The global market for electrical wiring and cabling products is experiencing steady growth, driven by rising infrastructure development, expanding industrial automation, and increased renewable energy installations. According to Mordor Intelligence, the global electrical wires and cables market was valued at USD 184.6 billion in 2023 and is projected to grow at a CAGR of 5.2% from 2024 to 2029. A critical component within this sector is 6/3 wire—commonly used in high-load applications such as electric ranges, subpanels, and RV hookups—demanding dependable manufacturing standards for ampacity, insulation, and durability. As demand for safe, code-compliant electrical solutions increases, so does the need for reliable 6/3 wire manufacturers capable of meeting rigorous performance specifications. This has elevated the prominence of leading producers who combine technical expertise, compliance with NEC standards, and scalable production capacity. The following analysis identifies the top four manufacturers of 6/3 wire based on product quality, industry reputation, technical specifications, and market presence.

Top 4 6/3 Wire Rating Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

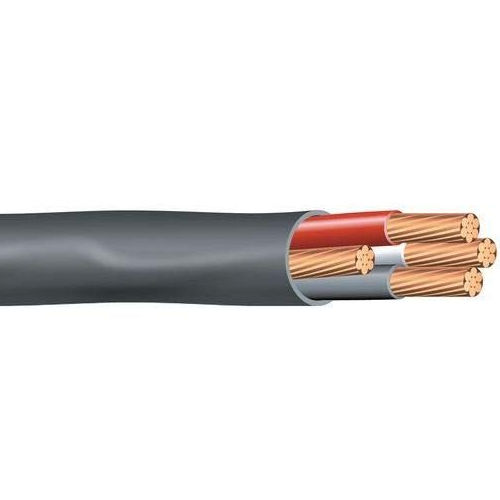

#1 Service Entrance Cable, Stranded, 6 AWG, 3 Conductors, Copper …

Domain Est. 1996

Website: stateelectric.com

Key Highlights: In stock $12 deliveryService Entrance Cable, Stranded, 6 AWG, 3 Conductors, Copper, Gray, 600 Volts. SKU: WCUSEU6/3. Manufacturer Part Number: SEU6/3. $3.87/foot….

#2 6

Domain Est. 1994

Website: southwire.com

Key Highlights: Specifications ; Cond. Size, 6 AWG 6 AWG ; Conductor Number, 3 3 ; Cond. Strands, 7 7 ; Diameter Over Conductor (in) (cm), 0.177 0.45, inch cm ; Insulation Thickness ……

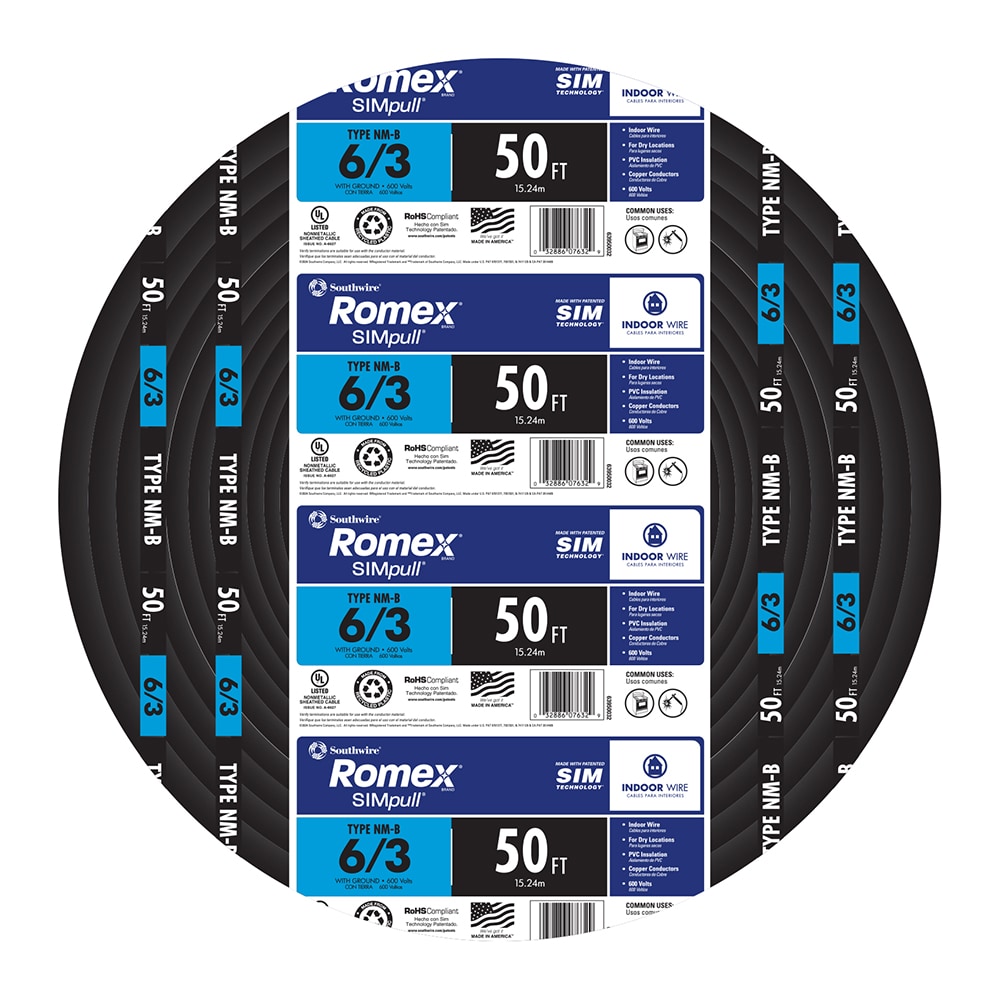

#3 6/3 NM

Domain Est. 2006

Website: marselectric.com

Key Highlights: Free delivery over $25 90-day returnsSouthwire Romex Brand SIMpull NM-B (nonmetallic-sheathed) cable may be used for both exposed and concealed work in normally dry locations at te…

#4 6/3 NM

Domain Est. 2015

Website: wireandcableyourway.com

Key Highlights: We sell by the foot, cut to length. This 6-gauge, 2-conductor black NM-B Wire works as a substitute for Romex. We also offer same day shipping….

Expert Sourcing Insights for 6/3 Wire Rating

H2: Projected 2026 Market Trends for 6/3 Wire Rating

The 6/3 wire, commonly used in residential and commercial electrical installations for high-power applications such as electric ranges, dryers, and subpanels, is expected to experience notable shifts in demand, technology, and regulation by 2026. This analysis outlines key market trends influencing the 6/3 wire rating segment over the next few years.

1. Increased Residential Construction and Renovation

The U.S. housing market is projected to remain robust through 2026, driven by ongoing urbanization and a growing demand for energy-efficient homes. As new housing units and renovation projects increase, so does the need for reliable electrical wiring solutions like 6/3 cable (typically rated for 55–60 amps at 60–75°C). Builders are increasingly specifying 6/3 NM-B (Romex) and USE-2 variants for branch circuits requiring higher current capacity, supporting market growth.

2. Electrification of Homes and Appliances

The transition toward all-electric homes—driven by environmental policies and incentives—will boost demand for 6/3 wire. Heat pumps, electric vehicle (EV) charging stations, induction cooktops, and electric water heaters often require dedicated 240V circuits, with many installations falling within the 50–60A range where 6/3 wire is standard. By 2026, widespread adoption of home electrification is expected to expand the use of 6/3 cable in both new builds and retrofits.

3. Regulatory and Safety Standards Evolution

The National Electrical Code (NEC), updated every three years, continues to emphasize safety and arc-fault protection. The 2026 NEC cycle may further tighten requirements for circuit protection and cable insulation, potentially influencing the adoption of advanced 6/3 wire variants with enhanced fire resistance or smart monitoring capabilities. Compliance with updated codes will drive demand for NEC-compliant 6/3 cables, particularly in high-density or multi-family developments.

4. Material and Supply Chain Dynamics

Copper prices remain a key factor affecting 6/3 wire costs. While aluminum-based 6/3 cables (e.g., SER or MC) offer cost savings, copper remains preferred for its conductivity and reliability in residential applications. Ongoing supply chain improvements and increased domestic copper production could stabilize pricing by 2026, making 6/3 copper wire more accessible. However, geopolitical factors and mining output may introduce volatility.

5. Growth in Renewable Energy Integration

As solar + storage systems become standard in homes, 6/3 wire is frequently used to connect inverters, battery systems, and main panels. With solar adoption expected to grow significantly by 2026—supported by federal tax credits and falling battery costs—this application will further drive demand for appropriately rated 6/3 cables, especially in configurations that handle bidirectional power flow.

6. Smart Building and IoT Integration

Though not directly related to wire rating, the rise of smart electrical panels and energy monitoring systems may impact installation practices. While 6/3 wire itself will remain fundamentally unchanged, its integration with intelligent load centers may require enhanced compatibility with low-voltage control systems and better labeling or shielding in future product designs.

Conclusion

By 2026, the market for 6/3 wire rating is poised for steady growth, fueled by construction activity, home electrification, regulatory updates, and clean energy trends. Manufacturers and distributors should anticipate higher demand, particularly for copper-based 6/3 NM-B and armored variants, while staying aligned with evolving safety and sustainability standards. Strategic positioning in the green building and EV-ready housing segments will be crucial for market leadership.

Common Pitfalls When Sourcing 6/3 Wire – Quality and IP Rating Concerns

Sourcing 6/3 wire (typically referring to a cable with three 6 mm² conductors) requires careful attention to both quality and Ingress Protection (IP) ratings, especially in industrial, commercial, or outdoor applications. Overlooking these factors can lead to safety hazards, equipment failure, and costly downtime. Below are key pitfalls to avoid:

Poor Quality Conductors and Insulation

One of the most common issues is sourcing cables with substandard materials. Low-quality 6/3 wire may use:

- Impure copper conductors: Some suppliers use copper-clad aluminum (CCA) or low-grade copper, which increases resistance, causes overheating, and reduces current-carrying capacity.

- Thin or inconsistent insulation: Inferior PVC or XLPE insulation may crack under temperature fluctuations, UV exposure, or mechanical stress, leading to short circuits or electric shock risks.

- Inaccurate gauge: Some cables marketed as 6 mm² may actually be undersized, failing to meet electrical standards and increasing fire risk.

Always verify compliance with recognized standards such as IEC 60228 (conductor sizing), IEC 60502 (insulation), or local equivalents (e.g., NEC in North America), and request test certifications from suppliers.

Misunderstanding or Ignoring IP Ratings

The IP (Ingress Protection) rating defines a cable’s resistance to solids and liquids—critical when installing in harsh environments. Common mistakes include:

- Assuming standard cables are weatherproof: A basic 6/3 cable without proper sheathing may have no IP rating or only IP44 (splash-resistant), making it unsuitable for outdoor or wet locations.

- Confusing cable rating with enclosure rating: The IP rating often applies to the final installation (e.g., junction box), not the cable itself. The cable must be compatible with the required environment (e.g., UV resistance, moisture barrier).

- Using non-armored cable in high-risk areas: In industrial settings, mechanical damage is a risk. Failing to use IP67-rated or armored (SWA) variants can expose conductors to dust, water, and physical impact.

Ensure the cable sheath material (e.g., PUR, PE, or halogen-free compounds) and construction (e.g., double insulation, steel wire armor) match the environmental demands.

Lack of Certification and Traceability

Many low-cost suppliers provide cables without proper documentation. Pitfalls include:

- Missing certification marks: Legitimate cables should carry marks like CE, UL, CSA, or TÜV, indicating third-party testing.

- No batch traceability: Without lot numbers or manufacturer data, it’s impossible to verify quality or initiate recalls if defects arise.

- Counterfeit products: Especially online, cables may appear compliant but fail under inspection or testing.

Always source from reputable distributors, request product datasheets, and conduct spot testing (e.g., insulation thickness, conductor resistance) when possible.

Incorrect Application for Environmental Conditions

Even with proper IP ratings, mismatched cable selection leads to failure. Examples include:

- Using indoor-rated 6/3 cable in direct burial or submerged applications.

- Exposing non-UV-resistant cables to sunlight, leading to jacket degradation.

- Installing standard cables in high-flex or vibration-prone areas without choosing flexible or oil-resistant variants.

Match the cable specification not just to electrical load, but to the full operational environment—temperature range, chemical exposure, and mechanical stress.

Avoiding these pitfalls ensures reliable, safe, and code-compliant installations. Always prioritize certified, application-specific cables over cost-saving alternatives.

Logistics & Compliance Guide for 6/3 Wire Rating

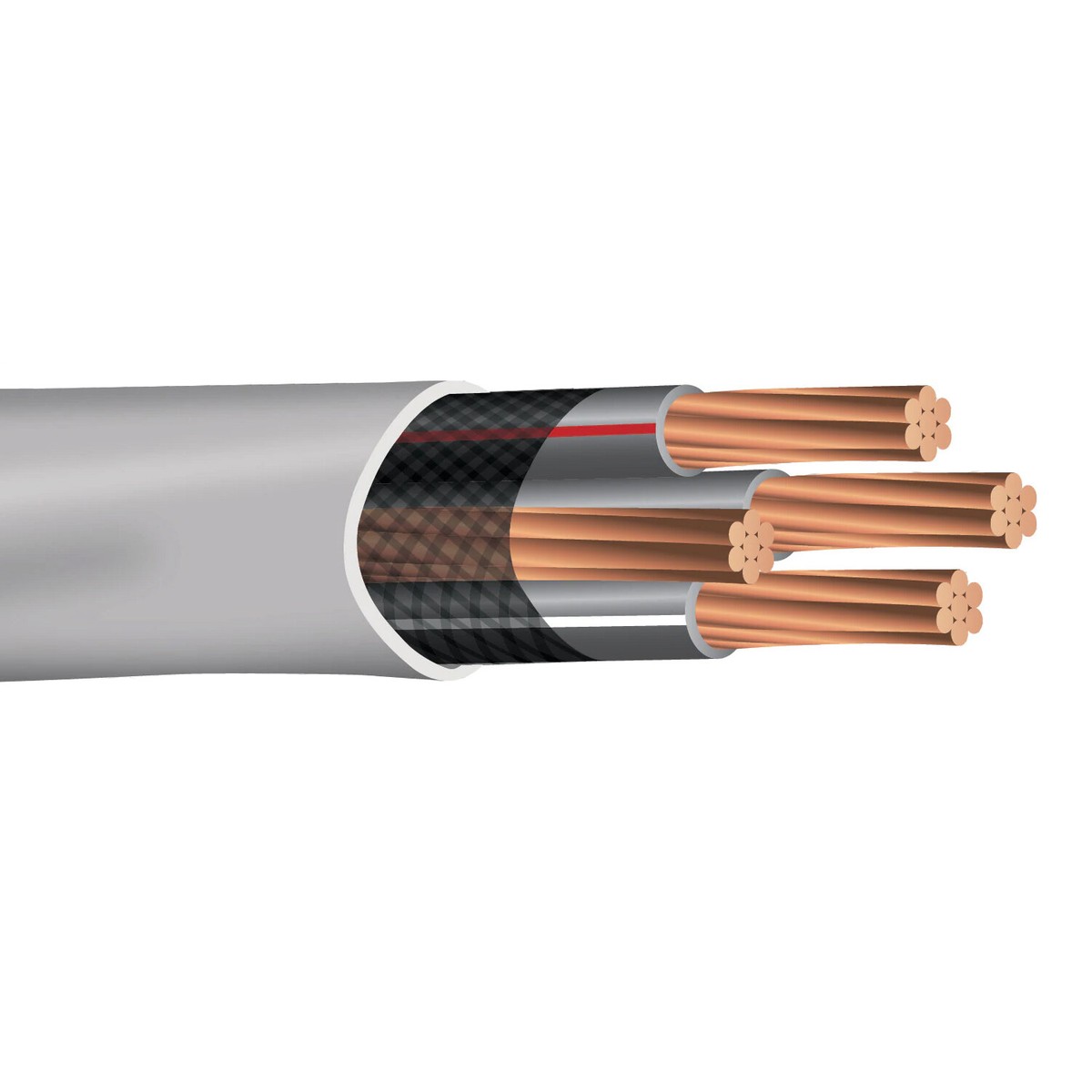

Overview of 6/3 Wire Specifications

6/3 wire refers to an electrical cable containing three 6-gauge conductors (typically black, red, and white) and a bare copper ground wire. The “6” indicates the American Wire Gauge (AWG) size, while the “3” denotes the number of insulated current-carrying conductors. This type of cable is commonly used for high-load applications such as electric ranges, subpanels, and large HVAC systems. Standard types include NM-B (non-metallic sheathed cable) for indoor use and underground feeder (UF) cable for outdoor or direct burial applications.

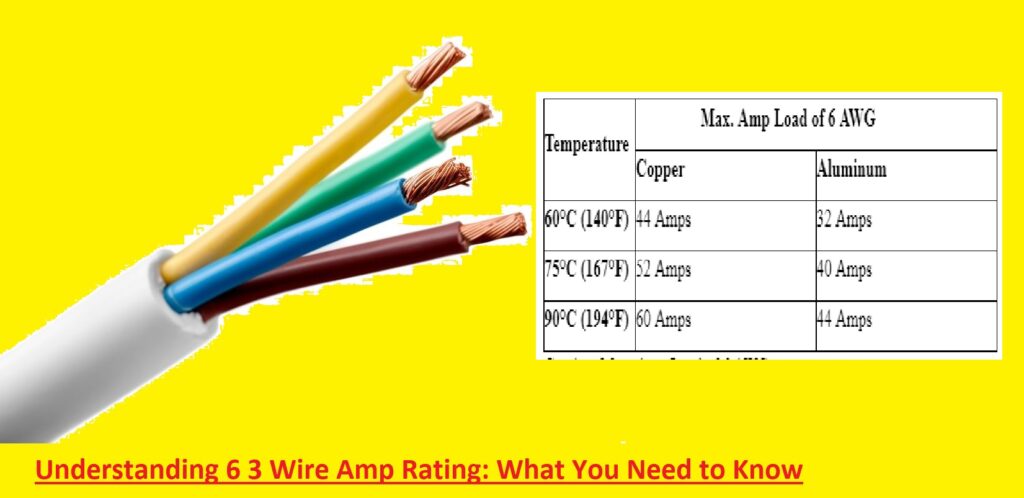

Ampacity and Voltage Rating

According to the National Electrical Code (NEC), a 6 AWG copper wire has an ampacity of 55 amps at 60°C, 65 amps at 75°C, and 75 amps at 90°C. However, the actual circuit breaker rating must align with the termination temperature rating, typically 60°C or 75°C. For most residential applications using 6/3 NM-B cable, the safe continuous load rating is 55–60 amps. The standard voltage rating for 6/3 wire is 600 volts, suitable for both 120/240V and 120/208V split-phase systems.

Compliance with National Electrical Code (NEC)

Installation of 6/3 wire must comply with the latest edition of the NEC (NFPA 70), particularly:

– Article 334: Covers NM-B cable use and installation requirements.

– Article 340: Applies to UF cable for wet or buried locations.

– Article 110: Addresses electrical safety and working clearances.

– Article 210: Specifies branch circuit ratings and applications.

Using 6/3 wire on a circuit protected by a 60-amp breaker is code-compliant when installed correctly. Larger breakers (e.g., 70 or 75 amps) require higher temperature-rated insulation and terminations.

Permits and Inspections

Electrical installations involving 6/3 wire typically require a permit and final inspection by a local authority having jurisdiction (AHJ). Submit detailed plans showing circuit routing, load calculations, and compliance with NEC standards. Inspectors will verify correct wire gauge, grounding, box fill, and protection from physical damage.

Shipping and Handling Logistics

When transporting 6/3 wire:

– Store reels in a dry, temperature-controlled environment to prevent jacket degradation.

– Use proper lifting equipment for large reels (typically 100–500 ft lengths).

– Avoid kinking or sharp bends during installation; minimum bend radius is 5 times the cable diameter.

– Use cable ramps or protective conduit where wires cross high-traffic areas.

Environmental and Safety Considerations

- Do not install NM-B 6/3 cable in wet, outdoor, or underground locations unless rated for such use (e.g., use UF-B instead).

- Protect wires from UV exposure, moisture, and mechanical damage.

- Ensure all connections are torque-rated and properly secured to prevent overheating.

Labeling and Documentation

Maintain accurate records including:

– Cable specifications (type, gauge, insulation rating)

– Circuit load calculations

– Permit numbers and inspection approvals

– Manufacturer data sheets and safety data (SDS) if applicable

Regional and International Variations

While NEC is standard in the U.S., other regions follow different codes:

– Canada: Comply with the Canadian Electrical Code (CEC), which may have different ampacity tables and installation rules.

– International: IEC standards may apply; 6 AWG is roughly equivalent to 16 mm², but consult local codes for exact requirements.

Best Practices for Compliance and Safety

- Always de-energize circuits before installation.

- Use appropriately rated connectors and junction boxes.

- Follow manufacturer instructions for termination and splicing.

- Train personnel on NEC standards and site-specific safety protocols.

Adhering to this guide ensures safe, compliant, and efficient use of 6/3 wire in electrical systems.

Conclusion for Sourcing 6/3 Wire Rating:

When sourcing 6/3 gauge electrical cable, it is essential to consider both the physical specifications and the appropriate application requirements. A 6/3 AWG cable consists of three 6-gauge insulated conductors (typically black, red, and white) plus a bare ground wire, making it suitable for 240-volt circuits that may also require a neutral, such as those serving electric dryers, ranges, subpanels, or EV chargers.

The ampacity of 6-gauge copper wire is generally rated for 55 to 65 amps depending on insulation type (e.g., 60°C, 75°C, or 90°C) and installation conditions, with most standard installations allowing up to 55 amps under NEC guidelines. Therefore, 6/3 wire is commonly used for circuits requiring up to 55 amps and should be protected by an appropriately sized breaker.

In summary, sourcing 6/3 wire should align with the load requirements, local electrical codes (such as NEC Article 310), and environmental conditions (e.g., indoor, outdoor, conduit use). Always verify voltage drop over long runs and consult a licensed electrician or engineer when necessary to ensure safety, compliance, and optimal performance.