhere to precise dimensional tolerances to ensure proper fit and sealing. Poor manufacturing processes can result in variations in inner/outer diameter or wall thickness, compromising system integrity. Request dimensional inspection reports from suppliers before bulk procurement.

3. Lack of Certification and Testing Documentation

Reputable suppliers should provide test reports, pressure ratings, and compliance certificates (e.g., WRAS, NSF, or ISO 9001). Sourcing without these documents increases the risk of non-compliance with industry or regulatory requirements.

4. Poor Workmanship and Surface Defects

Visual defects such as cracks, bubbles, or uneven molding indicate poor production control. These flaws can become stress points under operational conditions, leading to leaks or ruptures. Conduct sample inspections or third-party quality audits when onboarding new suppliers.

Intellectual Property (IP) Pitfalls

1. Infringement of Patented Designs

Some alve ferrule designs, especially proprietary locking mechanisms or sealing configurations, may be protected by patents. Sourcing generic copies of patented products—even unknowingly—can expose your business to legal action. Conduct due diligence to ensure the product design does not infringe on existing IP.

2. Unauthorized Use of Trademarks or Branding

Suppliers may falsely label products with well-known brand names to imply quality or authenticity. Purchasing such counterfeit items not only violates trademark laws but also risks receiving subpar components. Always verify the authenticity of branding with the original equipment manufacturer (OEM).

3. Lack of IP Clarity in Custom Designs

If you’re sourcing custom-designed 6-inch PVC alve ferrules, ensure that ownership of design specifications, molds, and technical drawings is clearly defined in the contract. Without explicit IP agreements, suppliers may retain rights or reuse your designs for competitors.

4. Reverse Engineering Risks

Some suppliers may reverse-engineer competitor products to replicate functionality. While this may seem cost-effective, it can lead to IP litigation if the original design is protected. Avoid suppliers that cannot demonstrate original design capability or legal design sourcing.

By addressing these quality and IP-related pitfalls, businesses can ensure reliable performance, regulatory compliance, and legal safety in their procurement of 6-inch PVC alve ferrules.

Logistics & Compliance Guide: 6-Inch PVC Alve Ferrule

Product Overview

The 6-inch PVC Alve Ferrule is a plumbing or industrial component typically used for connecting or reinforcing piping systems. It is made from polyvinyl chloride (PVC), a lightweight and durable thermoplastic material. Proper logistics and compliance procedures are essential to ensure safe transportation, regulatory adherence, and product integrity.

Transportation & Packaging

Packaging Requirements

– Ferrules must be packed in sturdy, moisture-resistant corrugated cardboard boxes or reusable plastic containers.

– Use internal dividers or cushioning (e.g., foam inserts or bubble wrap) to prevent surface damage during transit.

– Label each package with product description, quantity, batch/lot number, and handling instructions (e.g., “Fragile,” “Do Not Stack”).

– Palletize shipments securely using stretch wrap and corner boards to protect edges.

Storage Conditions

– Store in a dry, well-ventilated area away from direct sunlight and extreme temperatures (ideally 10°C to 30°C).

– Avoid contact with oils, solvents, or corrosive chemicals that may degrade PVC.

– Elevate pallets off the floor to prevent moisture absorption.

Transportation Guidelines

– Suitable for road, rail, air, and sea freight.

– For international shipments, use ISPM 15-compliant wooden pallets or alternative non-wood materials.

– Ensure temperature-controlled environments if shipping through regions with extreme climates.

– Declare as non-hazardous material under IATA, IMDG, and ADR regulations.

Regulatory Compliance

Material Safety & Environmental Standards

– Confirm PVC material complies with REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulations in the EU.

– Ensure compliance with RoHS (Restriction of Hazardous Substances) directives, particularly regarding lead and phthalates.

– Verify adherence to ASTM D1785 or equivalent standards for PVC pipe fittings, where applicable.

Country-Specific Regulations

– United States: Comply with EPA and NSF/ANSI 14 & 61 standards if used in potable water systems.

– European Union: CE marking may be required depending on application; ensure conformity with Construction Products Regulation (CPR) if used in construction.

– Canada: Follow CSA B137.1 standards for PVC pressure fittings.

– Australia/NZ: Comply with AS/NZS 1477.

Customs Documentation

– Provide accurate HS Code: Typically 3917.33 (Plastic tubes, pipes, and hoses fittings, rigid, of PVC). Confirm with local customs authority.

– Include commercial invoice, packing list, certificate of origin, and material compliance certificates.

– For shipments to the EU, include an EU Responsible Person (if applicable under REACH).

Handling & Safety

Workplace Safety

– No special PPE required under normal handling conditions.

– In case of cutting or machining, use standard workshop PPE (gloves, safety glasses).

– Avoid prolonged inhalation of dust if sawing or grinding.

Disposal & Recycling

– PVC is recyclable under resin identification code 3.

– Dispose of waste in accordance with local environmental regulations.

– Do not incinerate without proper emission controls due to potential dioxin release.

Quality Assurance & Traceability

- Maintain batch records for traceability, including material source, production date, and test results.

- Conduct periodic quality checks for dimensional accuracy, material integrity, and surface defects.

- Provide certificates of compliance (CoC) and, if requested, material test reports (MTRs).

Summary

Proper logistics planning and regulatory compliance are critical for the safe and legal distribution of 6-inch PVC Alve Ferrules. Adherence to packaging, transportation, environmental, and regional standards ensures product reliability and market access. Always verify requirements with destination country regulations and industry-specific applications.

Conclusion for Sourcing 6-Inch PVC Alve Ferrule

After a thorough evaluation of suppliers, material specifications, cost implications, and quality standards, sourcing a 6-inch PVC alve ferrule requires a strategic approach focused on reliability, compliance, and long-term value. It is essential to partner with certified manufacturers or suppliers who adhere to industry standards (such as ASTM or ISO) to ensure product durability, chemical resistance, and structural integrity.

Key considerations include confirming the correct dimensions, pressure ratings, and compatibility with existing piping systems. Bulk pricing, lead times, and logistical capabilities should also be factored into the supplier selection process. Additionally, requesting product samples and conducting quality inspections prior to large-scale procurement can mitigate risks related to performance and installation.

In conclusion, successful sourcing of the 6-inch PVC alve ferrule hinges on balancing cost-effectiveness with quality assurance, supported by due diligence in supplier vetting and ongoing supply chain management. Establishing long-term relationships with reputable vendors will ensure consistent product availability and support for infrastructure or industrial applications.