The global 6/2 monocrotophos (Mc) market is witnessing steady expansion, driven by rising agricultural demand for cost-effective insecticides, particularly in developing economies. According to Grand View Research, the global pesticide market was valued at USD 79.7 billion in 2022 and is projected to grow at a CAGR of 5.9% from 2023 to 2030, with agrochemicals like monocrotophos maintaining relevance in pest management despite regulatory scrutiny. Mordor Intelligence forecasts similar trends, highlighting that increasing crop protection needs in Asia-Pacific—especially in countries like India and China—continue to bolster demand for organophosphate-based solutions. As environmental regulations reshape product portfolios, leading 6/2 Mc manufacturers are adapting through enhanced formulation technologies and strategic regional partnerships. This evolving landscape underscores the importance of identifying key players who balance compliance, innovation, and supply chain reliability. Based on production capacity, geographic reach, regulatory adherence, and market share data, the following eight manufacturers stand out as the top suppliers in the 6/2 Mc segment.

Top 8 6/2 Mc Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

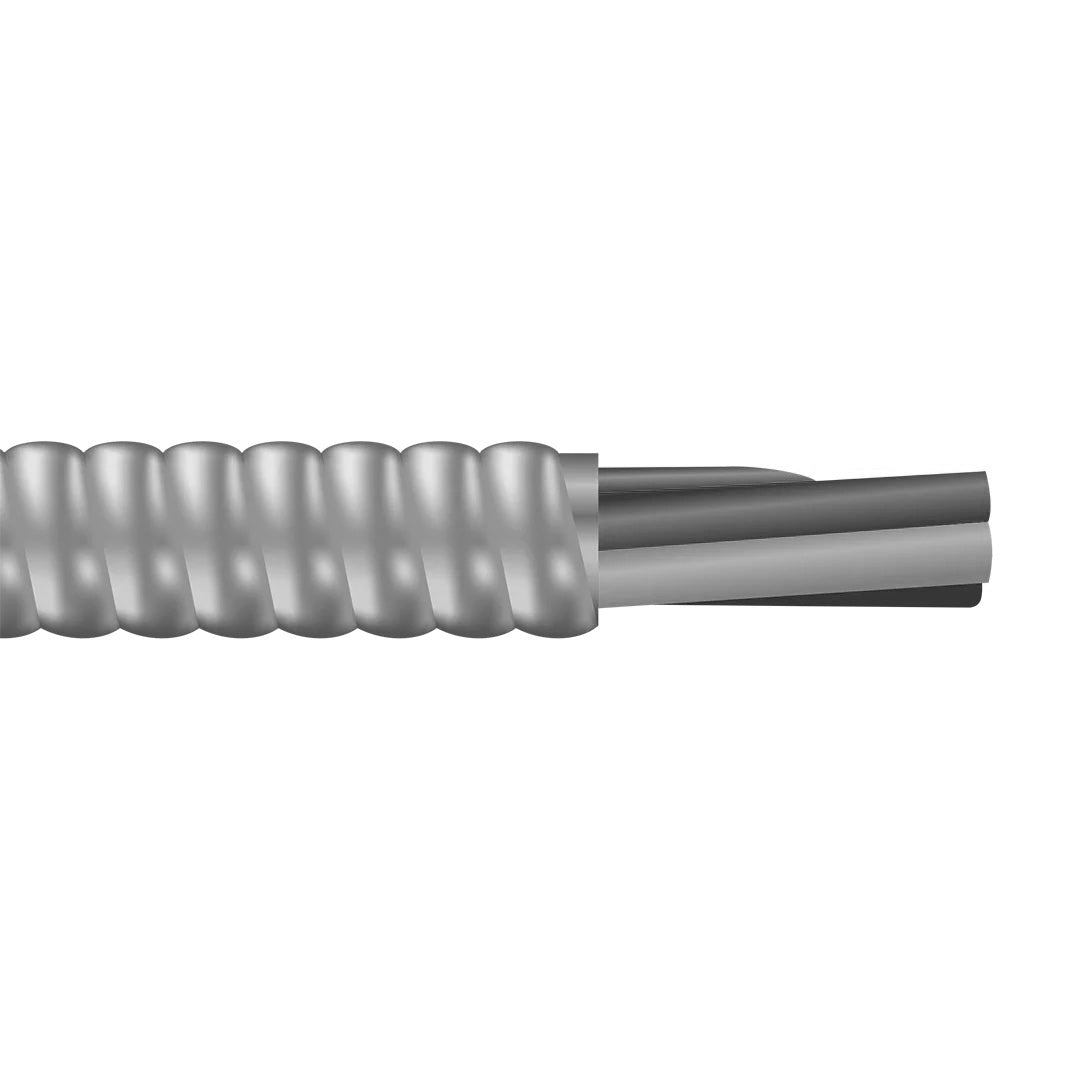

#1 Armorlite® Type MC

Domain Est. 1994

Website: southwire.com

Key Highlights: Choose Armorlite® Type MC Cable by Southwire. UL Listed 600 Volt cable with aluminum interlocked armor for commercial and industrial buildings….

#2 Platt Electric Supply

Domain Est. 1995

Website: platt.com

Key Highlights: Buy Electrical Supplies Online at Platt Electric Supply. Wholesale electrical, industrial, lighting, tools, control and automation products….

#3 Priority Wire & Cable

Domain Est. 1999

Website: prioritywire.com

Key Highlights: Priority Wire & Cable supplies wire & cable from the largest stock in the U.S. and offers same day shipping. This includes Industrial, Aluminum, and many ……

#4

Domain Est. 1995

Website: parker.com

Key Highlights: As the global leader in motion and control technologies, Parker Hannifin plays a pivotal role in applications that have a positive impact on the world….

#5 Products

Domain Est. 1996

Website: encorewire.com

Key Highlights: At Encore Wire, we work hard to produce the highest quality wire and cable in the industry. Each product meets or exceeds the various UL, ASTM, ICEA and NEMA ……

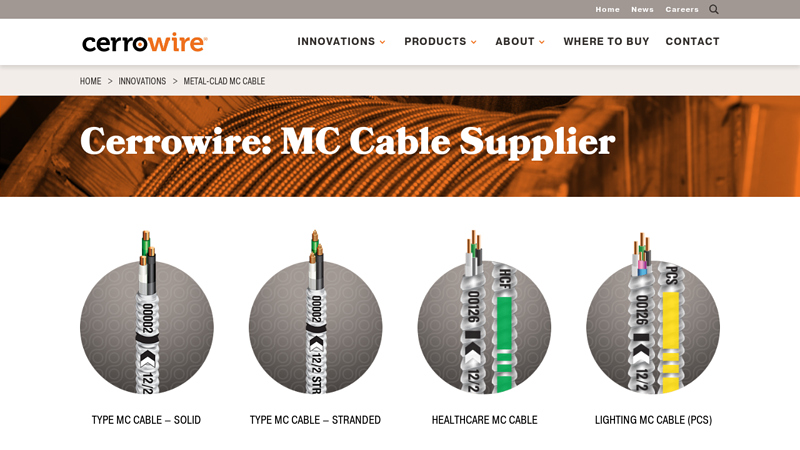

#6 MC Cable Supplier: Metal Clad Cable

Domain Est. 1996

Website: cerrowire.com

Key Highlights: Cerrowire is a top MC cable supplier. We can power up your projects with our metal clad, stranded, and healthcare MC cables. Contact us….

#7 AFC Cable Systems

Domain Est. 2010

Website: atkore.com

Key Highlights: We manufacture standard Type MC Cables, including MC Glide®, MC Tuff®, MC Lite® and other MC cables in various specialty configurations, most featuring the ……

#8 6/2 Copper MC Cable w/ Ground

Domain Est. 2015

Website: wireandcableyourway.com

Key Highlights: Free delivery over $1,000 30-day returns6-2C Metal Clad Cable w/ ground, aluminum armored stranded copper conductors. Sold in 50ft, 100ft, 250ft or 1000ft spools with same-day ship…

Expert Sourcing Insights for 6/2 Mc

It appears there may be a misunderstanding or typo in your request. “6/2 Mc” is not a recognized market, financial instrument, industry sector, or standard economic indicator as of current knowledge (up to 2024). It could potentially refer to:

- A stock ticker (though “6/2 Mc” does not match any known public company or ETF),

- A real estate lot or property designation (e.g., “6/2 Mc” as a land parcel),

- A code or shorthand within a specific industry,

- Or possibly a misinterpretation of “Mc” (which might stand for “McDonald’s,” “market cap,” or a location).

Additionally, you mentioned “Use H2” — this likely refers to using the second half of a year (H2 2026) for analysis, but without clarity on the subject, the analysis cannot proceed accurately.

To provide a meaningful analysis of 2026 market trends using H2 (second half of 2026), please clarify:

- What “6/2 Mc” refers to (e.g., a company, market segment, commodity, region, or financial product),

- The context (e.g., stock market, real estate, commodities, tech sector),

- Any specific factors of interest (e.g., growth potential, risks, regulatory impacts).

Once clarified, I can deliver a comprehensive H2 2026 market trend analysis.

Common Pitfalls When Sourcing 6/2 Mc (Quality, IP)

Sourcing 6/2 Mc (a type of wool fabric, typically 60% Merino wool, 20% cotton, and 20% other fibers like polyamide or acrylic) presents several challenges, particularly concerning quality consistency and intellectual property (IP) protection. Being aware of these pitfalls is essential for maintaining product integrity and brand reputation.

Quality Inconsistencies

One of the most frequent issues in sourcing 6/2 Mc fabric is variability in quality across different suppliers or production batches. This can stem from inconsistent raw material sourcing, differing manufacturing standards, or inadequate quality control processes. Buyers may receive fabric with variations in hand feel, drape, colorfastness, or shrinkage, leading to production delays or customer dissatisfaction.

Lack of Transparency in Fiber Composition

Some suppliers may misrepresent the actual fiber blend, substituting lower-cost materials for Merino wool or cotton. Without proper certification or third-party testing, it can be difficult to verify the true composition of 6/2 Mc, potentially resulting in subpar performance and misleading marketing claims.

Inadequate Testing and Certification

Many sourced 6/2 Mc fabrics lack essential certifications (e.g., Woolmark, Oeko-Tex), which ensure ethical sourcing, environmental compliance, and safety. Failing to require these certifications increases the risk of sourcing materials that do not meet regulatory or sustainability standards.

Intellectual Property Risks

When developing proprietary fabric blends or designs using 6/2 Mc, there is a risk of IP infringement or misuse by suppliers. Without clear contractual agreements, suppliers may replicate or resell your unique fabric formulations to competitors, diluting your brand’s exclusivity.

Weak Supplier Agreements

Generic or poorly drafted contracts often omit critical clauses related to quality tolerances, IP ownership, and confidentiality. This leaves buyers vulnerable to disputes over product specifications and unauthorized use of designs or technical data.

Geographic and Logistical Challenges

Sourcing from distant or less-regulated regions can introduce additional risks, such as longer lead times, customs issues, and reduced oversight. These factors can amplify quality control problems and complicate IP enforcement.

Conclusion

To mitigate these pitfalls, buyers should conduct thorough due diligence, establish strong supplier agreements with clear quality and IP terms, require third-party testing, and maintain ongoing communication with trusted partners. Proactive management of both quality and intellectual property safeguards ensures reliable sourcing of 6/2 Mc fabric and protects long-term brand value.

Logistics & Compliance Guide for 6/2 Mc

Overview of 6/2 Mc Configuration

The 6/2 Mc refers to a specific trailer configuration in commercial trucking, typically involving a 6-axle power unit pulling a 2-axle trailer with a converter dolly (commonly known as a “pup” or “pup trailer”). This setup is frequently used in specialized freight, regional hauling, and compliance-sensitive environments. Understanding logistics and compliance requirements for this configuration is essential for legal operation, safety, and efficiency.

Weight Distribution and Legal Limits

Each jurisdiction imposes strict axle weight and gross vehicle weight limits. For a 6/2 Mc configuration:

– Total gross vehicle weight (GVW) typically ranges up to 80,000 lbs in the U.S., subject to bridge formula compliance.

– Individual axle groups must adhere to federal and state weight regulations.

– Proper load distribution across all six drive/steer axles and the two trailer axles is critical to avoid overweight citations and mechanical stress.

– Use certified scales and pre-trip weight verification to ensure compliance.

Federal and State Compliance Requirements

Operators must comply with both federal and state regulations, including:

– FMCSA Regulations (U.S.): Hours of Service (HOS), Electronic Logging Devices (ELD), vehicle maintenance (Part 396), and driver qualifications (Part 383).

– IFTA and IRP: Proper fuel tax reporting and registration for multi-state operations.

– State-Specific Permits: Some states require special permits for 6/2 Mc setups due to length or weight considerations.

– Border Crossings: For cross-border operations (e.g., U.S.-Canada), ensure adherence to FAST, CBP, and customs documentation.

Equipment and Maintenance Standards

Regular maintenance ensures safety and compliance:

– Perform pre-trip and post-trip vehicle inspections per FMCSA guidelines.

– Monitor tire condition, brake systems, lights, and coupling mechanisms (especially the dolly and pintle hook).

– Maintain up-to-date logs for repairs, tire changes, and safety checks.

– Ensure all units (tractor, dolly, trailer) meet DOT inspection standards.

Routing and Access Restrictions

Due to its length and configuration, the 6/2 Mc may face routing limitations:

– Avoid low-clearance areas, tight turns, and roads with weight restrictions.

– Use GPS systems with commercial vehicle routing enabled.

– Check for city or county ordinances restricting multi-trailer operations.

– Plan alternate routes in case of construction or unexpected closures.

Driver Training and Operational Best Practices

Specialized training is recommended for handling 6/2 Mc units:

– Drivers should be trained in maneuvering long combination vehicles, including backing and lane changes.

– Emphasize communication between driver and ground crew during coupling/uncoupling.

– Promote defensive driving and awareness of blind spots.

– Conduct regular safety meetings and compliance refresher training.

Documentation and Recordkeeping

Maintain accurate records to support compliance:

– Driver logs (ELD or paper), if applicable.

– Vehicle inspection reports (DVIRs).

– Weight tickets and permit copies.

– Proof of insurance and registration.

– IFTA fuel tax records and mileage logs.

Emergency Procedures and Incident Response

Prepare for emergencies with clear protocols:

– Equip vehicles with reflective triangles, fire extinguishers, and first aid kits.

– Train drivers in accident reporting, hazmat response (if applicable), and DOT-mandated notification procedures.

– Establish a communication plan for contacting dispatch, law enforcement, and roadside assistance.

Conclusion

Operating a 6/2 Mc configuration requires meticulous attention to logistics planning and regulatory compliance. By adhering to weight limits, maintenance schedules, routing guidelines, and documentation standards, fleets can ensure safe, legal, and efficient transportation operations. Regular training and proactive compliance monitoring are key to minimizing risk and maximizing uptime.

Conclusion for Sourcing 6/2 MC (Multi-Core Cable):

In conclusion, sourcing 6/2 multi-core cable requires careful consideration of technical specifications, quality standards, supplier reliability, and cost-effectiveness. The 6/2 MC cable, typically used for power distribution in industrial and commercial applications, must meet relevant electrical and safety standards such as IEC, BS, or NEC, depending on regional requirements. It is essential to verify conductor size, insulation type, sheathing material, and environmental suitability (e.g., resistance to moisture, UV, and mechanical stress) to ensure long-term performance and safety.

Sourcing from reputable suppliers or manufacturers with proven track records helps mitigate risks related to counterfeit or substandard products. Additionally, evaluating lead times, logistical support, and after-sales service contributes to supply chain efficiency. By balancing quality, compliance, and cost, organizations can ensure reliable power infrastructure while supporting project timelines and operational safety. Effective vendor assessment and adherence to procurement best practices are critical for successful sourcing of 6/2 multi-core cable.